For "tube connectors" that work with standard binding posts you can try this:

Parts Express Gold Plated Screw Type Banana Plugs 14-8 AWG 16 Pcs.

Much cheaper and works fine.

Parts Express Gold Plated Screw Type Banana Plugs 14-8 AWG 16 Pcs.

Much cheaper and works fine.

There may be decreased resistance with those tube connectors - more surface area. But for the currents we are dealing with - don't need it. I have used the 5-way binding posts and they work well. At $2.63ea I can get many because I build a lot of speakers/amps.

I think Speakon connectors are well priced and probably have just as much current carrying power.

One can always solder straight to xo board and have long pigtail 16ga zip cord coming out of the speaker. That's the best connection.

I think Speakon connectors are well priced and probably have just as much current carrying power.

One can always solder straight to xo board and have long pigtail 16ga zip cord coming out of the speaker. That's the best connection.

There may be decreased resistance with those tube connectors - more surface area. But for the currents we are dealing with - don't need it. I have used the 5-way binding posts and they work well. At $2.63ea I can get many because I build a lot of speakers/amps.

I think Speakon connectors are well priced and probably have just as much current carrying power.

One can always solder straight to xo board and have long pigtail 16ga zip cord coming out of the speaker. That's the best connection.

Oh so have the pigtail, then solder your speaker wire to the pigtail using heat shrink tube after.. that'd be nice

Heck, sometimes I just twist two bare wires together and call it a day. Sounds fine.

Not me, e.g. I always keep a warmed up soldering iron next to my preamp for when I need to adjust volume. I have an array of vishay dale voltage dividers and solder to the appropriate pair, for each channel.

Haha

JK!

Any tips on getting a lovely finish on these MDF parts express enclosures?

Duratex or truck-bed liner is always the easiest fail proof option.

Painting requires treatment of seams, lots of priming then aa ding then more sanding then final color coat and possibly clear coat (depends on your gloss preference).

I prefer peel and stick wood veneer, then sand and 4-5 coats of Arm R Seal in the sheen of your choice.

I got really good results on my first try and I've only gotten better each time.

PS-great choice of kit I have the X-LS Encores and they are great kit well worth 2-3x's the price, and the stock XO parts sound great too.

Duratex or truck-bed liner is always the easiest fail proof option.

Painting requires treatment of seams, lots of priming then aa ding then more sanding then final color coat and possibly clear coat (depends on your gloss preference).

I prefer peel and stick wood veneer, then sand and 4-5 coats of Arm R Seal in the sheen of your choice.

I got really good results on my first try and I've only gotten better each time.

PS-great choice of kit I have the X-LS Encores and they are great kit well worth 2-3x's the price, and the stock XO parts sound great too.

Thanks I look forward to making the speakers. Any particular brand of stick on veneer I should buy? Where did you get yours and how much did it cost? What wood did you end up going with? Did you apply it in 6 different pieces? or maybe less pieces with some wrap around? Would love to see some photos or have a link to a web site that shows how you do it?

My go to veneer place is veneer supplies.com, he has how to's, a ton of selection and great specials on raw veneer.

I have done peel and stick 2x8 walnut and raw mottled sapele. Peel and stick is by far easier and would suggest for your first try.

Yes you can cut the veneer to "wrap" around the sides and top, bottom. Or however you like it, I've done both and people typically prefer one or the other in my experience.

I have done peel and stick 2x8 walnut and raw mottled sapele. Peel and stick is by far easier and would suggest for your first try.

Yes you can cut the veneer to "wrap" around the sides and top, bottom. Or however you like it, I've done both and people typically prefer one or the other in my experience.

