Having read thru all the pages on this thread I had to try my hand at a DIY linear tracking arm.

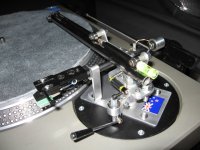

I have used a highly polished 10mm stainless steel tube instead of the preferred glass mainly because I already had it handy, and it works perfectly. The tube is mounted on two threaded studs tapped into the underside of the tube which is very secure and allows easy adjustment of height and level. The bearings are 10x5 with the seals and grease removed and running on brass tubes as recommended. I have managed to use a silicone damped cylinder to operate the cueing arm lever for nice smooth operation. It sound amazing on a very tired old BSR idler drive turntable so I am now looking for a better table to mount it on.

Cheers

Graham

I have used a highly polished 10mm stainless steel tube instead of the preferred glass mainly because I already had it handy, and it works perfectly. The tube is mounted on two threaded studs tapped into the underside of the tube which is very secure and allows easy adjustment of height and level. The bearings are 10x5 with the seals and grease removed and running on brass tubes as recommended. I have managed to use a silicone damped cylinder to operate the cueing arm lever for nice smooth operation. It sound amazing on a very tired old BSR idler drive turntable so I am now looking for a better table to mount it on.

Cheers

Graham

Last edited:

MkII, or the turntable Technics should have built but didn't.

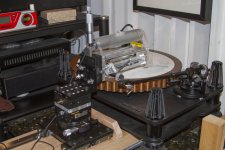

I gave up on the noisy old BSR and installed a slightly improved version of my DIY linear arm on a Technics SL120.

A rectangular alloy plate is bolted to the arm board and the arm base is mounted to that with just one bolt. The fine twisted signal wires are connected to an RCA junction on the back of the turntable. The only permanent modification to the Technics is the two holes drilled in the back for the RCA block. This way the whole arm, wires and RCAs can be quickly and easily removed if I get the crazy urge to mount it on another turntable.

This simple arm continues to impress me with the way it tracks even wavy off-centre records and is producing a lovely sound from the humble AT95E.

Thanks for the inspiration this forum thread has provided. Keep up the good DIY projects.

Graham.

I gave up on the noisy old BSR and installed a slightly improved version of my DIY linear arm on a Technics SL120.

A rectangular alloy plate is bolted to the arm board and the arm base is mounted to that with just one bolt. The fine twisted signal wires are connected to an RCA junction on the back of the turntable. The only permanent modification to the Technics is the two holes drilled in the back for the RCA block. This way the whole arm, wires and RCAs can be quickly and easily removed if I get the crazy urge to mount it on another turntable.

This simple arm continues to impress me with the way it tracks even wavy off-centre records and is producing a lovely sound from the humble AT95E.

Thanks for the inspiration this forum thread has provided. Keep up the good DIY projects.

Graham.

Attachments

HELP!

Hi all.

I've nearly finished the sub-chassis for the deck I'm building for my LT arm. It looks like it belongs to a megabucks TT. It just needs a bit of cosmetic finishing. Before I finish it. I have fitted arm, bearing etc to make sure everything lines up and works and that there are no sonic nasties. Luckily no problems here. I'm basically running the deck as a medium mass solid plinth design at the moment. The sound is definitely better than the temporary plinth I was using for arm evaluation, cleaner sounding with improved bass definition. Happy me. I have been running the deck like this for a couple of weeks with no problems. I then went on holiday for a week. My plan was to cosmetically finish and post pictures now that I'm home.

I fired up the system this morning. This is when the problem reared its ugly head. The arm keeps skipping. I've checked everything I can think of. The rails are clean, alignment is perfect as is tracking force. I've even redressed the arm wires in case the problem was here. No luck. It doesn't seem to skip at the same point of travel or at intervals equal to the circumference of the bearings. It's just as well I have long hair or I'd be bald by now.

What could have sitting in an enclosed cabinet, unused for a week done? I'm at a loss. Do any of my fellow diyers out there have any suggestions?

