What is the likelihood of an (electrolytic) cap causing an intermittent problem? In my limited experience, when a problem comes and goes, it is usually a bad connection, although I did tap on all the connectors I could reach, particularly the 17 pin piggy-back area.

There are a lot protection/limiter stuff in the PA amplifiers. Reliability is the most important, so they try to protect against everything, to keep it up and running. This is why the preamp section is mostly protection, not the amplifier itself...

I would check the C16 first. No other capacitor can hang up the limiter, as I see.

Sajti

...an intermittent problem? In my limited experience... it is usually a bad connection

My experience confirms yours, my Harman-Kardon has an intermittent problem and it's definitely bad connectors.

I've replaced one connector that was definitely bad but now others have started to fail. Worse product I have ever owned.

... that I have the toroid epoxy potted. This would have almost certainly caused clearance problems, in addition to, as you point out, thermal issues. Are (high)power transformers ever potted?

I would try to pot so it was more or less "shrink wrapped", basically no extra material thickness.

This should eliminate both clearance problems and thermal insulation.

Your Canadian compatriots, Plitron, do some substantial potted power transformers with extra low noise for audio.

Like you, I have wondered about this. I suspect a factor is that low noise transformers run at low flux levels and this also produces less heat.

So for this specific application it all works out fine but I would be careful before I potted a normal transformer.

Best wishes

David

If it hums when you use your microwave, then your house wiring is not sufficient to carry the load. I had this problem with a big receiver once, and eventually took it to another (friends) house that had 150A service and good house wiring. The problem disappeared at his location. I suggest you try that.

My experience confirms yours, my Harman-Kardon has an intermittent problem and it's definitely bad connectors.

I've replaced one connector that was definitely bad but now others have started to fail. Worse product I have ever owned.

There was almost no response about bad connection of that 17 pole connector. But there are many issues, with leaky capacitors in Crest amplifiers.

Sajti

Let's use some caution and a little common sense too:......Also regarding the thermal issue, there is a sensor inside the transformer windings which will open the speaker relays, and if this becomes a problem, the varnish seems to be easily removed with solvent....

If you think a solvent can be used to remove the lacquer after it has cured, you'd also have to consider the insulation on the wire as a likely casualty in the process. Any solvent strong enough enough to dissolve cured lacquer, has a high likelihood of doing damage to such a microscopically thin polymer layer.

Don't then attempt to power the transformer up again without a hi-pot. test before re-connecting to the mains supply. Be warned, there could well be fireworks as you have no way of knowing whether all varnish, softened varnish or raw solvent have been removed. One small fire in there will blow away all your efforts and whatever budget you had in mind.

A Hi Pot test would be good. But who has that equipment sitting on their shelf? Professionals who make a living by testing other folk's equipment.Let's use some caution and a little common sense too:

If you think a solvent can be used to remove the lacquer after it has cured, you'd also have to consider the insulation on the wire as a likely casualty in the process. Any solvent strong enough enough to dissolve cured lacquer, has a high likelihood of doing damage to such a microscopically thin polymer layer.

Don't then attempt to power the transformer up again without a hi-pot. test before re-connecting to the mains supply. Be warned, there could well be fireworks as you have no way of knowing whether all varnish, softened varnish or raw solvent have been removed. One small fire in there will blow away all your efforts and whatever budget you had in mind.

The saving grace for Peter is that almost no varnish has penetrated beyond that first layer of insulation.

He is coating just one layer of secondary windings. All the inner windings of which the Primary is the inner most, will have virtually no varnish to detract from the manufacturer's designed in insulation.

Wow! a lot of info to process!

Thanks, sajti;

I found C 16 in the 'auto-ramp' section on page 4 (of schematic, posted on page 26 of this thread). The owner's manual says the gain is also modulated by "ACL (Active Clip Limiting)" and "IGM Impedance Sensing (Instantaneous Gain Modulation)"

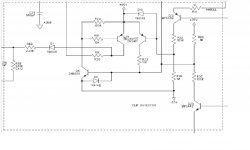

Just to mention; the clip LED for channel B illuminated when the signal was muted. Attached is the clip detect section, I don't see any electrolytics in this area.

I will now reveal more of my ignorance with the following dumb question; Is the name "sync" referring to a (DC) voltage that is used to control gain?

Even dumber question; are the volume control pots controlling this voltage rather than actual audio signal?

Is there a service manual that would possibly explain how the amp function, beyond just a schematic. The service (not owner's) manual for my old Phase Linear 700's explains this in depth. I have had no response from emails to Peavey.

Hi David;

If Harmon-Kardon is the worst you've ever had, you probably have not owned any Soundcraftsmen products. A third octave EQ for my backyard system had one channel brought back to life by removing an op amp IC from a socket and re-installing it. I only repaired it because I did not want that piece of **** getting the better of me. Now I can throw it out!

