What do you do with your old prototypes?

Most get stored in the basement until I need them later, many hang out in the Foam Core Lab, and some are given away as gifts or used throughout the house for listening. My wife really likes the 0.4x's in the kitchen with a 3.5mm jack for her to plug her phone into to listen to mp3's.

Foam Core Lab:

Hi Xrk971,

I am new to speaker building, can you advice how to scale it to a slim floor standing model (less than 10 inches for width)? The floor standing model should give a longer path for TL, would the base still be tight but stronger? I am searching for different model to try for a 4inches MA driver.

Thanks

I am new to speaker building, can you advice how to scale it to a slim floor standing model (less than 10 inches for width)? The floor standing model should give a longer path for TL, would the base still be tight but stronger? I am searching for different model to try for a 4inches MA driver.

Thanks

Hi Xrk971,

I am new to speaker building, can you advice how to scale it to a slim floor standing model (less than 10 inches for width)? The floor standing model should give a longer path for TL, would the base still be tight but stronger? I am searching for different model to try for a 4inches MA driver.

Thanks

Hi Skylab,

Your TPA3116D2's ought to work really well with these. You really can't stretch the height that much more with the MA 4in drivers. Maybe using two of them in parallel you may approach close to full scale Karlsonator which is about 30in high - a good floorstander. I would suggest using a bigger driver. But if you want, I can sim a dual MA 4in driver for you in a floorstander to see how big it needs to be. Get me the exact model of driver so I can model the T/S parameters.

or...

If you want a floor standing speaker for a 4in MA (CHR70 or A7), the FH3 is the way to go. They are normally made out of wood, but you can make it out of foam core if you want. I made an homage to one scaled down for a TC9FD. More info here:

http://www.diyaudio.com/forums/full-range/227460-fh3-inspired-foam-core-mini-build.html

For the 4in MA, just build it to full scale per the plans here:

http://www.p10hifi.net/FH/downloads/frugel-hornMk3-1v0-250212.pdf

More info in this thread here:

http://www.diyaudio.com/forums/full-range/172605-frugel-horn-mk3.html

Hi Xrk971,

I just started on this so I got a pair of entry level MA CHN70 to play with and try to see what I can get out of them. Your point in using twin 4 " drivers are very attractive, please kindly do a simulation on it.

As for the FH3, the foot print is a bit to big, it extended back quite a bit at the bottom so I have to skip that.

The foam core Karlson is an excellent way for prototyping this speaker, definitely will try on that first to get a grip on these.

Thanks

I just started on this so I got a pair of entry level MA CHN70 to play with and try to see what I can get out of them. Your point in using twin 4 " drivers are very attractive, please kindly do a simulation on it.

As for the FH3, the foot print is a bit to big, it extended back quite a bit at the bottom so I have to skip that.

The foam core Karlson is an excellent way for prototyping this speaker, definitely will try on that first to get a grip on these.

Thanks

Hi Xrk971,

I just started on this so I got a pair of entry level MA CHN70 to play with and try to see what I can get out of them. Your point in using twin 4 " drivers are very attractive, please kindly do a simulation on it.

As for the FH3, the foot print is a bit to big, it extended back quite a bit at the bottom so I have to skip that.

The foam core Karlson is an excellent way for prototyping this speaker, definitely will try on that first to get a grip on these.

Thanks

For dual CHN70's wired in parallel, you will get great sensitivity. Make the cabinet with a 0.60x scale for height and depth, and 0.45x scale in width. You should have a speaker that is 93dB sensitivity at 2.83v with 58Hz -3dB bass extension. It should not require any BSC circuit.

For dual CHN70's wired in parallel, you will get great sensitivity. Make the cabinet with a 0.60x scale for height and depth, and 0.45x scale in width. You should have a speaker that is 93dB sensitivity at 2.83v with 58Hz -3dB bass extension. It should not require any BSC circuit.

I will need to study more to understand what these scaling factors mean.

I havn't been in US for thanksgiving for many years, got to call my parent tonight.

Thanks and happy Thanksgiving.

I will need to study more to understand what these scaling factors mean.

I havn't been in US for thanksgiving for many years, got to call my parent tonight.

Thanks and happy Thanksgiving.

