wow - just remembered that somewhere I've got 50 feet x 6in. of that stuff - about how big to cut the damping piece? - better square or round-ish?

wow - just remembered that somewhere I've got 50 feet x 6in. of that stuff - about how big to cut the damping piece? - better square or round-ish?

I don't think the shape matters that much. I think I went with a 1cm square bit to damp the bender in the 3x7s I was testing.

thanks - I don't want to overdamp things. on the plasma ball discharge - there was a "zzzzztttttt" sound - something I associate with AC rather than a 'snap' with static electricity - could there been a spin induced as it formed off the power lines? - why might it sound something like a Jacob's ladder arc?

when trying to get enough space to apply the damping square to the bender, I pulled the cone off the bender - put a drop of Titebond on it as its the only glue in the house - don't know if it will adhere properly or not 😱

Believe it or not, I finally did (believe it) after they both told the same story.

Eventually my mother said she did not want to talk about it.

She was always very agitated when she had talked about the subject.

I have never found any mention of this in news stories, anywhere.

It happened in the mid '80's.

Dave

I would imagine that someone who sees something so rare and strange would have to become dispirited after telling the story so many times and being met with cynicism, blank stares, or the looks of disbelief, as if you are saying you saw Bigfoot riding a flying unicorn!

It is a shame that some sort of herd mentality tends to have people mistakenly equate rare stories with less credible stories, and the "Phoenix Lights" are an example that immediately come to my mind.. .....At one time here in Arizona a person might be considered a kookball nutjob if they say they saw some weird unexplainable things in the skies but during the 90s things really began to change when the frequency of UFO reports went through the roof ... It is interesting to see how people change their tune after enough folks see the same mysterious unexplainable things and everyone starts talking about it, or when it ends up on the news as it did here in the phoenix area back in those days due to hundreds upon hundreds of sightings within a short amount of time .... Even the Governor spotted these weird light formations and giant black hovering triangles or V shaped objects moving overhead..... This whole concept of something extremely peculiar taking place in our skies sprung out of kooky obscurity and transitioned into common acceptance (despite the lack of scientific evidence one way or another) for a time that is, until the activity subsided .... At the very least it was an interesting social experiment😛...

Phoenix Lights - Wikipedia, the free encyclopedia

Piezos driven by Ball Lightning !

I have used a little dab of epoxy to attach a cone back onto the bender , it worked .....

Freddi,

I am going to see if i can take a good picture of the GRS 1016 throat/phase-plug next to the Goldwood throat to post on here, i noticed that there is a significant difference between the two throats and the increased compression of the GW horn may be what is flattening out the response when making a Frankenpiezo .... I wonder if this can somehow be applied to the 1005 ..

Your posted response graph of the stock GRS 1005 is pretty wild looking ! EEK ! 😱

😱

Looking forward to seeing how that damping material tames the response for you ...

when trying to get enough space to apply the damping square to the bender, I pulled the cone off the bender - put a drop of Titebond on it as its the only glue in the house - don't know if it will adhere properly or not 😱

I have used a little dab of epoxy to attach a cone back onto the bender , it worked .....

Freddi,

I am going to see if i can take a good picture of the GRS 1016 throat/phase-plug next to the Goldwood throat to post on here, i noticed that there is a significant difference between the two throats and the increased compression of the GW horn may be what is flattening out the response when making a Frankenpiezo .... I wonder if this can somehow be applied to the 1005 ..

Your posted response graph of the stock GRS 1005 is pretty wild looking ! EEK !

😱

😱Looking forward to seeing how that damping material tames the response for you ...

- two big variables - well one - the re-glued cone using Titebond, then the speaker was sitting on bonded Dacron so may not be exactly where it was for the first graph

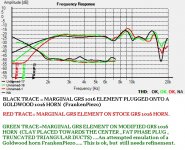

does this look plausible enough?

does this look plausible enough?

GRS , Goldwood throat comparison

Right on🙂 Well that does definitely look a little better, still some room for improvement though ...

