Hi All! I'm just getting started with a Linkwitz LX521 build, and I've decided that rather than buy off-the-shelf amplifiers I want to build my own using Hypex modules.

I've been asking questions on the OPLUG forum, and the consensus seems to be that eight channels of the UCD180HG should do what I want. It will be overkill (or at least very adequate) power for the tweeter and both mids, and apparently running the two subwoofers in parallel on the one channel of UCD180 will be OK too. It's a two ohm load, but apparently the active crossover shaping reduces the current demands. I had considered using UCD400HG modules for the woofers, but I don't know that they'll even be needed. I do live in an apartment so I don't listen at extreme levels right now.

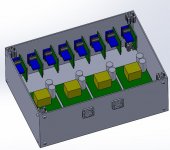

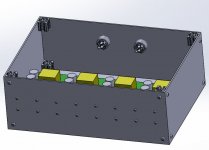

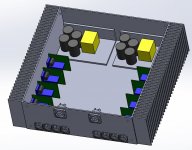

I looked around for a while to find an enclosure that I liked, but I wasn't crazy about the looks, size or cooling of anything. I can do some metalwork though, so here's my design idea. I want to use a 1/4" thick sheet of 1100 aluminum as a front panel, then use 1/8" thick panels for the rest. The corners can use pieces of 80/20 as 3D corner brackets... I already have plenty of scrap 80/20. The idea is that the front face will soak up the transient heat loads and act as the main heat dissipating surface.

Based on this convection calculator, assuming a 1/6th duty cycle for music compared to max power, assuming some paint to get radiation up and reasonably good thermal grease, the outer face of just the front panel should be able to dissipate the heat of the eight modules while keeping them all below 90C, indefinitely under worst case conditions. I've heard that 1/8th is a more realistic power figure for most music, but I want to be a little conservative.

I don't really want the front panel to be hot enough to burn skin, so I'll likely add a small fan to move air from the back of the unit to the front, exhausting through holes in the top and bottom plates.

So! The big question that I come here to ask you all, if anybody wants to offer an opinion-

I have a choice of two SMPS1200 power supplies, or four SMPS400 power supplies to run the thing. If I use four supplies then all four amps can connect to the DC error protection, and I get a nicer power supply rail for the tweeter and upper mid. However, if I use the SMPS then the maximum instantaneous current is a bit higher, and it will be possible to mount the power supplies into the side corners. This would give a central area for signal wires to pass through away from the power supplies, and it would enhance cooling.

For interconnects I'm using XLR balanced inputs, and output will be through two 8-pole Neutrik Speakon connectors.

I welcome any comments, and will be back with pictures as I build it up!

I've been asking questions on the OPLUG forum, and the consensus seems to be that eight channels of the UCD180HG should do what I want. It will be overkill (or at least very adequate) power for the tweeter and both mids, and apparently running the two subwoofers in parallel on the one channel of UCD180 will be OK too. It's a two ohm load, but apparently the active crossover shaping reduces the current demands. I had considered using UCD400HG modules for the woofers, but I don't know that they'll even be needed. I do live in an apartment so I don't listen at extreme levels right now.

I looked around for a while to find an enclosure that I liked, but I wasn't crazy about the looks, size or cooling of anything. I can do some metalwork though, so here's my design idea. I want to use a 1/4" thick sheet of 1100 aluminum as a front panel, then use 1/8" thick panels for the rest. The corners can use pieces of 80/20 as 3D corner brackets... I already have plenty of scrap 80/20. The idea is that the front face will soak up the transient heat loads and act as the main heat dissipating surface.

Based on this convection calculator, assuming a 1/6th duty cycle for music compared to max power, assuming some paint to get radiation up and reasonably good thermal grease, the outer face of just the front panel should be able to dissipate the heat of the eight modules while keeping them all below 90C, indefinitely under worst case conditions. I've heard that 1/8th is a more realistic power figure for most music, but I want to be a little conservative.

I don't really want the front panel to be hot enough to burn skin, so I'll likely add a small fan to move air from the back of the unit to the front, exhausting through holes in the top and bottom plates.

So! The big question that I come here to ask you all, if anybody wants to offer an opinion-

I have a choice of two SMPS1200 power supplies, or four SMPS400 power supplies to run the thing. If I use four supplies then all four amps can connect to the DC error protection, and I get a nicer power supply rail for the tweeter and upper mid. However, if I use the SMPS then the maximum instantaneous current is a bit higher, and it will be possible to mount the power supplies into the side corners. This would give a central area for signal wires to pass through away from the power supplies, and it would enhance cooling.