Hmmmm....curious, I put the parameters for the M165 woofer(the one used in the X-LS Encore kit) into a couple of cabinet design programs. WinISD comes up with a sealed box of 0.82 cubic feet, F3 of of 72Hz; or a ported box of 1.6 cubic feet, Fs of 38 Hz, 4"x11" port. Speaker Box Designer comes up with 0.76 cu.ft sealed, F3 of 70 Hz; or 1.5 cu.ft ported, F3 of 40 Hz, 2"x2" port. Both pretty close (except for the port size), but neither matches the box that GR recommends to use with the kit; which is ~0.55 cu.ft ported, F3 of 55Hz, 2" x `3.5"(?) port. GR's box is the smallest, yet claims an F3 of 55Hz. Who to believe??

Last edited:

Hmmmm....curious, I put the parameters for the M165 woofer(the one used in the X-LS Encore kit) into a couple of cabinet design programs. WinISD comes up with a sealed box of 0.82 cubic feet, F3 of of 72Hz; or a ported box of 1.6 cubic feet, Fs of 38 Hz, 4"x11" port. Speaker Box Designer comes up with 0.76 cu.ft sealed, F3 of 70 Hz; or 1.5 cu.ft ported, F3 of 40 Hz, 2"x2" port. Both pretty close (except for the port size), but neither matches the box that GR recommends to use with the kit; which is ~0.55 cu.ft ported, F3 of 55Hz, 2" x `3.5"(?) port. Who to believe??

Wish I knew

The GR research website does have a drawing for their box at http://gr-research.com/pdf/X-LS Encore box.pdf. The PE box is close enough to theirs that you can probably just use that for hole sizes and placement.Wish I knewBut I bought the pre-fab mdf .56 cu feet cabs from parts express so I guess I am gonna try them.. they might not even match the exact dimensions gr-research recommends. Oh well. I'll ask where to cut the holes when I get them in about 10 days

I also wrote to GR and asked them if one could purchase the kit without the crossovers; I think it might benefit greatly from a bi-amp setup using an LM4780/LM3886 and a 24db/octave Linkwitz-Riley active crossover.

I play with actives all the time but the XL-S has such nice behaving drivers that the second order xo it comes with is s tough act to beat. It's quite a well designed system that measures very flat and sounds excellent. If I went active, I would use a Harsch XO with 4th order BW low pass on woofer at about 2kHz and 2nd order Bessel high pass on tweeter with a 0.5ms delay on tweeter. Harsch xo is quasi transient perfect and gives excellent percussive detail and realism.

http://www.diyaudio.com/forums/multi-way/277691-s-harsch-xo.html

I just implemented it with an active 2-way bookshelf horn driven by VHEX+ amps by vzaichenko and Jwilhelm - super amp that beats the pants off my LM3886 amps.