I have to wonder if it would flatten out like a Frankenpiezo if we could squeeze the throat's CSA somewhat ...... The reason i say that is because of the differences i can see between the 1016 horn throats, I finally got a good picture of what i am talking about .....

Take a look at the attached photo, the Goldwood is on the right and the GRS is on the left .... You can see that they both have 6 little triangular shaped ducts that make up the throat, but the points of the triangles on the GW are truncated, and the bases of those triangles are smaller as well ..... This means that the Goldwood throat is considerably smaller. Could this increased compression be the reason for the flat response?

Could increasing the compression on a GRS horn (as in the 1005) be as easy as plugging 2 or 3 of the 6 vents? I know that with these extremely short wavelengths the throat geometry can get really tricky and critical so there are no guarantees it would work but it might be worth the experiment ..... I could try it with a GRS 1016 , but i don't have any 1005s ...

- two big variables - well one - the re-glued cone using Titebond, then the speaker was sitting on bonded Dacron so may not be exactly where it was for the first graph

does this look plausible enough?

Right on🙂 Well that does definitely look a little better, still some room for improvement though ...

I have to wonder if it would flatten out like a Frankenpiezo if we could squeeze the throat's CSA somewhat ...... The reason i say that is because of the differences i can see between the 1016 horn throats, I finally got a good picture of what i am talking about .....

Take a look at the attached photo, the Goldwood is on the right and the GRS is on the left .... You can see that they both have 6 little triangular shaped ducts that make up the throat, but the points of the triangles on the GW are truncated, and the bases of those triangles are smaller as well ..... This means that the Goldwood throat is considerably smaller. Could this increased compression be the reason for the flat response?

Could increasing the compression on a GRS horn (as in the 1005) be as easy as plugging 2 or 3 of the 6 vents? I know that with these extremely short wavelengths the throat geometry can get really tricky and critical so there are no guarantees it would work but it might be worth the experiment ..... I could try it with a GRS 1016 , but i don't have any 1005s ...

Attachments

Last edited:

good idea - either that - or whittle things so the phase plug is closer to the cone - -for a 2-way Karlflex, a standard compression driver on a homemade K-tube would be "hi-fi"

Karlflex is in cue =)

Got any clay Freddi? that might be a fun and fast temporary way to block a few of the little vents in the 1005 to get a measurement ..... I might try it here since i have so many of these GRS 1016 horn bodies left , but the only elements i have left are the ones that didn't measure well initially ... . hmmm ... I might still try it and see if i can match the response of the same element in the GW horn ... Or maybe i will just rob a good element from one of the arrays ...

🙂

I am getting around to starting the build on the Karflex boxes, i just have one project that kind of got in the way that needs to be finished ... I ended up with a couple of old BFM DR250s , one got dropped out of a truck and was damaged, i almost got it all patched up now ... I am thinking about finishing them with Duratex , people seem to love the stuff ...

good idea - either that - or whittle things so the phase plug is closer to the cone - -for a 2-way Karlflex, a standard compression driver on a homemade K-tube would be "hi-fi"

Got any clay Freddi? that might be a fun and fast temporary way to block a few of the little vents in the 1005 to get a measurement ..... I might try it here since i have so many of these GRS 1016 horn bodies left , but the only elements i have left are the ones that didn't measure well initially ... . hmmm ... I might still try it and see if i can match the response of the same element in the GW horn ... Or maybe i will just rob a good element from one of the arrays ...

🙂

I am getting around to starting the build on the Karflex boxes, i just have one project that kind of got in the way that needs to be finished ... I ended up with a couple of old BFM DR250s , one got dropped out of a truck and was damaged, i almost got it all patched up now ... I am thinking about finishing them with Duratex , people seem to love the stuff ...

Modeling clay (plastic oily stuff) works great to smooth horn throats. I have used it on several occasions with great (measurable) success. You can make a phase plug with that stuff if you are handy. In hot weather it gets too soft though.

Modeling clay (plastic oily stuff) works great to smooth horn throats. I have used it on several occasions with great (measurable) success. You can make a phase plug with that stuff if you are handy. In hot weather it gets too soft though.

