You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Filters

Show only:

Are separate outputs really separate on SMPS?

- By madmarcus

- Tubes / Valves

- 6 Replies

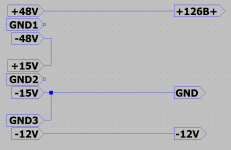

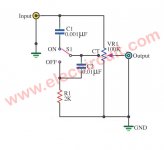

As mentioned in my thread on a workshop bluetooth amp project I have a random SMPS that I am considering for use in an amp. No it's not ideal or normal for a tube amp even if it is marketed as such. But I have it already due to another project that needed 48V with more current (that project is on hold).

Aliexpress SMPS

It's configured with three outputs

Output voltage: +48V GNG -48V / current: 2.6A

Output voltage: +15V GNG -15V / current: 1A

Output voltage: DC12V / current: 1A

Given that I can deal with only 1A of current is there anything I should worry about before stacking the +-48V and the +-15V to get a B+ of 126V?

Working with robots hasn't given me much experience with SMPS. The power supply was in my parts drawer but I'd still hate to blow it up with a dumb move based on expecting all three segments to act independently of each other.

Aliexpress SMPS

It's configured with three outputs

Output voltage: +48V GNG -48V / current: 2.6A

Output voltage: +15V GNG -15V / current: 1A

Output voltage: DC12V / current: 1A

Given that I can deal with only 1A of current is there anything I should worry about before stacking the +-48V and the +-15V to get a B+ of 126V?

Working with robots hasn't given me much experience with SMPS. The power supply was in my parts drawer but I'd still hate to blow it up with a dumb move based on expecting all three segments to act independently of each other.

Attachments

High impedance DI advice?

- By 6V6dude

- Instruments and Amps

- 11 Replies

I've got guitar amps with 1M impedance. But I need to split the signal to my mixer so I'm using 1M impedance FET DI box. That makes it 500ohm load on my guitar in total and I can hear the slight top end roll off and loosing some sound is annoying.

Is there anything I can do increase the DI box to at least 3M, perhaps modify it?

Another idea I had was to modify stand alone tube preamp by replacing input 1M resistor with 5M resistor and just run the output from cathode via cap to mixer. I'm just not sure what implications 5M on input would have if any.

I don't know how else I could achieve very high impedance signal splitting so I don't get any signal loss.

Thanks in advance for any advice

Is there anything I can do increase the DI box to at least 3M, perhaps modify it?

Another idea I had was to modify stand alone tube preamp by replacing input 1M resistor with 5M resistor and just run the output from cathode via cap to mixer. I'm just not sure what implications 5M on input would have if any.

I don't know how else I could achieve very high impedance signal splitting so I don't get any signal loss.

Thanks in advance for any advice

Help about High DC Offset

- By lim0nade

- Solid State

- 9 Replies

Hi guys.

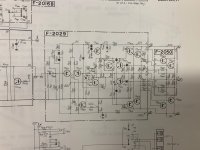

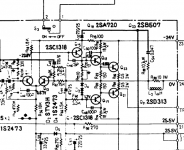

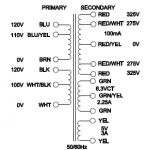

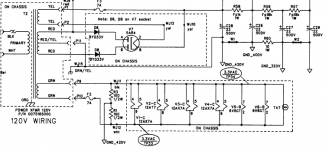

The left channel of my power amp RОТЕL has a high DC offset (13-14V).

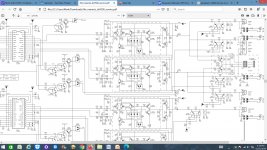

I apply a scheme.

In red are the higher voltages measured by me.

Transistors Q 609 and Q 615 have been replaced, but without effect.

Every help will be appreciated!

Greetings!

The left channel of my power amp RОТЕL has a high DC offset (13-14V).

I apply a scheme.

In red are the higher voltages measured by me.

Transistors Q 609 and Q 615 have been replaced, but without effect.

Every help will be appreciated!

Greetings!

Attachments

Welcome fellow diyAudio'ers

- By ukmart

- Introductions

- 5 Replies

Hello there,

My name is Martin and i'm from UK (Essex)

I'm generally into HiFi amplifiers. As I'm fairly new to this topic, I really look forward to learning as much as possible from you guys.

My name is Martin and i'm from UK (Essex)

I'm generally into HiFi amplifiers. As I'm fairly new to this topic, I really look forward to learning as much as possible from you guys.

Soekris dam1202-01 - you pay the shipping

- By bourbon-neat

- Swap Meet

- 4 Replies

Soekris dam0121-01 and Amanero USB input board. Bought in 2015 and never used.

Price = Free

Price = Free

FS: Many OP amps, few transistors

Old stock from inventory clearing of audio electronics company. Everything listed is in new condition and original bought from ELFA Distrelec, directly from the manufacturer, or Digikey throughout the years. Can ship anywhere but if you're outside the EU it might be pricy.

Mostly putting this here in so that someone who is looking for something specific can find it. For some of these components I've got several unopened IC sticks. Some I've only got a handfull left.

OP AMPs:

OPA134PA - Audio

*OPA2134A - Dual Audio

OPA4134A - Quad Audio

LM10CLN - OP AMP & Volt. Ref.

LM324N

TLC2201CP - Low Noise Rail to Rail

MAX477 - Wide BW Unity Gain

EL2044CN - High Speed

EL2444CN - Unity Gain

NE5532D - Dual Low Noise Internally Comp.

NE5532P

UAF771TC

OPA27GU - Prec.

OP284 - Dual

TL061

LM324 - Quad

TS462CN

LM6142BIN - Dual

*AD797 - Very Low Noise Very Low Distortion

TL071CP - JFET Input GP

TL072CN - Dual ^

TLE2062CP - Dual JFET Input High Out. Drive uPower

TLE2064CN - Qual ^

TLE2144ACN - 'Excalibur' Low Noise Prec.

LM6144BIN - Quad High Speed Rail to Rail

LT1028 - Ultra Low Noise

LM837N - Quad Low Noise

LMC6084IN - Prec. CMOS Amp.

LMV934 - BJT Pair

CA741CE

Other stuff:

2SJ115 and 2SK405 Pairs - Audio Transistor

CA3080E - Transconductance AMP.

STP60NE06 - NMOS

V23092-A1012-A301 - Relays 12V, 400V SW.

MTD20N03HDL - NMOS

I've got a lot more that I didn't list here, if you're looking for something specific throw me a message.

Edit: List items in *italics are no longer available.

Mostly putting this here in so that someone who is looking for something specific can find it. For some of these components I've got several unopened IC sticks. Some I've only got a handfull left.

OP AMPs:

OPA134PA - Audio

*OPA2134A - Dual Audio

OPA4134A - Quad Audio

LM10CLN - OP AMP & Volt. Ref.

LM324N

TLC2201CP - Low Noise Rail to Rail

MAX477 - Wide BW Unity Gain

EL2044CN - High Speed

EL2444CN - Unity Gain

NE5532D - Dual Low Noise Internally Comp.

NE5532P

UAF771TC

OPA27GU - Prec.

OP284 - Dual

TL061

LM324 - Quad

TS462CN

LM6142BIN - Dual

*AD797 - Very Low Noise Very Low Distortion

TL071CP - JFET Input GP

TL072CN - Dual ^

TLE2062CP - Dual JFET Input High Out. Drive uPower

TLE2064CN - Qual ^

TLE2144ACN - 'Excalibur' Low Noise Prec.

LM6144BIN - Quad High Speed Rail to Rail

LT1028 - Ultra Low Noise

LM837N - Quad Low Noise

LMC6084IN - Prec. CMOS Amp.

LMV934 - BJT Pair

CA741CE

Other stuff:

2SJ115 and 2SK405 Pairs - Audio Transistor

CA3080E - Transconductance AMP.

STP60NE06 - NMOS

V23092-A1012-A301 - Relays 12V, 400V SW.

MTD20N03HDL - NMOS

I've got a lot more that I didn't list here, if you're looking for something specific throw me a message.

Edit: List items in *italics are no longer available.

great capacitor video

- By ga77a

- The Lounge

- 25 Replies

Which Capacitor Do I Use? Tech Tips Tuesday - YouTube

hi diyaudio lad's

while on my journey of trying to understand audio circuits i came across this guy a couple of months ago. today i watched this video and was so impressed by it that i had to share. i'm sure that some of you would have already seen it, so this is really for other novice's like my self. enjoy 🙂

gaz

hi diyaudio lad's

while on my journey of trying to understand audio circuits i came across this guy a couple of months ago. today i watched this video and was so impressed by it that i had to share. i'm sure that some of you would have already seen it, so this is really for other novice's like my self. enjoy 🙂

gaz

Measuring speakers T/S values - DATS v.3.0 vs factory specs

- By portakalx2

- Multi-Way

- 38 Replies

Hi, I've seen a similar thread where someone asked whether to rely on DATS measurements or the factory specs. I bought a SEAS coaxial driver and measured it with DATS v3.0. I was very careful in testing/calibration etc and broke the drivers in for several hours at 30Hz beforehand. The T/S values came out very different than the specs and I know that this happens a lot. When I simmed it, the box size and the f3 were different as well. So I contacted SEAS and asked them for guidance. The SEAS engineer assured me that their measurements are correct and insisted that I should use their measurements. So I made the boxes using the factory data. Somewhere else in the forum, I read that the DATS "guesses" the Qms, Qes and Qts values based on the impedance graph. So now I'm wondering how reliable measuring is. How can I make sure I'm using the right T/S values in my sims?

