In a big horn (not these little wings), I got down to 600Hz and it sounded fantastic.

You could make an AMT synergy horn with it. A single 6.5in mid side injected into the horn will give you the mids you need and sound fantastic.

I have shown this before and it remains the best speaker I have ever heard anywhere at any price. I am using a B&C 6MDN44 mid range.

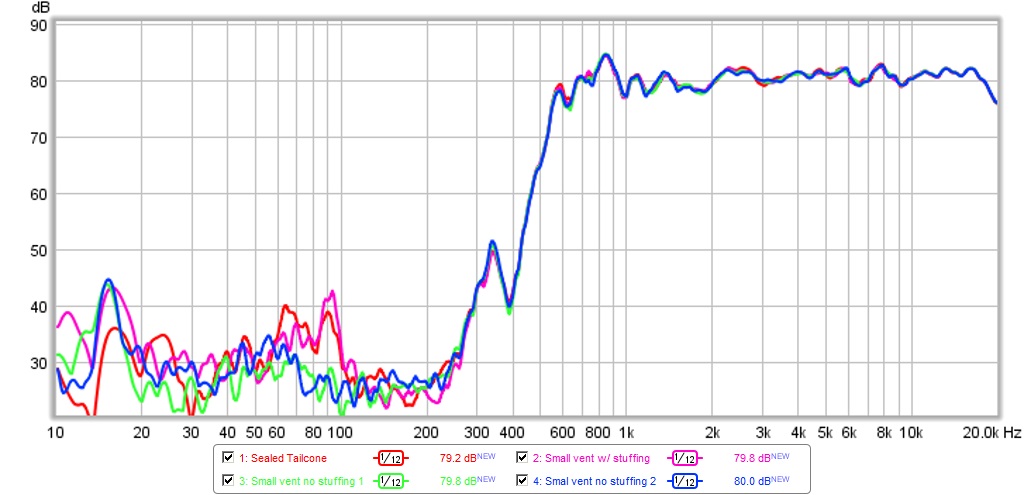

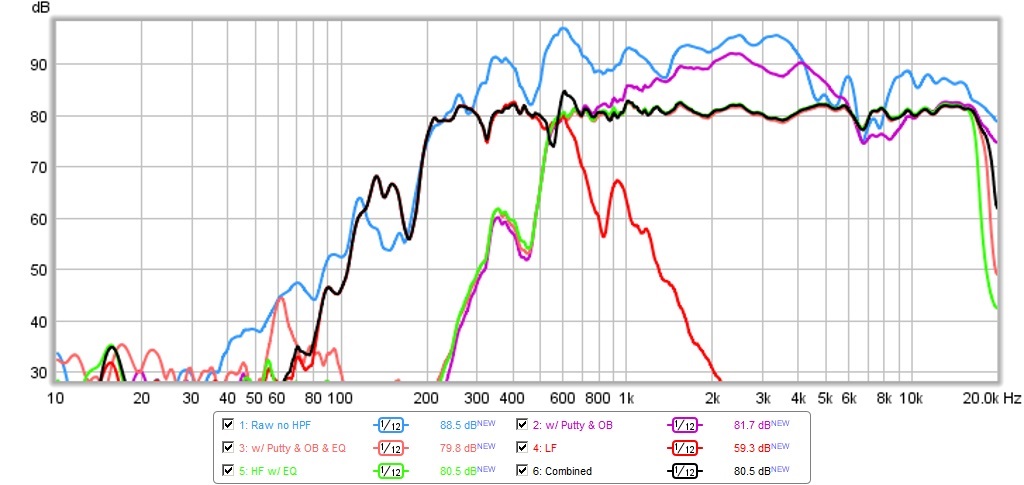

Here is response with the midrange:

Then a front loaded bass horn takes it from this to down to 40Hz.

You could make an AMT synergy horn with it. A single 6.5in mid side injected into the horn will give you the mids you need and sound fantastic.

I have shown this before and it remains the best speaker I have ever heard anywhere at any price. I am using a B&C 6MDN44 mid range.

