Design Phase - 35Hz Tapped Horn w/ Compression Chamber (Hog Scoop + Inverted Driver)

This project has been inspired by all the love for Hog Scoops... And the fair share of hate they get as well.

This will bee my first attempt at an 18" horn subwoofer.

Proposed plan is based on the well known "Hog Scoop",

a tried and tested free design hosted over on the freespeakerplans.com forum.

https://www.freespeakerplans.com/?view=article&id=31:hog-scoop

Drawn up nearly 20 years ago, this well proven classic has stood the test of time and is a very

clever piece of speaker box design, still to this day.

Credit for this creation must go to Stipe Ercegovic, more commonly known a Staiper, a well respected member on the Speakerplans Scoop subforum for a long time,

but he disappearred from there several years ago and doesn't seem to frequent these places anymore.

The Hog Scoop, technically an F1 hybrid of sorts, the offspring of two genetically similar species,

living a life somewhere between a tapped horn and a traditional back loaded "scoop".

A rear loaded horn with the bonus of the driver shooting into the horn path, or a tapped horn enclosure

equipped with a compression chamber.... Call it what you will, this quarter wave resonator is well capable of

hitting the low bass notes and producing high SPL when equipped with the right hardware.

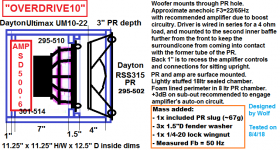

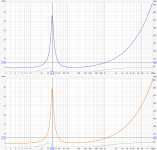

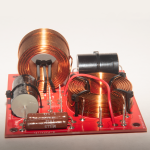

So, I would like to run inverted drivers in a slightly tweaked version of this enclosure, something similar to the image attached to the end of this post.

These are the M4.18 subwoofers, made by MM-Acoustics in Europe, a Macedonian outfit headed by Marjan Milosevic, a regular poster and long time member over on SP.

My god, they look absolutely amazing, so business like.

This is the look I am going for.... They are absolutely badass indeed.

Anyway..... enough airy introductions, and down to business then !!

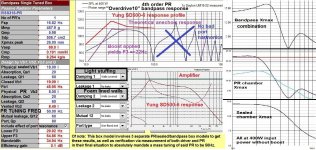

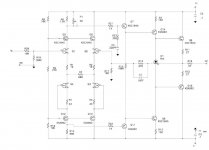

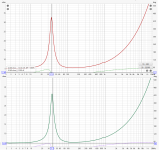

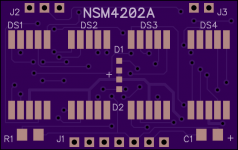

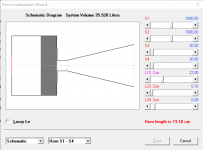

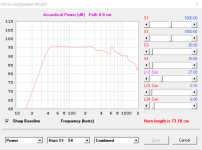

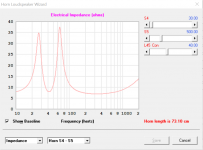

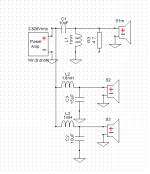

Hog Scoop Hornresp input parameters

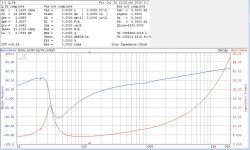

First things first, I decided it would bee prudent to simulate a hog scoop with a driver in it's normal orientation first..... Cone side out.

This was to bee my baseline sim, a benchmark to work from before l went tweaking the original design.

And staight away I ran into problems.

For a start, the speakerplans.com forum isn't very active these days..... And a huge amount of information from back when it was is just lost.

Many externally hosted images are not there any more, there are many dead links, hosted plans, you name it, gone !!!

It didn't make my research easy but I did what I could with what I had.

That said, there were many helpful and informative threads to bee found amongst all the bickericking and the politics in the Scoop subforum.

So, lets discuss what was available to find on the net first.... Multiple posts regarding the Hog Scoop hornresp input parameters were scattered around the web....

And just not consistent.

I was hoping to pull some numbers out of a post or a sketch somewhere but straight off the bat, numbers and posts were conflicting.

Unfortunately, I found more than one set of digits, which only infuriated and confused me even more.

Here are the most posted (and reposted) HR Hog Scoop numbers, I beleive they orignally came from Staiper, and these ones were the most common to bee found online,

copy and pasted in at least 4 different places, so I am inclined to stick with the guy who originally penned the Hog Scoop design. He did create it after all.