http://www.diyaudio.com/forums/multi-way/277691-s-harsch-xo.html

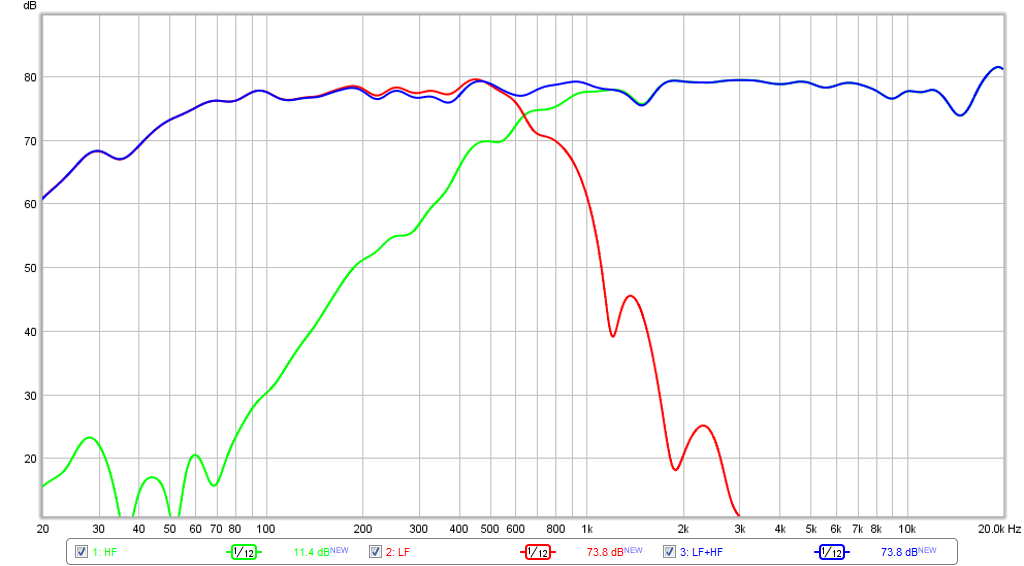

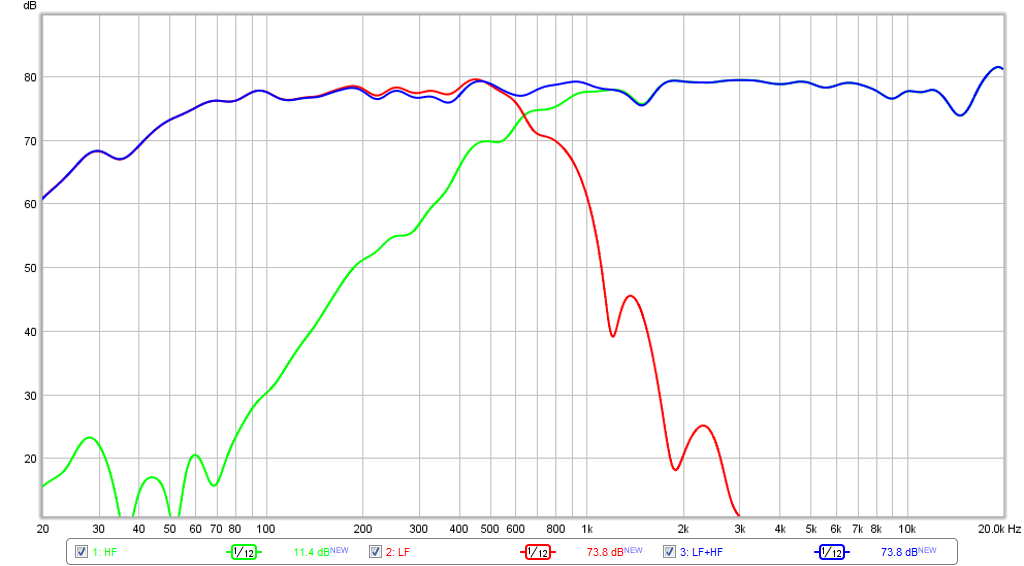

Here is the Harsch as applied to a point source bookshelf horn.

http://www.diyaudio.com/forums/mult...ti-way-point-source-horn-143.html#post4738528