From post #1, taken GregB's original Karlsonator drawing and scale it like I have suggested in height and depth by 0.60x, and 0.45x in width. Or take one of the 0.53x drawings (like the one made by Tb46 here (http://www.diyaudio.com/forums/attachments/full-range/385287d1385943691-mini-karlsonator-0-53x-dual-tc9fds-karlsonator_.53x_dual_vifa_tc9fd.pdf ) and scale that by 0.60/0.53=1.13x. Then make the width 6.75in wide (internal width).

Happy customer, with this insta dry glue called nextabond 2500s I assembled this in under 3 hours (about 2 more hours for cutting, I'm slow I know). The glue take 5-7 minutes to cure but 1 minute to be tacky enough to move on, 5 seconds if you spray accelerant (no joke).

The k-wing baffle was routed using a custom 15 inch radius arm jig I made. That's why the end is curved rather than square. Sounds pretty impressive for a 3 inch driver, I can only imagine what the 8's must sound like. Only one built at the moment, I think I'm the first on this thread to do MDF though and I have to say it is forgiving and decently strong (see concrete pic).

The k-wing baffle was routed using a custom 15 inch radius arm jig I made. That's why the end is curved rather than square. Sounds pretty impressive for a 3 inch driver, I can only imagine what the 8's must sound like. Only one built at the moment, I think I'm the first on this thread to do MDF though and I have to say it is forgiving and decently strong (see concrete pic).

Attachments

Great work Sabaspeed! That is a fast build. The foam core version can be made in about 2 hrs including cutting. This is the single middle strip score and fold method. Only need to cut the sides, top, wings, and one long strip for internals. Then hot melt glue sets in 40 seconds. Glad they worked out🙂 the 0.4x models seem to be universally liked upon listening.

I'm almost in tears over how good this little sucker sounds with a 65 HZ HP and like 2 bands of eq (not really necessary but personal preference house eq). Absolutely astounding output after HPing out the lows but still sounds very full (considering). These cost me more in glue than wood/drivers, but still have extremely solid sound quality. Almost magical. I can push them so much harder while still being crisp when filtering the sub 65. And I don't even have the second one yet (wood/mdf shortage). Can't wait!

Those are my mini's in that video...

Hi, it's a first post for me here at diyAudio.

Been a member for about almost a year and a half now, but mostly just reading and studying... 😀

Anyway, thanks to GregB, XRK971, freddii, and all of the helpful folks here at DiyAudio, I finished my first set of foamcore Karlsonators.

Those are my mini's in the video freddii linked, but my first couple of videos on Youtube wasn't recorded right, so I made some new ones in case if somebody wants to check them out😉

Here's the pics...

hi walters - hey - here's a nice pair of 2 inch BMR Karlsonators playing on YouTube Mini Karlsonator 2 inch BMR 01 - YouTube

Hi, it's a first post for me here at diyAudio.

Been a member for about almost a year and a half now, but mostly just reading and studying... 😀

Anyway, thanks to GregB, XRK971, freddii, and all of the helpful folks here at DiyAudio, I finished my first set of foamcore Karlsonators.

Those are my mini's in the video freddii linked, but my first couple of videos on Youtube wasn't recorded right, so I made some new ones in case if somebody wants to check them out😉

Here's the pics...

