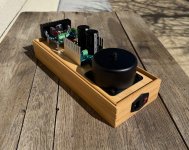

My final build is finally final, at least for the time being. This has been a very long journey for me, I started thinking about building an amp 20 years ago. My first implementation was a p2p gainclone, but I did not like the sound, and I quit for a while. When I started again last summer, I diverged to SMD soldering just to find out if it's worth considering. Then I decided to go with the modulus-86. I thought the 286 was not diy enough for me.

The easy part was populating the amplifier board, although I did manage to screw up even the easy part (see post #6407).

A more difficult but very enjoyable part was designing the power supply. I love using KiCad, but I never really had a purpose, so I did not practice too much. I also got some help here, when I was not sure. I designed and made one version, it burned due to either a cold solder joint or a loose screw terminal. So I designed another version, and thoroughly enjoyed the process again.

The really hard part was fitting the whole thing is the case that I designed way back when. Not very practical, but at least unique.

Here are a few things that I learned in the process.

1. Screw terminals are for single core wires, period. Using them with multi stranded wires is unstable. There was a lot of twisting and turning involved in putting my build together, but I was also very careful and retightened the screws multiple times to no avail. At least use ferrules.

2. Using ferrules does not come without it's own complications. The simple budget brand blanking-and-crimping pliers are not going to cut it. Picking the right size ferrule is crucial. All in all: even something so simple and common as screw terminals need good tools and some practice.

3. If you don't want to spend your money on tools, use the connectors that RC people use in their builds, like the Amass XT series or something similar. They are cheap, reliable, easy to work with and they have a very small footprint. And you only need your soldering iron to make them work.

4. You are going to make mistakes. If you are not a pro, there are always going to be things that you are doing for the first time. You are going to make mistakes, and your mistakes are going to cost money and time. A lot of money, and a lot of time. And it's ok.

5. It's going to be ugly at times. Especially when you make mistakes, or have friends who help but think very differently (see the pictures). Have a friend! Have someone to encourage you and laugh with you when you screw up.

6. Do it! There is no point in waiting. Do with whatever you have at hand, try and fail. Fantasize, do research, prototype. Design! There are so many tools that you can use even for free.

So it's done, I would love to make more PCB design and soldering, but it's hard to find the justification for it now, so I am probably finished for some time. It works, it sounds really good, though it did not change the way I listen to music, it did not make me go through my cd collection again, I probably grew too old to really care. Thanks for all the support and help, torzsok out

The easy part was populating the amplifier board, although I did manage to screw up even the easy part (see post #6407).

A more difficult but very enjoyable part was designing the power supply. I love using KiCad, but I never really had a purpose, so I did not practice too much. I also got some help here, when I was not sure. I designed and made one version, it burned due to either a cold solder joint or a loose screw terminal. So I designed another version, and thoroughly enjoyed the process again.

The really hard part was fitting the whole thing is the case that I designed way back when. Not very practical, but at least unique.

Here are a few things that I learned in the process.

1. Screw terminals are for single core wires, period. Using them with multi stranded wires is unstable. There was a lot of twisting and turning involved in putting my build together, but I was also very careful and retightened the screws multiple times to no avail. At least use ferrules.

2. Using ferrules does not come without it's own complications. The simple budget brand blanking-and-crimping pliers are not going to cut it. Picking the right size ferrule is crucial. All in all: even something so simple and common as screw terminals need good tools and some practice.

3. If you don't want to spend your money on tools, use the connectors that RC people use in their builds, like the Amass XT series or something similar. They are cheap, reliable, easy to work with and they have a very small footprint. And you only need your soldering iron to make them work.

4. You are going to make mistakes. If you are not a pro, there are always going to be things that you are doing for the first time. You are going to make mistakes, and your mistakes are going to cost money and time. A lot of money, and a lot of time. And it's ok.

5. It's going to be ugly at times. Especially when you make mistakes, or have friends who help but think very differently (see the pictures). Have a friend! Have someone to encourage you and laugh with you when you screw up.

6. Do it! There is no point in waiting. Do with whatever you have at hand, try and fail. Fantasize, do research, prototype. Design! There are so many tools that you can use even for free.