There is a Hobby & Art Supply store down the street, i will drop in on them tomorrow and have me some modeling clay! 🙂

Get DAS, or FIMO, or whatever the brand is in your country. It's a clay that you work into the shape that you want, then bake it in the oven at a low heat for a while and it hardens. Once it has hardened it can be worked with hand tools - file, drill etc. The Hobby and Art store should have it - just ask for "modeling clay that bakes hard in the oven".

By accident I found out that the new kids "Play Dough" brand has been reformulated. It used to dry into brittle salt encrusted dough. Now it hardens into a smooth hard plastic like material that feels almost like corian in hardness and "click" when you tap it against a hard surface after it dries.

CLAY PIEZO FUN AND FUNKYNESS, Experiments and Adventures!

Ok , i ended up getting some clay from my artist friend who makes clay figurines .... He gave me two different types, one is something that he called a polymer clay which is a type that you can harden by baking in the oven like Don Hills recommended and the other was a type of modeling clay .... I ended up using the softer of the two (the polymer clay i believe) for ease of use and i knew this was all going to be very temporary, so the soft stuff works , if i wanted the modifications to last longer i would use the harder modeling clay....

I basically only wanted to see if i could modify the GRS 1016 throat to match the performance of the Goldwood horn with the GRS element/cone assembly loaded onto the back of it ....

IMPORTANT NOTE:

I WANT TO MAKE SURE TO POINT OUT THAT THIS GRS ELEMENT IS NOT AS GOOD AS THE ONES WE USED IN THE FRANKENPIEZOS , this particular GRS element used in this experiment was one of the rejected elements i had left over from other projects ..... It wasn't really smooth enough to be included into the Franken-arrays but i hung on to this one and a few of the other marginal GRS elements just in case i would find a less critical use for them in the future ..... Needless to say this element will never measure as flat as some of the better GRS elements....... The Piezo is also not using any crossover or step-up transformer in these measurements, in other words this would be considered a very poor implementation, so one cannot realistically expect any miracles, all that we are looking for here in these tests are relative changes in an attempt to get an idea about which direction to take the geometry .....

All of this experimentation gives me a good idea of what changes would have to be made to the GRS horn to make it perform more similarly to the Goldwood horn .... It seems like (at least part of) the magik of the FrankenPiezo revolves around a much thicker phase plug and ducts that have a trapezoidal shape ..... I feel as though performance could have been improved further if this same (GW style) trap duct shape and large phase plug were used along with enlarging the triangular duct's bases (outer facing edge) ...

Another worthwhile experiment would be going to 8 or 10 smaller ducts instead of 6 large ones but i suppose that might make them difficult to manufacture ...

I am sure there are other minor geometric alterations that a very patient enthusiast could perfect to further optimize the horn, and it could be fully sorted out with lots of trial and error , but i'm not sure what anyone would do with this information unless someone with the right machinery is willing to create the molds of the optimized horn and start producing them....................... It would be a great accomplishment (and also quite practical) to be able to manufacture a knock-off of a Motorola Piezo product that actually has a smoother response than the original Motorola 1016 unit!!!!

, but i'm not sure what anyone would do with this information unless someone with the right machinery is willing to create the molds of the optimized horn and start producing them....................... It would be a great accomplishment (and also quite practical) to be able to manufacture a knock-off of a Motorola Piezo product that actually has a smoother response than the original Motorola 1016 unit!!!!

It is really a shame that PE isn't selling the Goldwood 1016 horn lately, it really was an extraordinary match for the GRS element , like Brian Steele said it was so perfect that discovering the combination was like "winning the lottery"!

, like Brian Steele said it was so perfect that discovering the combination was like "winning the lottery"!

Ok , i ended up getting some clay from my artist friend who makes clay figurines .... He gave me two different types, one is something that he called a polymer clay which is a type that you can harden by baking in the oven like Don Hills recommended and the other was a type of modeling clay .... I ended up using the softer of the two (the polymer clay i believe) for ease of use and i knew this was all going to be very temporary, so the soft stuff works , if i wanted the modifications to last longer i would use the harder modeling clay....