Attachments

-

IMG_1506.jpg265.8 KB · Views: 292

IMG_1506.jpg265.8 KB · Views: 292 -

IMG_1505.jpg237 KB · Views: 320

IMG_1505.jpg237 KB · Views: 320 -

IMG_1503.jpg322.2 KB · Views: 635

IMG_1503.jpg322.2 KB · Views: 635 -

IMG_1494.jpg355.4 KB · Views: 1,246

IMG_1494.jpg355.4 KB · Views: 1,246 -

IMG_1491.jpg355.8 KB · Views: 654

IMG_1491.jpg355.8 KB · Views: 654 -

IMG_1487.jpg411.5 KB · Views: 649

IMG_1487.jpg411.5 KB · Views: 649 -

IMG_1485.jpg219.3 KB · Views: 630

IMG_1485.jpg219.3 KB · Views: 630 -

IMG_1510.jpg366.7 KB · Views: 319

IMG_1510.jpg366.7 KB · Views: 319 -

IMG_1511.jpg281.4 KB · Views: 340

IMG_1511.jpg281.4 KB · Views: 340 -

IMG_1512.jpg296.4 KB · Views: 312

IMG_1512.jpg296.4 KB · Views: 312

I'm almost in tears over how good this little sucker sounds with a 65 HZ HP and like 2 bands of eq (not really necessary but personal preference house eq). Absolutely astounding output after HPing out the lows but still sounds very full (considering). These cost me more in glue than wood/drivers, but still have extremely solid sound quality. Almost magical. I can push them so much harder while still being crisp when filtering the sub 65. And I don't even have the second one yet (wood/mdf shortage). Can't wait!

Sabaspeed,

Thank you for the great feedback. So glad you like them and good tip on running them with a high pass filter. Have you tried running them with your mass loaded tapped pipe sub? Looking forward to your stereo experience.