So it's done, I would love to make more PCB design and soldering, but it's hard to find the justification for it now, so I am probably finished for some time. It works, it sounds really good, though it did not change the way I listen to music, it did not make me go through my cd collection again, I probably grew too old to really care. Thanks for all the support and help, torzsok out

Attachments

I love the wood + steel. Nicely done.

The terminals on the Modulus-86 can be used both with solid and stranded wire. So says Phoenix who makes them. I've never had issues with either, so I wonder what went on in your case.

Tom

The terminals on the Modulus-86 can be used both with solid and stranded wire. So says Phoenix who makes them. I've never had issues with either, so I wonder what went on in your case.

Tom

I chose the Neurochrome Modulus-86 (10th Anniversary Edition) to replace a 30 year old Carver PM-300 which had begun to “leak noise” which I could hear on my speakers between songs. The noise was barely audible but I could hear it if I put my ear close enough to a speaker. I thought about recapping the Carver but stumbled across the Neurochrome website and saw the low noise Modulus-86 and decided to give it a try. It has not disappointed. It is perfectly quiet - or rather absolutely quiet between songs.

A Modulus-86 monoblock now sits atop each speaker. The speakers are Klipsch La Scala, vintage 1979. The drivers are original but I did recap the crossovers last year. Next project is likely to be refinishing them for WAF.

Attachments

Antek power supply? I was curious about those Epsilon caps. Any info anywhere?It turned out to be just right for a Modulus-86 monoblock. I’ve built a pair now using the same “bamboo chassis” for both.

Ya know... You really ought to ground that bamboo... 😉

On a serious note: That's a really neat build. I like chassis options like that. If one is concerned about EMI or small fingers poking where they shouldn't, one could make a cover from perf plate. Similar to what Heathkit did: https://www.radiomuseum.org/r/heath_hp_23a_hp23a.html

Tom

On a serious note: That's a really neat build. I like chassis options like that. If one is concerned about EMI or small fingers poking where they shouldn't, one could make a cover from perf plate. Similar to what Heathkit did: https://www.radiomuseum.org/r/heath_hp_23a_hp23a.html

Tom

I could spray it with cold galv but it's only available in gray. I prefer the natural look. 🤓Ya know... You really ought to ground that bamboo...

I've been thinking of various ways to make a cover. I'm not worried about EMI since none is detected thus far. I do have grandkids with little fingers though.

The Dynaco ST-70 I built as a kit some decades ago had a perforated metal cover. The steel and aluminum perf plate I can find here in town is either too small or the sheet is too large or too thick or too expensive. I am also considering wire mesh. It should be cheaper and easier to form. Something like this minus bamboo cover and upside down.

Attachments

I like natural wood too.

Online Metals might come in handy if you go the perf plate route. It's usually pretty soft aluminum, i.e., not 6061. You could easily bend it with a box break. I believe you can get solder that'll work on aluminum so you could solder the corners together. https://www.onlinemetals.com/

Tom

Online Metals might come in handy if you go the perf plate route. It's usually pretty soft aluminum, i.e., not 6061. You could easily bend it with a box break. I believe you can get solder that'll work on aluminum so you could solder the corners together. https://www.onlinemetals.com/

Tom

A few days ago I was searching Digi-Key's web site for NEUtrik connectors (they don't carry them, BTW), but happened across what would have been the adjacent manufacturer -- NEUrochrome. That was news to me. But, apparently Tom is selling some of his products via Digi-Key and the listings on Digi-Key appear to be the same items as on Neurochrome.com . Perhaps that's to make it easier for a certain type of customer for whom ordering straight from Tom's web site brings some difficulties?

If Tom sees this, perhaps he might comment.

If Tom sees this, perhaps he might comment.

Yeah. I've slowly been populating my products on the Digikey Marketplace. My Grande Plan (for world domination) was that this would make it easier for folks in Europe to order my products as Digikey would collect the sales tax up front. That's what Digikey told me a year ago when I first approached them about this.