Information Overload

- Multi-Way

- 5 Replies

Maybe some of you fine folks could help lead me in the right direction. I need help choosing the right DIY build.

I'm looking for plans. I don't need a flat pack or anything. I can take care of the woodworking.

I have a budget of around $600.

I have a large, open room that's not the best, it's a bit reverb-y.

I'm using a Marantz HT receiver.

Although this is the beginning of my audiophile journey, I've been a professional musician/music lover my entire life and spent a lot of time in studios/stages.

I used to build SQ car audio systems.

I'd really like a floorstander, if possible.

My #1 main concern is fidelity, accuracy, detail, soundstage, clarity, etc.

I will be running a subwoofer so it doesn't matter about subterranean bass.

I'm looking for plans. I don't need a flat pack or anything. I can take care of the woodworking.

I have a budget of around $600.

I have a large, open room that's not the best, it's a bit reverb-y.

I'm using a Marantz HT receiver.

Although this is the beginning of my audiophile journey, I've been a professional musician/music lover my entire life and spent a lot of time in studios/stages.

I used to build SQ car audio systems.

I'd really like a floorstander, if possible.

My #1 main concern is fidelity, accuracy, detail, soundstage, clarity, etc.

I will be running a subwoofer so it doesn't matter about subterranean bass.

Help expert designers with xover

- By magnethead

- Multi-Way

- 4 Replies

Good morning! Hope everyone had a wonderful and joyous Christmas considering the circumstances. I am starting a new ported 2way, drivers will be a Dayton Dc200-8 woofer----29hz to 3,000hz and a Dayton Dc28 F tweeter 1,300 to 20,000 in a 1.2 cu ft box and a 2inX 6.5in long port. The big question is where would you cross these two drivers? And what order xover would you use. Any advice would be greatly appreciated. Thanks!

LX mini analog crossover

- By Dennis Hui

- The diyAudio Store

- 13 Replies

Hi Jason,

I wonder if you there's an ETA on the availability of the lx-mini crossover?

Thanks,

Dennis

I wonder if you there's an ETA on the availability of the lx-mini crossover?

Thanks,

Dennis

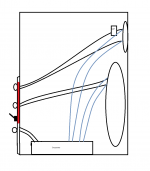

Francesco Campedelli T-Line

- By DIYampNOOB

- Full Range

- 63 Replies

I got bored one night and made a Google Sketchup model of Francesco Campedelli's TiLine for HIVI's B3S and BSN. I myself will be using the Aurasound NS3-193-4A. Hope this helps someone!

Attachments

300B SE as my first tube amp

- By tamra

- Tubes / Valves

- 42 Replies

Hi all.

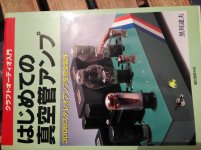

I would like to share building 300B se amp from a book.

Posting might push my self...

Its my first experience and I had no knowledge/understanding tubes, cirkit etc.

Reading book, gathering items took me 6 month now.

I put copper tape for shield(May be it works?)

I would like to share building 300B se amp from a book.

Posting might push my self...

Its my first experience and I had no knowledge/understanding tubes, cirkit etc.

Reading book, gathering items took me 6 month now.

I put copper tape for shield(May be it works?)

Attachments

-

P_20181030_184416.jpg546.3 KB · Views: 1,248

P_20181030_184416.jpg546.3 KB · Views: 1,248 -

P_20181030_183541.jpg438.1 KB · Views: 1,237

P_20181030_183541.jpg438.1 KB · Views: 1,237 -

P_20181030_184044.jpg558 KB · Views: 1,246

P_20181030_184044.jpg558 KB · Views: 1,246 -

P_20181106_202710 (1).jpg465.8 KB · Views: 1,174

P_20181106_202710 (1).jpg465.8 KB · Views: 1,174 -

P_20181106_202727 (1).jpg709.3 KB · Views: 1,131

P_20181106_202727 (1).jpg709.3 KB · Views: 1,131 -

P_20181106_195359 (1).jpg508.2 KB · Views: 508

P_20181106_195359 (1).jpg508.2 KB · Views: 508 -

P_20181106_201828 (1).jpg651.5 KB · Views: 537

P_20181106_201828 (1).jpg651.5 KB · Views: 537 -

P_20181106_202909.jpg527.2 KB · Views: 626

P_20181106_202909.jpg527.2 KB · Views: 626

Amp Section: What kind of film capacitor is used between voltage power supplies?

- By gghodg

- Solid State

- 9 Replies

Hi All,

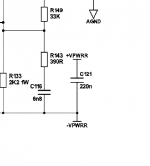

I'm trying to figure out what kind of film capacitor is pictured here (C121). I know its

220nF rated at 275 VAC. I'm limited to sizes 13mmx5mm or 13x6mm which narrows down my options on mouser to general purpose or power factor correction capacitors. I know I can find more information like used for EMI suppression by digging deeper in the data sheets. I don't know what their purpose is though, and they don't show the X2 rating. Are these capacitors "across-the-line"? Any help would be appreciated. Thanks and good day / evening.

I'm trying to figure out what kind of film capacitor is pictured here (C121). I know its

220nF rated at 275 VAC. I'm limited to sizes 13mmx5mm or 13x6mm which narrows down my options on mouser to general purpose or power factor correction capacitors. I know I can find more information like used for EMI suppression by digging deeper in the data sheets. I don't know what their purpose is though, and they don't show the X2 rating. Are these capacitors "across-the-line"? Any help would be appreciated. Thanks and good day / evening.

Attachments

(Quantity = 4) populated Bob Cordell Super gainclone LM3886 boards

info: https://www.diyaudio.com/forums/chi...-pcb-lm3886-stripped-version-compact3886.html

saves you a ton of money and time on ordering parts:

includes new LM3886 chips that i bought from mouser

all parts are exactly as the BOM and all parts are highest quality and no used parts. all new.

price $199 plus $10 to $15 for shipping depending on destination

saves you a ton of money and time on ordering parts:

includes new LM3886 chips that i bought from mouser

all parts are exactly as the BOM and all parts are highest quality and no used parts. all new.

price $199 plus $10 to $15 for shipping depending on destination

nuvistor MC step up

- By reinhard

- Tubes / Valves

- 88 Replies

Hello tubies,

can anyone help with information on nuvistor MC step up amplifier. As I know Conrad Johnson has made such things in the past. What about noise? Is the nuvistor a good part for that application?

Reinhard

can anyone help with information on nuvistor MC step up amplifier. As I know Conrad Johnson has made such things in the past. What about noise? Is the nuvistor a good part for that application?

Reinhard

Replacing MR752 for MUR860 diodes

- By legarem

- Solid State

- 3 Replies

Hello

I plan to replace power supply diodes in a Linn LK280 amp

They use MR752 diodes 6 A (Ta) 22 A (TL), 400A (IFSM) I was planning to use MUR860 rated 8A (Iav), 100A (IFSM)

Should I only compare MR752 6A to MUR860 8A specs ?

Is it finally safe to replace the MR752 to MUR860?

Thanks

I plan to replace power supply diodes in a Linn LK280 amp

They use MR752 diodes 6 A (Ta) 22 A (TL), 400A (IFSM) I was planning to use MUR860 rated 8A (Iav), 100A (IFSM)

Should I only compare MR752 6A to MUR860 8A specs ?

Is it finally safe to replace the MR752 to MUR860?

Thanks

CNC plans for planet10 designs

- By itsikhefez

- Planet 10 hifi

- 1 Replies

Is it possible to buy the CNC plans that were used to cut the various flat-paks that were sold over the years?

Such as FH3's, types of onkens and baby wodens?

I have someone local that can CNC cut wood, so having those plans on hand is very useful.

Thanks

Such as FH3's, types of onkens and baby wodens?

I have someone local that can CNC cut wood, so having those plans on hand is very useful.

Thanks

Newbie questions re phono pre build (esp PH16)

- By Rossputin

- Analogue Source

- 9 Replies

Hello all,

I'm hoping to get some good advice from you experts as I embark on building a tube phono pre. Thinking about PH16. A couple of basic questions:

Is it a good idea to put the power supply in a separate box/chassis?