Regards,

X

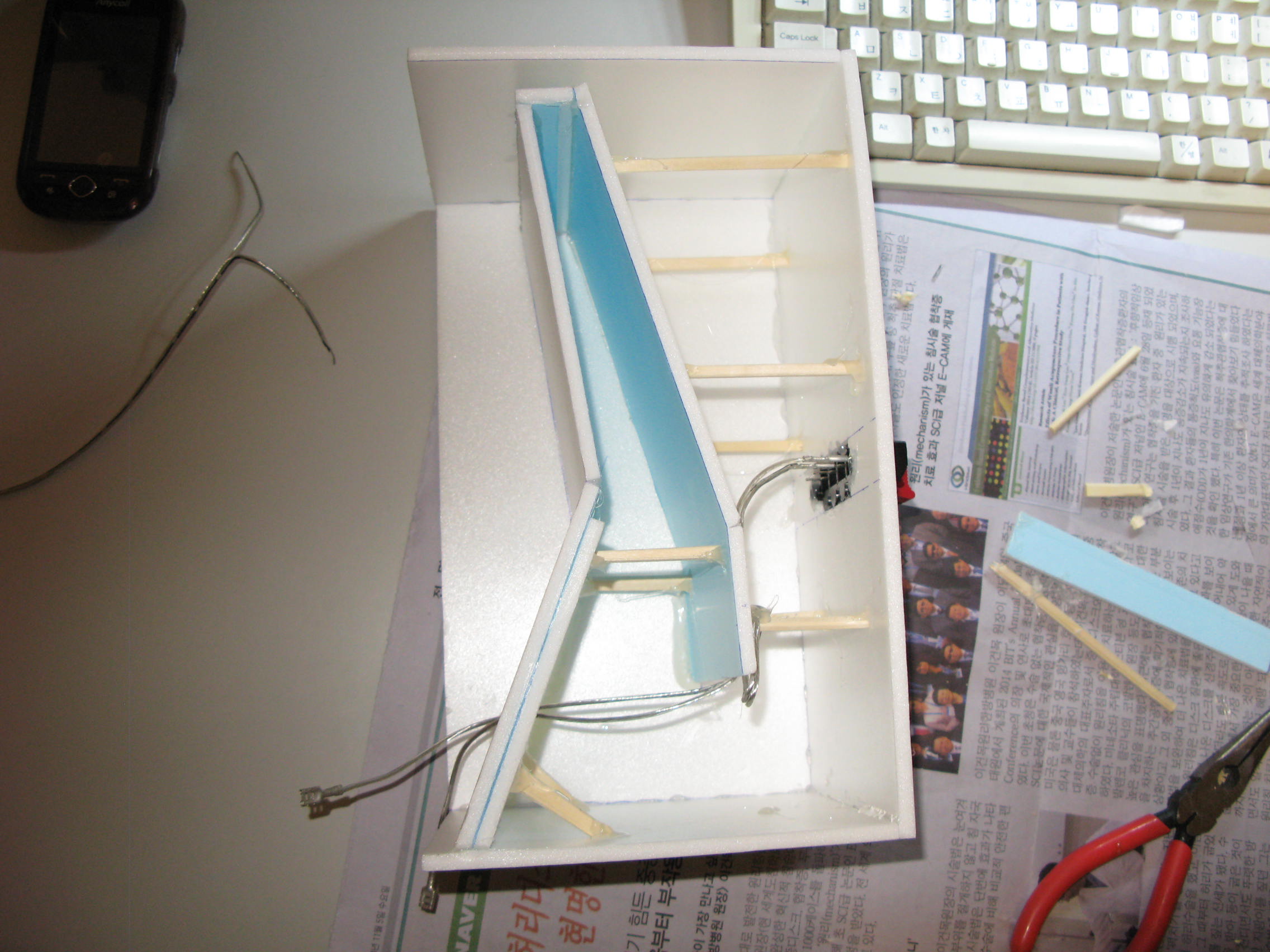

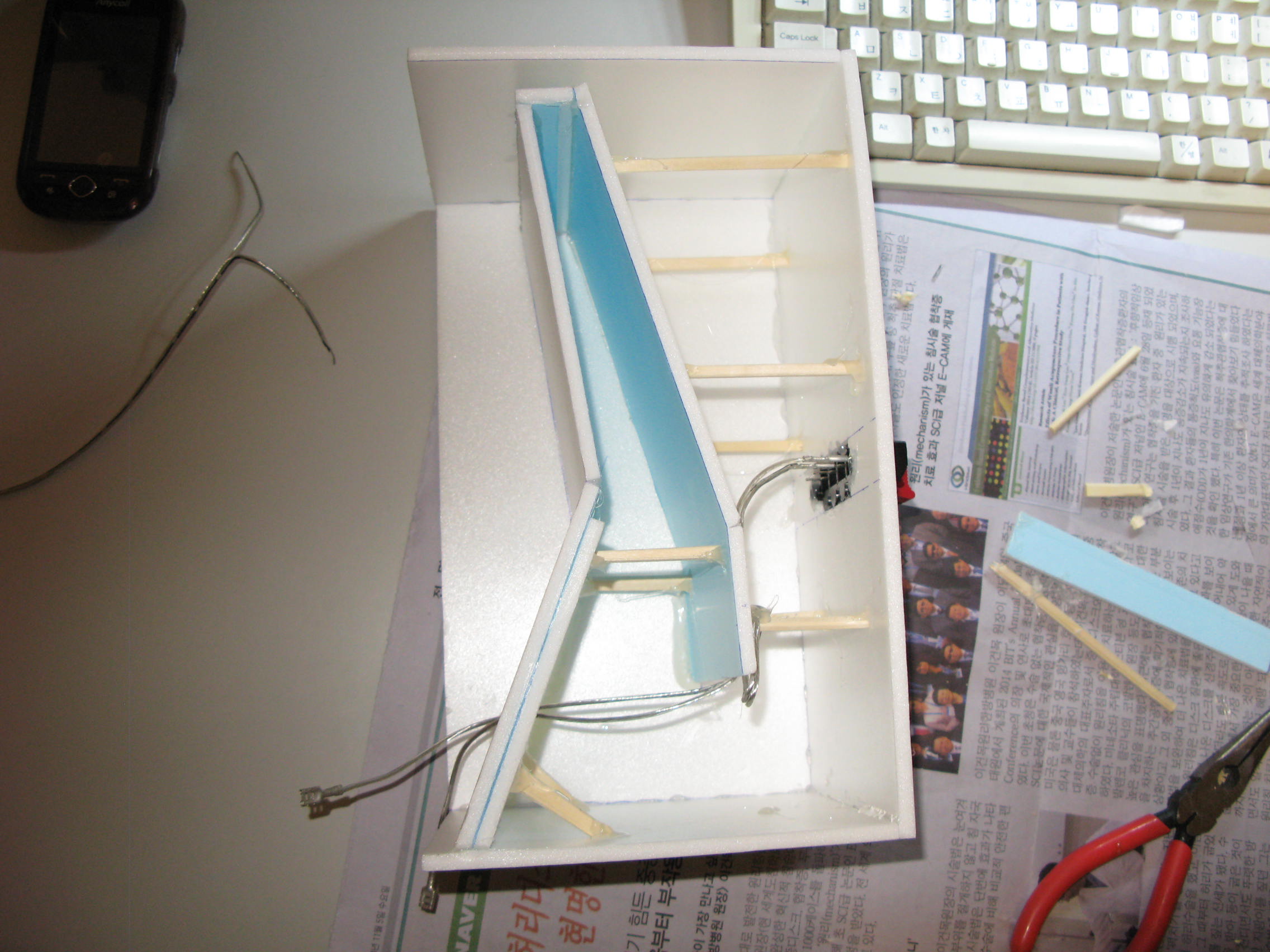

Hi, it's a first post for me here at diyAudio.