Hi M1K35R;

This thread is getting a bit long, but on previous pages I mentioned that the house has dedicated power transformer on the Hydro pole, a 200 amp service, and four 15 Amp circuit breakers just for the audio rack; one for each amp (LF, MF, and HF) and one for all the other small signal equipment. Ontario Hydro allowed me to have a 4-gang outlet box, fed by alternate breakers so that all power was on the same phase. The box had to be marked; "Warning, more than one power source".

Thanks Ian;

The reaction of the solvent in the Varnish with the thin winding insulation is a concern.

The Varnish is Electrical grade, from a motor rewinding facility, and intended for this wire. As mentioned however, the solvent has been very slow in evaporating from the interior.

Hi Andrew and jwilhelm;

I will test the toroid, out of the amp, with a variac and amp meter, but it will sit in front of my portable heater for several days after my last dip ( hang in there, Dave). I don't have ready access to a megger, would checking the secondary windings with my Fluke DVM for any voltage with reference to the primary neutral be of any use?

PS; failing a service manual for the CA-18, specifically, does anyone have a link to info regarding class H amp operation, in general, and/or voltage controlled gain circuits.

Thanks, sajti;

I found C 16 in the 'auto-ramp' section on page 4 (of schematic, posted on page 26 of this thread). The owner's manual says the gain is also modulated by "ACL (Active Clip Limiting)" and "IGM Impedance Sensing (Instantaneous Gain Modulation)"

Just to mention; the clip LED for channel B illuminated when the signal was muted. Attached is the clip detect section, I don't see any electrolytics in this area.

I will now reveal more of my ignorance with the following dumb question; Is the name "sync" referring to a (DC) voltage that is used to control gain?

Even dumber question; are the volume control pots controlling this voltage rather than actual audio signal?

Is there a service manual that would possibly explain how the amp function, beyond just a schematic. The service (not owner's) manual for my old Phase Linear 700's explains this in depth. I have had no response from emails to Peavey.

Hi David;

If Harmon-Kardon is the worst you've ever had, you probably have not owned any Soundcraftsmen products. A third octave EQ for my backyard system had one channel brought back to life by removing an op amp IC from a socket and re-installing it. I only repaired it because I did not want that piece of **** getting the better of me. Now I can throw it out!

Hi M1K35R;

This thread is getting a bit long, but on previous pages I mentioned that the house has dedicated power transformer on the Hydro pole, a 200 amp service, and four 15 Amp circuit breakers just for the audio rack; one for each amp (LF, MF, and HF) and one for all the other small signal equipment. Ontario Hydro allowed me to have a 4-gang outlet box, fed by alternate breakers so that all power was on the same phase. The box had to be marked; "Warning, more than one power source".

Thanks Ian;

The reaction of the solvent in the Varnish with the thin winding insulation is a concern.

The Varnish is Electrical grade, from a motor rewinding facility, and intended for this wire. As mentioned however, the solvent has been very slow in evaporating from the interior.

Hi Andrew and jwilhelm;

I will test the toroid, out of the amp, with a variac and amp meter, but it will sit in front of my portable heater for several days after my last dip ( hang in there, Dave). I don't have ready access to a megger, would checking the secondary windings with my Fluke DVM for any voltage with reference to the primary neutral be of any use?

PS; failing a service manual for the CA-18, specifically, does anyone have a link to info regarding class H amp operation, in general, and/or voltage controlled gain circuits.

Attachments

I think a Megger tests to about 500Vpk.

That would be better than no testing.

I remember asking a tech at work to check a couple of the capacitors from my car (automobile) points type distributor on his Megger. One was faulty, the other worked. That explained my starting problem.

That would be better than no testing.

I remember asking a tech at work to check a couple of the capacitors from my car (automobile) points type distributor on his Megger. One was faulty, the other worked. That explained my starting problem.

a megger can test up to 5kv depending on the model....

some meggers have this burn function, so that marginally safe devices can undergo destructive testing...

the BM21 megger:

some meggers have this burn function, so that marginally safe devices can undergo destructive testing...

the BM21 megger:

Thanks guys;

It's always interesting to learn more about a subject that is near and dear to me.

However, my thought was; when I'm finally finished dipping, just 'slam' the power to it, because, at this point, if there is a short in the toroid, it would likely be beyond repair, and this amp becomes a donor for another CA-18!

If you folks don't mind me sidetracking the thread even further, I recently purchased another Crest amp, model 8001. Previous owner claims the speaker wires were accidentally shorted, and the amp would not come out of 'protect' mode'. I powered the up the amp, with some sacrificial speakers and a signal generator and it works!