What's the best way to get PH16 (or similar) to work with 0.4mV MC cartridge?

What's the best way to cut my own holes in a blank chassis, and any specific recommendation for rectangular holes?

Would you typically go with the parts kit (separate from the tubes) that are available for purchase with the PCBs or buy your own parts?

Are there important factors other than "it looks cool" vs "more issues with dust" in whether to have the tubes coming up out of the top of the chassis?

Thanks very much for any advice!

Ross in Colorado

I'm hoping to get some good advice from you experts as I embark on building a tube phono pre. Thinking about PH16. A couple of basic questions:

Is it a good idea to put the power supply in a separate box/chassis?

What's the best way to get PH16 (or similar) to work with 0.4mV MC cartridge?

What's the best way to cut my own holes in a blank chassis, and any specific recommendation for rectangular holes?

Would you typically go with the parts kit (separate from the tubes) that are available for purchase with the PCBs or buy your own parts?

Are there important factors other than "it looks cool" vs "more issues with dust" in whether to have the tubes coming up out of the top of the chassis?

Thanks very much for any advice!

Ross in Colorado

ES9018K2M vs PCM5102A "other things equal"

- By dandreye

- Digital Line Level

- 7 Replies

Hi All,

Apologies for the offtopic as there's no DIY involved... which of these 2 can be expected to give better SQ via RCA output: Version A (PCM5102A) or Version B (ES9018K2M)?

Lossless HIFI CSR8675 APTX HD Bluetooth 5.0 Wireless Receiver Adapter ES9018K2M PCM5102A I2S DAC Decoding 24BIT TWS 3.5M RCA|Digital-to-Analog Converter| - AliExpress

The former one is GBP5 (~17%) cheaper elsewhere (it's no longer available at the advert above).

Many thanks in anticipation!

Apologies for the offtopic as there's no DIY involved... which of these 2 can be expected to give better SQ via RCA output: Version A (PCM5102A) or Version B (ES9018K2M)?

Lossless HIFI CSR8675 APTX HD Bluetooth 5.0 Wireless Receiver Adapter ES9018K2M PCM5102A I2S DAC Decoding 24BIT TWS 3.5M RCA|Digital-to-Analog Converter| - AliExpress

The former one is GBP5 (~17%) cheaper elsewhere (it's no longer available at the advert above).

Many thanks in anticipation!

Tweeter attenuation help

Hi my first post so please be kind 😱

First a bit of background about me: I've built my own speakers in the past, but nothing advanced or complex. I essentially bought an off the shelf cross over and carefully chose tweeters and mid bass (all SEAS units) of the same stated SPL levels. Wired them all up and put them in a box that i built (having used the t/s parameters of the mid bass to design the box). So I've never done anything complex with crossovers hence my question here.

I have a pair of second hand Monitor Audio GR20 speakers, which are at least 15 years old I believe. These:

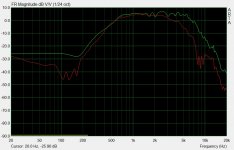

This is the measured (from here SoundStage! Measurements - Monitor Audio Gold Reference 10 Loudspeakers (10/2001)) listenting window frequency response of the GR10 which uses the same mid and tweeter (though obviously will have more bass weight and extension):

I've never been quite happy with the treble performance. Difficult to describe but overall it was qualitatively uneven (cymbals and guitars just didn't sound quite right). Oddly even though the graph above doesn't seem to show it the top end was just too loud overall (i ended up using the speaker grills which helped but led to other compromises), though of course that may be due to the room.

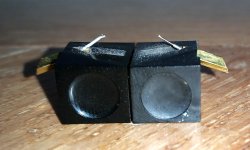

So having done a bit of reasearch and finding that MA use modified SEAS tweeters (attached is a picture of the old units) i decided to take a bit of a risk and get some replacement tweeters from SEAS. (having used SEAS units in the past I felt i at least knew they wouldn't be bad units). The units I chose are the 27TBFC/G. As i had no idea what the SPL of the existing units were I was expecting to have to pad them down as I thought it was unlikely that the exiting units had a higher sensitivity. But I decided just to swap them out first and see what i was left with. I was surprised that my first reaction was "they sound dull". As it happens it would seem like (purely from listening) that actualy the overal vocal range and mids are just much better balanced and the new tweeters are actually overall better integrated (again purely from listening) than the old ones.

Anyway to finally get to why I'm here (sorry for the long preamble). After a few days adjusting to the new balance I feel like the new tweeters could do with a tiny bit of a drop. The lower treble (going to guess the 3-5k region) feels just a touch too hot, (clearly i was expecting this region to be hotter as i expected the new tweeters to fill out the the suckout the old tweeters had, but it's gone just a touch too far). So i'd like to try padding down the tweeters by just 1db to see how they sound. I've measured the DC resistance of the old and new tweeters at 5.3 ohms, (about .5 ohm higher than SEAS state for the new tweeters, and presumably the old, but i'm going to put that down to my mulitmeters accuracy - it seems very sensitive to how the probes are positioned). According to MA the cross over is 2.7khz.

Attached is a picture of the exitsing crossover that i've managed to find. Going purely by a thread on this forum about the GS20 crossover, (here: Please help for Monitor Audio GS20 crossover tuning), I'm guessing the current one is a 2nd order HF (with a 3.3 Ohm resistor in series before the filter ciruit), first order mid (with notch filter) and first order bass.

So finally to my question 😱: As i don't want to mess around with cutting and soldering any of the existing wiring (and defintely not going to pull the speaker apart to start changing the original cross over) I was thinking of trying just a shunt resistor in parallel with the new tweeter to pad it down.

a) would this work?

b) what value resistor will i need to use to achieve a 1db drop? (according to the SEAS specs impedance runs 5 to 7 ohms between 2khz and 20khz on the new tweeters). I'd like to minimise any top octave drop in level/shelving of the response as much as possible. I'm thinking somewhere between 30 and 40 ohms?

Anyway goal is to drop the overall tweeter level by just 1db at this time, preferably using just a parrallel resistor, which I could solder on the existing wiring tags (thus avoiding having to put a soldering iron anywhere near the new tweeters).

I have no means to measure the speakers, and in all honesty I don't really want to get caught up in the effort all of that would entail. The speakers sound much better than they did previously, I'd just like to bring down the overall level of the tweeters a touch as i think they'd sound a bit better still if i did.

First a bit of background about me: I've built my own speakers in the past, but nothing advanced or complex. I essentially bought an off the shelf cross over and carefully chose tweeters and mid bass (all SEAS units) of the same stated SPL levels. Wired them all up and put them in a box that i built (having used the t/s parameters of the mid bass to design the box). So I've never done anything complex with crossovers hence my question here.

I have a pair of second hand Monitor Audio GR20 speakers, which are at least 15 years old I believe. These:

This is the measured (from here SoundStage! Measurements - Monitor Audio Gold Reference 10 Loudspeakers (10/2001)) listenting window frequency response of the GR10 which uses the same mid and tweeter (though obviously will have more bass weight and extension):

I've never been quite happy with the treble performance. Difficult to describe but overall it was qualitatively uneven (cymbals and guitars just didn't sound quite right). Oddly even though the graph above doesn't seem to show it the top end was just too loud overall (i ended up using the speaker grills which helped but led to other compromises), though of course that may be due to the room.

So having done a bit of reasearch and finding that MA use modified SEAS tweeters (attached is a picture of the old units) i decided to take a bit of a risk and get some replacement tweeters from SEAS. (having used SEAS units in the past I felt i at least knew they wouldn't be bad units). The units I chose are the 27TBFC/G. As i had no idea what the SPL of the existing units were I was expecting to have to pad them down as I thought it was unlikely that the exiting units had a higher sensitivity. But I decided just to swap them out first and see what i was left with. I was surprised that my first reaction was "they sound dull". As it happens it would seem like (purely from listening) that actualy the overal vocal range and mids are just much better balanced and the new tweeters are actually overall better integrated (again purely from listening) than the old ones.

Anyway to finally get to why I'm here (sorry for the long preamble). After a few days adjusting to the new balance I feel like the new tweeters could do with a tiny bit of a drop. The lower treble (going to guess the 3-5k region) feels just a touch too hot, (clearly i was expecting this region to be hotter as i expected the new tweeters to fill out the the suckout the old tweeters had, but it's gone just a touch too far). So i'd like to try padding down the tweeters by just 1db to see how they sound. I've measured the DC resistance of the old and new tweeters at 5.3 ohms, (about .5 ohm higher than SEAS state for the new tweeters, and presumably the old, but i'm going to put that down to my mulitmeters accuracy - it seems very sensitive to how the probes are positioned). According to MA the cross over is 2.7khz.

Attached is a picture of the exitsing crossover that i've managed to find. Going purely by a thread on this forum about the GS20 crossover, (here: Please help for Monitor Audio GS20 crossover tuning), I'm guessing the current one is a 2nd order HF (with a 3.3 Ohm resistor in series before the filter ciruit), first order mid (with notch filter) and first order bass.

