Very glad to see you're making progress. Doing measurements isn't for the forum's amusement. It's essential for you to establish objective information at each stage of your project. A sad old joke among the DIY crowd is that every stupid change sounds better, if you do it yourself. That's why you need objective assessment.

I'm sure others are more sophisticated with REW, but here's a start.

The basic measurement is just a frequency plot and you can see distortion along with it by just clicking a tab on REW.

Put your mic in the church pews, on a stand or otherwise not sitting on a surface, and in such a way that you can keep it there indefinitely or replace it in the same place for future runs. Likewise for settings on amps to be reproducible in the future.

Set measurement for 15 to 12,000 Hz, 256k, 1 sweep, and -10dB (and use your amp to adjust to sort of typical loudness). Don't worry about any calibrations for now.

When the sweep is done and the plot appears, choose "Distortion" tab. There will be camera glyph in the upper left corner; a mouse click will take a snapshot of your plot that can be posted.

That's maybe 50% of the knobs you need to play with. Always easy the second time you do it.

Ben

Thanks, Ben.

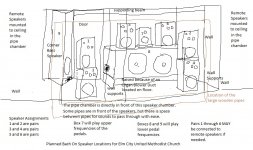

But here - once again - is my challenge. I can't do any practical or useful measurements of our speaker system from out in the Sanctuary yet. There are large wooden pipes blocking 90% of the opening to the pipe chamber, and thus, into the Sanctuary. There's less than an eighth of an inch of distance between those pipes. Sadly, this will remain so for at least a couple more months. It is frustrating, but that's the way it must remain. Those big speakers are the ONLY very low pipes we have on the organ. They are eventually going to be removed and the Artisan Digital Sound Engine will be allocated to replace them. Trying to play the organ for church without them would leave the sound painfully lacking.

My attempt now is to get the speaker wiring done so that when those pipes are removed and we are able to reorganize the speaker chamber, all the connections can be performed quickly.

We're going to have SpeakOn connectors at the amp ends. Then we'll have spade lugs at the speaker ends. I'm currently measuring distances and making the cables for those connections. I'm also trying to label all cables clearly so we aren't having to experiment. The amps are on a cart that will be housed in a closet right below the speaker chamber. I'll be making a hole in the closet ceiling to route the cables. I bought new speaker wire (16 gauge - two conductor color coded).

My assigned task is to have the sound system ready. That includes testing that the speaker sound is balanced. But it is like taking a shower in a raincoat.

I cannot do the organ console actions, though I would if I could. The order of actions on the organ console is that we are having 41 new tabs made. The tabs are what the organist uses to designate which sounds will be played from the manuals (hands) and the pedalboard (feet). The organ cannot be played without these. The turnaround for this is from two to three months. 😡 The folks doing this are a very busy company. Then the guys from that company will come and install the tabs and wire in the MIDI controller in our console. Wires have to be run between the MIDI controller and all keys, pedals and tabs. Some carpentry work on the console will also be required. ONLY after this is done can we actually play sounds from the Artisan Sound Engine from the organ. At that point we can remove the two sets of pipes that are destined for that.

So I'm stuck in limbo for testing the speaker sounds out in the Sanctuary until these steps are completed. The good news is that this will give me time enough to build the new corner cabinet for that Stereo Integrity HT18. I'm still waiting for it to get here. I start to salivate every time a UPS or FedEx truck goes by. 😛

We're going to pull most of the speakers out and reorganize some of the speakers - but even that won't put all of them in their final location until those big pipes have been removed.

The sound measurements I'm able to do have been taken "near field" with the mike about 6 to 12 inches from the speakers. I plan to order the sound engine this week. When it arrives, I'll try to get it connected to the amps. I bought 8 color coded patch cables. Then I'm hopeful that I can use MIDI from my laptop computer to become familiar with the software and begin to adjust the sound levels correctly. Some of this will, no doubt, have to be changed later. But it will get us in the ballpark and it will allow me to become familiar with the software and the process. I'm sure that days and weeks of regular adjustment will be required after we get everything connected.

I wish the tabs could be done faster, but faster would cost us much more. We're already over budget because of the labor and equipment bid from our organ tech.

