try this link for more info about the design.

http://www.epanorama.net/links/componentinfo.html

http://www.classictesla.com/download/resonance_tips.pdf#search="toroid transformer design"

http://www.ferronics.com/files/Toroid.pdf

rlg. 😉 😉 😉

http://www.epanorama.net/links/componentinfo.html

http://www.classictesla.com/download/resonance_tips.pdf#search="toroid transformer design"

http://www.ferronics.com/files/Toroid.pdf

rlg. 😉 😉 😉

The concept that having a limited frequency response in a power transformer will filter supply noise is interesting. Especially as the charging current to the main filter caps has a large HF component. If you have a transformer with a lower frequency response that will lead to poor supply regulation and hence greater dynamic compression in the amp.

After a few quick measurements with a variac and some EI and torroid transformers I can assure all that their saturation curves are very similar. Which has higher saturation margin? It depends on which transformer I test not it's core type. Much as theory would suggest.

The quality of the transformer is more important than the core type, IMHO. I'll still stick to using torroids for my original reasons.

Regards Walker

After a few quick measurements with a variac and some EI and torroid transformers I can assure all that their saturation curves are very similar. Which has higher saturation margin? It depends on which transformer I test not it's core type. Much as theory would suggest.

The quality of the transformer is more important than the core type, IMHO. I'll still stick to using torroids for my original reasons.

Regards Walker

My rule of thumb... whatever type I can find for a particular project at a reasonable cost, as long as it's not a hunk of junk, I use.

My rule of thumb... whatever type I can find for a particular project at a reasonable cost, as long as it's not a hunk of junk, I use.

well said.🙂

Big thing to remember about toroidals is that they exhibit a large inrush current on powerup, and that must be attended to in any design using them. Otherwise they are excellent in terms of efficiency, compactness and low radiation & noise.

toroids are run at much higher flux densities than a comparable EI would be...

toroids do not have an effective air gaps unlike EI's with three gaps...

toroids do not have an effective air gaps unlike EI's with three gaps...

In addition, toroidal transformers operate near/at saturation and generate an abundance of high frequency harmonic bursts - at a reasonable cost.

The assumptions in post #43 are incorrect.

The assumptions in post #43 are incorrect.

oh, yes, the quality of any transformer is in the core, for EI's M6/z11 is the best easily available cores, M18 are still audio grade, while M58 are lowest in quality....

as a guide, the higher the number after "M" the lower the quality,

then there is a matter of grain oriented or GOSS or non goss,

lamination thickness also, .035mm lams are good quality...

while standard ones are 0.5mm

as a guide, the higher the number after "M" the lower the quality,

then there is a matter of grain oriented or GOSS or non goss,

lamination thickness also, .035mm lams are good quality...

while standard ones are 0.5mm

i simply use moderate quality EI with dual bridge, works great. Though i see no wrong in traditional split supply with EI transformers. As a hobbyist why waste lot of money on gainclones, its all about fun. DIY

One downside of toroidal transformer is they dont like dc on the mains.

Mains DC and Transformers

At idle, the transformer's core is already at maximum flux density, and a DC offset causes partial saturation, but only of one polarity. The transformer's magnetising current waveform becomes asymmetrical, and when the core saturates in this way it leads to magnetostriction, a condition where the physical size of the core changes. It's only a small change, but it often causes the core to 'growl' or buzz. This can be very audible, and (somewhat predictably) it's not something that anyone likes to hear. Big transformers (500VA and above) are the worst affected because the winding resistance is so low.

Mains DC and Transformers

At idle, the transformer's core is already at maximum flux density, and a DC offset causes partial saturation, but only of one polarity. The transformer's magnetising current waveform becomes asymmetrical, and when the core saturates in this way it leads to magnetostriction, a condition where the physical size of the core changes. It's only a small change, but it often causes the core to 'growl' or buzz. This can be very audible, and (somewhat predictably) it's not something that anyone likes to hear. Big transformers (500VA and above) are the worst affected because the winding resistance is so low.

Last edited:

the quality of any transformer is in the core

Of course.

nigelwright7557,

it is a matter of core permeability not of winding resistance.

I get my transformers wound by Tiger Toroids in Norfolk UK. (Stephen Foster).

To get a quiet torroid, you have to specify a ‘stabilized’ core. On big transformers, they use a single piece of metal tape that has a thin plastic insulation tape on both sides. This is wound on a former and then overmoulded in plastic but with 3-4 small holes on the top side. For transformers that have to be mechanically quiet, there is an additional step which is to dip the whole assembly in varnish and vacuum impregnate it. This causes varnish to be sucked into the voids inside the plastic overmoulding between the tape would core. After that, the core is baked and the transformer wound over it in the normal way. After winding, they double dip- impregnate and bake the transformer after cloth wrapping it. These kinds of transformers make no mechanical noise ie buzzing.