So finally to my question 😱: As i don't want to mess around with cutting and soldering any of the existing wiring (and defintely not going to pull the speaker apart to start changing the original cross over) I was thinking of trying just a shunt resistor in parallel with the new tweeter to pad it down.

a) would this work?

b) what value resistor will i need to use to achieve a 1db drop? (according to the SEAS specs impedance runs 5 to 7 ohms between 2khz and 20khz on the new tweeters). I'd like to minimise any top octave drop in level/shelving of the response as much as possible. I'm thinking somewhere between 30 and 40 ohms?

Anyway goal is to drop the overall tweeter level by just 1db at this time, preferably using just a parrallel resistor, which I could solder on the existing wiring tags (thus avoiding having to put a soldering iron anywhere near the new tweeters).

I have no means to measure the speakers, and in all honesty I don't really want to get caught up in the effort all of that would entail. The speakers sound much better than they did previously, I'd just like to bring down the overall level of the tweeters a touch as i think they'd sound a bit better still if i did.

Attachments

Nagaoka MP11 Boron

- Analogue Source

- 14 Replies

Hi all. I have a question re. a possible design change to a vintage stylus I have and am hoping someone can shed some light on it.

With reference to the attached photograph:

I have a Nagaoka MP11 boron cartridge that I have had since about 1983 and a few weeks ago I decided I would like to start listening to it once again, but long story short, in the process of swapping headshells I dropped it and damaged the stylus.

Anyhow the desire to hear it play once again did not abate and I managed to track down a second-hand example and bought it. On comparing the styli I find that they are significantly different. My original one, on the left is a plain tubular design, flattened off at the tip, whereas the replacement example has a shaft mounted into a collar near the base and has no flattening of at the tip at all.

These seem to be very different designs and I find it strange to find that they are both designated the same model number - MP11 Boron. Surely such different approaches to presentation of the tip must result in significant differences in performance?

Can anyone explain what I am seeing here, or shed any light onto the history of this cartridge/stylus?

Thank you and regards.

With reference to the attached photograph:

I have a Nagaoka MP11 boron cartridge that I have had since about 1983 and a few weeks ago I decided I would like to start listening to it once again, but long story short, in the process of swapping headshells I dropped it and damaged the stylus.

Anyhow the desire to hear it play once again did not abate and I managed to track down a second-hand example and bought it. On comparing the styli I find that they are significantly different. My original one, on the left is a plain tubular design, flattened off at the tip, whereas the replacement example has a shaft mounted into a collar near the base and has no flattening of at the tip at all.

These seem to be very different designs and I find it strange to find that they are both designated the same model number - MP11 Boron. Surely such different approaches to presentation of the tip must result in significant differences in performance?

Can anyone explain what I am seeing here, or shed any light onto the history of this cartridge/stylus?

Thank you and regards.

Attachments

LTC spice clean up

- By steveu

- Software Tools

- 0 Replies

If you use LTC spice, you probably have a bunch of large temporary files that hang around using up disk space. I have found it very useful to place a file delete utility in the windows sendto folder. The Windows sendto folder has moved around with different windows versions but the current location is something like

%userprofile%\AppData\Roaming\Microsoft\Windows\SendTo

The file itself is a very simple bat file "spice cleaner.bat":

%~d1

cd %1

del /S *.raw *.log *.fft

pause

You just right click a folder, sendto -> "spice cleaner.bat". I prefer to pause the script before it closes so that I can see what has been found and deleted.

cheers,

Steve

%userprofile%\AppData\Roaming\Microsoft\Windows\SendTo

The file itself is a very simple bat file "spice cleaner.bat":

%~d1

cd %1

del /S *.raw *.log *.fft

pause

You just right click a folder, sendto -> "spice cleaner.bat". I prefer to pause the script before it closes so that I can see what has been found and deleted.

cheers,

Steve

Wanted Sony BX269A IC / TA-8650

Hello I am looking for the above IC, it is from the tone control stage in my TA-8650 Amplifier.

Thanks

Gary

Thanks

Gary

DSP Decisions

- Car Audio

- 5 Replies

I've been building my system for the past year or so. Here's my setup so far

Front: Focal ES165 K2 & Matching tweeters biamped

Rear: Hertz Hi Energy 165 component set

Subs: JL 12W3 shallow subs

Amps: JL 1000/1 (class D) and two Mosconi amps for the front/rear speakers

DSP: DBX Driverack PA2 modified to run on 12v

Sound deadoning 80% complete. Required removal of seats and carpet

The Focals take up four of the six channels of the driverack since they are biamped. This has a huge advantage since the tweeters a bit overpowering at high volumes. The DSP's limiter takes care of this. The other two channels are used as a limiter for the subs. This is essential as it's difficult or impossible to hear when they're reaching their limit.

With the recent addition of Hertz in the rear, I'll need a couple more channels of processing. Here are my thoughts so far:

Front: Focal ES165 K2 & Matching tweeters biamped

Rear: Hertz Hi Energy 165 component set

Subs: JL 12W3 shallow subs

Amps: JL 1000/1 (class D) and two Mosconi amps for the front/rear speakers

DSP: DBX Driverack PA2 modified to run on 12v

Sound deadoning 80% complete. Required removal of seats and carpet

The Focals take up four of the six channels of the driverack since they are biamped. This has a huge advantage since the tweeters a bit overpowering at high volumes. The DSP's limiter takes care of this. The other two channels are used as a limiter for the subs. This is essential as it's difficult or impossible to hear when they're reaching their limit.

With the recent addition of Hertz in the rear, I'll need a couple more channels of processing. Here are my thoughts so far:

- Put a compressor on the subs to free up a couple of channels on the driverack

- Use a SigmaStudio compatible DSP chip

- MiniDSP C-DSP 8x12

- Add another driverack

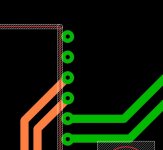

Sprint Layout 5.0 Double side pcb question

- By mot on/off

- Software Tools

- 6 Replies

Hi everybody!

Merry Christmas 🙂

Till now i'm using Sprint Layout 5.0 for one sided pcbs fine.

I'm in the procedure of designing a double sided pcb for a DAC and i'm realy confused.

I put lets say a DIL28 (CS8412) in C2 side and now i need to add a track in C1 side connected to a pin of IC.

How i can add the pin pads in C1 side too? Only manualy?

Thank you very much.

I added 3 photos.

Merry Christmas 🙂

Till now i'm using Sprint Layout 5.0 for one sided pcbs fine.

I'm in the procedure of designing a double sided pcb for a DAC and i'm realy confused.

I put lets say a DIL28 (CS8412) in C2 side and now i need to add a track in C1 side connected to a pin of IC.

How i can add the pin pads in C1 side too? Only manualy?

Thank you very much.

I added 3 photos.

Attachments

Thermalright Heatsinks and fans

I'm listing these in hope that someone has a use for them for some kind of DIY project.

Enermax T.B. Silence 120mm Ultra Quiet Twister Bearing Cooling Fan (quantity 2)

link: https://www.amazon.com/Enermax-Silence-Twister-Bearing-UCTB12/dp/B003IB2HYA

price each: $9.99

Thermalright Ultra 120 eXtreme CPU cooler

Link: Ultra-120 eXtreme Rev.C – Thermalright

price: $29.99

Thermalright IFX-14

link: IFX-14 – Thermalright

price: $29.99

intel 115x and AMD AM4 mounting hardware for thermalright Ultra eXtreme 120 and IFX-14 (quantity 1)

https://www.amazon.com/Thermalright-100700553-Optional-Mounting-Installation/dp/B00UN05Q6A

as a bundle together $90 shipped and paypal'd

Enermax T.B. Silence 120mm Ultra Quiet Twister Bearing Cooling Fan (quantity 2)

link: https://www.amazon.com/Enermax-Silence-Twister-Bearing-UCTB12/dp/B003IB2HYA

price each: $9.99

Thermalright Ultra 120 eXtreme CPU cooler

Link: Ultra-120 eXtreme Rev.C – Thermalright

price: $29.99

Thermalright IFX-14

link: IFX-14 – Thermalright

price: $29.99

intel 115x and AMD AM4 mounting hardware for thermalright Ultra eXtreme 120 and IFX-14 (quantity 1)

https://www.amazon.com/Thermalright-100700553-Optional-Mounting-Installation/dp/B00UN05Q6A

as a bundle together $90 shipped and paypal'd

Selection guidance for LEDs

- By wgh52

- Solid State

- 12 Replies

Hello Folks!

My LED application is supposed to signal OK with a green (3mm) LED and "not OK" with a red LED. The two LEDs are in different parts of the circuit and don't have common ground or supply.

I'm looking for a green and a red LED each providing the about same subjective brightness, but don't know which brightness (in mcd) to choose.