I basically only wanted to see if i could modify the GRS 1016 throat to match the performance of the Goldwood horn with the GRS element/cone assembly loaded onto the back of it ....

IMPORTANT NOTE:

I WANT TO MAKE SURE TO POINT OUT THAT THIS GRS ELEMENT IS NOT AS GOOD AS THE ONES WE USED IN THE FRANKENPIEZOS , this particular GRS element used in this experiment was one of the rejected elements i had left over from other projects ..... It wasn't really smooth enough to be included into the Franken-arrays but i hung on to this one and a few of the other marginal GRS elements just in case i would find a less critical use for them in the future ..... Needless to say this element will never measure as flat as some of the better GRS elements....... The Piezo is also not using any crossover or step-up transformer in these measurements, in other words this would be considered a very poor implementation, so one cannot realistically expect any miracles, all that we are looking for here in these tests are relative changes in an attempt to get an idea about which direction to take the geometry .....

- First of all i tried plugging a few of the throat ducts on the GRS horn throat to increase compression in an attempt to match the total CSA of the Goldwood's throat, and this method produced ragged response with two ducts plugged , and then with three ducts plugged it made the response even more erratic so it became clear that this isn't going to be as simple as needing some increased compression, there is going to be more to this Frankenmystery 😛 ...

- Second: I added the clay to the inward-facing point of the triangular ducts making them truncated triangle shapes just like the Goldwood 1016 uses , and the clay lined the inside of those ducts all the way through the channels up to where all the channels merge at the other side of the phase plug .... This basically results in a thicker phase plug (more girth), once again resembling the Goldwood horn ....... THIS METHOD PRODUCED THE BEST RESULTS ... A reasonable improvement over the stock GRS horn , and almost as good as the Goldwood horn (and in some respects better, such as less of a dip at 18khz) ...

- Third attempt: I attempted the opposite of the above by moving the clay to the outer edge of the throat ducts , basically filling in the bases of the triangles ..... This produced terrible results with a response that was even inferior to the stock GRS horn .....

- Fourth attempt: A combination of the above methods filling in all points of the triangular ducts making them more like tubular ducts and the results were mediocre at best, no real improvement over the stock GRS horn ....

All of this experimentation gives me a good idea of what changes would have to be made to the GRS horn to make it perform more similarly to the Goldwood horn .... It seems like (at least part of) the magik of the FrankenPiezo revolves around a much thicker phase plug and ducts that have a trapezoidal shape ..... I feel as though performance could have been improved further if this same (GW style) trap duct shape and large phase plug were used along with enlarging the triangular duct's bases (outer facing edge) ...

Another worthwhile experiment would be going to 8 or 10 smaller ducts instead of 6 large ones but i suppose that might make them difficult to manufacture ...

I am sure there are other minor geometric alterations that a very patient enthusiast could perfect to further optimize the horn, and it could be fully sorted out with lots of trial and error

, but i'm not sure what anyone would do with this information unless someone with the right machinery is willing to create the molds of the optimized horn and start producing them....................... It would be a great accomplishment (and also quite practical) to be able to manufacture a knock-off of a Motorola Piezo product that actually has a smoother response than the original Motorola 1016 unit!!!!

, but i'm not sure what anyone would do with this information unless someone with the right machinery is willing to create the molds of the optimized horn and start producing them....................... It would be a great accomplishment (and also quite practical) to be able to manufacture a knock-off of a Motorola Piezo product that actually has a smoother response than the original Motorola 1016 unit!!!! It is really a shame that PE isn't selling the Goldwood 1016 horn lately, it really was an extraordinary match for the GRS element

, like Brian Steele said it was so perfect that discovering the combination was like "winning the lottery"!

, like Brian Steele said it was so perfect that discovering the combination was like "winning the lottery"!

