There is a picture from the Amp Camp of a father with his daughter, who was stuffing a cap on the board..... she cant have been more than 5.

Get em going now, your children nor you will regret it.

She was 4 actually. That was an adorable shot! With help,I know of a couple of 8 yr olds in my extended family that have built ACA's with their Dads at their shoulders. They can solder quite well..just need advice and someone to check that they get the parts right. Best to do it in two sessions. One of the amps is now in the "kitchen audio system" , and the boy is quite proud.

Last edited:

I'd like to add that the self contained, sealed, power supplies that are included drastically increase the safety for young or old kids working on and testing this amp.

Room treatments for headphone users

Room treatments for headphone users

Heatsink too small

Hi cuong.vn.

I would say only a little bit in summer temperature.

In could winter evening you can good heat up your feeds. ;-).

I am on work to add a heat sink on top or change R15.

Cheers Bangla.

Hi Bangla H,Hi cuong.vn.

I would say only a little bit in summer temperature.

In could winter evening you can good heat up your feeds. ;-).

I am on work to add a heat sink on top or change R15.

Cheers Bangla.

Nice xD 😀

Thx!!!

Good evening everybody,

Having had a 20 year break from DIY audio, I was inspired to build two ACA, and I have to say, I am pretty astounded with the resulting sound. I have a fairly modest setup, Oppo 101 blu-ray (excellent CD reproduction), 10-year old Rotel RA-04 (using pre-out sockets), KEF IQ3 bookshelfs (about 89-90dBm I think). What a step up in finesse compared to the Rotel power amp stage! Much more detail, better dynamics, overall more realism. And for my tastes, plenty loud enough.

Anyhow, you can see by attached pics that I am using Hammond die cast aluminium enclusures, horizontal heatsinks (250x150x40mm) on stand-offs to let the air get around, PCB's upside down with access by taking off the bottom plate of the boxes. Sort of Quad II style if you like! I have the R15 mod, and it is possible to touch the sinks indefinitely without discomfort, so they must be <45C I suppose.

I have to say that the power resistors do get hot, but I have tried with the amplifier upside down (PCB upright) and still pretty hot. The situation is not really worsened by the PCBs being normally upside down I think. I will have to monitor the situation though...

Having had a 20 year break from DIY audio, I was inspired to build two ACA, and I have to say, I am pretty astounded with the resulting sound. I have a fairly modest setup, Oppo 101 blu-ray (excellent CD reproduction), 10-year old Rotel RA-04 (using pre-out sockets), KEF IQ3 bookshelfs (about 89-90dBm I think). What a step up in finesse compared to the Rotel power amp stage! Much more detail, better dynamics, overall more realism. And for my tastes, plenty loud enough.

Anyhow, you can see by attached pics that I am using Hammond die cast aluminium enclusures, horizontal heatsinks (250x150x40mm) on stand-offs to let the air get around, PCB's upside down with access by taking off the bottom plate of the boxes. Sort of Quad II style if you like! I have the R15 mod, and it is possible to touch the sinks indefinitely without discomfort, so they must be <45C I suppose.

I have to say that the power resistors do get hot, but I have tried with the amplifier upside down (PCB upright) and still pretty hot. The situation is not really worsened by the PCBs being normally upside down I think. I will have to monitor the situation though...

Attachments

Very nice work Niceonecyril! One of the nicest designs I've seen using he Hammond enclosures. My power resistors don't get very hot, but I haven't done the mod on them yet. Perhaps that is why. Thanks for the pics.Good evening everybody,

Having had a 20 year break from DIY audio, I was inspired to build two ACA, and I have to say, I am pretty astounded with the resulting sound. I have a fairly modest setup, Oppo 101 blu-ray (excellent CD reproduction), 10-year old Rotel RA-04 (using pre-out sockets), KEF IQ3 bookshelfs (about 89-90dBm I think). What a step up in finesse compared to the Rotel power amp stage! Much more detail, better dynamics, overall more realism. And for my tastes, plenty loud enough.

