Hi, I originally posted this in another forum, but felt members here may benefit from this also, so I am re-posting some key elements in the processes I used.

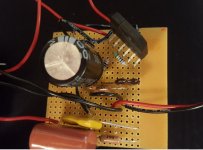

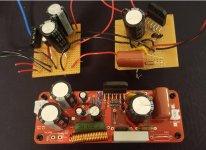

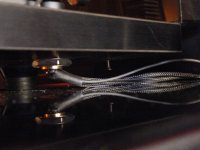

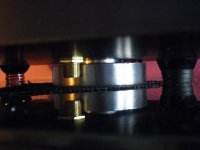

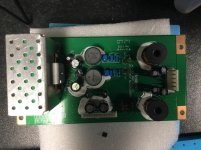

I just rewired my RB300 tonearm, with Isokinetik silver plated wire (Cardas cartridge clips with Mundorf supreme silver lead free solder) : straight loom to the phono preamp..., and finished making a custom 3kg disc to mount the motor from the Rega Planar 3 on. I also dampened the tonearm with 7 expandable earplugs, and put 2 very thin slithers of earplug foam inbetween the spring coils in the weight adjustment part of the tonearm (they ring like a bell), while it was set at 3.5g (maximum-opens the spring up totally) and then set the weight via jewellers scales - leaving the setting at 3.5g.

I have NEVER heard a Rega sound soooooooooOOOOOOO GOOOOOD...!!!

Extra wide soundstage, depth, transparancy, black-silent background, detail, with a laid back clarity...yet so much PUNCH and tight bass....

...and its still in the initial hours of being 'burnt-in'....I cant tear myself away from it.....I also have a ruby bearing in it, and acrylic platter. In the lead base, which I made from a jar stainless lid, I drilled a hole, got a paper-mate biro pen, and took the spring out, cut it in half, and put it in the hole, and used the steel bearing I replaced with the ruby one, for the platter, and used it for a 'thrust bearing' as part of the lead base.....

...man, what a rewarding effort...., some tracks evoked pure emotion....WoW

... I still need to finalise a few minor points...ie: ext-cable clamp, 3 point mini-feet on base etc...,

... that is an 'ancient' Shure M75EJ Type II on there with a near-new Swiss Huco Hyper-elliptical .2 x .7 stylus...The Nagoaka MP-200 is looking like a good cartridge/stylus....for future consideration hmmm