Don't know what happened then but I'd be interested in ordering one. Had a Cantus and sold it. Don't think I gave it enough effort to get it up and running.

glass tube cutting - YouTube

of course making a horizontal cut as per cantus would require another technique . not tried

that one yet .

Real thing.

Tube glass cutter.wmv - YouTube

cantus glass tube dims

Please , someone , come up with the cantus glass tube dims .

ID / OD / Lenght , and width of the sleeve .

I'm visiting the medical glass shop next week , so I need the details soon 😉

THX

Paul

Please , someone , come up with the cantus glass tube dims .

ID / OD / Lenght , and width of the sleeve .

I'm visiting the medical glass shop next week , so I need the details soon 😉

THX

Paul

Please , someone , come up with the cantus glass tube dims .

ID / OD / Lenght , and width of the sleeve .

I'm visiting the medical glass shop next week , so I need the details soon 😉

THX

Paul

http://www.diyaudio.com/forums/analogue-source/238027-diy-linear-tonearm-123.html#post3773350

opus 3 glass tube dims

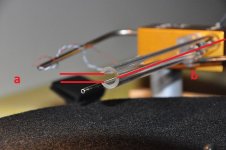

I have seen the ID and OD specs , but please have a look at the attached foto , I must know the distance in MilliMeter of point A ( between the red lines ) + of course the lenght of tube , including the invisible fraction sticking into the base 😀

THX !!

I have seen the ID and OD specs , but please have a look at the attached foto , I must know the distance in MilliMeter of point A ( between the red lines ) + of course the lenght of tube , including the invisible fraction sticking into the base 😀

THX !!

Attachments

I will send measurements later but you just asked a loaded question which is really answered by "that depends" and it depends on your build the size of bearings and the size of bearing ID you use and the physical size of carriage you build (smaller is going to be better). Think about it and you will see what I mean. I can give you numbers but they are relevant only to the parts used in the Cantus your build will likely vary. Best regards Moray James.

I will send measurements later but you just asked a loaded question which is really answered by "that depends" and it depends on your build the size of bearings and the size of bearing ID you use a d the physical size of carriage you build (smaller is going to be better). Think about it and you will see what I mean. I can give you numbers but they are relevant only to the parts used in the Cantus your build will likely vary. Best regards Moray James.

Thanks Moray for so nicely phrasing your answer. Please allow me to rephrase it in a somewhat less genteel manner. I can not understand this hangup on precise physical dimensions of parts in a Cantus or any other variation thereof. It doesn't matter what the dimensions are as long as they allow the desired action to take place. . The tube has to be long enough that the carriage won't fall off before getting to the end of the recorded music. The slot needs to be wide enough to let the bearing mount rods pass through and not hit the slot edges as the arm goes up and down. This can be easily measured from a simple sketch full size on fish paper. We know from actual measurements the ID and OD of the tube. Again this is arbitrary based on the size of bearing used. It has to run from one end to the other without getting stuck. But we have those numbers. How long for the tube to stick into the mounting block? Long enough so it won't fall out. More pertinent would be to ask how s the tube going to be fastened.

I'll go away now! I was just being annoyed with the lack of thought and basic understanding of such a simple device. This sort of thing happens far to often.

With my apologies,

BillG

E Shouldn't this stuff be moved to the Cantusthread?

Rather than copy, or stealing a proven design, shouldn't we be trying to make a better one?. Not implying in any way shape or form is my design better but this is starting to turn into a cantus knockoff thread 😀.

Colin

Rather than copy, or stealing a proven design, shouldn't we be trying to make a better one?. Not implying in any way shape or form is my design better but this is starting to turn into a cantus knockoff thread 😀.

Colin

Bill: you can rephrase me any time you like thank you. I think that given the cost of a new Cantus and the fact that Hakan has worked so very hard to improve Bo's design in terms of fit and finish that the best project a lot of people here could do is to save the money to buy one and give their business to Hakan and then learn how to set up the Cantus and then after using it and enjoying it wade into a DIY project with some fresh ideas. Best regards Moray James.

PS: I had my own little rant in semi private. I think that yours was much more productive. Thanks.

PS: I had my own little rant in semi private. I think that yours was much more productive. Thanks.

Thanks for the replies. I did find the thread Chrismas week and read it over two nights when it was 70+ pages long, gripped as I was. Since joining I've been flitting about looking at photos. And the reason for wanting to use glass rod is because when I looked for tubing on eBay in the UK I. Couldn't find anything long enough. Doing a Google search I found a rod supplier that supplies single rods 1.5 mtrs cut into 3 or 4 at quite a modest cost. And it does away with the threaded rod.