Sadly, either Digikey told me incorrect information or they've changed their ways since then, because now that my products are live on their Marketplace, they still show as "duties and taxes collected on delivery" when I view them through Digikey's international pages. I spent about six weeks of email back/forth getting my products uploaded to Digikey's platform so it is insanely frustrating to then not get the benefit I was promised.

So what is the benefit? Well... From the customer's perspective there really is no benefit of ordering through Digikey, which is why I haven't advertised it. If you order through Digikey you will still receive high-quality products made in Canada shipped directly by me from Calgary, AB, Canada. So you might as well order directly through my website - www.neurochrome.com.

Digikey charges a 25% commission on sales, so I lose 25% off the bat on every sale through Digikey. Since money doesn't grow on trees at my latitude, this means I will have to eat less...

So what is in it for me/Neurochrome? Aside from the already sunk cost of getting my products onto Digikey's Marketplace, there's no cost to me as long as nobody buys through Digikey. Digikey says they'll handle search engine optimization (SEO) and such so it is theoretically possible that my presence on Digikey Marketplace will increase traffic to my website and make my products bubble up higher in online searches. That'd be a benefit worth taking. If all this makes people flock to Digikey to order my products, hopefully the increased volume will make the commission worth it.

I figure I'll give it a year and see if it makes any difference in the SEO or web traffic.

Tom

Sadly, either Digikey told me incorrect information or they've changed their ways since then, because now that my products are live on their Marketplace, they still show as "duties and taxes collected on delivery" when I view them through Digikey's international pages. I spent about six weeks of email back/forth getting my products uploaded to Digikey's platform so it is insanely frustrating to then not get the benefit I was promised.

So what is the benefit? Well... From the customer's perspective there really is no benefit of ordering through Digikey, which is why I haven't advertised it. If you order through Digikey you will still receive high-quality products made in Canada shipped directly by me from Calgary, AB, Canada. So you might as well order directly through my website - www.neurochrome.com.

Digikey charges a 25% commission on sales, so I lose 25% off the bat on every sale through Digikey. Since money doesn't grow on trees at my latitude, this means I will have to eat less...

So what is in it for me/Neurochrome? Aside from the already sunk cost of getting my products onto Digikey's Marketplace, there's no cost to me as long as nobody buys through Digikey. Digikey says they'll handle search engine optimization (SEO) and such so it is theoretically possible that my presence on Digikey Marketplace will increase traffic to my website and make my products bubble up higher in online searches. That'd be a benefit worth taking. If all this makes people flock to Digikey to order my products, hopefully the increased volume will make the commission worth it.

I figure I'll give it a year and see if it makes any difference in the SEO or web traffic.

Tom

Assuming for the moment that Digikey would be "ok" with it, I would seriously entertain adding that fee to the price that you charge direct, or maybe better offering an equivalent discount or perennial 25% off sale on your site, from the list price as reflected on Digikey. I do that with personal/used musical/audio items on sites such as Reverb.

Reverb definitely needs their take and I'm 100% totally fine with that. In that case, they charge approximately 10%, everything included, and I consider that a bargain in my particular situation. I wouldn't consider 25% to be, unless that means you can rely on a certain amount of volume (which I know isn't the case at present) and can plan business accordingly. That's just me and my .00002c of course.

Reverb definitely needs their take and I'm 100% totally fine with that. In that case, they charge approximately 10%, everything included, and I consider that a bargain in my particular situation. I wouldn't consider 25% to be, unless that means you can rely on a certain amount of volume (which I know isn't the case at present) and can plan business accordingly. That's just me and my .00002c of course.

I agree. Digikey provides a service and they should get paid for this service. I can just make my products more expensive on Digikey and I may do that. But as of now I have no sales through that channel, so it's not really an issue.

25% commission is actually on the low side, believe it or not. I've talked to Audiophonics in France about carrying my products and they told me to F... right off when I offered them that. They wanted more like 40%. That's a lot to have my products presented in a webshop. They'd still dump all the sales and support on me, I'm sure.

Tom

25% commission is actually on the low side, believe it or not. I've talked to Audiophonics in France about carrying my products and they told me to F... right off when I offered them that. They wanted more like 40%. That's a lot to have my products presented in a webshop. They'd still dump all the sales and support on me, I'm sure.