I'm also somehow missing a diagram in LED datasheets telling me the typical brightness vs. Diode current or/and voltage which would also be helpful in judging circuit sensitivity.

Any help enabling me to choose or proposal of specific LEDs for the purpose is thankfully appreciated!

Greetings,

Winfried

My LED application is supposed to signal OK with a green (3mm) LED and "not OK" with a red LED. The two LEDs are in different parts of the circuit and don't have common ground or supply.

I'm looking for a green and a red LED each providing the about same subjective brightness, but don't know which brightness (in mcd) to choose.

I'm also somehow missing a diagram in LED datasheets telling me the typical brightness vs. Diode current or/and voltage which would also be helpful in judging circuit sensitivity.

Any help enabling me to choose or proposal of specific LEDs for the purpose is thankfully appreciated!

Greetings,

Winfried

Quad 909 question

- By Roksan

- Solid State

- 7 Replies

Hi I just wondered if anybody knows whether the 0.1uf cap (yellow) which connects from D14 to R16 (as per pic) is a valid quad modification or not. I would also be interested if anybody has any idea's on the purpose of this capacitor. I purchased the amp many years ago secondhand (unmodified at the time) however the capacitor was present at the time of purchase.

t

t

Attachments

3-way hifi speakers: diy or not?

Hi,

I finally have time and funds to start completing my

HiFi, and speakers are first part I want to get done.

I have a budget of about 2000 euro for speakers. While I do realize this isn't much in HiFi world, I hope I can get a decent result at this budget.

My listening room is 4.5x5m, I mostly listen jazz, soul, and pop music.

So I'm thinking about 3 way speakers (floorstander or big stand on).

I have average woodworking skills, some experience in diy electronics and a very good equipped workshop, but my experience in speaker designing is poor.

So I'm asking you, is diy a good idea for me or shoud I go with some commercial solution?

Ps, I was thinking about some of the Gravesen projects, they seem to be very detailed and with little-to-none tweaking required.

Thanks

I finally have time and funds to start completing my

HiFi, and speakers are first part I want to get done.

I have a budget of about 2000 euro for speakers. While I do realize this isn't much in HiFi world, I hope I can get a decent result at this budget.

My listening room is 4.5x5m, I mostly listen jazz, soul, and pop music.

So I'm thinking about 3 way speakers (floorstander or big stand on).

I have average woodworking skills, some experience in diy electronics and a very good equipped workshop, but my experience in speaker designing is poor.

So I'm asking you, is diy a good idea for me or shoud I go with some commercial solution?

Ps, I was thinking about some of the Gravesen projects, they seem to be very detailed and with little-to-none tweaking required.

Thanks

Advice on what to match with a 15" woofer

- Multi-Way

- 2 Replies

Hi all,

I found in the basement a RCF L17/64AF (15 inch) speaker, and it triggered me to try & build my own speaker set. As I'm an absolute beginner and I'm here to get some advice.

- What other speakers should I match with the RCF I already have? (tweeters etc)

- Should I try to get another RCF box to have everything in twofold, or can I look for a similar woofer as the RCF for the matching box? If so, any advice on which one?

- I'm a guitarist. Should I better make a guitar amp out of the RCF I have?

Sorry for this absolute beginner questions. I really want to learn!

I really want to learn!

All best and many thanks,

Simon trinidad

I found in the basement a RCF L17/64AF (15 inch) speaker, and it triggered me to try & build my own speaker set. As I'm an absolute beginner and I'm here to get some advice.

- What other speakers should I match with the RCF I already have? (tweeters etc)

- Should I try to get another RCF box to have everything in twofold, or can I look for a similar woofer as the RCF for the matching box? If so, any advice on which one?

- I'm a guitarist. Should I better make a guitar amp out of the RCF I have?

Sorry for this absolute beginner questions.

I really want to learn!

I really want to learn!

All best and many thanks,

Simon trinidad

Identifying drive units

I have a pair of Monitor Audio GR20 speakers and I was wondering if anybody could identify the mid/bass unit (I've seen mentioned elsewhere that MA often use modified SEAS units):

Mid Bass:

It doesn't look like any SEAS unit i can find on their website. To start wtih I can't find any SEAS aluminium coned driver that has that inverted surround. But there are older units on the site that don't ave actual pictures. This one for example:

http://www.seas.no/images/stories/vintage/pdfdataheet/h1008_l17rep.pdf

Barring anyone here knowing anything about this mid bass unit, what would be the best way of finding out it's frequency response and impedance curves? (not worried about it's t/s paramaters as obviously it's already in a cabinet designed for it by MA).

I've asked MA for advice on replacing the tweeters in the past, but go no response to two emails. So i don't hold any hope that they'll give me the tech specs on one of their drivers. Must admit I was very surprised by their lack of response, as I was half asking them if there were any units they could sell me that would be better than the originals.

Mid Bass:

It doesn't look like any SEAS unit i can find on their website. To start wtih I can't find any SEAS aluminium coned driver that has that inverted surround. But there are older units on the site that don't ave actual pictures. This one for example:

http://www.seas.no/images/stories/vintage/pdfdataheet/h1008_l17rep.pdf

Barring anyone here knowing anything about this mid bass unit, what would be the best way of finding out it's frequency response and impedance curves? (not worried about it's t/s paramaters as obviously it's already in a cabinet designed for it by MA).

I've asked MA for advice on replacing the tweeters in the past, but go no response to two emails. So i don't hold any hope that they'll give me the tech specs on one of their drivers. Must admit I was very surprised by their lack of response, as I was half asking them if there were any units they could sell me that would be better than the originals.

input for ACA?

Hi,

I want to build my first solid state audio amp, and I've decided to build an ACA. I have built vintage clone guitar tube amps, a few active speakers, repaired vintage integrated amps, turntables, and speakers, and built various small solid state projects, so I'm not anticipating difficulty. I'll be using a linear power supply (AnTek toroidal Xformer, etc), it will not be monoblocks, just one stereo amp.

My quandry is that I don't know how to deal with the input. Do I have to use a preamp? If so a passive one or an active one or just a buffer? I've never owned separates before, just integrated amps all my life, and I'm ignorant about this. I thought "line level" was a standard thing but apparently it varies from one source to another. Of courses the ACA doesn't have input sensitivity control.

The music sources that I imagine using are

1) a turntable

2) a CD player

3) a Raspberry Pi music server with a DAC hat.

Any advice or knowledge on this would be greatly appreciated.

Thanks,

Rob

I want to build my first solid state audio amp, and I've decided to build an ACA. I have built vintage clone guitar tube amps, a few active speakers, repaired vintage integrated amps, turntables, and speakers, and built various small solid state projects, so I'm not anticipating difficulty. I'll be using a linear power supply (AnTek toroidal Xformer, etc), it will not be monoblocks, just one stereo amp.

My quandry is that I don't know how to deal with the input. Do I have to use a preamp? If so a passive one or an active one or just a buffer? I've never owned separates before, just integrated amps all my life, and I'm ignorant about this. I thought "line level" was a standard thing but apparently it varies from one source to another. Of courses the ACA doesn't have input sensitivity control.

The music sources that I imagine using are

1) a turntable

2) a CD player

3) a Raspberry Pi music server with a DAC hat.

Any advice or knowledge on this would be greatly appreciated.

Thanks,

Rob

Quad 44 Preamp - Is it worth keeping and upgrading

- By eldarvanyar

- Solid State

- 15 Replies

Hi,

I have a Quad 44 which I bought a couple of years ago. It's all standard and a mark II version according to the Dada Electronics website.

I have been doing some reading regarding the Quad 44 and I am unsure about the real potential of this preamp and whether I should invest some money in it before using it, or just sell it and put the money into something else.

I am also thinking about having a passive preamp made by BTE Designs as well, so have to decide on which to do first.

Either amp would feed into a Quad 606 MK1 power amp, which I bought earlier this year and immediately sent to Quad for a service, and they also upgraded the PSU to 909 spec.

I am aware that there is the DIY route with DADA Electronics

Quad 44 MKII DIY Upgrade and Revision kit Deluxe

Quad 44 MKII DIY Upgrade and Revision kit Deluxe

I would have to get someone to do the soldering and upgrading for me due to being post stroke and my eyesight not being very good close up

Redhill Audio

QUAD 44 PREAMP UPGRADE - STAGE 1

Elna Cerafine audio-grade electrolytic capacitors

Additional, high-quality Panasonic PPS film capacitor decoupling added to remove noise from critical areas

Solid Film MKS signal path capacitors

Unnecessary signal path capacitors bypassed for reduced grain and a cleaner sound

A well chosen blend ofLME49710NA/LM4562NA National Semi & Texas Instruments Op amps for better refinement and improved detail

Quad 44 Preamp Upgrade - Stage 1

QUAD 44 PREAMP UPGRADE - STAGE 2

Increased capacity Low-ESR Power Supply Capacitors

Output signal path capacitors upgraded to solid film types

Elna Cerafine Decoupling capacitors

LME49710 & TI/National Semi Opamps

Panasonic PPS Bypass Capacitors

2 x Red Hill Audio Mini-Shunt Voltage Regulators +/-15v

Signal Path Improved with Audio Wire "Silver Signal"

http://redhillaudio.co.uk/hifi-upgr...reamp-upgrades/quad-44-preamp-upgrade-stage-2

Amplabs who do upgrades as well.

http://www.amp-labs.co.uk/q44fs-a.htm

Rob from Amplabs serviced and upgraded a Quad 303 that I bought a couple of years ago

http://www.amp-labs.co.uk/servicing.htm

He originally serviced a Yamaha CR1000 for me which I stupidly sold a couple of years ago but he only works on Quad now I think.

