Super,

As you get further through the thread the design changes alot. Namely going from a single tube 4 bearing to a 2 tube 2 bearing design with much thanks to pdr in his trials. To this day it has performed flawlessly and save for the odd swipe of the glass track with a dry qtip every two months or so it requires no maintenance .

Colin

I will use same arm base for two different designs. One is mine and another will be yours. So, I can compare both.

I do have one question for you. Do you use brass shim? I have read somewhere in the thread. You said brass shim is not good. Or, it is just my misunderstanding because there are too much to read.

Best

Jim

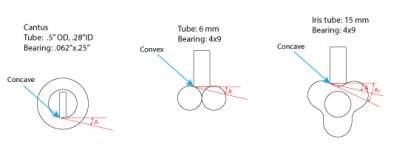

For linear arm tracking, you may use either convex bearing inside glass tube( Clear Audio) or concave bearing outside glass tube( my plan). But it is hard to find these special bearings. You have to make your own.

Here is an idea.

You may buy convex or concave stainless steel rings. They are cheap and come in different sizes. Then, you can put the ring on regular miniature bearing. You get your special bearings!

Jim

Here is an idea.

You may buy convex or concave stainless steel rings. They are cheap and come in different sizes. Then, you can put the ring on regular miniature bearing. You get your special bearings!

Jim

Attachments

Last edited:

Super,

I have tried a few flavors of 2-point contact in my Cantus and i am sticking to 4-point . 4-point is subjectively more dry and dynamic in the lower end of the spectrum, at least in my set-up. I know that Bo advised Peter Suchy against the convex bearing at some point before he left their co-op on the Clearaudio arms. This does not mean that 2-point is bad, just that i like 4-point better...soo far

. 4-point is subjectively more dry and dynamic in the lower end of the spectrum, at least in my set-up. I know that Bo advised Peter Suchy against the convex bearing at some point before he left their co-op on the Clearaudio arms. This does not mean that 2-point is bad, just that i like 4-point better...soo far

For a simple 4-point one could use bearing with flanges on both sides, rolling on top of a rod/tube. It would be a bit flimsy to handle though since it probably would fall off the rail quite easily if not carefully designed.

//Anders

I have tried a few flavors of 2-point contact in my Cantus and i am sticking to 4-point

For a simple 4-point one could use bearing with flanges on both sides, rolling on top of a rod/tube. It would be a bit flimsy to handle though since it probably would fall off the rail quite easily if not carefully designed.

//Anders

Anders: I think that the fact that a four point suspension has such high back and forth friction and the fact that at its limit it must be dragged up the wall to ride a very bad warp is a very important aspect of Bo's design as this prevents the resonant rocking action of a two point contact bearing system or what I would describe as a "rolling rocking knife edge". I had many discussions with Bo about this and it took me some time to understand what he was doing. The arm is intended to be rigid or as rigid as possible in all but the horizontal plane (even there some small component of drag or friction if you like helps damp resonances), this reduces or damps resonance and it to stiffens the assembly and helps to enhance transfer of energy. Bo's idea is incredibly deceptive in its simplicity and that also goes for his choice in bearings. Simple slack in the bearing assembly accounts for most necessary arm motion for record surface fluctuations and if necessary the whole assembly can be pulled up the tube wall then gravity will take it back to where it belongs as soon as the problem of the warp has passed. So very elegant it always makes me smile. I expect that many readers may also misunderstand Bo's intent as I did since it is counter intuitive to "common expectations".

Anders I like your computer drawings and the asymmetrical arm assembly looks very interesting but I expect a fuss to construct. Please keep posting. You knew Bo so much better than I. Bo is gone and I miss him. Best regards Moray James.

Anders I like your computer drawings and the asymmetrical arm assembly looks very interesting but I expect a fuss to construct. Please keep posting. You knew Bo so much better than I. Bo is gone and I miss him. Best regards Moray James.

Concave bearings

Search for Yoyo bearings (ebay.de - Yoyo Kugellager, Konkav /10-Ball-Bearing-Center-Track-Kugellager von Magicyoyo), extremely smooth running.

For linear arm tracking, you may use either convex bearing inside glass tube( Clear Audio) or concave bearing outside glass tube( my plan). But it is hard to find these special bearings. You have to make your own.

Here is an idea.

You may buy convex or concave stainless steel rings. They are cheap and come in different sizes. Then, you can put the ring on regular miniature bearing. You get your special bearings!

