Voltage-regulator chips sound bad (to DHT constructors who have compared). The feedback of the chip is across the filament - so the chip can't tell between the heating voltage which it must control, and the music-signal across the filament (which it must leave alone!).

with LT 1764 the broadband noise is around 30uV rms typ. - not much better than a LM317 (75uV rms at 2,5V dc), and both of these chips are worse than a purpose designed current-drive regulator - where low numbers of microvolts can be expected for a 2A3.

with LT 1764 the broadband noise is around 30uV rms typ. - not much better than a LM317 (75uV rms at 2,5V dc), and both of these chips are worse than a purpose designed current-drive regulator - where low numbers of microvolts can be expected for a 2A3.

Hi.

Just had reached 20 hours on Rod Coleman V7 regulators, which has replaced his v4 in my 2a3 amp.

My Amp is a clone of the famous Loftin-White Design so it does not use any coupling caps in the direct signal path.

After 20 hours, will do a follow up when I'm closer to the 100, I can say this is a great upgrade.

It's like the music is more alive "naturally". There's a better perspective between bass, midrange and treble.

V4 could be a little to bright thin side, where the v7 has more form and body.

This could be changed when I have had more "hours" on v7.

In my 2a3 where space is an issue. I can not have the luxury to have huge heat sinks. So even though my corsair fan beneath my 2a3 now rotates so slow that I almost can count the rotations.

So I can confirm that the extended heat is way better handled in v7.

PS! I haven't tweaked anything on the regulators v7 or v4 , They are just as it.

Just had reached 20 hours on Rod Coleman V7 regulators, which has replaced his v4 in my 2a3 amp.

My Amp is a clone of the famous Loftin-White Design so it does not use any coupling caps in the direct signal path.

After 20 hours, will do a follow up when I'm closer to the 100, I can say this is a great upgrade.

It's like the music is more alive "naturally". There's a better perspective between bass, midrange and treble.

V4 could be a little to bright thin side, where the v7 has more form and body.

This could be changed when I have had more "hours" on v7.

In my 2a3 where space is an issue. I can not have the luxury to have huge heat sinks. So even though my corsair fan beneath my 2a3 now rotates so slow that I almost can count the rotations.

So I can confirm that the extended heat is way better handled in v7.

PS! I haven't tweaked anything on the regulators v7 or v4 , They are just as it.

Hi.

My Amp is a clone of the famous Loftin-White Design so it does not use any coupling caps in the direct signal path.

...... I can say this is a great upgrade.

Thanks for posting your experience. Can you comment on if you used the regulators on all the tubes or only the 2A3? If all the other tubes, were they DHT? The reason I ask is I'd like to get a better idea if I should upgrade from V4 as well. The V4 made a HUGE difference. My amp is all DHT; 3C24 driver and GM70. I am using fixed bias throughout.

Thanks,

Adrien.

Thanks for posting your experiences indeed! Perhaps in my listening test the improvement was not noticeable because the power amplifier masked or prevented me from hearing the improvement in the preamp (where I used the Coleman regs)It's like the music is more alive "naturally". There's a better perspective between bass, midrange and treble.

V4 could be a little to bright thin side, where the v7 has more form and body.

Voltage-regulator chips sound bad (to DHT constructors who have compared). The feedback of the chip is across the filament - so the chip can't tell between the heating voltage which it must control, and the music-signal across the filament (which it must leave alone!).

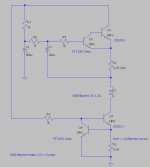

What about the attached regulator? (which, admittedly, I have not built yet..)

Feedback loop is closed before the filament, separated by an inductor. Values shown are for 2.5v @ 1Ohm (2A3).

Attachments

What about the attached regulator? (which, admittedly, I have not built yet..)

Feedback loop is closed before the filament, separated by an inductor. Values shown are for 2.5v @ 1Ohm (2A3).

5uH has such a low impedance at audio frequency that it makes no difference to the regulator interfering with the music signal. And the Elko capacitors are across the music signal (differential signal) on the filament.

Try using the same kind of chip (eg LT1084) in current-mode versus voltage mode, and listen to both ways. A purpose-designed current-drive regulator is better still, but this comparison will help to demonstrate why everyone loves this DHT upgrade.

Last edited:

Thanks for posting your experience. Can you comment on if you used the regulators on all the tubes or only the 2A3? If all the other tubes, were they DHT? The reason I ask is I'd like to get a better idea if I should upgrade from V4 as well. The V4 made a HUGE difference. My amp is all DHT; 3C24 driver and GM70. I am using fixed bias throughout.

Thanks,

Adrien.

Hi Adrien..

I'm only using v7 on my 2A3 tubes. But in my experience, close to 100 hours way better than my old v4. Start to mod a very simple tube riaa ecc83 so things need to settle a little before the final conclusion.

Try using the same kind of chip (eg LT1084) in current-mode versus voltage mode, and listen to both ways. A purpose-designed current-drive regulator is better still, but this comparison will help to demonstrate why everyone loves this DHT upgrade.