I have read online that the Quad 44 suffers from the 4066 CMOS Chip which was originally designed for and used in the Plessey System X Telephone exchanges, and is naturally bandwidth limited.

Other issues include the use of the Op-Amp TL071 as was used in the 405 power amp.

With the modular design and ability to have different boards the Quad 44 could be quite an asset if it sounds any good. Are the MM and MC cards any good or able to be upgraded to anything worthwhile?

Any advice, thoughts or experience much appreciated

Thanks

Lee

I have a Quad 44 which I bought a couple of years ago. It's all standard and a mark II version according to the Dada Electronics website.

I have been doing some reading regarding the Quad 44 and I am unsure about the real potential of this preamp and whether I should invest some money in it before using it, or just sell it and put the money into something else.

I am also thinking about having a passive preamp made by BTE Designs as well, so have to decide on which to do first.

Either amp would feed into a Quad 606 MK1 power amp, which I bought earlier this year and immediately sent to Quad for a service, and they also upgraded the PSU to 909 spec.

I am aware that there is the DIY route with DADA Electronics

Quad 44 MKII DIY Upgrade and Revision kit Deluxe

Quad 44 MKII DIY Upgrade and Revision kit Deluxe

I would have to get someone to do the soldering and upgrading for me due to being post stroke and my eyesight not being very good close up

Redhill Audio

QUAD 44 PREAMP UPGRADE - STAGE 1

Elna Cerafine audio-grade electrolytic capacitors

Additional, high-quality Panasonic PPS film capacitor decoupling added to remove noise from critical areas

Solid Film MKS signal path capacitors

Unnecessary signal path capacitors bypassed for reduced grain and a cleaner sound

A well chosen blend ofLME49710NA/LM4562NA National Semi & Texas Instruments Op amps for better refinement and improved detail

Quad 44 Preamp Upgrade - Stage 1

QUAD 44 PREAMP UPGRADE - STAGE 2

Increased capacity Low-ESR Power Supply Capacitors

Output signal path capacitors upgraded to solid film types

Elna Cerafine Decoupling capacitors

LME49710 & TI/National Semi Opamps

Panasonic PPS Bypass Capacitors

2 x Red Hill Audio Mini-Shunt Voltage Regulators +/-15v

Signal Path Improved with Audio Wire "Silver Signal"

http://redhillaudio.co.uk/hifi-upgr...reamp-upgrades/quad-44-preamp-upgrade-stage-2

Amplabs who do upgrades as well.

http://www.amp-labs.co.uk/q44fs-a.htm

Rob from Amplabs serviced and upgraded a Quad 303 that I bought a couple of years ago

http://www.amp-labs.co.uk/servicing.htm

He originally serviced a Yamaha CR1000 for me which I stupidly sold a couple of years ago but he only works on Quad now I think.

I have read online that the Quad 44 suffers from the 4066 CMOS Chip which was originally designed for and used in the Plessey System X Telephone exchanges, and is naturally bandwidth limited.

Other issues include the use of the Op-Amp TL071 as was used in the 405 power amp.

With the modular design and ability to have different boards the Quad 44 could be quite an asset if it sounds any good. Are the MM and MC cards any good or able to be upgraded to anything worthwhile?

Any advice, thoughts or experience much appreciated

Thanks

Lee

Hello from S.M.Infesta- Portugal

- By antpaubarcar

- Introductions

- 8 Replies

Hello everybody,

Another one to share and search for knowledge...

Merry Christmas and Happy New Year for ALL

Another one to share and search for knowledge...

Merry Christmas and Happy New Year for ALL

Quad 606 Power amplifier

- By eldarvanyar

- Solid State

- 4 Replies

Hi guys,

I have Quad 606 power amplifier and the input states 500mv.

I stupidly connected the 1.5v output from my Quad 44 Preamp to it and turned it on.

Would this have damaged the power amp?

Thanks

I have Quad 606 power amplifier and the input states 500mv.

I stupidly connected the 1.5v output from my Quad 44 Preamp to it and turned it on.

Would this have damaged the power amp?

Thanks

Compact WAW, maybe cardioid, maybe first order series

I thought I'd document this project here.

I've recently taken delivery of 2x Kartesian Acoustics Sub120 Ferrite drivers, 3x SB65 full-range units, and 2x SB Acoustics 5x8" passive radiators.

The Kartesian mini-subwoofers are newly-released (I got a pair from the first batch), and the specs are very impressive - check out the Klippel curves in the link above. These drivers should have very low distortion up until 11mm p/p travel, where the motor force starts to drop off.

They make it well into the kHz region before the response gets messy (with a peak around 7kHz), so there's plenty of overlap with...

The SB65 unit, which routinely receives high praise around here, so I've been wanting to try them out for a while.

There are a few different projects I can think of which would be interesting:

- First up, something like Xrk's Micro WAW, which is a nice little project. There are opportunities for first-order passive crossovers with excellent time-domain performance. The Kartesian LF driver should have a more extended LF response. Hornresp suggests extension down into the mid-30s should be possible, at useful SPLs.

- Next, a speaker inspired by Barleywater's omni+dipole=cardioid speaker, which resulted in excellent cardioid characteristics over a full decade (100Hz-1kHz). The smaller SB65 unit for the mid-high range would likely mean that cardioid range would move up by a couple of octaves, but some distortion testing (for the bottom of the cardioid bandwidth) will reveal how far they can be pushed.

In order to take the concept a step further, I'm planning on mounting the SB65 in a small U-frame enclosure with some acoustic stuffing & vents, with the hope of extending the cardioid bandwidth further into the kHz range with passive cancellation.

It would be nice if such a speaker could be made with passive crossovers, but for now I'll try with some DSP.

- A larger WAW with 2x woofers, mounted for force cancellation. That would allow more LF headroom, but I don't know how the drivers stack up in terms of output yet. If the Kartesian driver can out-run the SB65's >1kHz output, then I'll be looking for alternative wide-range units.

- Some kind of portable bluetooth speaker, if the rest aren't as good as I'd like them to be.

Each project would involve the 5x8" PRs to extend the LF response. This will allow me to change the LF tuning easily, avoid port chuffing, 1/4-wave resonances, etc.

The extra SB65 driver will be the subject of some experiments. Basket shaping? Cone damping? Phase plug? All of the above? Who knows.

A further option would be to double up the SB65 units for more output - might be particularly useful for the cardioid speaker.

At the moment, I have a couple of prototype boxes half-built, but have paused for now. I'll post some photos of the drivers and cabinets when I can.

Interesting stuff coming soon.

Seasons Greetings,

Chris

I've recently taken delivery of 2x Kartesian Acoustics Sub120 Ferrite drivers, 3x SB65 full-range units, and 2x SB Acoustics 5x8" passive radiators.

The Kartesian mini-subwoofers are newly-released (I got a pair from the first batch), and the specs are very impressive - check out the Klippel curves in the link above. These drivers should have very low distortion up until 11mm p/p travel, where the motor force starts to drop off.

They make it well into the kHz region before the response gets messy (with a peak around 7kHz), so there's plenty of overlap with...

The SB65 unit, which routinely receives high praise around here, so I've been wanting to try them out for a while.

There are a few different projects I can think of which would be interesting:

- First up, something like Xrk's Micro WAW, which is a nice little project. There are opportunities for first-order passive crossovers with excellent time-domain performance. The Kartesian LF driver should have a more extended LF response. Hornresp suggests extension down into the mid-30s should be possible, at useful SPLs.

- Next, a speaker inspired by Barleywater's omni+dipole=cardioid speaker, which resulted in excellent cardioid characteristics over a full decade (100Hz-1kHz). The smaller SB65 unit for the mid-high range would likely mean that cardioid range would move up by a couple of octaves, but some distortion testing (for the bottom of the cardioid bandwidth) will reveal how far they can be pushed.

In order to take the concept a step further, I'm planning on mounting the SB65 in a small U-frame enclosure with some acoustic stuffing & vents, with the hope of extending the cardioid bandwidth further into the kHz range with passive cancellation.