Anyhow, you can see by attached pics that I am using Hammond die cast aluminium enclusures, horizontal heatsinks (250x150x40mm) on stand-offs to let the air get around, PCB's upside down with access by taking off the bottom plate of the boxes. Sort of Quad II style if you like! I have the R15 mod, and it is possible to touch the sinks indefinitely without discomfort, so they must be <45C I suppose.

I have to say that the power resistors do get hot, but I have tried with the amplifier upside down (PCB upright) and still pretty hot. The situation is not really worsened by the PCBs being normally upside down I think. I will have to monitor the situation though...

Thanks for showing your chassis/heatsink/PC configuration. I've just altered my ACA concept to fit some heatsinks I have that should work very well in that arrangement.

Skip

Skip

Nice one niceonecyril 😀

I've been running my with the heatsink in the same vertical layout with no issues. My ACA is from the first run of complete kits and the heat sinks are smaller than yours.

It's at least 3yrs old and there's been no issues, just sweet sweet music

I've been running my with the heatsink in the same vertical layout with no issues. My ACA is from the first run of complete kits and the heat sinks are smaller than yours.

It's at least 3yrs old and there's been no issues, just sweet sweet music

mikegranger, Skip Pack, JRKO,

Thanks for your comments, I'm glad its not just me: yes, the heatsink dissipation is fine in this orientation, perhaps a little less efficient than with baseplate vertical, but adequate. I am thinking of getting the power resistors more up above the board though, maybe 1/2inch and not so close together. Power dissipation in these is roughly 2x unmodified version.

I am still amazed by the sound of these amps: playing Eddie Martin "Keep on Working" blues CD now, properly realistic feel to it that I am just not used to! Very exciting.

Niceonecyril

Thanks for your comments, I'm glad its not just me: yes, the heatsink dissipation is fine in this orientation, perhaps a little less efficient than with baseplate vertical, but adequate. I am thinking of getting the power resistors more up above the board though, maybe 1/2inch and not so close together. Power dissipation in these is roughly 2x unmodified version.

I am still amazed by the sound of these amps: playing Eddie Martin "Keep on Working" blues CD now, properly realistic feel to it that I am just not used to! Very exciting.

Niceonecyril

Thank you tdr. I bought them from RS Components (supplier ABL Heatsinks):

http://uk.rs-online.com/web/p/heatsinks/9033074/

They are good match size-wise for the Hammond enclosure:

1550JBK HAMMOND, Enclosure, Diecast, IP54, Instrument, 275 mm, 175 mm, 66.6 mm, Aluminium Alloy, Black | Farnell element14

One thing that I didn't bargain for is that heatsinks of this size are quite often not entirely flat: these have about a 0.8mm upright hump across the width of the base plate as bought in from the metal supplier. This was a good reason to stand them off the box a little. I was told by ABL support that if you really want flat, you have to do a milling/grinding operation on the bottom face. With a 10mm base there is no bending them easily either. Bolting them hard on the enclosure might result in the Hammond losing the battle.

http://uk.rs-online.com/web/p/heatsinks/9033074/

They are good match size-wise for the Hammond enclosure:

1550JBK HAMMOND, Enclosure, Diecast, IP54, Instrument, 275 mm, 175 mm, 66.6 mm, Aluminium Alloy, Black | Farnell element14

One thing that I didn't bargain for is that heatsinks of this size are quite often not entirely flat: these have about a 0.8mm upright hump across the width of the base plate as bought in from the metal supplier. This was a good reason to stand them off the box a little. I was told by ABL support that if you really want flat, you have to do a milling/grinding operation on the bottom face. With a 10mm base there is no bending them easily either. Bolting them hard on the enclosure might result in the Hammond losing the battle.

Niceon....where did you procure those heatsinks? Love your build.

You might want to check out heatsinkusa.com - sell them by the inch. The 10in wide model x 6in may be about the same size as this European model.