Jim

Search for Yoyo bearings (ebay.de - Yoyo Kugellager, Konkav /10-Ball-Bearing-Center-Track-Kugellager von Magicyoyo), extremely smooth running.

Back on page 161 Bob690 posted a couple of links to Boca bearings and small parts. Various sizes of bearings with V and U grooves were available as well as bearings with convex outer races. Check these out, they might have something that suits your designs. Boca also make very good ceramic hybrid bearings, these are the ones that I am using. I think that the lower friction of the ceramic bearings probably outweighs any benefit a different outer profile might give.

Many pages ago Frank posted a design that used an inner race as a concave grooved wheel. This idea could be revisited to allow the use of ceramic bearings a concave groove and the advantage of a larger wheel diameter.

Niffy

Many pages ago Frank posted a design that used an inner race as a concave grooved wheel. This idea could be revisited to allow the use of ceramic bearings a concave groove and the advantage of a larger wheel diameter.

Niffy

Thanks for the info, Cornelis Spronk and Niffy!

I kept reading. It is up to p149 now.

It seems to me that the design has been changed. It is two glass tubes now.

Here is what I found.

http://www.pegasus-glass.com/Home/P...ing/IrisTubing15mm24mm/tabid/276/Default.aspx

The large size of iris tubing is 24 mm. It can be perfect for glass track.

I kept reading. It is up to p149 now.

It seems to me that the design has been changed. It is two glass tubes now.

Here is what I found.

http://www.pegasus-glass.com/Home/P...ing/IrisTubing15mm24mm/tabid/276/Default.aspx

The large size of iris tubing is 24 mm. It can be perfect for glass track.

Attachments

Last edited:

Hi super.

I'd hang fire on ordering tubes just yet. This thread get interesting in the next 20 pages or so from where you are. Read on. I think the general consensus zeroed in on 6mm tubes/rods for use with 4mm wide bearings. 15mm tubes are a bit big unless you are planning on big wheels.

Niffy

I'd hang fire on ordering tubes just yet. This thread get interesting in the next 20 pages or so from where you are. Read on. I think the general consensus zeroed in on 6mm tubes/rods for use with 4mm wide bearings. 15mm tubes are a bit big unless you are planning on big wheels.

Niffy

I am not surprised if two 6 mm tubes and wider width bearing is better. I did some analysis.

On Cantus arm, the angle between bearing and inner tube is A. If using two 6 mm tubes and 4x9 bearing, its angle is very close to Cantus'. If using 15 mm iris tube, the angle will be A1, which is larger than A.

But on Cantus, since the bearing travels inner tube. It travels on a concave channel. See blue arrow line. The bearing travels on a convex kind of channel if using two round tubes. The bearing travels on a concave channel same as Cantus's if using iris tube.

In theory, I am not sure which one is better. Two round tubes or one iris tube?

Maybe, use 5x9 bearing and 15 mm iris tube?

Reading now……..

Best regards,

Jim

On Cantus arm, the angle between bearing and inner tube is A. If using two 6 mm tubes and 4x9 bearing, its angle is very close to Cantus'. If using 15 mm iris tube, the angle will be A1, which is larger than A.

But on Cantus, since the bearing travels inner tube. It travels on a concave channel. See blue arrow line. The bearing travels on a convex kind of channel if using two round tubes. The bearing travels on a concave channel same as Cantus's if using iris tube.

In theory, I am not sure which one is better. Two round tubes or one iris tube?

Maybe, use 5x9 bearing and 15 mm iris tube?

Reading now……..

Best regards,

Jim

Attachments

Last edited:

Hi Jim.

Sorry, I didn't release the iris was a shaped tube, thought it was a brand, I should have checked the link first.

Regardless, two tubes/rods will allow the pivot point to be kept closer to the record surface thus minimizing warp wow. Which ever tube type you choose try to keep the contact angle at about 20degrees.

Niffy

Sorry, I didn't release the iris was a shaped tube, thought it was a brand, I should have checked the link first.

Regardless, two tubes/rods will allow the pivot point to be kept closer to the record surface thus minimizing warp wow. Which ever tube type you choose try to keep the contact angle at about 20degrees.

Niffy

If any one wants to order bearings, here is the link you may be interested.