For interconnects I'm using XLR balanced inputs, and output will be through two 8-pole Neutrik Speakon connectors.

I welcome any comments, and will be back with pictures as I build it up!

Attachments

It might be a bit much with shipping and all, but Modushop in Italy does nice enclosures. You want the Dissipante or Mini Dissipante series with 3mm alu rears and cover and 10mm front.

Modushop by Hi-Fi 2000

Johan-Kr

Modushop by Hi-Fi 2000

Johan-Kr

Thanks! I'd seen those before, but for some reason I thought they were even more costly. I'm mulling it over. They look good, and might result in temperatures low enough that it the electronics will last much longer.

I'm still trying to figure out the SMPS400 vs SMPS1200... In a four-way active speaker I definitely want to avoid crosstalk, but I still don't have a handle on how close that is to being a problem. The spec that seems to say how well I can avoid that is the PSRR, which is 65db. That sounds like if one amp module was causing serious ripple in the power supply rails, that would show up in the output of the other amp channel but attenuated by 65db. Obviously there would be more isolation if each module had its own supply, but I can't fit that and don't want to pay for it. I'm not even sure it's a problem. My best guess here is that by having two 1200 watt power supplies that I'm not fully taxing, the rails will hold a nice solid voltage and the 65db PSRR will keep the spurious signal *very* far down in the noise. I'm dogonne close to pulling the trigger on the eight UCD180HG and two SMPS1200A180.

I'm still trying to figure out the SMPS400 vs SMPS1200... In a four-way active speaker I definitely want to avoid crosstalk, but I still don't have a handle on how close that is to being a problem. The spec that seems to say how well I can avoid that is the PSRR, which is 65db. That sounds like if one amp module was causing serious ripple in the power supply rails, that would show up in the output of the other amp channel but attenuated by 65db. Obviously there would be more isolation if each module had its own supply, but I can't fit that and don't want to pay for it. I'm not even sure it's a problem. My best guess here is that by having two 1200 watt power supplies that I'm not fully taxing, the rails will hold a nice solid voltage and the 65db PSRR will keep the spurious signal *very* far down in the noise. I'm dogonne close to pulling the trigger on the eight UCD180HG and two SMPS1200A180.

I'm not all that sure that this should be much of a problem, as long as one PSU serves only one side. If you want to be certain, use a SMPS1200 for the woofers, and a separate SMPS400 for the mid, upper mid and tweeter channels, as these channels doesn't really draw much power... That'll run you €180 extra.In a four-way active speaker I definitely want to avoid crosstalk, but I still don't have a handle on how close that is to being a problem. The spec that seems to say how well I can avoid that is the PSRR, which is 65db. That sounds like if one amp module was causing serious ripple in the power supply rails, that would show up in the output of the other amp channel but attenuated by 65db.

Johan-Kr

Thanks, Johan-Kr! I've ordered the 450mm deep 3U Dissipante enclosure. It's more than I was really hoping to spend, but it will let me move the power supplies to a reasonable distance from the modules and greatly simplify wire routing. It seems like wire routing and device proximity is something that separates the best from the rest, and if I'm going to jump into this thing then I shouldn't hamstring myself for no good reason.

The latest layout is attached. I'll run the AC power line along the centerline of the bottom panel, route the signal lines in twisted pairs out to the side walls for routing, and then run the speaker wires up near the roof (twisted) to keep them away from the signal lines. I'm happy enough with what this does for the SMPS1200 supplies that I think it's worth the potential drawback of sharing the supply between different frequency ranges. Lets be realistic- the majority of the time I listen with peaks below 90 db at two meters.

The latest layout is attached. I'll run the AC power line along the centerline of the bottom panel, route the signal lines in twisted pairs out to the side walls for routing, and then run the speaker wires up near the roof (twisted) to keep them away from the signal lines. I'm happy enough with what this does for the SMPS1200 supplies that I think it's worth the potential drawback of sharing the supply between different frequency ranges. Lets be realistic- the majority of the time I listen with peaks below 90 db at two meters.

