I just put in an order yesterday.

So what upgrades do people recommend for this? What resistors, etc.? Like how many resistors of what ohm rating?

What about the power switch mechanism? Did anyone do an upgrade, and then have a story to tell about before-and-after testing?

I guess I've become converted to the idea that everything in the signal path, or connected to the signal path, probably has an effect. I figure a few extra dollars for possible extra sound fidelity is worth it if I'm shelling out money for a new preamp and spending the time to build it, etc.

So what upgrades do people recommend for this? What resistors, etc.? Like how many resistors of what ohm rating?

What about the power switch mechanism? Did anyone do an upgrade, and then have a story to tell about before-and-after testing?

I guess I've become converted to the idea that everything in the signal path, or connected to the signal path, probably has an effect. I figure a few extra dollars for possible extra sound fidelity is worth it if I'm shelling out money for a new preamp and spending the time to build it, etc.

Okay I finished the assembly a couple days ago. At first I was just amazed that it worked! It's kind of a miracle that all those little resistors and so on can work together to help make beautiful music.

So my initial reaction is that it sounds better than my old dirt-cheap tube phono stage, and provides just as much amplification to my turntable & MM cartridge. And it only has a handful of hours of burn-in so far.

I did upgrade some of the capacitors and resistors. Now I wonder if I should have tried to replace the jumpers with silver wire, etc. I used a leaded solder with silver added - can some parts be removed later on, or is there a danger of damaging something when redoing the solder on a joint? Or does it depend on how sensitive the component is (like a microchip) and how high the melting temperature of the solder is?

So my initial reaction is that it sounds better than my old dirt-cheap tube phono stage, and provides just as much amplification to my turntable & MM cartridge. And it only has a handful of hours of burn-in so far.

I did upgrade some of the capacitors and resistors. Now I wonder if I should have tried to replace the jumpers with silver wire, etc. I used a leaded solder with silver added - can some parts be removed later on, or is there a danger of damaging something when redoing the solder on a joint? Or does it depend on how sensitive the component is (like a microchip) and how high the melting temperature of the solder is?

@edward9

In general, it's safe to replace parts depending on how you remove them. I replaced resistors and caps in the TU-8900 and the TU-8550 multiple times. I ended up getting a powered desoldering tool a while back in my DIY adventures, which made it a lot easier, but you need to heat and remove the old solder with a solder sucker and/or solder wick. The trick is to not overheat the soldering pad to the point where it may peel off from the PCB, and never yank on a component attached to a pad if the joint isn't heated enough. The Elekit boards are single-sided, which does make it a bit easier to remove components.

Regarding replacing jumpers with silver wire, I did it as I happened to have silver wire around from other projects. I think you are likely going to get more noticeable gains from higher-end caps, resistors, and tubes. For me, the tubes made the most noticeable difference.

In general, it's safe to replace parts depending on how you remove them. I replaced resistors and caps in the TU-8900 and the TU-8550 multiple times. I ended up getting a powered desoldering tool a while back in my DIY adventures, which made it a lot easier, but you need to heat and remove the old solder with a solder sucker and/or solder wick. The trick is to not overheat the soldering pad to the point where it may peel off from the PCB, and never yank on a component attached to a pad if the joint isn't heated enough. The Elekit boards are single-sided, which does make it a bit easier to remove components.

Regarding replacing jumpers with silver wire, I did it as I happened to have silver wire around from other projects. I think you are likely going to get more noticeable gains from higher-end caps, resistors, and tubes. For me, the tubes made the most noticeable difference.