Here is response with the midrange:

Then a front loaded bass horn takes it from this to down to 40Hz.

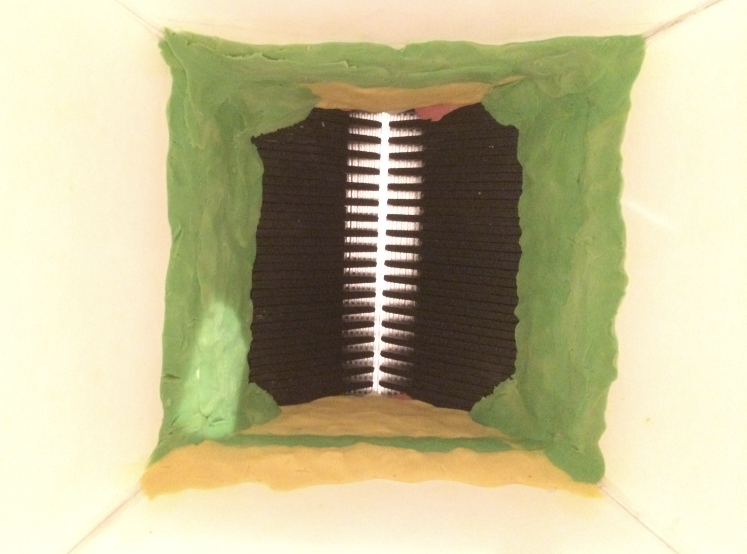

Just a couple of slots on the top wall for the mid injection. The horn throat uses a lot of plastic modeling clay to smooth out the transition. This was before I could print one in 3D.

Here is a closeup of the modeling clay throat transition. Not pretty, but proves that it works. Just avoid any sharp edges, joints, or protrusions near the throat:

Here is a closeup of the modeling clay throat transition. Not pretty, but proves that it works. Just avoid any sharp edges, joints, or protrusions near the throat:

Attachments

Last edited:

In a big horn (not these little wings), I got down to 600Hz and it sounded fantastic.

Would love to hear those! Such an interesting design.

p.s. if you ever do renovate these you could 3D print the 4 sides of the horn with a true exponential profile and glue the sides together (or 3D print one side, make a mould and then cast four sides, if that works out better).

I tried to replicate this in the synergy spreadsheet but failedI am just measuring the AMT to make a 3D model for attachment of a fully 3D printed horn and back cover.

It looks like the initial angle is smaller than the angle of the opening, which is 90 degrees?

I think it was a 45 deg Horiz and 30 deg Vertical horn, adjusted frequency supported to produce exactly a 30in wide mouth horizontally as that was max width of my foamcore panels. The throat was square but I used putty to transition it to rectangular aperture of AMT. This is where a 3D printed adapter would come in handy.

It’s a big horn, I would not want to print those spade walls. That would take forever and use a lot of filament. Better off making curved foam core or bendy ply tractrix profile. Like this simple 4in throat tractrix I made:

Or this much larger one for a 5MR450NDY driver:

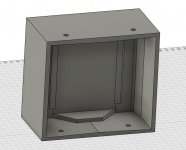

Added layer of constrained damping foam:

Driver and rear chamber:

PRV 5MR450-NDY for FAST/WAW applications

Polars:

They are crazy sensitive - about 105dB at 2.83v. Definitely need earplugs to do sweeps.

These could be used to make molds or even covered with fiberglass like a surfboard.

Thanks for the pictures!

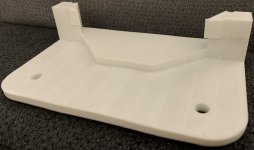

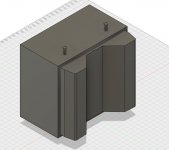

I made a 3D model of the AMT and a negative of it - and a small test print. The final will be printed in two parts. This one fits like a glove (I was surprised with 0.3 mm layer), it needs only some minor adjustments - a flat part with a groove for the wire output.

I need to think about a way how to make the front horn and how to attach it to the printed adapter.