It is full of dust, cigarette smoke, and dust and corrosion. My thought was to build a better dummy load, test the amp a little more, disassemble it and clean it, then see if it still works. Am I on the wrong track?

Attached is a 100 Amp 240 VAC furnace element set that I thought I could reconfigure for 8 ohms. I understand that resistance increases with temp, but given the size of the elements, is this a large factor, (should I go for 6 or seven ohms, cold?)

It's always interesting to learn more about a subject that is near and dear to me.

However, my thought was; when I'm finally finished dipping, just 'slam' the power to it, because, at this point, if there is a short in the toroid, it would likely be beyond repair, and this amp becomes a donor for another CA-18!

If you folks don't mind me sidetracking the thread even further, I recently purchased another Crest amp, model 8001. Previous owner claims the speaker wires were accidentally shorted, and the amp would not come out of 'protect' mode'. I powered the up the amp, with some sacrificial speakers and a signal generator and it works!

It is full of dust, cigarette smoke, and dust and corrosion. My thought was to build a better dummy load, test the amp a little more, disassemble it and clean it, then see if it still works. Am I on the wrong track?

Attached is a 100 Amp 240 VAC furnace element set that I thought I could reconfigure for 8 ohms. I understand that resistance increases with temp, but given the size of the elements, is this a large factor, (should I go for 6 or seven ohms, cold?)

Attachments

I think it might be a good idea to give that thing a bath before any serious testing. Those dust bunnies might become conductive if the soak up any moisture and may possibly be combustible. At least blow the major stuff out with compressed air first.

Thanks jwilhelm, the screws holding the output modules look a little tired, it must have been repaired a few times before, although all visible outputs look original. I was tempted to get the dirt out of it, I'll do that first.

Any thoughts on info re; "Class H amplifiers for dummies"? This amp looks similar to the Crest CA series, I wonder what the difference is between the two series.

Hi Kevin; I know the neutral is tied to the ground stake, in the panel, how can I test for a 'lost' neutral?

Any thoughts on info re; "Class H amplifiers for dummies"? This amp looks similar to the Crest CA series, I wonder what the difference is between the two series.

Hi Kevin; I know the neutral is tied to the ground stake, in the panel, how can I test for a 'lost' neutral?

If you are going to disassemble it for thorough cleaning at some point, Knights Grez-Off (Spray Nine Product) works good for removing cigarette goo and anything else, followed be a good rinse under warm water, then re-rinse with distilled water. Let everything dry for at least a day after. If there are unsealed pots or switches on board, they will need proper cleaning after doing this.

Hi bryaudioguy; I got your reply in my email but do not see it in this thread.

I have a large listening area, and not tremendously efficient sub woofers, (and I am fond of insane listening levels), Before I removed the toroid from the amp, I was blown away by the 'punch' that this amp has, I may loose a window in the house! My Phase 700 can't supply enough umph for the 18" RCF's. I actually saw the clip light illuminate, with some 'Steely Dan'. I was shocked, I think This needs looking into. I tested the amp into my first dummy load and seems to deliver about 1100 watts pc into 8 ohms! About (95 volts rms IIRC)

Attached is my self designed systeem

I have a large listening area, and not tremendously efficient sub woofers, (and I am fond of insane listening levels), Before I removed the toroid from the amp, I was blown away by the 'punch' that this amp has, I may loose a window in the house! My Phase 700 can't supply enough umph for the 18" RCF's. I actually saw the clip light illuminate, with some 'Steely Dan'. I was shocked, I think This needs looking into. I tested the amp into my first dummy load and seems to deliver about 1100 watts pc into 8 ohms! About (95 volts rms IIRC)

Attached is my self designed systeem

Attachments

Knights Grez-Off (Spray Nine Product) works good

uhh please be very careful spraying or dipping any "product" not designed for cleaning PCB assemblies on an analog device with gain esp. near pots and switches. they often leave residues that can actually ruin things until they are replaced. I don't care if you've been lucky or not using said product. /grease removers often contain powerful petrochemical detergents that can also remove paint. If u gotta use some 'juice' or solvent, the electronics industry uses at least >90% ethanol, scub using acid brushes and Kim-wipes , repeat as necessary. Look for quart bottles of 91% rubbing alcohol, its less than a few bucks in most big box pharmaciesIf there are unsealed pots or switches on board, they will need proper cleaning after doing this.

Last edited:

perhaps it helps in principle to improve all transformer noise , cap inrush and size of the transformer and the cap :see STS Application , older , use a PFC at the secondary side, not at the primary as usual , it causes a sinusoidal secondary currentshape , you have no peak current at the cap .. the transformer can be smaller , because the RMS current is lower , we can discuss it ...

- Status

- Not open for further replies.

- Home

- Amplifiers

- Solid State

- Toroidal Transformer Noise