I read thru more of this thread and understand better now, I believe. Thanks. The basic topology should be:

Gyrator / cap multiplier -> Filament -> CCS(ink)

right? Look at the attached circuit, do you think it would work? I am not an opamp expert (not even electronics, to be precise 😀).. I was just looking for something to run a 2A3 from a 5V (AC) xfrmr. Your circuit needs a bit more overhead, right?

Attachments

Current source, not voltage source

The brute force way to use a 5VAC to heat a 2A3 would be RLCRCRL with the middle R acting as your "dropper". You can (shunt) regulate between the C's if you feed the need. The first R is to keep things quiet as much as to make the rectifier less efficient. The last R doesn't do much except help keep everything overdamped. The second C should be BIG

The whole point is to have the filament "see" a high impedence.Look at the attached circuit, do you think it would work?

The brute force way to use a 5VAC to heat a 2A3 would be RLCRCRL with the middle R acting as your "dropper". You can (shunt) regulate between the C's if you feed the need. The first R is to keep things quiet as much as to make the rectifier less efficient. The last R doesn't do much except help keep everything overdamped. The second C should be BIG

The brute force way to use a 5VAC to heat a 2A3 would be RLCRCRL with the middle R [...]

There's a little problem with the low R of the 2A3 filament, which is only 1 ohm... 5V AC rectified would give ~6V DC, so the series R of all the dropper resistors and chokes must not be more than 1.4 ohms.. Try finding some nice effective chokes rated for 2.5A and that Rdc... And the Cs would indeed have to be HUGE!

Choke input rectification - less noise, better regulation, lower voltage

The first choke is no bigger than the actual transformer (strangely enough) - because you are pulling so much current you don't need a large H

But given that you want to lose voltage a "lossy gyrator" (for want of a better word) might do after a conventional cap input recitifier

The problems you outline are exactly what Mr. Coleman's regulator solves, and by all reports, quite reliably.

Hence the choke input => ~4.2VDC raw (see article at r-type.org)5V AC rectified would give ~6V DC

The first choke is no bigger than the actual transformer (strangely enough) - because you are pulling so much current you don't need a large H

But given that you want to lose voltage a "lossy gyrator" (for want of a better word) might do after a conventional cap input recitifier

The problems you outline are exactly what Mr. Coleman's regulator solves, and by all reports, quite reliably.

But given that you want to lose voltage a "lossy gyrator" (for want of a better word) might do after a conventional cap input recitifier

The problems you outline are exactly what Mr. Coleman's regulator solves, and by all reports, quite reliably.

You're quite right about the overall view. You can preregulate with chokes, but the cost far exceeds the price of the regulators, and the solid-state solution gives far higher performance.

The sound improvements for the V7 regulator stem from increased, and flatter, dynamic impedance looking out from the filament. I'm pleased that they are audible (without having to apply my own subjective opinion!).

Update.

With 500+ hours on ver 7 in my 2A3, It was time for some improvements.

So I've soldered a Mills MRA-5 (0.39 ohm) + replaced Caps with Panasonic Os-con.

Furthermore I have added a Clarity TCaps 20uF to my PSU, as the last one.

Right out of the box this was a great upgrade. Clarity is even better now. I can heard things in recordings I've had never heard before.

I'll run at least 100+ hours as my 2A3 is quite close to what I really like.

Next week I'll add my new output transformer from monolith S-9. After that I can't hardly think of more to do in my heavy modified Loftin-White.

Only need to replace diodes in the PSU. Will come later on.

But properly Rod would make a ver 8 in the future, which I'll try when it's ready 🙂

With 500+ hours on ver 7 in my 2A3, It was time for some improvements.

So I've soldered a Mills MRA-5 (0.39 ohm) + replaced Caps with Panasonic Os-con.

Furthermore I have added a Clarity TCaps 20uF to my PSU, as the last one.

Right out of the box this was a great upgrade. Clarity is even better now. I can heard things in recordings I've had never heard before.

I'll run at least 100+ hours as my 2A3 is quite close to what I really like.

Next week I'll add my new output transformer from monolith S-9. After that I can't hardly think of more to do in my heavy modified Loftin-White.

Only need to replace diodes in the PSU. Will come later on.

But properly Rod would make a ver 8 in the future, which I'll try when it's ready 🙂

So I've soldered a Mills MRA-5

Hi,

Is sufficient 5W resistor?

Mills dissipation classification is a little funny, MRA-5 was deep smoked brown after few hours using even at 2W. :-(

I use 10-12W resistors (Welwyn W24, MRA-12) in my R.C. regulators, and these large resistors heat dissipation is quite noticeable.

I'm thinking about to make graphite resistors (tentatively).

Hello

I have tried CS and gyrator with 6C4C, as you can see on the picture (found somewhere in this thread).

Did you ever observe what is going on with filament voltage when temperature of the tube is changing?

Try to blow some air on the tube, voltage is changing + 0,1 V and more V so we have over 6,3 V (I saw even 6,5 V).