Fishing Ceramic Dry Bearing 5x10x4 Shielded ABEC-5 Bearings:Fishing-Reel-Bearings

These bearings have ceramic balls. Although these bearings are shielded, they are dry bearings. It means no lubrication.

Regards,

Jim

Fishing Ceramic Dry Bearing 5x10x4 Shielded ABEC-5 Bearings:Fishing-Reel-Bearings

These bearings have ceramic balls. Although these bearings are shielded, they are dry bearings. It means no lubrication.

Regards,

Jim

CLICKABLE LINK

A suggestion on eBay UK.

Search for:

ABU REPLACEMENT 4 X 10 X 4 CERAMIC BEARINGS ABEC 9'S

Thanks!

ABEC9! That is great! Just bought two.

Is better better?

Hi all.

The ABEC ratings mainly cover the eccentricity of the races and the amount of play between the races. The higher the ABEC number the lower the level of each of these factors.

Reducing the level of eccentricity is a good thing. If the bearing is eccentric it will mean the centre of the bearing/axle will rise and fall slightly as the bearing rolls along. This has the same effect as slightly tilting the rail from horizontal. This will cause a variation in the lateral force applied to the stylus and therefore how tangential the cantilever stays to the groove. Also if the eccentricity of the two bearings are not aligned one side of the carriage might be going up whilst the other down effecting azimuth. However the max level of eccentricity for even lower ABEC ratings are still quite low.

I believe it was BillG who first pointed out the importance of bearing play and was one Bo's design concepts for the cantus. When playing records with normal levels of warp the entire vertical motion of the arm is accommodated by the play in the bearing, the outer race doesn't move at all. This is what I have observed with my arm. I did originally design my arm with pin bearings that had virtually no play so all vertical motion had to be accommodated by sliding the outer race on the glass rods. After many hours of listening and swapping between the two types of bearing I concluded that the ball races were better mainly due to this factor. The higher ABEC ratings might not have sufficient play to keep the entire vertical motion within the bearings play especially if you are not using an effective clamp.

The bearings found on eBay appear to have removable shields. I would recommend removing them as this significantly reduces friction.

Niffy

Hi all.

The ABEC ratings mainly cover the eccentricity of the races and the amount of play between the races. The higher the ABEC number the lower the level of each of these factors.

Reducing the level of eccentricity is a good thing. If the bearing is eccentric it will mean the centre of the bearing/axle will rise and fall slightly as the bearing rolls along. This has the same effect as slightly tilting the rail from horizontal. This will cause a variation in the lateral force applied to the stylus and therefore how tangential the cantilever stays to the groove. Also if the eccentricity of the two bearings are not aligned one side of the carriage might be going up whilst the other down effecting azimuth. However the max level of eccentricity for even lower ABEC ratings are still quite low.

I believe it was BillG who first pointed out the importance of bearing play and was one Bo's design concepts for the cantus. When playing records with normal levels of warp the entire vertical motion of the arm is accommodated by the play in the bearing, the outer race doesn't move at all. This is what I have observed with my arm. I did originally design my arm with pin bearings that had virtually no play so all vertical motion had to be accommodated by sliding the outer race on the glass rods. After many hours of listening and swapping between the two types of bearing I concluded that the ball races were better mainly due to this factor. The higher ABEC ratings might not have sufficient play to keep the entire vertical motion within the bearings play especially if you are not using an effective clamp.

The bearings found on eBay appear to have removable shields. I would recommend removing them as this significantly reduces friction.

Niffy

Hello Niffy

As you know, there are two ways to protect ball bearings from contamination: Shields and seals. They are both retained by the outer race. Shields do not touch the inner race, while seals touch the inner race and are a source of friction. Having built several tangential tone arms, I prefer the bearings with shields, not seals. Since the bearings with shields are most likely lubricated, I wash the lubricant out and run them dry.

Sincerely,

Ralf

The bearings found on eBay appear to have removable shields. I would recommend removing them as this significantly reduces friction.

Niffy

As you know, there are two ways to protect ball bearings from contamination: Shields and seals. They are both retained by the outer race. Shields do not touch the inner race, while seals touch the inner race and are a source of friction. Having built several tangential tone arms, I prefer the bearings with shields, not seals. Since the bearings with shields are most likely lubricated, I wash the lubricant out and run them dry.

Sincerely,

Ralf

- Home

- Source & Line

- Analogue Source

- DIY linear tonearm