I'm sure all this sounds like an awful way to do things. But I'm trying to make do with exigencies I simply cannot change. 😡

Bach On

Bach On -

It's your project and none of us are anything but curious observers. Who wish you success. Just offering the usual web, anonymous, free advice, for what that's ever worth.

Having said that, I'd do measurements however imperfectly to inform yourself about each coming step. See where you are, before heading off in some direction.

For example, trying to guess what gauge of wire you'll need, at today's copper prices? Wondering how the sound will sound coming out of a crowded closet?

Ben

It's your project and none of us are anything but curious observers. Who wish you success. Just offering the usual web, anonymous, free advice, for what that's ever worth.

Having said that, I'd do measurements however imperfectly to inform yourself about each coming step. See where you are, before heading off in some direction.

For example, trying to guess what gauge of wire you'll need, at today's copper prices? Wondering how the sound will sound coming out of a crowded closet?

Ben

I'm still with you!

And I think we are a patient bunch.

Take your time.

Just make it snappy!

Mark,

You guys probably don't do much with grits up your way.

But I'll allow you to come down here and kiss my grits! 😀

Bach On

Last edited:

I've been over at the church this evening wiring up SpeakOn connectors. I'd ordered some on eBay. They have no numbers or identifiers on the terminals. So I've been experimenting to get the polarity right. I ordered 8, but I'll need at least a couple more.

The cable I bought is described as 14 gauge for each terminal. But I think it is closer to 16#. The Allen speakers use spade lugs. I bought a tool for crimping them on. But I need to buy some more spade lugs.

The church is preparing for Bible School - June 21st through the 25th. This is a big deal. They go all out for it. So I'm having to wait on bringing out the speakers until the big show is over.

We sent $15,000 to the organ tab crew and $2,500 for the sound engine. ETA on the organ work is sometime in August. Thus, I'll have the last few days of June and July to do my speaker placement and get the wiring ready. That includes making the corner cabinet. I got the wood last week.

I will say it again - thanks to everyone for your support and advice. I'm cautiously optimistic that all the speakers will function as hoped. If not, we make do until funds are available to improve the situation.

PLEASE REMEMBER: I cannot measure speaker sound levels out in the Sanctuary until those big pipes blocking the opening are removed. We can't remove those pipes until we have the sound engine connected to the organ.

Bach On

The cable I bought is described as 14 gauge for each terminal. But I think it is closer to 16#. The Allen speakers use spade lugs. I bought a tool for crimping them on. But I need to buy some more spade lugs.

The church is preparing for Bible School - June 21st through the 25th. This is a big deal. They go all out for it. So I'm having to wait on bringing out the speakers until the big show is over.

We sent $15,000 to the organ tab crew and $2,500 for the sound engine. ETA on the organ work is sometime in August. Thus, I'll have the last few days of June and July to do my speaker placement and get the wiring ready. That includes making the corner cabinet. I got the wood last week.

I will say it again - thanks to everyone for your support and advice. I'm cautiously optimistic that all the speakers will function as hoped. If not, we make do until funds are available to improve the situation.

PLEASE REMEMBER: I cannot measure speaker sound levels out in the Sanctuary until those big pipes blocking the opening are removed. We can't remove those pipes until we have the sound engine connected to the organ.

Bach On

dear ben as a fellow audiophile in toronto would you be interested in getting together yours truly ampman

Once speakers are more than a few feet apart, you need to establish polarity according to what frequency plot response looks better since they will differ in ways that are consterning (if there is such a word).

Are you sure those pipes are really much of a block to the sound getting out? I'd be impressed to see somebody model their blockage.

Heard Toronto's wildest organist yesterday - his name is apt, "Adair". He was doing a transcription of the Water Music. Lots of reeds although there are local organs with lots louder reeds that would have been better. Last piece quite rousing! Takes a lot of horsepower to rouse a church, even a smallish one (that's 746 watts per horse).

Ben

Are you sure those pipes are really much of a block to the sound getting out? I'd be impressed to see somebody model their blockage.

Heard Toronto's wildest organist yesterday - his name is apt, "Adair". He was doing a transcription of the Water Music. Lots of reeds although there are local organs with lots louder reeds that would have been better. Last piece quite rousing! Takes a lot of horsepower to rouse a church, even a smallish one (that's 746 watts per horse).