Attachments

-

FourthAttempt-Front-Fail.jpg340.2 KB · Views: 111

FourthAttempt-Front-Fail.jpg340.2 KB · Views: 111 -

Fourth Attempt2-Back-Fail.jpg229.7 KB · Views: 116

Fourth Attempt2-Back-Fail.jpg229.7 KB · Views: 116 -

Attempt3-Back.jpg234.3 KB · Views: 249

Attempt3-Back.jpg234.3 KB · Views: 249 -

Attempt3-Front.jpg258.9 KB · Views: 264

Attempt3-Front.jpg258.9 KB · Views: 264 -

Attempt2---Successs-Front.jpg238.6 KB · Views: 266

Attempt2---Successs-Front.jpg238.6 KB · Views: 266 -

Attempt2---Success--Back.jpg252.5 KB · Views: 269

Attempt2---Success--Back.jpg252.5 KB · Views: 269 -

ThroatDesign-Left=GRS___Right=GW.JPG626.2 KB · Views: 282

ThroatDesign-Left=GRS___Right=GW.JPG626.2 KB · Views: 282 -

Piezo-GRS-GW-Franken(black)---STOCK GRS with damping (red)----GRS with clay fattened phase plug .JPG250.8 KB · Views: 126

Piezo-GRS-GW-Franken(black)---STOCK GRS with damping (red)----GRS with clay fattened phase plug .JPG250.8 KB · Views: 126 -

AdamClay.jpg129.3 KB · Views: 132

AdamClay.jpg129.3 KB · Views: 132

Last edited:

FAB experiments - perhaps you can get a job with GRS !!!! - if you do, please put a stronger mud magnet on their BOFU and ditch the foam surround. I tried to get another model Le Son but the online really didn't have them in stock. I'm looking for clay to kludge a Saulsalito cavity - is the new Play-doh good nuff? - Crayola's oven-bake clay gets horrible reviews.

Last edited:

hYpNoRaMpAgE!

Freddi,

What is a "Saulsalito cavity" ?

and YES work for GRS? maybe ... Or I could just use my powers of hypnosis and compel them to: " use newly optimized throats in your piezo horns

use newly optimized throats in your piezo horns  and use better surrounds in their BOFU (like Santoprene or a rolled/treated cloth) and higher grade magnetic material

and use better surrounds in their BOFU (like Santoprene or a rolled/treated cloth) and higher grade magnetic material  "....

"....

Then i would drop in on the MCM guys and say: " Use a better grade of ferrite

Use a better grade of ferrite in your house brand drivers

in your house brand drivers " ....

" ....

Then my next stop would be Goldwood to urge them to: " Use better piezo benders

Use better piezo benders  that are similar to what GRS uses

that are similar to what GRS uses "

"

...........

😉

....

Ok, Seriously though, any one of these companies should be able to call their Chinese OEMs and request changes like this if they really wanted to right?

Is it possible that they really don't care enough to bother with it? Or is it simply a lack of control? I would hope that these brands have at least some amount of control in their relationship with their manufacturing sources, if not it sounds like a bad marriage to me 😛

Really, the changes might cost them an additional 10 cents per unit (in the case of the Piezos) , BUT i know people would be willing to pay an extra dollar per piezo horn if it performed like a GRS/GW Frankenpiezo.........In the case of the woofers their cost may increase an extra dollar per unit but i would assume that people would be willing to pay an extra 5 dollars for an MCM woofer that has a strong motor and proper T/S parameters (reasonably low QES/QTS and high efficiency like what is published) so it would SEEM to be an intelligent business decision to order the changes because the long term benefits would be obvious (increased profit margin, higher sales, improved reputation) ....

FAB experiments - perhaps you can get a job with GRS !!!! - if you do, please put a stronger mud magnet on their BOFU and ditch the foam surround. I tried to get another model Le Son but the online really didn't have them in stock. I'm looking for clay to kludge a Saulsalito cavity - is the new Play-doh good nuff? - Crayola's oven-bake clay gets horrible reviews.