Been a member for about almost a year and a half now, but mostly just reading and studying... 😀

Anyway, thanks to GregB, XRK971, freddii, and all of the helpful folks here at DiyAudio, I finished my first set of foamcore Karlsonators.

Those are my mini's in the video freddii linked, but my first couple of videos on Youtube wasn't recorded right, so I made some new ones in case if somebody wants to check them out😉

Here's the pics...

Bolexsbm,

Beautiful work on your foam core creations. Which driver is this and did you decide to just try it out or was there a sim for it somewhere? Neat new construction method you did with the wood skewers for bracing!

Can you post the link to the video again?

Thanks,

X

Bolexsbm,

Just noticed the link was quoted in above post - so never mind. I saw your other video of a synergy and see what looks like a tractrix in the periphery. Very cool - have you seen the foam core tractrix synergy or Trynergy?

http://www.diyaudio.com/forums/full-range/261427-presenting-trynergy-full-range-tractrix-synergy.html

This is the best sounding speaker I have heard or built.

Just noticed the link was quoted in above post - so never mind. I saw your other video of a synergy and see what looks like a tractrix in the periphery. Very cool - have you seen the foam core tractrix synergy or Trynergy?

http://www.diyaudio.com/forums/full-range/261427-presenting-trynergy-full-range-tractrix-synergy.html

This is the best sounding speaker I have heard or built.

I'm currently with my parents over break so subless at the moment, as soon as I get back I'll be trying them with my t60 and dual tapped horn, I'm in the process of selling the mltp's so I don't actually have those at my house at school.Sabaspeed,

Thank you for the great feedback. So glad you like them and good tip on running them with a high pass filter. Have you tried running them with your mass loaded tapped pipe sub? Looking forward to your stereo experience.

Regards,

X

Thanks, xrk!Bolexsbm,

Beautiful work on your foam core creations. Which driver is this and did you decide to just try it out or was there a sim for it somewhere? Neat new construction method you did with the wood skewers for bracing!

Can you post the link to the video again?

Thanks,

X

The drivers I used are Hiwave BMR's. 2 inchers which were at hand.

I didn't want to bother you for the sims as this was just a test.

I just made it after your 0.27x version.(maybe just a bit bigger)

And the wood skewers are chopsticks that came with the box of cup noodles(!).

Oh, and did I mention that they sound great?

xrk971,Bolexsbm,

Just noticed the link was quoted in above post - so never mind. I saw your other video of a synergy and see what looks like a tractrix in the periphery. Very cool - have you seen the foam core tractrix synergy or Trynergy?

http://www.diyaudio.com/forums/full-range/261427-presenting-trynergy-full-range-tractrix-synergy.html

This is the best sounding speaker I have heard or built.

Yes. I have been following that thread with interest from the beginning.

For the past year, I have been trying to understand and build myself many of the cool designs you guys have been sharing here.

And Tom Danley's Synergy horns and Paralines in particular have been quite fun to study.

(And then came the Karlson...)

I'll post my build pics in the 'Suitable midrange drivers' thread when I get the chance.

Duratexed Mini-karlsons

Yep, if they are worth building then they are worth cleaning up and duratexing.

Spent today buying more mdf (for another 3 pairs of these things) building the second one, scrape/sand/finish/painting both of them, and boy can I not wait until they are dry in the morning. They are hanging so I could paint all 6 sides at once, wonderful thing the k-aperture is.

Yep, if they are worth building then they are worth cleaning up and duratexing.

Spent today buying more mdf (for another 3 pairs of these things) building the second one, scrape/sand/finish/painting both of them, and boy can I not wait until they are dry in the morning. They are hanging so I could paint all 6 sides at once, wonderful thing the k-aperture is.

Attachments

- Home

- Loudspeakers

- Full Range

- Mini Karlsonator (0.53X) with Dual TC9FDs