It would be nice if such a speaker could be made with passive crossovers, but for now I'll try with some DSP.

- A larger WAW with 2x woofers, mounted for force cancellation. That would allow more LF headroom, but I don't know how the drivers stack up in terms of output yet. If the Kartesian driver can out-run the SB65's >1kHz output, then I'll be looking for alternative wide-range units.

- Some kind of portable bluetooth speaker, if the rest aren't as good as I'd like them to be.

Each project would involve the 5x8" PRs to extend the LF response. This will allow me to change the LF tuning easily, avoid port chuffing, 1/4-wave resonances, etc.

The extra SB65 driver will be the subject of some experiments. Basket shaping? Cone damping? Phase plug? All of the above? Who knows.

A further option would be to double up the SB65 units for more output - might be particularly useful for the cardioid speaker.

At the moment, I have a couple of prototype boxes half-built, but have paused for now. I'll post some photos of the drivers and cabinets when I can.

Interesting stuff coming soon.

Seasons Greetings,

Chris

Arcam FMJ silver shades?

- By XsamuraiX

- Everything Else

- 2 Replies

Does anyone know the exact shade of grey which Arcam used on there FMJ equipment?

I just bought a pre/power amp by them, work great but the paint, awful!!! So going to sand it all down, use a god primer and respray both of them. Have had a look online but I can't seem to find any colour codes.

I just bought a pre/power amp by them, work great but the paint, awful!!! So going to sand it all down, use a god primer and respray both of them. Have had a look online but I can't seem to find any colour codes.

Volume Control Potentiometer for Cambridge Audio A1 Amplifier

The mechanical part of the volume potentiometer on my Cambridge Audio A1 Amplifier has broken, and I'm currently trying to see if I can superglue it back together etc, but I'm not sure this will be successful, so it may be better/safer to purchase a new one.

I don't have a schematic so can't check what value it is, but hopefully the attached pics may help someone more knowledgeable advise what part I need to buy.

Thanks, Rob

I don't have a schematic so can't check what value it is, but hopefully the attached pics may help someone more knowledgeable advise what part I need to buy.

Thanks, Rob

Attachments

Sansui AU-9500 Channel Issue

- By Diyengineer

- Solid State

- 1 Replies

Hello,

I have a Sansui AU-9500. I noticed that one of the channels is lacking some mid frequencies making the vocals a little muddy on one channel.

Doing some troubleshooting I swapped the left and right driver boards and the problem followed. I'm not sure what I should go after on this driver board that might cause this problem.

I've attached some pics of the board and schematic for reference.

Thanks

I have a Sansui AU-9500. I noticed that one of the channels is lacking some mid frequencies making the vocals a little muddy on one channel.

Doing some troubleshooting I swapped the left and right driver boards and the problem followed. I'm not sure what I should go after on this driver board that might cause this problem.

I've attached some pics of the board and schematic for reference.

Thanks

Attachments

The addiction continues...

- Introductions

- 3 Replies

Hello All,

I've been playing with audio since I was a young kid. It's been unshakeable addiction ever since. I also started a small production company about 12 years ago that offers sound, lighting and video services. Right now my audio focus is on car audio. I started building my system about a year ago. Some nice focal speakers up front, Hertz in the rear and JL subs and amp for the lows. At the heart of the system is a DBX Driverack PA2 that's been modified to run on 12v. With the addition of the Hertz I will be needing to add at least one more DSP channel (Focal's use four channels) and am about to start down the road of SigmaStudio compatible processors

I've been playing with audio since I was a young kid. It's been unshakeable addiction ever since. I also started a small production company about 12 years ago that offers sound, lighting and video services. Right now my audio focus is on car audio. I started building my system about a year ago. Some nice focal speakers up front, Hertz in the rear and JL subs and amp for the lows. At the heart of the system is a DBX Driverack PA2 that's been modified to run on 12v. With the addition of the Hertz I will be needing to add at least one more DSP channel (Focal's use four channels) and am about to start down the road of SigmaStudio compatible processors

Adding trimpot for bias control on pioneer SX-434

- By stofbj

- Solid State

- 7 Replies

Hi, Could anyone recommend where I should install a trimpot to adjust the current on the output transistors on a pioneer sx-434, cutting the wires as per service manual is not very accurate. I know the picture is not very clear but it is all I have, thanks in advance, Happy Christmas to all.

Attachments

Marantz dv9500 muting transistors...

- By Htguy

- Digital Source

- 3 Replies

Hi,

I want to try shorting the muting transistors on my DV9500. I can find the 12v mute feed, but I need some help to make sure I don't short across the wrong transistor 🙂

I want to try shorting the muting transistors on my DV9500. I can find the 12v mute feed, but I need some help to make sure I don't short across the wrong transistor 🙂

Attachments

Series plate load resistors

- By force of 1/2

- Tubes / Valves

- 30 Replies

Hi All,

Quick, question:

For the purposes of a plate load, is there any difference between a 4k and 8k wired in series, and a single 12k resistor?

Hope this is not a ridiculous question!

Thanks in advance for you help!

Best regards,

John

Quick, question:

For the purposes of a plate load, is there any difference between a 4k and 8k wired in series, and a single 12k resistor?

Hope this is not a ridiculous question!

Thanks in advance for you help!

Best regards,

John

Motor controller on a vibraphone

- By NatJS

- Everything Else

- 4 Replies

I have an old Deagan vibraphone I'm restoring. It's an instrument made in Chicago and imported to the UK in the 70s.

I want to be able to use it in the UK (240V line voltage) without having to use a 240v > 110v transformer, which is annoying to have to lug around to gigs and also adds ti to the weight of everything I'm carrying.

The motor is this Model 0737 - K-2 Series Parallel Shaft AC Gearmotor - AC Parallel Shaft Gearmotors - Bodine Electric

In the control panel is a 1uF capacitor rated at 250vac, a VR and this adjustable voltage regulator CSR1004A | United Automation, 230 V Voltage Regulator, 10A, Adjustable 3-Pin CSR1004A | RS Components which is rated at 230vac. It's wired up as in the schematic on the controller datasheet.

Will I be able to run it directly at UK mains voltage and get it in the right speed range just by adding a resistor in series with the VR on the controller? Or am I misunderstanding how it works?

Thanks!

I want to be able to use it in the UK (240V line voltage) without having to use a 240v > 110v transformer, which is annoying to have to lug around to gigs and also adds ti to the weight of everything I'm carrying.

The motor is this Model 0737 - K-2 Series Parallel Shaft AC Gearmotor - AC Parallel Shaft Gearmotors - Bodine Electric

In the control panel is a 1uF capacitor rated at 250vac, a VR and this adjustable voltage regulator CSR1004A | United Automation, 230 V Voltage Regulator, 10A, Adjustable 3-Pin CSR1004A | RS Components which is rated at 230vac. It's wired up as in the schematic on the controller datasheet.

Will I be able to run it directly at UK mains voltage and get it in the right speed range just by adding a resistor in series with the VR on the controller? Or am I misunderstanding how it works?

Thanks!

TDA1541A Dual differential MK1

- By batteryman

- Digital Line Level

- 51 Replies

More on my dual 1541a Rainbow_hui dac saga..

This has now been configured for differential working using a pair of Sowter 9545 transformers in MK1 test version.

Using one dac for normal and the other for inverted data operation meant just interposing a spare inverter in IC11 - a 74HC14 before pin3 of dac 2.

To prove that I had connected the transformers correctly, with both dacs receiving the same data, there was no ouput ( as good as!) as expected.

Next step is to use the dacs in simultaneous mode with one dac per channel. However this requires 2s complement to offset binary conversion and a simple method of doing so has been devised which I hope to test next week.

In the meantime more listening to be done for the consequences of the lsb error due to inverting the data. (Nothing audible with a quick listen)

I found a mistake on the pcb, the unused gates of IC11 are shown correctly as having the inputs tied to ground except that its actually pin 6 (output) that was grounded instead of pin 5.

Ianj

This has now been configured for differential working using a pair of Sowter 9545 transformers in MK1 test version.

Using one dac for normal and the other for inverted data operation meant just interposing a spare inverter in IC11 - a 74HC14 before pin3 of dac 2.

To prove that I had connected the transformers correctly, with both dacs receiving the same data, there was no ouput ( as good as!) as expected.

Next step is to use the dacs in simultaneous mode with one dac per channel. However this requires 2s complement to offset binary conversion and a simple method of doing so has been devised which I hope to test next week.

In the meantime more listening to be done for the consequences of the lsb error due to inverting the data. (Nothing audible with a quick listen)

I found a mistake on the pcb, the unused gates of IC11 are shown correctly as having the inputs tied to ground except that its actually pin 6 (output) that was grounded instead of pin 5.