10.000" - HeatsinkUSA

$3.42/in x 6in = $20.52 (plus shipping and $5 cutting fee). They make nice heatsinks though.

This one is double the price but fins are twice as deep:

10.080" - HeatsinkUSA

Awesome. Thanks for the tip.You might want to check out heatsinkusa.com - sell them by the inch. The 10in wide model x 6in may be about the same size as this European model.

10.000" - HeatsinkUSA

$3.42/in x 6in = $20.52 (plus shipping and $5 cutting fee). They make nice heatsinks though.

This one is double the price but fins are twice as deep:

10.080" - HeatsinkUSA

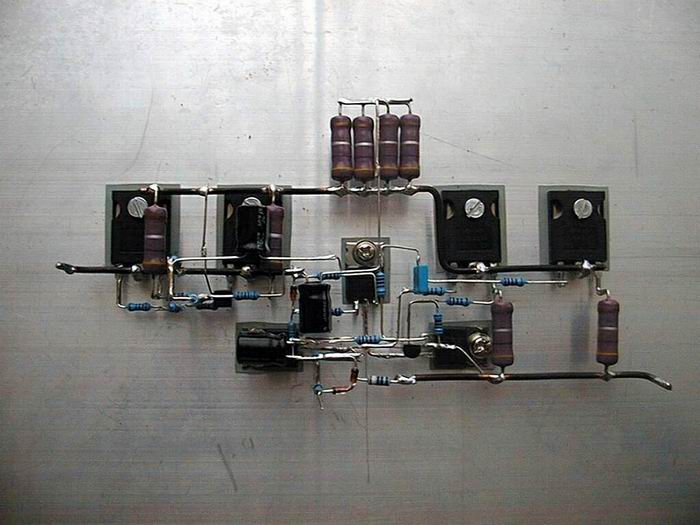

I am thinking of making my next ACA in this style - not sure where this came from but it's an Aleph made entirely point-to-point in 3d space.

Has anyone done this for ACA?

I really like that! Thanks for showing it.

That's called Dead Bug Style around here. I was once thinking of a contest for the most cleverly cheap ACA, and thought Dead Bug is a way to be cheap but it also does look cool. It could be like a sculpture, sitting on a heatsink base or backplane.

My original plans were to also have a bargain ACA kit with the heatsink on its back with bolts for legs but it sure looked kinda unfinished. Niceonecyril came up with a design that looks great! The box below could also be a thick wooden plank with a hole in the middle. It would have to be longer than the heatsink so the terminals etc. could be vertical through the plank at the rear. That would look cool too and be quite reasonable.

Possible noise/hum issues but probably not...

My original plans were to also have a bargain ACA kit with the heatsink on its back with bolts for legs but it sure looked kinda unfinished. Niceonecyril came up with a design that looks great! The box below could also be a thick wooden plank with a hole in the middle. It would have to be longer than the heatsink so the terminals etc. could be vertical through the plank at the rear. That would look cool too and be quite reasonable.

Possible noise/hum issues but probably not...

Last edited:

Here is my minimalist version of a stereo ACA amplifier. It was built early on using the only thing I could find in stock at the DIYAudio store ... The excellent heat sinks. It is bolted together using threaded rod and acorn nuts. Stick on rubber feet on the four heat sink corners keep the sinks slightly elevated for better air flow. The barrier strip adds additional strength and provided the connections to the outside world. Pretty ugly compared to what others here have done, but it has very good ventilation!

Attachments

ACA circuit resistors are 1/4w, unless otherwise specified? Article BOM shows .4w.

Thanks

Vince

Thanks

Vince

Mikegranger,

I like this for a prototyping style. I may use for a mono f5 prototype, 1 output transistor per side. It is easy to get too precious then be afraid to experiment!

Niceonecyril

I like this for a prototyping style. I may use for a mono f5 prototype, 1 output transistor per side. It is easy to get too precious then be afraid to experiment!

Niceonecyril

- Home

- Amplifiers

- Pass Labs

- Amp Camp Amp - ACA