Niffy

Hi all.

I've nearly finished the sub-chassis for the deck I'm building for my LT arm. It looks like it belongs to a megabucks TT. It just needs a bit of cosmetic finishing. Before I finish it. I have fitted arm, bearing etc to make sure everything lines up and works and that there are no sonic nasties. Luckily no problems here. I'm basically running the deck as a medium mass solid plinth design at the moment. The sound is definitely better than the temporary plinth I was using for arm evaluation, cleaner sounding with improved bass definition. Happy me. I have been running the deck like this for a couple of weeks with no problems. I then went on holiday for a week. My plan was to cosmetically finish and post pictures now that I'm home.

I fired up the system this morning. This is when the problem reared its ugly head. The arm keeps skipping. I've checked everything I can think of. The rails are clean, alignment is perfect as is tracking force. I've even redressed the arm wires in case the problem was here. No luck. It doesn't seem to skip at the same point of travel or at intervals equal to the circumference of the bearings. It's just as well I have long hair or I'd be bald by now.

What could have sitting in an enclosed cabinet, unused for a week done? I'm at a loss. Do any of my fellow diyers out there have any suggestions?

Niffy

Hello niffy

From your description, everything seems to be perfect, except the bearings.

Please refresh my memory, do you or do you not have grease in your bearings?

If there is grease, sitting for a week could possibly have something to do with your problem. I know, from speaking with an engineer at New Hampshire Precision Bearings, that the presence of any lubricant increases the torque required to rotate a bearing. Sitting for a week, could cause some of the grease to migrate to the bottom of the bearing. If there is no grease, I am not much help I'm afraid.

Sincerely,

Ralf

From your description, everything seems to be perfect, except the bearings.

Please refresh my memory, do you or do you not have grease in your bearings?

If there is grease, sitting for a week could possibly have something to do with your problem. I know, from speaking with an engineer at New Hampshire Precision Bearings, that the presence of any lubricant increases the torque required to rotate a bearing. Sitting for a week, could cause some of the grease to migrate to the bottom of the bearing. If there is no grease, I am not much help I'm afraid.

Sincerely,

Ralf

Hi Ralf, Arch.

Thanks for your replies. I think you are correct in thinking the problem is with the bearings. The bearings are ceramic hybrid and were supplied dry so lubrication isn't the problem. Dust may well be the problem. The rail was cleaned with a cotton bud before the first record and more thoroughly after the problem was discovered. If dust on the rail is the cause I would expect the skip to occur at the same place each time, which it doesn't so this isn't the cause. The bearings have no shields so it is possible that a particle has got into the bearing. Why this should happen when the deck was not in use and covered and not when in use is puzzling. Spinning the bearings with a flick a couple of times seems to have reduced the problem but not eliminated it, supporting the dust as cause hypothesis. I think I might try to use a compressed air in a can duster to blast any dust out of the bearings. If this works I'll have to seriously consider adding a dust cover over the rail. Fingers crossed.

Thank once again for your input.

Niffy

Thanks for your replies. I think you are correct in thinking the problem is with the bearings. The bearings are ceramic hybrid and were supplied dry so lubrication isn't the problem. Dust may well be the problem. The rail was cleaned with a cotton bud before the first record and more thoroughly after the problem was discovered. If dust on the rail is the cause I would expect the skip to occur at the same place each time, which it doesn't so this isn't the cause. The bearings have no shields so it is possible that a particle has got into the bearing. Why this should happen when the deck was not in use and covered and not when in use is puzzling. Spinning the bearings with a flick a couple of times seems to have reduced the problem but not eliminated it, supporting the dust as cause hypothesis. I think I might try to use a compressed air in a can duster to blast any dust out of the bearings. If this works I'll have to seriously consider adding a dust cover over the rail. Fingers crossed.

Thank once again for your input.