Ianj

Questions About Bridging An Amp

- By jaagut

- Solid State

- 13 Replies

Currently there was a talk and an attempt in our local audio community to build an amp which will utilize two bridged amp to be connected again in bridge mode. Since the debate is not yet close, I would like to ask your expert opinion whether it is possible or not, or any of you has done this, or is true that Crown or any manufacturer made the bridged-bridged amp and already sold this in the market?

Combo Active/Passive crossover design

- By DIYhopeful

- Multi-Way

- 0 Replies

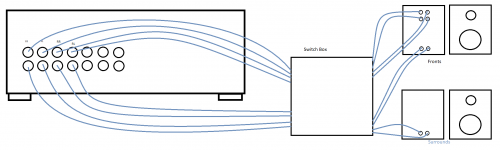

Hi,

I'm currently designing my first 2 way speakers. I was torn between active and passive so I decided why not both since I love music and a surround setup for movies.

For the music setup front 2 channel:

I will be using 4 amplifier channels for the 2 mids and 2 tweeters via PC REW Jriver setup. This is strictly for the fronts.

Also I was wondering if I could create a switch box type setup for the AVR output jacks since I have one AVR and not enough amplifier channels for a surround setup with passive crossovers as well as a dedicated music (active) setup. Initially there was a switch system inside the speaker but I realized I won't need that with the switch box.

My question is, is this safe? It won't blow up on me right? Any feedback and criticism will be appreciated. I don't really know my electrics tbh.

I'm currently designing my first 2 way speakers. I was torn between active and passive so I decided why not both since I love music and a surround setup for movies.

For the music setup front 2 channel:

I will be using 4 amplifier channels for the 2 mids and 2 tweeters via PC REW Jriver setup. This is strictly for the fronts.

Also I was wondering if I could create a switch box type setup for the AVR output jacks since I have one AVR and not enough amplifier channels for a surround setup with passive crossovers as well as a dedicated music (active) setup. Initially there was a switch system inside the speaker but I realized I won't need that with the switch box.

My question is, is this safe? It won't blow up on me right? Any feedback and criticism will be appreciated. I don't really know my electrics tbh.

Attachments

Removing Rubber Speaker Surrounds

- By CliffR52

- Construction Tips

- 11 Replies

Hi All.

I'm having a go at restoring 2 Loudspeakers.

They are of 2 way design featuring cTs Model 8W9R Woofers.

The Woofers are fitted with rubber surrounds.

To improve sensitivity I'm considering the removal of the rubber in preference to foam surrounds.

Removing deteriorated foam surrounds is straight forward.

How should I go about removing the rubber types without damaging the cones?

thanks

Cliff

I'm having a go at restoring 2 Loudspeakers.

They are of 2 way design featuring cTs Model 8W9R Woofers.

The Woofers are fitted with rubber surrounds.

To improve sensitivity I'm considering the removal of the rubber in preference to foam surrounds.

Removing deteriorated foam surrounds is straight forward.

How should I go about removing the rubber types without damaging the cones?

thanks

Cliff

Crossover question

In this article by Dick Olsher he has this crossover for the SAL fulrange driver and the Hawthorn Augie 15" woofer. The woofer just uses a first order crosover using a 5mh inductor. Then the SAL uses a 2 order crossover made from a 76uf cap and a 3mh inductor. My question is what is the crossover type and frequency used for the SAL is it a Linkwitz-Riley, Butterworth, Besel, Chebychev or some other type ?

Tip_85

Tip_85

Burson Op-Amps Vs....

First, by way of disclosure, this post was made possible by Burson Audio, who supplied me with their Classic and Vivid op-amps after I responded to a post they made elsewhere on this site. I sent those to my friend Robert, whose observations are included here, and ordered more for myself from Parts Connexion.

Second, the system(s) used for comparison: The component in which the op-amps themselves were used was a Pass DIY Whammy headphone amp. Robert's was built from the kit (by me). My Whammy was 'upscale', built with New Class D discrete regulators; Takman REY metal film resistors; Nichicon Muse FG and Elna Silmic II electrolytics outside the power supply; Jantzen Superior Z-Caps for the input coupling caps, and Vishays for the ones around the optocoupler; the pot in mine was an Audio Note Noble-style (which was also in Robert's, as opposed to ALPS in the stock kit). Phones in my case are Focal Utopias; Robert's are Audeze LCD-2s.

The source, in my case, was a DIY turntable with a Graham 2.2 arm and Soundsmith Hyperion Mk II ES cartridge fed through a Pass XP-17 phono preamp. Cables were self-terminated Gotham Audio GAC-4/1 Ultra Pro. Robert also has a DIY turntable with a very obscure arm whose name I can't recall and some Koetsu cartridge. He uses a tube phono stage whose name I also can't recall. Suffice it to say that his his system (VTL Signature MB-450 monoblocks, heavily modified Magnepan 3.6s) is the best I've ever heard outside a high-end audio store. (My system may now be equally good, due to some major pandemic-excused upgrades.)

So, to the op-amps. The various ones used for comparison were: (i) the stock op-amp supplied with the Whammy kit, which I believe is a TI part, about $1; (ii) an Analog Devices op-amp that is about $10; (iii) the Burson V6 Vivid and Classic, which tend to go for about $70; and (iv) the New Class D dual op-amp, which is about the same price as the Bursons. Unfortunately, I do not (yet!) have a SparkoS op-amp to compare.

First point: No matter which of these op-amps you use, the Whammy sounds quite good---totally listenable even with the stock part, if you hadn't heard the others. But, by comparison, the stock (presumably TI) op-amp is pretty terrible. So much so that there's no point describing the ways the other ones are better. Spend the extra $10 at the very least.

Second point: In agreement with almost everyone else who has posted about this, the Vivid is way too bright in the Whammy. It may well be that the Vivid is perfect for other circuits (ones that tend to be a bit dark). If you're replacing an op-amp in a CD player, e.g., then it may well be worth comparing the Vivid and the Classic. Once you take out the old op-amp, make sure you solder in a DIP socket, so then you can swap all kinds of things in and out until you know what's best. But, in the Whammy, as I said, the Vivid is too bright, annoyingly so.

Third point: It's a very close call between the Burson V6 Classic and the New Class D. I think if I had to have just one I'd go for the New Class D, but I've not done enough comparative listening to be really sure. I'm very happy to have both and have swapped them in and out without feeling like I was losing very much. I'm quite sure I'd be happy enough to live with the Burson Classic. Both the Burson Classic and the New Class D are fully capable of revealing details I'd not heard before, but without feeling 'etched'; i.e., they both make music sound like music and leveraging the extra detail to make the music sound MORE like music.

Second, the system(s) used for comparison: The component in which the op-amps themselves were used was a Pass DIY Whammy headphone amp. Robert's was built from the kit (by me). My Whammy was 'upscale', built with New Class D discrete regulators; Takman REY metal film resistors; Nichicon Muse FG and Elna Silmic II electrolytics outside the power supply; Jantzen Superior Z-Caps for the input coupling caps, and Vishays for the ones around the optocoupler; the pot in mine was an Audio Note Noble-style (which was also in Robert's, as opposed to ALPS in the stock kit). Phones in my case are Focal Utopias; Robert's are Audeze LCD-2s.

The source, in my case, was a DIY turntable with a Graham 2.2 arm and Soundsmith Hyperion Mk II ES cartridge fed through a Pass XP-17 phono preamp. Cables were self-terminated Gotham Audio GAC-4/1 Ultra Pro. Robert also has a DIY turntable with a very obscure arm whose name I can't recall and some Koetsu cartridge. He uses a tube phono stage whose name I also can't recall. Suffice it to say that his his system (VTL Signature MB-450 monoblocks, heavily modified Magnepan 3.6s) is the best I've ever heard outside a high-end audio store. (My system may now be equally good, due to some major pandemic-excused upgrades.)

So, to the op-amps. The various ones used for comparison were: (i) the stock op-amp supplied with the Whammy kit, which I believe is a TI part, about $1; (ii) an Analog Devices op-amp that is about $10; (iii) the Burson V6 Vivid and Classic, which tend to go for about $70; and (iv) the New Class D dual op-amp, which is about the same price as the Bursons. Unfortunately, I do not (yet!) have a SparkoS op-amp to compare.

First point: No matter which of these op-amps you use, the Whammy sounds quite good---totally listenable even with the stock part, if you hadn't heard the others. But, by comparison, the stock (presumably TI) op-amp is pretty terrible. So much so that there's no point describing the ways the other ones are better. Spend the extra $10 at the very least.

Second point: In agreement with almost everyone else who has posted about this, the Vivid is way too bright in the Whammy. It may well be that the Vivid is perfect for other circuits (ones that tend to be a bit dark). If you're replacing an op-amp in a CD player, e.g., then it may well be worth comparing the Vivid and the Classic. Once you take out the old op-amp, make sure you solder in a DIP socket, so then you can swap all kinds of things in and out until you know what's best. But, in the Whammy, as I said, the Vivid is too bright, annoyingly so.