Freddi,

What is a "Saulsalito cavity" ?

and YES work for GRS? maybe ... Or I could just use my powers of hypnosis and compel them to: "

use newly optimized throats in your piezo horns

use newly optimized throats in your piezo horns  and use better surrounds in their BOFU (like Santoprene or a rolled/treated cloth) and higher grade magnetic material

and use better surrounds in their BOFU (like Santoprene or a rolled/treated cloth) and higher grade magnetic material  "....

".... Then i would drop in on the MCM guys and say: "

Use a better grade of ferrite

Use a better grade of ferrite in your house brand drivers

in your house brand drivers " ....

" .... Then my next stop would be Goldwood to urge them to: "

Use better piezo benders

Use better piezo benders  that are similar to what GRS uses

that are similar to what GRS uses "

"...........

😉

....

Ok, Seriously though, any one of these companies should be able to call their Chinese OEMs and request changes like this if they really wanted to right?

Is it possible that they really don't care enough to bother with it? Or is it simply a lack of control? I would hope that these brands have at least some amount of control in their relationship with their manufacturing sources, if not it sounds like a bad marriage to me 😛

Really, the changes might cost them an additional 10 cents per unit (in the case of the Piezos) , BUT i know people would be willing to pay an extra dollar per piezo horn if it performed like a GRS/GW Frankenpiezo.........In the case of the woofers their cost may increase an extra dollar per unit but i would assume that people would be willing to pay an extra 5 dollars for an MCM woofer that has a strong motor and proper T/S parameters (reasonably low QES/QTS and high efficiency like what is published) so it would SEEM to be an intelligent business decision to order the changes because the long term benefits would be obvious (increased profit margin, higher sales, improved reputation) ....

sometimes a cheap speaker is so close to being a good speaker but a decision for cosmetic appeal occurs to ruin the design - I bought a 10" Boss speaker for @20 delivered - decent motor, etc. - fancy all metal phase "plug" - but the voice coil former was terminated with a chrome plastic ring which I think screwed with the response.

here's the famous Saulsalito lens with a dome - a compression driver could be used http://i.ytimg.com/vi/wzZwJjQelmE/maxresdefault.jpg

here's the famous Saulsalito lens with a dome - a compression driver could be used http://i.ytimg.com/vi/wzZwJjQelmE/maxresdefault.jpg

Oh i see! That lens looks like it could be reproduced with clay , my artist friend has been able to create objects with intricate detail, and then he bakes them and they become hard like plastic ...

I asked him about what type he uses and he says it is "SUPER SCULPEY" .

I asked him about what type he uses and he says it is "SUPER SCULPEY" .

Attachments

Question for Freddi

Mr Freddi ,

🙂

I am getting ready to make some sawdust soon and i am just going over some details ....

I have a question for you since you are very familiar with the K boxes ..

Do any of the Karlsons have the driver facing into the vertical midpoint of the aperture instead of facing into the bottom of the aperture (largest area/mouth) like i have seen in most K cabs?

I am simming these Karlflex boxes in akabak and it really seems that the Dayton PA310 likes to be placed about halfway up the baffle to give it a little more offset in the path, unlike the rest of the drivers such as the Alpines and the LAB15-4 prefer a little less offset and can be mounted towards the bottom of the baffle firing into the Aperture's largest opening ( standard K placement) ..

Mr Freddi ,

🙂

I am getting ready to make some sawdust soon and i am just going over some details ....

I have a question for you since you are very familiar with the K boxes ..

Do any of the Karlsons have the driver facing into the vertical midpoint of the aperture instead of facing into the bottom of the aperture (largest area/mouth) like i have seen in most K cabs?

I am simming these Karlflex boxes in akabak and it really seems that the Dayton PA310 likes to be placed about halfway up the baffle to give it a little more offset in the path, unlike the rest of the drivers such as the Alpines and the LAB15-4 prefer a little less offset and can be mounted towards the bottom of the baffle firing into the Aperture's largest opening ( standard K placement) ..

Last edited:

- Home

- Loudspeakers

- Subwoofers

- New sub design? Constricted Transflex, simple build (series tuned 6th order)