Niffy

dust will likely be picked up by the bearing and move about. If you touch the rail or the bearing you will deposit oil from your finger which is sticky and will then attract dust. One last think to remember is that graphite lubricant is considered to be and is known as a "Dry Lubricant" you might want to check that no graphite powder was uses in the bearing. Graphite is used in locks as well rather than oils or grease. Best regards Moray James.

Hi Moray.

Thanks for your reply. The bearings were "specified free of all lubrication and oil". My best guess is that a particle of dust has managed to get into one of the bearings. Spinning the bearing moves the dust particle around but hasn't expelled it hence the change in the severity of the skipping. I'll buy a can of compressed air duster tomorrow and see if this helps. Unfortunately this product is ridiculously expensive for what it is.

Thanks again

Niffy

Thanks for your reply. The bearings were "specified free of all lubrication and oil". My best guess is that a particle of dust has managed to get into one of the bearings. Spinning the bearing moves the dust particle around but hasn't expelled it hence the change in the severity of the skipping. I'll buy a can of compressed air duster tomorrow and see if this helps. Unfortunately this product is ridiculously expensive for what it is.

Thanks again

Niffy

My DIY linear arm has now been converted to the twin tube/twin bearing configuration and works so much better. The reduction in horizontal friction is most noticeable and even the vertical movement of the arm/cartridge is improved. You can see that I am still using stainless steel tubes which I have highly polished using 1200 grade paper finished with metal polish. Glass may be superior but I used what I had on hand. This mod also reduced the total weight of the arm so much so that I had to make up a much lighter counterweight. It now tracks even my most off-centre 'test' records perfectly and I notice that the side to side flexing of the cantilever has been reduced dramatically compared to the original 4 bearing set up. It's amazing what you can build from a handful of bits and pieces.

Graham

Graham

Attachments

Hi Graham.

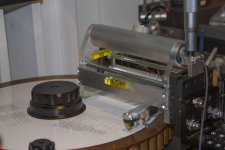

I wouldn't say this thread is dead. It has slowed a bit in recent weeks but it has had slow patches in the past and picked up again. Agreed, allot of the theory side of design has been covered in detail, but there's always new ideas and refinements. The last two pages have shown three new arms, each a very different take on the basic design. I believe you are responsible for two of them. Nice work. I'm having trouble working out your lift/lower device from the pictures, it looks like a damper operating a lever operating a cam?

Super.

That things a beast.

A couple of questions. What is the arm-base sourced from? It looks like you have micrometer adjusters for alignment, are these otf? Does the entire arm swivel to facilitate record changes? Without checking back through too many pages I seem to recall that you were planning on running the arm tube above the rails. If so I'd be very interested to hear how well that works.

Niffy

I wouldn't say this thread is dead. It has slowed a bit in recent weeks but it has had slow patches in the past and picked up again. Agreed, allot of the theory side of design has been covered in detail, but there's always new ideas and refinements. The last two pages have shown three new arms, each a very different take on the basic design. I believe you are responsible for two of them. Nice work. I'm having trouble working out your lift/lower device from the pictures, it looks like a damper operating a lever operating a cam?

Super.

That things a beast.

A couple of questions. What is the arm-base sourced from? It looks like you have micrometer adjusters for alignment, are these otf? Does the entire arm swivel to facilitate record changes? Without checking back through too many pages I seem to recall that you were planning on running the arm tube above the rails. If so I'd be very interested to hear how well that works.

Niffy

Super.

A-ha! I've just spotted it. The whole arm slides away to facilitate record changing. Sliding was my choice as it's easier to maintain alignment with multiple record changes.

Niffy.

Ps nice deck, though that doesn't look like an original platter.

That is an outer ring clamp which sits atop the record.

- Home

- Source & Line

- Analogue Source

- DIY linear tonearm

Nice....!!! Been thinkin' about that for some time, but unless surplus, it COSTS......

Nice....!!! Been thinkin' about that for some time, but unless surplus, it COSTS......