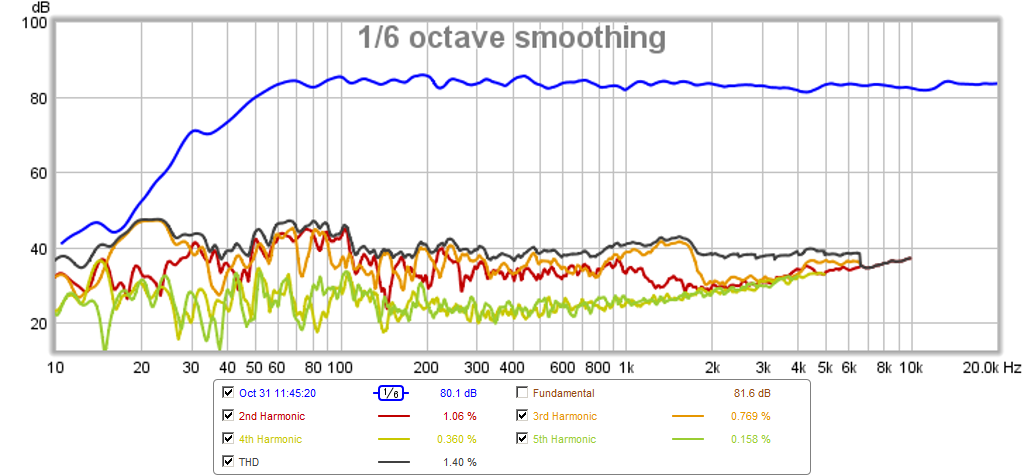

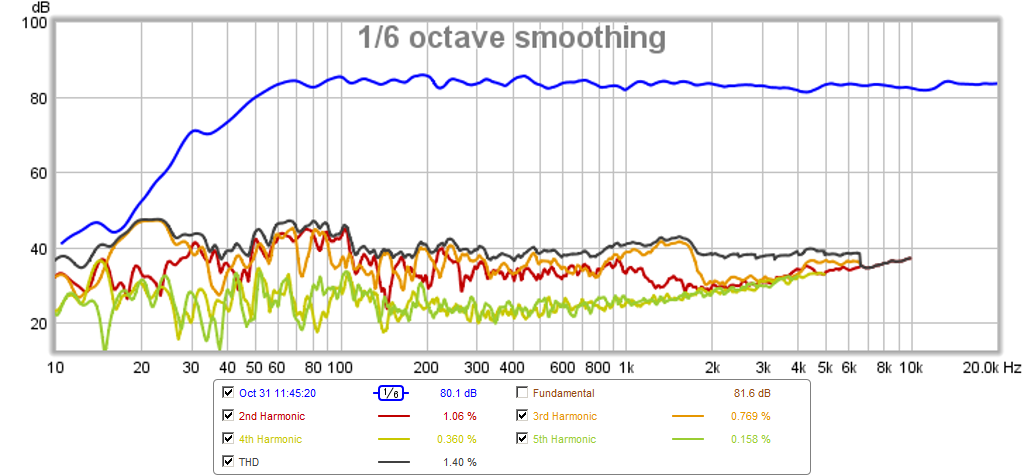

Measured response:

http://www.diyaudio.com/forums/multi-way/277691-s-harsch-xo.html

I just implemented it with an active 2-way bookshelf horn driven by VHEX+ amps by vzaichenko and Jwilhelm - super amp that beats the pants off my LM3886 amps.

http://www.diyaudio.com/forums/multi-way/277691-s-harsch-xo.html

Here is the Harsch as applied to a point source bookshelf horn.

http://www.diyaudio.com/forums/mult...ti-way-point-source-horn-143.html#post4738528

Measured response:

VHEX+ amps by vzaichenko and Jwilhelm - super amp that beats the pants off my LM3886 amps.

Hi X,

This is subjective or it also measures much better?

How does it do compared to your other amps like Dug PBTL TPA 3116D2 and Folsome Audio amp?

How are putting together quite a collection of amps too.

I am still trying to figure out a rig to measure my amps. In the meantime I test speakers and can see increased bass extension with the discrete class AB amps. The bass authority is also subjectively better. Tighter with more control and deeper impact. The highs sound more clear. The VHex amp as measured by the designers have very low THD compared to a TPA3116D2. For example at 50w the VHex has 0.005% THD at 1kHz whereas the TPA3116 is at 0.1% THD at 40w. So when driving very low distortion drivers at higher volume it sounds cleaner.

vzaudio

The Folsom amp is very nice and a great performer THD wise - I don't have spec but it probably achieves theoretical best for that TDA7297. But chip amps cannot compete with a big well designed discrete SS amp like this, or even like the FH9 that I made. Another very excellent amp is the JFET input Circlophone - it is class A without all the class A excessive heat.

http://www.diyaudio.com/forums/solid-state/189599-my-little-cheap-circlophone-160.html#post4736183