Ben

The wooden 16' Bourdon pipes have about an eighth of an inch clearance between them - just enough to prevent them vibrating against one another. The receiver sits on the floor of the opening. Several of the largest pipes were mitered with a 90 degree angle that blocks the upright opening and space at the ceiling area too. The rank covers at least 90 percent of the opening. There are two small areas at the ceiling on the left and right of the speaker chamber that has perhaps a rectangular opening about the size of four or five stacked hymn books.

I've setup the CD player to play with two Allen speakers and the Bass speaker. I sat in the Sanctuary on the front row. I can just hear the music (shades open). But it has the sort of volume you would hear from the kitchen of music being played in another room. Most of that seems to be coming through the doorways. I tried putting those Allen Presence Presenters in those openings at the ceiling. They're just small enough to fit. They could be heard. But the bass is missing from their signal because of the built-in crossovers.

😉 Ben, I can see that you won't be satisfied until I do some measurements from the Sanctuary with things plugged up. And I'll take some pictures up in the pipe chamber so you will see what I'm describing. I will try to do so sometime this week while I'm over there wiring up the SpeakOn connectors.

Bach On

I've setup the CD player to play with two Allen speakers and the Bass speaker. I sat in the Sanctuary on the front row. I can just hear the music (shades open). But it has the sort of volume you would hear from the kitchen of music being played in another room. Most of that seems to be coming through the doorways. I tried putting those Allen Presence Presenters in those openings at the ceiling. They're just small enough to fit. They could be heard. But the bass is missing from their signal because of the built-in crossovers.

😉 Ben, I can see that you won't be satisfied until I do some measurements from the Sanctuary with things plugged up. And I'll take some pictures up in the pipe chamber so you will see what I'm describing. I will try to do so sometime this week while I'm over there wiring up the SpeakOn connectors.

Bach On

Takes a lot of horsepower to rouse a church, even a smallish one (that's 746 watts per horse)

Naaayyyyy! Says I.

Herr Bach On

A little trick for polarity verification is your friend the 9 volt battery. Positive to positive will when properly wired internally push the cones out briefly as you touch the terminals to see the push. A little reminder that a second or so will not melt things. Longer and you are on your own with the smoke. Once you let out the smoke, well you know.

It is not uncommon to find polarity reversals on older loudspeakers.

Sounds like you are starting to test-out your system. You don't need a white lab coat to collect very valuable intelligence. You're off to a good start in testing. At last.

Next you need to nail down how loud is the signal the amp is putting into the speaker. You can use one of those $10 multi-tester meters set to AC.

My interest is helping a person with lots of grit and energy accomplish their purposes. Your large hall application (and electric organs) have almost no relevance to me. So please stop making it sound, again, like I am urging you to produce data for my consumption.

Ben

Next you need to nail down how loud is the signal the amp is putting into the speaker. You can use one of those $10 multi-tester meters set to AC.

My interest is helping a person with lots of grit and energy accomplish their purposes. Your large hall application (and electric organs) have almost no relevance to me. So please stop making it sound, again, like I am urging you to produce data for my consumption.

Ben

Sounds like you are starting to test-out your system. You don't need a white lab coat to collect very valuable intelligence. You're off to a good start in testing. At last.

Next you need to nail down how loud is the signal the amp is putting into the speaker. You can use one of those $10 multi-tester meters set to AC.

My interest is helping a person with lots of grit and energy accomplish their purposes. Your large hall application (and electric organs) have almost no relevance to me. So please stop making it sound, again, like I am urging you to produce data for my consumption.

Ben

Ben - sometimes things don't come across as intended. I meant my comment as a joke. You've been helpful. I'm not callous enough to insult people who help me.

Bach On

For sure. Thanks. PM sent.dear ben as a fellow audiophile in toronto would you be interested in getting together yours truly ampman

B.

As a fellow-traveler in working on Church audio systems, I do appreciate how difficult the bureaucracy and general sluggishness most changes are confronted with. A year ago, our Church Trustees decided it was time to investigate a ramp within the Sanctuary to make it easier for handicapped to gain access to the upper area.