I have seen the ID and OD specs , but please have a look at the attached foto , I must know the distance in MilliMeter of point A ( between the red lines ) + of course the lenght of tube , including the invisible fraction sticking into the base 😀

THX !!

I don't know the dimensions for the slot neither the tube length. However, I did some work in my 3D eng. software with the 16/10mm tube I have and the 614/8 SKF bearing. The slot should be at least 2mm wider than the bearing shaft - meaning, if the bearing is attached/fixed on a 3mm shaft, you would need at least a 5mm wide gap to be able to set the tonearm to a position where it can move freely from a position where the needle is at it's lowest - on the record and upward so it can be raised enough to slide it safely away from the vinyl surface. An additional millimeter can't hurt. I also found that a 170-180mm of length should do - a tube that's too short might compromise the ease of positioning the whole arm construction. I opted for a 200mm long tube, that should give plenty of room to play with.

cantus tube

Hi everone ,

I was thinking as many debating a diy cantus arm here , that a bit help from my side would be apreciated . after all .. it's called DIY Audio here , right ?

On the other side , I understand that some people have other point of view in that respect . which I of course also respect !

Anyhow , I'm not intending to hi-jack this thread of course , and details will be shown elsewhere on this forum soon .

Please apologize me for being cruel 😀 must be my enthousiasm .

THX

Paul

Hi everone ,

I was thinking as many debating a diy cantus arm here , that a bit help from my side would be apreciated . after all .. it's called DIY Audio here , right ?

On the other side , I understand that some people have other point of view in that respect . which I of course also respect !

Anyhow , I'm not intending to hi-jack this thread of course , and details will be shown elsewhere on this forum soon .

Please apologize me for being cruel 😀 must be my enthousiasm .

THX

Paul

Show of hands......who would of bought a Cantus but because of this thread

wont? Probably none of us....

The people here are hands on, thats why they come here, they read, they're

inspired, they build. Maybe in the course of it they might even improve upon it.

My final build is different than both Colins and the Cantus.

It works spectacularly, am very happy with it, if it wasnt for this thread

I'd have a much lesser system.

I look forward to any off shoot threads this one produces.

wont? Probably none of us....

The people here are hands on, thats why they come here, they read, they're

inspired, they build. Maybe in the course of it they might even improve upon it.

My final build is different than both Colins and the Cantus.

It works spectacularly, am very happy with it, if it wasnt for this thread

I'd have a much lesser system.

I look forward to any off shoot threads this one produces.

Hello,

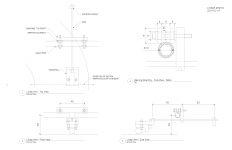

I've read through this thread a couple times now. I am very interested to start my own arm. I have also noted many of the critical dimensions and design decisions mentioned and created a basic drawing of the arm as intended by the OP.

Hopefully I can get some feedback as to the drawing for correctness. I am happy to revise the drawings and create a basic bill of materials for all to use.

I've read through this thread a couple times now. I am very interested to start my own arm. I have also noted many of the critical dimensions and design decisions mentioned and created a basic drawing of the arm as intended by the OP.

Hopefully I can get some feedback as to the drawing for correctness. I am happy to revise the drawings and create a basic bill of materials for all to use.

Attachments

Hello,

I've read through this thread a couple times now. I am very interested to start my own arm. I have also noted many of the critical dimensions and design decisions mentioned and created a basic drawing of the arm as intended by the OP.

Hopefully I can get some feedback as to the drawing for correctness. I am happy to revise the drawings and create a basic bill of materials for all to use.

I've read through this thread a couple times now. I am very interested to start my own arm. I have also noted many of the critical dimensions and design decisions mentioned and created a basic drawing of the arm as intended by the OP.

Hopefully I can get some feedback as to the drawing for correctness. I am happy to revise the drawings and create a basic bill of materials for all to use.

Steve,

A fellow vancouverite i see, should be easy for you to access the bearings used by myself locally 🙂. PDR, you have the right idea, if anything this thread should be a push for originality and hopefully success. All the details have been given for an easy build, but I've noticed without adherence to the design results may vary. To say I'm happy with my arm is an understatement, every vinyl session brings pure musical enjoyment!.

Colin

A fellow vancouverite i see, should be easy for you to access the bearings used by myself locally 🙂. PDR, you have the right idea, if anything this thread should be a push for originality and hopefully success. All the details have been given for an easy build, but I've noticed without adherence to the design results may vary. To say I'm happy with my arm is an understatement, every vinyl session brings pure musical enjoyment!.

Colin

- Home

- Source & Line

- Analogue Source

- DIY linear tonearm