Tom

40% is nuts imo. I don't know what challenges Audiophonics might have on the technical end of things (and absolutely not dissing our French friends, much respect!) but - that's a lot for maintaining a website. I'm assuming that they would provide you with a blank-ish set of pages, editing capabilities, and maybe a link to a payment processor.

Now if they were responsible for handling support for payments, charge backs and that kind of thing, then maybe that's somewhat more reasonable. It just seems more likely that would be offloaded to a company that specializes in that. If I was setting up a company to sell online, that would be the way I do it anyhow.

I'm happy to tell anyone to check out Neurochrome. I would rather own 386 amps rather than eg Purify modules (as well as expensive, boutique stuff) for a few good reasons, and you consistently posting wisdom and offering some superb support here are big ones. Maybe there's some way to improve the effectiveness of "word-of-internet" marketing - I know I'm doing my part 😉

Now if they were responsible for handling support for payments, charge backs and that kind of thing, then maybe that's somewhat more reasonable. It just seems more likely that would be offloaded to a company that specializes in that. If I was setting up a company to sell online, that would be the way I do it anyhow.

I'm happy to tell anyone to check out Neurochrome. I would rather own 386 amps rather than eg Purify modules (as well as expensive, boutique stuff) for a few good reasons, and you consistently posting wisdom and offering some superb support here are big ones. Maybe there's some way to improve the effectiveness of "word-of-internet" marketing - I know I'm doing my part 😉

I went a bit down the road with Audiophonics. They downloaded the pictures from my website and added some text that they in part copied from my website and in part just made up. So what they showed the customers was actually wrong. They also told the customers that my product had been discontinued even though they were available in plain view and for sale on my website.

Audiophonics never asked for my input on or approval of the product pages. We never agreed on the pricing so I assumed that it was a dead end. It wasn't until I started getting multiple customers asking if my products had been discontinued that I thought to ask how they'd developed that impression and came across the pages on Audiophonics. The pages were not accessible through any menu on the Audiophonics website but showed up in a Google search. So basically, Audiophonics hampered my business by telling my prospective customers that my products had been discontinued. On top of that they put up a fight when I asked them to take the product pages down.

They would handle the payment and they'd also - I think - have some limited inventory on hand. So they said. They've completely lost my trust at this point so who knows what they'd actually have done in reality.

But if anyone here has a suggestion for a reputable DIY audio distributor located within the EU feel free to mention them. I would love to develop stronger ties with Europe given the situation "elsewhere" at the moment.

Tom

Audiophonics never asked for my input on or approval of the product pages. We never agreed on the pricing so I assumed that it was a dead end. It wasn't until I started getting multiple customers asking if my products had been discontinued that I thought to ask how they'd developed that impression and came across the pages on Audiophonics. The pages were not accessible through any menu on the Audiophonics website but showed up in a Google search. So basically, Audiophonics hampered my business by telling my prospective customers that my products had been discontinued. On top of that they put up a fight when I asked them to take the product pages down.

They would handle the payment and they'd also - I think - have some limited inventory on hand. So they said. They've completely lost my trust at this point so who knows what they'd actually have done in reality.

But if anyone here has a suggestion for a reputable DIY audio distributor located within the EU feel free to mention them. I would love to develop stronger ties with Europe given the situation "elsewhere" at the moment.

Tom

That's really not cool, at all. If they haven't done so already, I would of course demand immediate removal of their inaccurate information with the threat of legal action. But what do I know about international law, at least at the present? Not a whole lot. That's bad karma on their part.

I'm evaluating how I might get another citizenship abroad, meaning EU, Canada and maybe certain not-yet-EU societies. That really seems like an attractive business for someone like myself to get into, without looking at the numbers. I know I'll not be starting up anything like that here, for multiple reasons including unknown financials.

I'm evaluating how I might get another citizenship abroad, meaning EU, Canada and maybe certain not-yet-EU societies. That really seems like an attractive business for someone like myself to get into, without looking at the numbers. I know I'll not be starting up anything like that here, for multiple reasons including unknown financials.

Last edited:

- Home

- Amplifiers

- Chip Amps

- Modulus-86 build thread