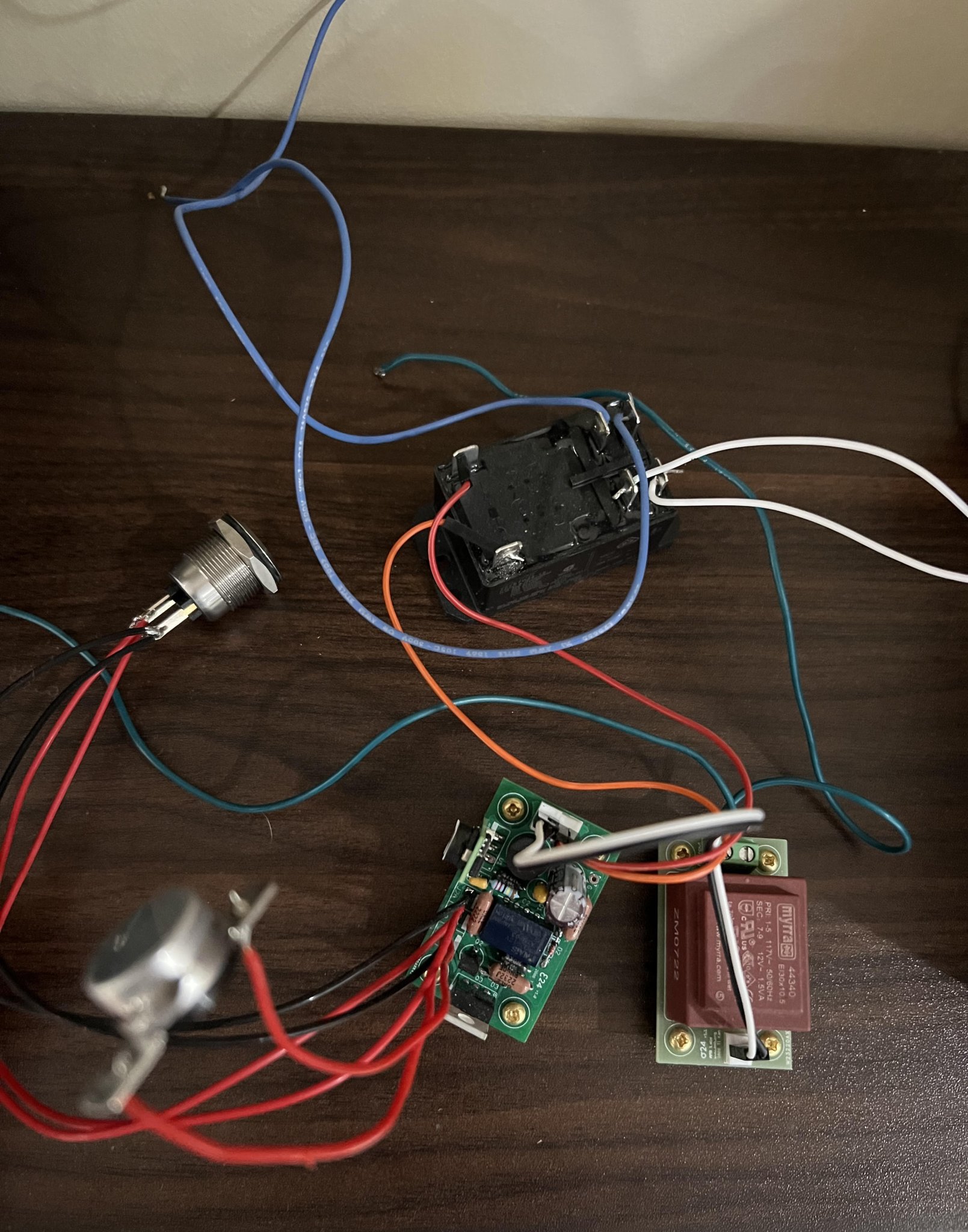

Here is the rig I ended up building to replace the janky power switch mechanism on my TU-8900 and TU-8550 (sorry I don't have pics with it installed yet):

I used:

1 x AMB Tranformer board (https://www.amb.org/audio/sigma24/)

1 x AMB Power button control board with thermal shutdown (https://www.amb.org/audio/epsilon24/)

1 x Small stepdown transformed (powers the control board and LED, always on)

1 x Bulgin red/green power button (Green is on, red only shows on thermal overheat/shutdown)

1 x Single pole mechanical 12VDC relay (It clicks when turned on/off, which I like)

1 x Stancor STO-170 Termal sensor

I had to widen the faceplate hole for the power button by about 1.5mm for the Bulgin to fit through, which was easy with a Dremel, and the switch has a ring that hides the cutout anyway. Overall it works very well for me, no issues at all. The only caveat being the 12VDC transformer is always on in order to power the LED and relay. Everything fits nicely inside the case, and I just drilled holes in the bottom to bolt down the transformer, control board, and relay.