For DC on the mains (growling) there is a separate trick to reduce susceptibility. The core is oversized and run at about 20% lower flux density so 1-1,1 T vs the typical 1.3 T.

On one of my amps I use a 1.2 kVA transformer that for straight industrial applications would be rated at 2kVA. It weighs 13 kgs. But, if I run a normal transformer next to it, the normal one buzzes (worst at certain times of the day) but the low flux density one is absolutely silent.

To reduce electrical noise, I always specify an interwinding screen and a GOSS band - makes a huge difference. An interwinding screen on the 1.2 kVA reduced the primary-secondary capacitance from 1.3 nF to <100 pF

To get a quiet torroid, you have to specify a ‘stabilized’ core. On big transformers, they use a single piece of metal tape that has a thin plastic insulation tape on both sides. This is wound on a former and then overmoulded in plastic but with 3-4 small holes on the top side. For transformers that have to be mechanically quiet, there is an additional step which is to dip the whole assembly in varnish and vacuum impregnate it. This causes varnish to be sucked into the voids inside the plastic overmoulding between the tape would core. After that, the core is baked and the transformer wound over it in the normal way. After winding, they double dip- impregnate and bake the transformer after cloth wrapping it. These kinds of transformers make no mechanical noise ie buzzing.

For DC on the mains (growling) there is a separate trick to reduce susceptibility. The core is oversized and run at about 20% lower flux density so 1-1,1 T vs the typical 1.3 T.

On one of my amps I use a 1.2 kVA transformer that for straight industrial applications would be rated at 2kVA. It weighs 13 kgs. But, if I run a normal transformer next to it, the normal one buzzes (worst at certain times of the day) but the low flux density one is absolutely silent.

To reduce electrical noise, I always specify an interwinding screen and a GOSS band - makes a huge difference. An interwinding screen on the 1.2 kVA reduced the primary-secondary capacitance from 1.3 nF to <100 pF

I get my transformers wound by Tiger Toroids in Norfolk UK. (Stephen Foster).

To get a quiet torroid, you have to specify a ‘stabilized’ core. On big transformers, they use a single piece of metal tape that has a thin plastic insulation tape on both sides. This is wound on a former and then overmoulded in plastic but with 3-4 small holes on the top side. For transformers that have to be mechanically quiet, there is an additional step which is to dip the whole assembly in varnish and vacuum impregnate it. This causes varnish to be sucked into the voids inside the plastic overmoulding between the tape would core. After that, the core is baked and the transformer wound over it in the normal way. After winding, they double dip- impregnate and bake the transformer after cloth wrapping it. These kinds of transformers make no mechanical noise ie buzzing.

For DC on the mains (growling) there is a separate trick to reduce susceptibility. The core is oversized and run at about 20% lower flux density so 1-1,1 T vs the typical 1.3 T.

On one of my amps I use a 1.2 kVA transformer that for straight industrial applications would be rated at 2kVA. It weighs 13 kgs. But, if I run a normal transformer next to it, the normal one buzzes (worst at certain times of the day) but the low flux density one is absolutely silent.

To reduce electrical noise, I always specify an interwinding screen and a GOSS band - makes a huge difference. An interwinding screen on the 1.2 kVA reduced the primary-secondary capacitance from 1.3 nF to <100 pF

i go with 1T tops, 240 vac primary line and 50hz even if my power is 60hz...

and oversize, things i like to do with my traffos...

for EI's 0.6 to 0.9T

To get totally silent toroid, I use 400V/2x50V 500VA transformer to get 230V/2*29V 250VA. Interwind screening is a must, to reduce incoming HF noise from the mains.

Sajti

Sajti

To get totally silent toroid, I use 400V/2x50V 500VA transformer to get 230V/2*29V 250VA. Interwind screening is a must, to reduce incoming HF noise from the mains.

Sajti

By running a 400V input transformer at 220V you are in effect running the transformer at a much lower flux density - the result is you get much better tolerance to DC mains.

By running a 400V input transformer at 220V you are in effect running the transformer at a much lower flux density - the result is you get much better tolerance to DC mains.

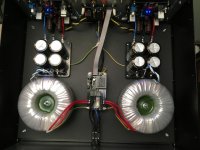

Yes. This means about 40% reduction of the flux density. Picture about my 2x70W amplifier runs with this transformers.

Sajti

Attachments

The lowest impedance you can get is with the MD core transformers. Here is the list for the same nominal power transformers:

M core 100% (highest impedance)

Ei core 94%

Toroidal 66%

PM core 38%

MD core 28% (lowest impedance)

For audio it would be best to use MD core transformer. But there are no manufacturers who produce such transformers, or are they very rare.

M core 100% (highest impedance)

Ei core 94%

Toroidal 66%

PM core 38%

MD core 28% (lowest impedance)

For audio it would be best to use MD core transformer. But there are no manufacturers who produce such transformers, or are they very rare.

- Home

- Amplifiers

- Solid State

- Are toroidal transformers best?

...

...