I made a 3D model of the AMT and a negative of it - and a small test print. The final will be printed in two parts. This one fits like a glove (I was surprised with 0.3 mm layer), it needs only some minor adjustments - a flat part with a groove for the wire output.

I need to think about a way how to make the front horn and how to attach it to the printed adapter.

Attachments

Super adapter Pelanj! If it works out can you share STL?

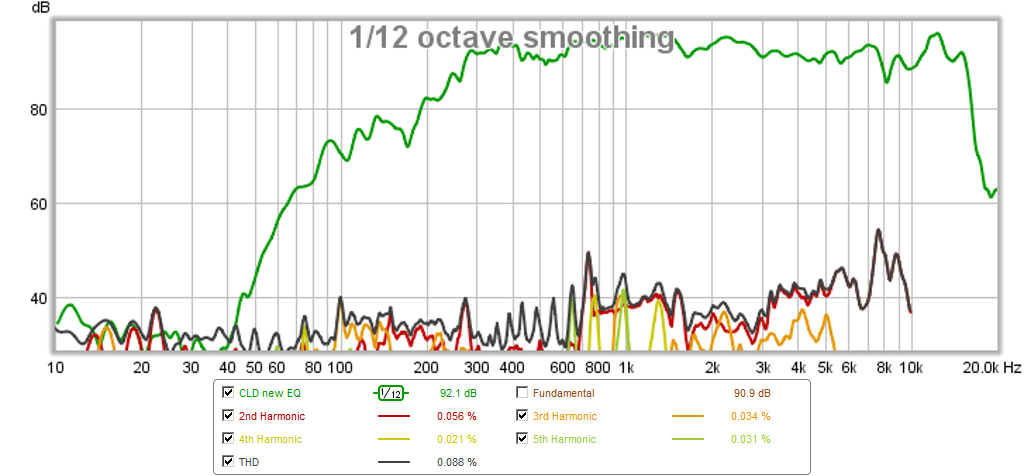

@Pharos : there is no honk. This is one of the best sounding speakers I have heard. I believe a honk is the harmonic profile that gives a brass horn it’s characteristic sound. If you look at the HD components, there is no peak of higher orders at the honk frequency.

@Pharos : there is no honk. This is one of the best sounding speakers I have heard. I believe a honk is the harmonic profile that gives a brass horn it’s characteristic sound. If you look at the HD components, there is no peak of higher orders at the honk frequency.

Last edited:

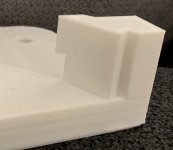

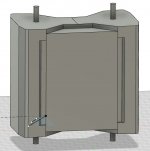

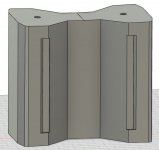

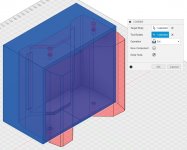

Here is a simplified STEP model of the AMT based on my measurements. I would estimate the precision to +- 0.5 mm. The "cutting tool" for making the front/back attachment is based on this (see the picture) - anyone can do his own choosing his preferred horn mounting method on the other side. It should be OK for the front down to where the stacked metal part starts.

I just made a 3D cube and hollowed it out with the cutting tool - and then it needs only shaping the front as desired.

Edit: There is a slight inaccuracy around the front grooves - that is one thing that needs to be sorted out. I modified this part on the cutting tool a bit, but maybe I should have left it as it was, there is a small edge that I removed - and I actually should have left it in because now the print would need to have this little part removed (easy to do by filing/sanding).

I just made a 3D cube and hollowed it out with the cutting tool - and then it needs only shaping the front as desired.

Edit: There is a slight inaccuracy around the front grooves - that is one thing that needs to be sorted out. I modified this part on the cutting tool a bit, but maybe I should have left it as it was, there is a small edge that I removed - and I actually should have left it in because now the print would need to have this little part removed (easy to do by filing/sanding).

