Dear All,

We have a number of threads related to (various) coatings applications but I decided to start a new thread as it is related to preparation for coating application only.

Recent coatings are more environmentally friendly and based on (I think) water-soluble acrylics or polyurethanes which is great.

However, regardless of the type of coating, there is always a question of how easy/difficult coating application is and the wettability of the used diaphragm film.

A long, long time ago (could be a decade ago

🙂 ) SY mentioned that corona treatment prior to application of coatings should be beneficial.

SY also said that a corona or plasma treatment could be done using a small Tesla coil.

There are small commercial corona treaters like BD-20AC Lab Corona Treater, however, I'm not prepared to pay $US 1,000 (my wife would kill me).

So before I refurbish my old ESLs, the challenge was to corona treat a sample film.

TAKE 1 - Build and use Tela coil -

FAILURE

The idea was to build a small Tesla coil and replace the HV coil load (sphere or doughnut) with something suitable for film treatment - something like a coat-hanger.

So I built this "small" Tesla coil and it was great fun (for my kids) as it produced copious sparks - to be honest, I was a little bit scared, it was also very noisy.

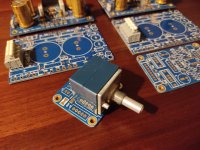

TAKE 2 - Use AC flyback to make a treater -

SUCCESS

Build a driver for AC flyback and use a 300mm long 19mm Dia (3/4in) copper pipe as an electrode.

This is a small treater that does 100W at approximately 30kHz and the photos of the unit in action are below.

To my surprise, this treatment's effectiveness exceeded my expectation by a country mile - and I am serious.

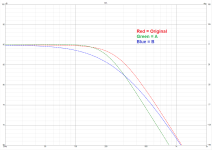

I treated an A4 sheet of acetate (from my local craft store) and the difference between the treated and non-treated areas is amazing - refer to the images below.

I used plain filtered water to check and compare the wettability.

CONCLUSION - I will treat all membranes prior to coating for sure. -

thanks for the advice SY 👍 !!!

The treated section has a uniform film of water over the whole area.

The treater in action (feediing diriver with 20V dc & 5 amps)