Attachments

I can't help noticing that you've attached the PSU cooling profile to the front. Wouldn't it be better to have it attached to the front part of the cooling fins, or are you trying to minimize space usage?The latest layout is attached. I'll run the AC power line along the centerline of the bottom panel, route the signal lines in twisted pairs out to the side walls for routing, and then run the speaker wires up near the roof (twisted) to keep them away from the signal lines. I'm happy enough with what this does for the SMPS1200 supplies that I think it's worth the potential drawback of sharing the supply between different frequency ranges. Lets be realistic- the majority of the time I listen with peaks below 90 db at two meters.

The only problem with the LX521 is that it doesn't have a convenient backplate to hang amp modules on 😛

Johan-Kr

It would be nice to have them on the fin walls, but as long as they are, it just doesn't leave a lot of space for the modules. I suppose I could try it out to see if the power supplies fit on one side while the modules run along the other side.... I did get the 450mm 3u version, and I have seen people fit seven channels and two smps1200s into smaller spaces.

If I used the four pieces of smps400 they don't even have heat sink attachment brackets, so I assumed (maybe incorrectly) that these don't have the greatest need for cooling beyond a big flat plate.

If I used the four pieces of smps400 they don't even have heat sink attachment brackets, so I assumed (maybe incorrectly) that these don't have the greatest need for cooling beyond a big flat plate.

Very very nice, thank you! I just got my DHL tracking number. Is that the 3U size?

I did order the two SMPS1200, so that's which way I'm headed. I've already received 8 XLR connectors and all of the Speakon Neutrik 8-pole connectors. They're big!

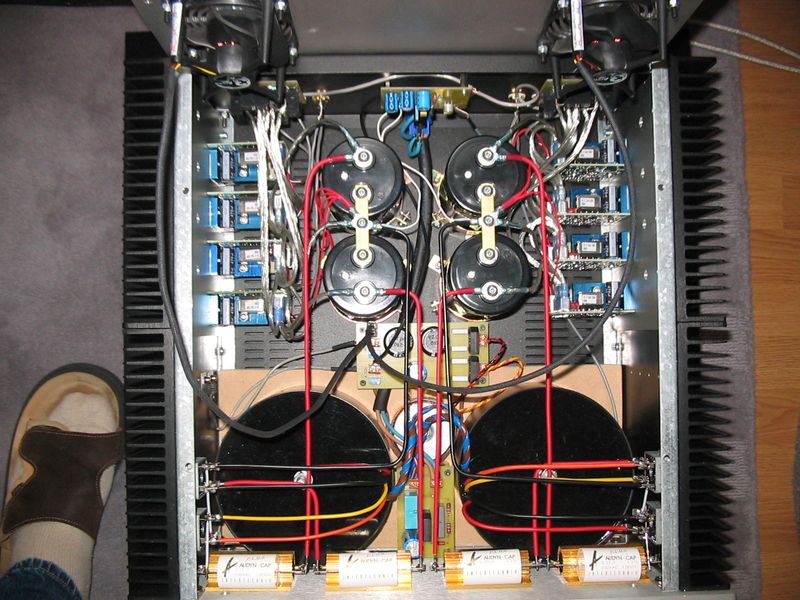

Also, if you don't mind my asking, how did you attach the UCDs to the heat sink? They looked to me like the blue T-parts are tapped, so the screws would need to come from outside the enclosure, through the heat sink. It looks like you made a machined interface plate between the parts and the sinks... is that right? That's what I had assumed I would need to do.

I did order the two SMPS1200, so that's which way I'm headed. I've already received 8 XLR connectors and all of the Speakon Neutrik 8-pole connectors. They're big!

Also, if you don't mind my asking, how did you attach the UCDs to the heat sink? They looked to me like the blue T-parts are tapped, so the screws would need to come from outside the enclosure, through the heat sink. It looks like you made a machined interface plate between the parts and the sinks... is that right? That's what I had assumed I would need to do.

Very very nice, thank you! I just got my DHL tracking number. Is that the 3U size?

I did order the two SMPS1200, so that's which way I'm headed. I've already received 8 XLR connectors and all of the Speakon Neutrik 8-pole connectors. They're big!

Also, if you don't mind my asking, how did you attach the UCDs to the heat sink? They looked to me like the blue T-parts are tapped, so the screws would need to come from outside the enclosure, through the heat sink. It looks like you made a machined interface plate between the parts and the sinks... is that right? That's what I had assumed I would need to do.