When you power anode voltage tube is getting warmer and voltage is dropping down about 0,1 V and more.

I wonder if conts. current is the best way to power heater?

I know why you use CS and gyrator, I am afraid, it is the best way to isolate heater supply from signal path but not from filament power point of view.

For example, GM70 is very sensitive and require +/- 1V on the heater !

Does anybody care about heater voltage at all?

I've read almost whole thread and I can see only happy ppl with no hum in loudspeakers, and nobody is worried.

Did I miss something?

I have tried CS and gyrator with 6C4C, as you can see on the picture (found somewhere in this thread).

Did you ever observe what is going on with filament voltage when temperature of the tube is changing?

Try to blow some air on the tube, voltage is changing + 0,1 V and more V so we have over 6,3 V (I saw even 6,5 V).

When you power anode voltage tube is getting warmer and voltage is dropping down about 0,1 V and more.

I wonder if conts. current is the best way to power heater?

I know why you use CS and gyrator, I am afraid, it is the best way to isolate heater supply from signal path but not from filament power point of view.

For example, GM70 is very sensitive and require +/- 1V on the heater !

Does anybody care about heater voltage at all?

I've read almost whole thread and I can see only happy ppl with no hum in loudspeakers, and nobody is worried.

Did I miss something?

Attachments

Hi,

Is sufficient 5W resistor?

Mills dissipation classification is a little funny, MRA-5 was deep smoked brown after few hours using even at 2W. :-(

I use 10-12W resistors (Welwyn W24, MRA-12) in my R.C. regulators, and these large resistors heat dissipation is quite noticeable.

I'm thinking about to make graphite resistors (tentatively).

Hi...

After 20 min the temperature is on 57 degrees celsius. Will post another later on, but I think it's not an issue in my 2A3 amp..

Hello

I have tried CS and gyrator with 6C4C, as you can see on the picture (found somewhere in this thread).

Did you ever observe what is going on with filament voltage when temperature of the tube is changing?

Try to blow some air on the tube, voltage is changing + 0,1 V and more V so we have over 6,3 V (I saw even 6,5 V).

When you power anode voltage tube is getting warmer and voltage is dropping down about 0,1 V and more.

I wonder if conts. current is the best way to power heater?

I know why you use CS and gyrator, I am afraid, it is the best way to isolate heater supply from signal path but not from filament power point of view.

For example, GM70 is very sensitive and require +/- 1V on the heater !

Does anybody care about heater voltage at all?

I've read almost whole thread and I can see only happy ppl with no hum in loudspeakers, and nobody is worried.

Did I miss something?

3 Separate things:

1. Drop of 0,1V when B+ applied.

Yes, this is expected. But the current should be adjusted to achieve the correct filament voltage when B+ is applied - no problem. Running without B+ is not normal use.

2. Temperature sensitivity.

Using a very basic CCS like the one in the picture has poor temperature stability. My regulator uses temperature compensated CCS to get stable output. Just set it up once, when warmed up, and the filament voltage will be will be consistent, even over long periods.

So you are right - CCS can be a bad solution for heating - unless the regulator is able to keep filament voltage stable.

In your solution, when you blow on the tube, cover the regulator, and try it.

3. Unregulated supplies

The real problem for DHTs is use of ac-heat, or unregulated dc to heat the filament. AC mains tolerance is ±10% here in the UK, (and other locations, I am sure). Running anywhere near these extremes, for more than a few minutes, will degrade the filament life-time, fast.

Hello Rod

I agree with you about unregulated DC/AC power supply to heat DHT.

And I don't talk about CS temperature sensitive.

I am worry about changing temperature of filament.

Filament works like current regulator, if it gets warmer resistance gets higher and prevents change of the current.

When it gets colder resistance get lower and current is higher.

It works only when you stabilize voltage of the filament.

But it doesn't work when we use CS. So we got trouble with voltage across filament when temperature of the whole tube is changing.

Filament wasn't design to work with stabilized current :-(

How do you prevent changing of filament voltage in your products?

I cannot find any information about it in this thread :-(

I agree with you about unregulated DC/AC power supply to heat DHT.

And I don't talk about CS temperature sensitive.

I am worry about changing temperature of filament.

Filament works like current regulator, if it gets warmer resistance gets higher and prevents change of the current.

When it gets colder resistance get lower and current is higher.

It works only when you stabilize voltage of the filament.

But it doesn't work when we use CS. So we got trouble with voltage across filament when temperature of the whole tube is changing.

Filament wasn't design to work with stabilized current :-(

How do you prevent changing of filament voltage in your products?

I cannot find any information about it in this thread :-(

Hi...

After 20 min the temperature is on 57 degrees celsius. Will post another later on, but I think it's not an issue in my 2A3 amp..

Hi.

After 6 hours Mills MRA-5 is on 84 degrees celsius. A lot lower than their max specs

on -65 to 250, from datasheet http://www.vishay.com/docs/31801/mra.pdf

Not an issue on my 2A3 at all..

- Home

- Amplifiers

- Tubes / Valves

- New DHT heater