But mostly subjective and I do see that bass extension is improved. Don't know if you listened to sound clips in my latest subjective listening thread - but the VHex amp was used there with a passive FAST XO and the recorded sound clips are very close to the original source. The amp can do amazing things with a passive crossover.

http://www.diyaudio.com/forums/full...-blind-abx-test-enabled-ff85wk-round-6-a.html

vzaudio

The Folsom amp is very nice and a great performer THD wise - I don't have spec but it probably achieves theoretical best for that TDA7297. But chip amps cannot compete with a big well designed discrete SS amp like this, or even like the FH9 that I made. Another very excellent amp is the JFET input Circlophone - it is class A without all the class A excessive heat.

http://www.diyaudio.com/forums/solid-state/189599-my-little-cheap-circlophone-160.html#post4736183

But mostly subjective and I do see that bass extension is improved. Don't know if you listened to sound clips in my latest subjective listening thread - but the VHex amp was used there with a passive FAST XO and the recorded sound clips are very close to the original source. The amp can do amazing things with a passive crossover.

http://www.diyaudio.com/forums/full...-blind-abx-test-enabled-ff85wk-round-6-a.html

My next amp will be the ACA. Just got the boards in the mail yesterdayHave you built this one xrk971?

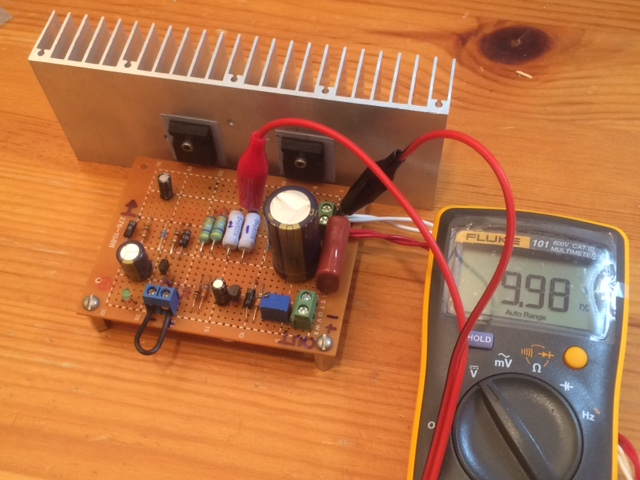

Yes, but I made my own point-to-point wiring. Sounds very nice - you may want to go with the 24vdc smps and the small resistor mod to boost the gain a bit. Stock gain of 14dB is too low for most of my uses. My ACA now has a small 40mm 12vdc cpu fan (fitted with four 220R resistors in parallel to slow speed down to silent) and it stays cool. Without fan, the same heatsink you have on your 3886 gets too hot.

Here is mine:

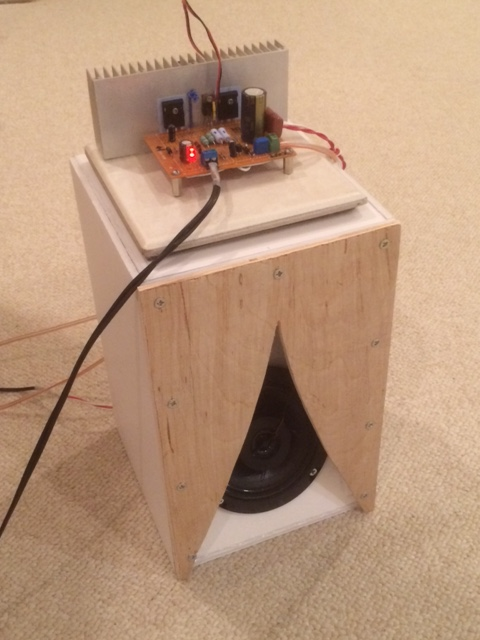

Here it is driving an XKi fitted with a PA130-8 custom coaxial in an XKi 6th order bandpass Karlson aperture:

I really like the looks of these enclosures someone did for the X-LS Encore:

I love the choice of veneer and how they wrapped it around the top. Also liked how they painted the front plate black. So there are no veneer seams whatsoever, which to me is nice.