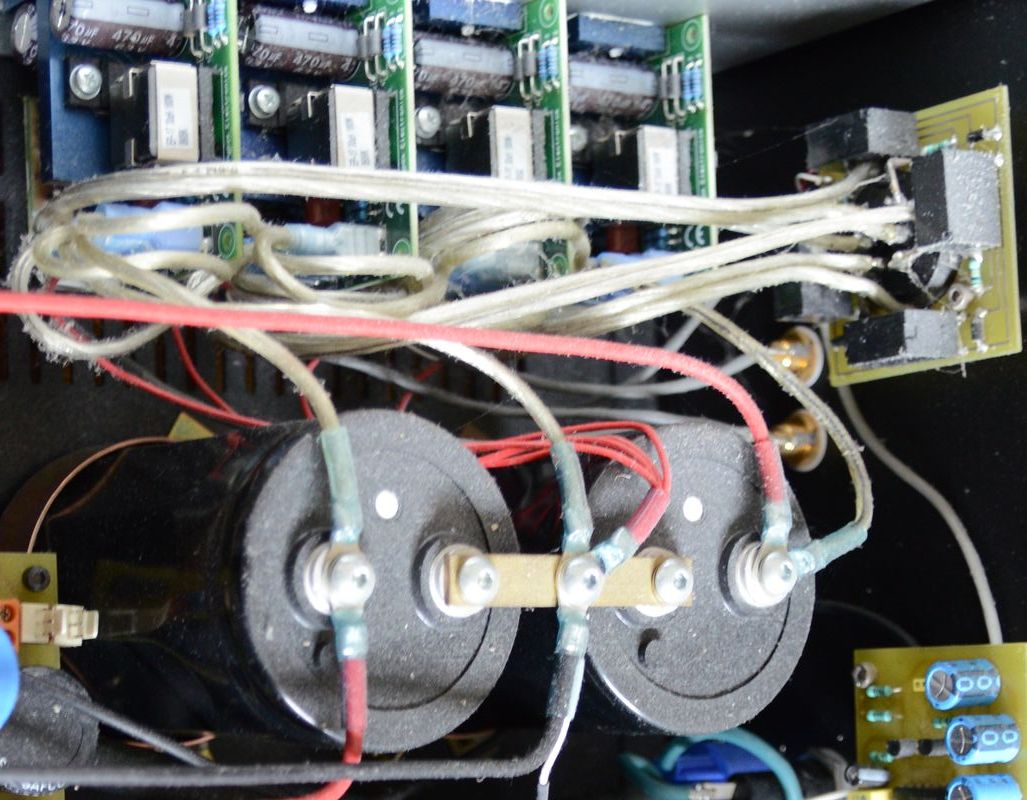

4U (210mm) and it is too big for the UCD but it has been retrofited with them.

The eight amps were AB class big solid state

You are right, the UCD modules are interfaced by a CNC milled aluminium plate :

Front Panel Express: Front Panel Design Software and CAD Conversion Service: Home

The NL8 connectors attached on the Sommer Elephant SPM825 is an absolute enormous massive and heavy speaker cable.

But there is nothing else on the market...

Ah, thanks! I might be able to machine the interface plates myself with a drill press, although I have a good relationship with a few local machinists who may do it for me cheaply.

Those wires are huge! I couldn't find any suitable four-pair wire, so each connector will have two cables, each with its own jacket and two 14AWG twisted pairs. I may use a nylon mesh to make the two cables look like one. They'll weigh about a kilo each 😱

Those wires are huge! I couldn't find any suitable four-pair wire, so each connector will have two cables, each with its own jacket and two 14AWG twisted pairs. I may use a nylon mesh to make the two cables look like one. They'll weigh about a kilo each 😱

Ah, thanks! I might be able to machine the interface plates myself with a drill press, although I have a good relationship with a few local machinists who may do it for me cheaply.

Those wires are huge! I couldn't find any suitable four-pair wire, so each connector will have two cables, each with its own jacket and two 14AWG twisted pairs. I may use a nylon mesh to make the two cables look like one. They'll weigh about a kilo each 😱

Yes 😀 but the quality and the mechanical resistance of this cable is amazing and each wire has its own numero on the insulation... believe me, it is very very useful when you make the final connections because an error should be fatal for the expensive loudspeakers.

The nylon mesh is great but the Techflex multifilament sleeving is much better choice IMHO... i was not aware of that 10 years ago 🙄

I plan on being very careful with a multimeter as the first check and a little full-range dummy speaker as a second check before I finalize the connections to the expensive speakers. Fortunately for LX521 the tweeters are quite cheap compared to the latest version of the Orion. Thanks for the tip on the Techflex, I just ordered a roll!