Thanks,

Pete

I used:

1 x AMB Tranformer board (https://www.amb.org/audio/sigma24/)

1 x AMB Power button control board with thermal shutdown (https://www.amb.org/audio/epsilon24/)

1 x Small stepdown transformed (powers the control board and LED, always on)

1 x Bulgin red/green power button (Green is on, red only shows on thermal overheat/shutdown)

1 x Single pole mechanical 12VDC relay (It clicks when turned on/off, which I like)

1 x Stancor STO-170 Termal sensor

I had to widen the faceplate hole for the power button by about 1.5mm for the Bulgin to fit through, which was easy with a Dremel, and the switch has a ring that hides the cutout anyway. Overall it works very well for me, no issues at all. The only caveat being the 12VDC transformer is always on in order to power the LED and relay. Everything fits nicely inside the case, and I just drilled holes in the bottom to bolt down the transformer, control board, and relay.

Thanks,

Pete

Thanks Pete for your comments. Hey, what gauge of silver wire did you use for your jumpers? I noticed that my stock jumpers stuck to a magnet, before I added them to the PCB, which just made me wonder. There is a speaker designer I like named Danny Richie who says any time you have ferrous metals in (or near) the signal path, it doesn't help the sound quality.

During my assembly, I upgraded about half the resistors to non-magnetic resistors, and I upgraded four of the 0.47 microfarad capacitors to "Jupiter" ones that I bought from Victor (108, 112, 208, 212 on the circuit board).

There is way less "hiss" in this device compared to my old, $250 tube-based phono stage. And it sounds better overall. But it's hard for me to fully evaluate the sound until I also replace my cheap power amp with the TU-8900 and give both of them time to "burn in".

The power switch on my TU-8550 works great so far. It was a little strange putting it together, and it took me a while to find the courage and clarity to really SHOVE that plastic arm all the way in so it's full-seated at both ends, but now that it's assembled it seems to work just fine for me, so far.

During my assembly, I upgraded about half the resistors to non-magnetic resistors, and I upgraded four of the 0.47 microfarad capacitors to "Jupiter" ones that I bought from Victor (108, 112, 208, 212 on the circuit board).

There is way less "hiss" in this device compared to my old, $250 tube-based phono stage. And it sounds better overall. But it's hard for me to fully evaluate the sound until I also replace my cheap power amp with the TU-8900 and give both of them time to "burn in".

The power switch on my TU-8550 works great so far. It was a little strange putting it together, and it took me a while to find the courage and clarity to really SHOVE that plastic arm all the way in so it's full-seated at both ends, but now that it's assembled it seems to work just fine for me, so far.

Can I ask another question?

If I had to replace the fuse someday, and needed to buy a new fuse, should I buy "fast-blow" or "slow-blow"? I could not find this information in the owners manual or on the existing fuse, but maybe I was just not looking in the right place.

Yes, here in America I want 4-amp, 20mm size. But what about the fast/slow designation?

If I had to replace the fuse someday, and needed to buy a new fuse, should I buy "fast-blow" or "slow-blow"? I could not find this information in the owners manual or on the existing fuse, but maybe I was just not looking in the right place.

Yes, here in America I want 4-amp, 20mm size. But what about the fast/slow designation?

Is anyone interested Lundahl Preamp output Transformer for TU-8550?

I would suggest the LL1570, https://www.lundahltransformers.com/wp-content/uploads/datasheets/1570_0xl.pdf

I would suggest the LL1570, https://www.lundahltransformers.com/wp-content/uploads/datasheets/1570_0xl.pdf

Yes please send your order to info@vkmusic.ca

I will reply to you

For the stepup

You can order the complete box or kit Lundahl ll1931

I will reply to you

For the stepup

You can order the complete box or kit Lundahl ll1931

I'm definitely interested. What's the price?Is anyone interested Lundahl Preamp output Transformer for TU-8550?

I would suggest the LL1570, https://www.lundahltransformers.com/wp-content/uploads/datasheets/1570_0xl.pdf