Cone loaded Smith horn

Hey all,

I have been a diy speaker builder for the last 10 years and have built a number of successful projects over the journey.

Recently I started to get into horns. I built my dad a ecconowave type speaker a few years back and more and more as time has gone on I seem to love how they sound. I have a very large shed/man cave and so horns make a lot of sense for my next speakers.

This project started as I had a bunch of material left over from various woodworking and renovation works.

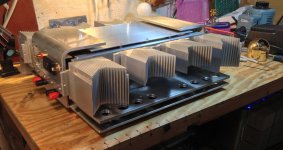

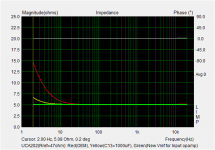

Basically a year or so ago I built some smith horns with left over 26mm laminated beech that I had from making bathroom vanities. Taken from plans on another forum and Adjusted to 5 cell and 90* horizontal pattern. I'm aware that diffraction horns have a mixed reception but they look cool af so that's where I started.

I have recently picked up some new in box faital pro 3fe22 8ohm drivers of Facebook marketplace for a very good price decided to give it a go in the smiths as I have some time at the moment to play with things- self employed, wife and 2 young kids......

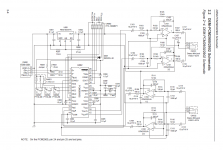

Started with a very rudimentary 2 litre airtight bucket filled with polystuff as the back chamber (obviously this is too big but just playing as a test of concept). Made a 15mm ply and 3mm mdf ring with a 25mm square hole for the entry to the horn- see attached (this is before file work to make it all neat and even so it looks pretty basic in the pic).

More to follow

I have been a diy speaker builder for the last 10 years and have built a number of successful projects over the journey.

Recently I started to get into horns. I built my dad a ecconowave type speaker a few years back and more and more as time has gone on I seem to love how they sound. I have a very large shed/man cave and so horns make a lot of sense for my next speakers.

This project started as I had a bunch of material left over from various woodworking and renovation works.

Basically a year or so ago I built some smith horns with left over 26mm laminated beech that I had from making bathroom vanities. Taken from plans on another forum and Adjusted to 5 cell and 90* horizontal pattern. I'm aware that diffraction horns have a mixed reception but they look cool af so that's where I started.

I have recently picked up some new in box faital pro 3fe22 8ohm drivers of Facebook marketplace for a very good price decided to give it a go in the smiths as I have some time at the moment to play with things- self employed, wife and 2 young kids......

Started with a very rudimentary 2 litre airtight bucket filled with polystuff as the back chamber (obviously this is too big but just playing as a test of concept). Made a 15mm ply and 3mm mdf ring with a 25mm square hole for the entry to the horn- see attached (this is before file work to make it all neat and even so it looks pretty basic in the pic).

More to follow