At the moment, I'm running 10AWG solid core cable to the speakers. The maker of those cables offered up to 7AWG solid core biwire cables - now that would be stiff stuff for a stiff price...Those wires are huge! I couldn't find any suitable four-pair wire, so each connector will have two cables, each with its own jacket and two 14AWG twisted pairs. I may use a nylon mesh to make the two cables look like one. They'll weigh about a kilo each 😱

For the project, I'm thinking of active XO, and a 3 channel amp hanging on the back of the speaker. Now, if I could find something like a car amp enclosure, suitable for a couple of UcD 180, a UcD 400 and a couple of power supplies, I would be a happy camper... A single cable with 4 twisted pairs of silver coated copper wire and a Neutrik Netcon in each end sounds like an ideal solution to me. I'll need a power cable too, but that doesn't need to go to the XO...

Johan-Kr

Great news! The enclosure just arrived!

Bad news.... the instructions are extremely unclear. There are seven or eight different types of screws and nuts, and the printed page doesn't label them at all or show them large enough to make it clear which ones go where. This wouldn't normally be a big deal because I'm fairly mechanically inclined and would just figure it out, but there are a number of self-tapping screws, and I don't want to mess up a hole that wasn't intended for one or break off a screw in a hole that was too small to be a pilot. Is there a better instruction available? Or would you be so kind as to show me a closer view of the screws in your corners so that I can see where the self-tapping ones go?

Thank you!

It looks like I am too late to edit... but a quick edit is that I just figured out where the self tapping screws go, and can see how most of the rest go together. It's not obvious how the plastic feet go on though, they aren't even on the diagram. Overall I'm still fairly happy with the purchase, but for the price I'd have hoped for just a little more documentation.

It looks like I am too late to edit... but a quick edit is that I just figured out where the self tapping screws go, and can see how most of the rest go together. It's not obvious how the plastic feet go on though, they aren't even on the diagram. Overall I'm still fairly happy with the purchase, but for the price I'd have hoped for just a little more documentation.

Well done !

Here is what you can expect within ten years :

Last edited:

Alright, I have my plates arriving this week!

Now I think that I understand all of the connections in the various documentation, but there is one issue that I really can't quite figure out. I've emailed Hypex, but I'll ask here too. Does anybody know how to hook up multiple UCD180HG to the DC error pin of the SMPS1200a180? I've searched around a lot and it looks like the SMPS400 has two pins on J6, where each one goes to LS+ of the respective UCD180 module, but it *really* doesn't seem like the right thing to do to tie together all of the loudspeaker outputs at the pin 10 of J4 on the SMPS1200a180. Maybe with some current limiting resistors? Am I missing something else? Is it safe to just skip the DC protection?

Edit- just got the response from Hypex, the DC protection doesn't work with the SMPS1200. I guess I just skip it then...

Now I think that I understand all of the connections in the various documentation, but there is one issue that I really can't quite figure out. I've emailed Hypex, but I'll ask here too. Does anybody know how to hook up multiple UCD180HG to the DC error pin of the SMPS1200a180? I've searched around a lot and it looks like the SMPS400 has two pins on J6, where each one goes to LS+ of the respective UCD180 module, but it *really* doesn't seem like the right thing to do to tie together all of the loudspeaker outputs at the pin 10 of J4 on the SMPS1200a180. Maybe with some current limiting resistors? Am I missing something else? Is it safe to just skip the DC protection?

Edit- just got the response from Hypex, the DC protection doesn't work with the SMPS1200. I guess I just skip it then...

Last edited:

I have my speakers 90% built, now it's time to get the amp going!

I just have one quick question; does anybody have a power switch that looks good with the Modushop 10mm panel? I'm looking for something that can switch both of the SMPS1200 supplies at once, and can be done with a circular hole so that I can just drill it. I ordered one from Parts Express, but it seems a little short for the nut to reach and I don't want to have to mill the panel from behind if I don't have to.

I just have one quick question; does anybody have a power switch that looks good with the Modushop 10mm panel? I'm looking for something that can switch both of the SMPS1200 supplies at once, and can be done with a circular hole so that I can just drill it. I ordered one from Parts Express, but it seems a little short for the nut to reach and I don't want to have to mill the panel from behind if I don't have to.

Don't forget the 37A input rush current on each SMPS... 74A for the two.

You should use a big relay.

You should use a big relay.

- Status

- Not open for further replies.

- Home

- Amplifiers

- Class D

- New multi-channel Hypex build for LX521