The ramp will impact several committees, and we're still wrangling about the placement, a year later. No work is scheduled yet. "It will affect the Christmas tree". "I don't like it.". "We've got to do this.". . .

Nothing happens quickly in a Church.

The ramp will impact several committees, and we're still wrangling about the placement, a year later. No work is scheduled yet. "It will affect the Christmas tree". "I don't like it.". "We've got to do this.". . .

Nothing happens quickly in a Church.

As a fellow-traveler in working on Church audio systems, I do appreciate how difficult the bureaucracy and general sluggishness most changes are confronted with. A year ago, our Church Trustees decided it was time to investigate a ramp within the Sanctuary to make it easier for handicapped to gain access to the upper area.

The ramp will impact several committees, and we're still wrangling about the placement, a year later. No work is scheduled yet. "It will affect the Christmas tree". "I don't like it.". "We've got to do this.". . .

Nothing happens quickly in a Church.

For Youth Day, some of the young people took some of the hymns and changed the words. I remember part of one based on the old song, "Onward, Christian Soldiers".

"Like a herd of turtles,

Moves the church of God.

Brothers, we are trodding

Where we've always trod.."

But I've been lucky. They didn't make me go through countless meetings. That's why I'm being so pro-active. I know who will be responsible - and get blamed if things don't turn out right. 😡

Bach On

We've had some spurious sounds in our PA system. I've been working with one of the "I'll get it done" guys to troubleshoot the issue, but it's taken many months to get a handle on where it's been coming from. Finally substituted one of my own mics for the pulpit mic, and that's solved it, though the actual cause is still murky. We're thinking that 30 year old XLR connectors may be part of it, plus that 30 year old condenser mic (my mic is dynamic, so doesn't require phantom power).

Our organist has been making noises about the age of our Rogers organ, too, though I've assured him we can keep the amps and speaker drivers working for quite some time yet.

Our organist has been making noises about the age of our Rogers organ, too, though I've assured him we can keep the amps and speaker drivers working for quite some time yet.

Behringer makes a small diaphragm mike called the C-2. I've used these for many purposes. They are actually pretty good mikes. It's about the size of a magic marker - so it would work well for a pulpit situation - though it is silver, rather than black. They use phantom power and come in a package of two - with a stand clip and a foam pop shield. Seems like I paid $50 for a pair. They work pretty well for pulpit mikes too. 30 years of weekly use is pretty old for a mike.

It's good to have someone who can help with the amps and speakers go bad. But you must know there is more than amps and speakers in an organ. What specific noises is the the organist saying he/she sees as the problems..

I guess corrosion on 30 year old XLR solder joints is possible. Can you identify the cable causing the problem by process of elimination? But if the problem disappeared when you used a dynamic mike, I'd think that replacing that cable might be wise.

Good luck!

.

Bach On

It's good to have someone who can help with the amps and speakers go bad. But you must know there is more than amps and speakers in an organ. What specific noises is the the organist saying he/she sees as the problems..

I guess corrosion on 30 year old XLR solder joints is possible. Can you identify the cable causing the problem by process of elimination? But if the problem disappeared when you used a dynamic mike, I'd think that replacing that cable might be wise.

Good luck!

.

Bach On

We will certainly look into the Behringer mic as a replacement. The old mic is a Shure, and other than the random pops seems to work just fine. Of course, everybody is happy with the sound from my old Beyer 160, because there are no such pops.

Replacing one cable in the "snake" isn't going to happen any time soon. Nobody is going to crawl through the plenum where it's routed, but changing connectors on the ends is possible.

We tried for months to isolate the problem by unplugging stuff.. Never actually got anywhere because the problem is so random...

Thanks for the input, I appreciate it.

Replacing one cable in the "snake" isn't going to happen any time soon. Nobody is going to crawl through the plenum where it's routed, but changing connectors on the ends is possible.

We tried for months to isolate the problem by unplugging stuff.. Never actually got anywhere because the problem is so random...

Thanks for the input, I appreciate it.

- Status

- Not open for further replies.

- Home

- Loudspeakers

- Subwoofers

- 16Hz for church organ