So, with the voltage regulator... the hardware kit to attach it to the heat sink came with a small piece of plastic that looks as though it should go between the regulator and the sink. This doesn't seem right- wouldn't we want the regulator in direct contact with the sink? Even using thermal paste to attach it?

Coming from a background in building and overclocking computers I would think this is the most efficient way to transfer heat.

Coming from a background in building and overclocking computers I would think this is the most efficient way to transfer heat.

... a small piece of plastic...... using thermal paste to attach it?

Coming from a background in building and overclocking computers I would think this is the most efficient way to transfer heat.

Maybe the regulator needs to be insulated from the sink for some reason?

yes, it should not make contact, because one leg is connected to metal base

In an ideal world the black anodize coating on the heatsink should not conduct electricity.

Even at these voltages (18VDC) 3A can give you quite a surprise.

All it would take is a bit of anodize scraped off while you inserted the bolt or one of the corners of the regulator to pierce and you could have a hazardous situation.

I would say feel free to use non conductive thermal paste on both sides of the insulator sheet if you are really concerned with temperature.

I did not put any thermal paste on my regulator and it (the actual regulator) barely gets warm after hours of operation.

I chose the 2.5" heatsink with my kit and now I think unless I was in the desert or something I would not need that much.

I on the other hand am running 12.6V regulated (down from 17VDC) so there is not as much heat to be sinked.

If you are using 6.3V regulated you may need the extra heatsink.

Even at these voltages (18VDC) 3A can give you quite a surprise.

All it would take is a bit of anodize scraped off while you inserted the bolt or one of the corners of the regulator to pierce and you could have a hazardous situation.

I would say feel free to use non conductive thermal paste on both sides of the insulator sheet if you are really concerned with temperature.

I did not put any thermal paste on my regulator and it (the actual regulator) barely gets warm after hours of operation.

I chose the 2.5" heatsink with my kit and now I think unless I was in the desert or something I would not need that much.

I on the other hand am running 12.6V regulated (down from 17VDC) so there is not as much heat to be sinked.

If you are using 6.3V regulated you may need the extra heatsink.

So, with the voltage regulator... the hardware kit to attach it to the heat sink came with a small piece of plastic that looks as though it should go between the regulator and the sink. This doesn't seem right- wouldn't we want the regulator in direct contact with the sink? Even using thermal paste to attach it?

Coming from a background in building and overclocking computers I would think this is the most efficient way to transfer heat.

Yes its a mica insulator. There is also a shoulder washer to use for the screw so the screw does not touch the metal part of the regulator.

I would not use paste...the mica does a good job and we are not dropping that many watts.

You do not want the heat sink charged with 2-3A of juice...that could be a bad end to the day.

nah, its them pins that are mounted at the wrong end of the stick

Looks like the hole for the regulator was drilled on the wrong end of the sink.

I got the PCB done, just waiting for the chassis from Par Metal and some bits from Parts Express.

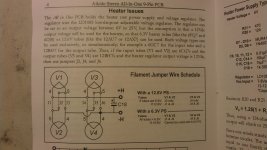

For those that are using a toroidal transformer, how did you hook it up? I'm running 12V to the heaters and installed J2 and J5 to reduce voltage for four 6CG7's.

For those that are using a toroidal transformer, how did you hook it up? I'm running 12V to the heaters and installed J2 and J5 to reduce voltage for four 6CG7's.

Attachments

I'm running 12V to the heaters and installed J2 and J5 to reduce voltage for four 6CG7's.

I sure hope you are right about that

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Amplifiers

- Tubes / Valves

- Aikido 9 pin All in One Build