Stipe Hog Scoop

S1 = 750

Con = 112.8

S2 = 1062

Con = 42

S3 = 1770

Con = 51

S4 = 2544

Con = 47

S5 = 5700

Vrc = 0

Lrc = 0

Fr = 0

Tal = 0

Vtc = 49456

Atc = 86

Re-posted by bitzo,

https://forum.speakerplans.com/forum_posts.asp?TID=16974&PID=214119&title=database-simulation#214119

toastyghost,

https://forum.speakerplans.com/forum_posts.asp?TID=16974&PID=727583&title=database-simulation#727583

Bee,

https://forum.speakerplans.com/forum_posts.asp?TID=72607&PID=828911&title=hog-scoop-drivers#828911

and salzburgsound system

The next set of input data numbers to bee found were these ones you see below.....

--------S1 = 750

Par = 0.10

S2 = 750

Par = 200.90

S3 = 1700

Par = 61.00

S4 = 4740

Par = 12.10

S5 = 5700

Vrc = 0

Ap1 = 0

Lrc = 0

Lpt = 0

Vtc = 37060

Atc = 1453.10

Posted by Heathrow B Line

https://forum.speakerplans.com/foru...=901195&title=scoop-hr-reference-guide#901195

epa

Freddi

And one more, with newer and revised numbers, taken from a post by user "epa" from 2014.

S1 = 750

Par = 0.10

S2 = 750

Par = 187.90

S3 = 1700

Par = 52.00

S4 = 4740

Par = 12.10

S5 = 5700

Vrc = 0

Lrc = 0

Ap1 = 0

Lpt = 0

Vtc = 41091

Atc = 2210.00

Posted by epa

Other than these three sets of input parameters, I did find a few posts by Staiper himself, modeling the Hog Scoop as an exponential horn,

in quite a numerically sparce fashion I must add.... It would seem this stripped down form of modelling came from Rog Mogale himself.

i will link after the following

---------->

Staiper Exponential Hog

S1 = 750

S2 = 5700

L = 260 EXP

Vtc = 36000 (with driver)

Atc = 1000

https://forum.speakerplans.com/forum_posts.asp?TID=8887&PID=218876&title=hog-scoop#218876

Staiper Exponential Again....

S1 = 750

S2 = 5700

L = 257 EXP

Vtc = 37000

Atc = 9000

https://forum.speakerplans.com/forum_posts.asp?TID=8329&PID=77534&title=tapped-horn-design#77534

And finally....... An attempt at simming a Hog Scoop by the man, Rog Mogale himself.

S1 = 750

S2 = 5700

L = 240 EXP

Vtc = 35000

Atc = 890

https://forum.speakerplans.com/forum_posts.asp?TID=8329&PID=77097&title=tapped-horn-design#77097

And here is a good thread full of interesting tit bits where Rog discusses his exponential scoop modelling methods with others.

https://forum.speakerplans.com/forum_posts.asp?TID=8329&PID=77097&title=tapped-horn-design#77097

A must read for anyone into this line of work.

Annd..... Time to take stock.

All my research and reading paid off, but unfortunately I still feel I do not have any concrete numbers for a Hog Scoop simulation binge.

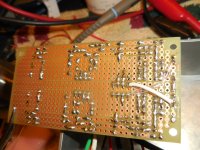

So, I took some time out and drew up a scaled plan of the Hog, just enough to play with.

it gave me a much more definite idea of the direction I asm going in, speaker boxes ofthen quite literally build themselves as the project goes on.

Solutions are often just so obvious when you have the material object taking shape before your eyes.

And measurements can bee taken from the plan and scaled up to something that resembles real world numbers.

(Drawing attached)

And just to bee sure, I am going to get my hands on one side panel first, (18mm sheet board 986 x 950mm) and draw it out @ a life size scale on the floor.

Drivers for this design

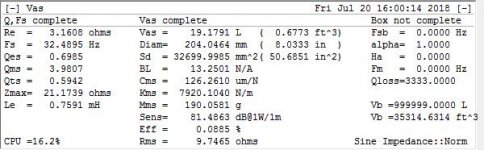

I currently have 2 B&C 18TBX100 (4 ohm) belonging to a friend to use for the first 2 boxes and am debating which drivers to buy for the rest.

Quite likely B&C as well, I like the power handling (1500w) and price of the 18SW1OO.

When given the option, I usually buy 4 ohm versions of any driver when I can.

They can often bee had for the same price as their 8ohm equivalents but sometimes not. Sometimes they are just more hassle to obtain but I do make an effort to

use 4 ohm drivers when ever I can.

I am also open to other brands, I do know I need a certain type of driver to do well in these boxes and if one particular driver turns out to bee

especially suited to the task it will surely bee strongly considered.

So far, everything is going well.... The only other uncertainty I have right now is the design of the rear chamber.

I am not sure exactly how it will end up but I am confident the design (and build) process will answer it's own questions if and when they arise.

More on that in detail later.

Okay, I think I have written enough for now.... Any advice and criticism is warmly welcomed.

Please feel free to join me on my journey of discovery and don't bee shy to interject or comment if need bee.

)

)