I wonder if they temporarily put it together by screwing down the faceplate, then once everything was ok, unscrewed it and finished the back part... then at a later time finished the front part.. screwed it back down, this time with glue, then filled the screw holes in the front and touch up the finish on the very front.

Maybe one of you guys can enlighten me the technique you think was used. It looks very attractive and would like to duplicate this with a very pretty piece of wood veneer like they chose.

An externally hosted image should be here but it was not working when we last tested it.

I love the choice of veneer and how they wrapped it around the top. Also liked how they painted the front plate black. So there are no veneer seams whatsoever, which to me is nice.

I wonder if they temporarily put it together by screwing down the faceplate, then once everything was ok, unscrewed it and finished the back part... then at a later time finished the front part.. screwed it back down, this time with glue, then filled the screw holes in the front and touch up the finish on the very front.

Maybe one of you guys can enlighten me the technique you think was used. It looks very attractive and would like to duplicate this with a very pretty piece of wood veneer like they chose.

One way to do it is to mount the front baffle to the box using countersunk screws to cleats. This allows the baffle to be removable which is covenient for servicing or adjusting stuffing or damping. Once you feel it is good and can be sealed up you can glue the front on and cover screw holes with nice plastic covers or putty and touch up paint. Or use black hex cap screws for a nice look. Here is one of my speakers with numerous countersunk screw holes for a completely removable front baffle. I did not have black screws which would have been less visible.

http://www.diyaudio.com/forums/multi-way/285030-bookshelf-multi-way-point-source-horn.html

http://www.diyaudio.com/forums/multi-way/285030-bookshelf-multi-way-point-source-horn.html

One way to do it is to mount the front baffle to the box using countersunk screws to cleats. This allows the baffle to be removable which is covenient for servicing or adjusting stuffing or damping. Once you feel it is good and can be sealed up you can glue the front on and cover screw holes with nice plastic covers or putty and touch up paint. Or use black hex cap screws for a nice look. Here is one of my speakers with numerous countersunk screw holes for a completely removable front baffle. I did not have black screws which would have been less visible.

http://www.diyaudio.com/forums/multi-way/285030-bookshelf-multi-way-point-source-horn.html

Thank you.

I notice you use plywood. It was recommended to my by Dave it was believe to use plywood over MDF. What's your take on this? I guess it'd have to do with resonance? I've heard that guitar amp/speaker cabinets sound best with pine or plywood vs particle/mdf as well.

Plywood is more durable and doesn't have nasty dust when you cut it. It supposedly has better sound damping properties. It's several glued together layers so perhaps the glue interfaces serves as dampening material. If you can use Baltic Birch go for it - costs a lot more though. In your case, a prefab flat pack cabinet from PE for the price you paid is a good value and if you put veneer on and paint sand and paint multiple coats - can look very nice. I think of you add felt sheets on internal walls you will be fine acoustically. Afterall, most of my speakers are made of flimsy foam core. When needed, I add a layer of latex caulk and another layer foam core for constrained layer damping (CKd) and they actually sound very good (and measure well too).

Look at this speaker for example - all 3/16in Dollar Store foam core with double layer face on front with cardboard and caulking for CLD.

http://www.diyaudio.com/forums/multi-way/281778-low-cost-pmc-inspired-tl-monitor-dc130a-dc28f.html

Look at this speaker for example - all 3/16in Dollar Store foam core with double layer face on front with cardboard and caulking for CLD.

http://www.diyaudio.com/forums/multi-way/281778-low-cost-pmc-inspired-tl-monitor-dc130a-dc28f.html

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Multi-Way

- My first DIY speakers -- full range bookshelf.