Attachments

Last edited:

Yes, that is the model on the picture on the left - if you subtract that from another solid, you have a part that fits on the AMT front. It is made by extracting the holes to turn into a cylinder and a part in front of the diaphragm is added where there should be hollow place in the front attachment - on the bottom and the top I left ca 5 mm for creating the chamber. It is like a negative of the front attachment.

Edit: Added pictures to illustrate

Edit: Added pictures to illustrate

Attachments

Last edited:

ESS Heil

This entire post is one of the most interesting I can recall on DIYAUDIO. I had no idea people were double stacking them, adding wings, etc. I don't think I can resist trying that.

Looking at the ESS site, they sell these in 3 sizes, for very little difference in price.

At the site linked to, most of those people were mating these to efficient bass bins. I wonder how it would work if instead the ESS was mated to a highly efficient cone mid-bass (100db) and use infinite baffle for the lower octaves?

Another project I'm playing with (a vintage speaker, Alnico woofer at 100 db, with a horrid 800 hz horn) might do well to use one, or a stack of these on and see what happens. I'd likely just do an electronic crossover to start with, then possibly buy into the whole DSP route.

If I was ESS, I'd quickly be offering a kit to double stack these. Since I'm not, I'll just dig into my pile of Appleply.....

It depends where you crossover of course, mine do at 1.8k. ESS did it at 800, 900, and 1k. Looking at both your graphs I think 1.8k is pretty optimal.

This entire post is one of the most interesting I can recall on DIYAUDIO. I had no idea people were double stacking them, adding wings, etc. I don't think I can resist trying that.

Looking at the ESS site, they sell these in 3 sizes, for very little difference in price.

At the site linked to, most of those people were mating these to efficient bass bins. I wonder how it would work if instead the ESS was mated to a highly efficient cone mid-bass (100db) and use infinite baffle for the lower octaves?

Another project I'm playing with (a vintage speaker, Alnico woofer at 100 db, with a horrid 800 hz horn) might do well to use one, or a stack of these on and see what happens. I'd likely just do an electronic crossover to start with, then possibly buy into the whole DSP route.

If I was ESS, I'd quickly be offering a kit to double stack these. Since I'm not, I'll just dig into my pile of Appleply.....

ESS

pelanj: thank you for your original post. This is very, very interesting info.

Yes, that is the model on the picture on the left - if you subtract that from another solid, you have a part that fits on the AMT front. It is made by extracting the holes to turn into a cylinder and a part in front of the diaphragm is added where there should be hollow place in the front attachment - on the bottom and the top I left ca 5 mm for creating the chamber. It is like a negative of the front attachment.

Edit: Added pictures to illustrate

pelanj: thank you for your original post. This is very, very interesting info.

This entire post is one of the most interesting I can recall on DIYAUDIO. I had no idea people were double stacking them, adding wings, etc. I don't think I can resist trying that.

Looking at the ESS site, they sell these in 3 sizes, for very little difference in price.

At the site linked to, most of those people were mating these to efficient bass bins. I wonder how it would work if instead the ESS was mated to a highly efficient cone mid-bass (100db) and use infinite baffle for the lower octaves?

If I was ESS, I'd quickly be offering a kit to double stack these. Since I'm not, I'll just dig into my pile of Appleply.....

Another project I'm playing with (a vintage speaker, Alnico woofer at 100 db, with a horrid 800 hz horn) might do well to use one, or a stack of these on and see what happens. I'd likely just do an electronic crossover to start with, then possibly buy into the whole DSP route.

Whatever mid/woofer, it has to be a wide band breakup/decoupling rather than anything pistonic which reduces what is available because at the large size, 12" fewer are made these days. The original ESS ones had a 2" coil and a conical cone rather than curvilinear, which is not so good for the HF end.

I rebuilt to AMT 1E spec, and then changed to using a BBC LS 5/8 mid/woofer with a curvilinear cone. More accurate I think.

Whatever woofer you use it is unlikely to be as efficient as the Heil, which will need to be attenuated if passive; I used 25W French pots at £25 each in '02. The Heil is an amazing driver, especially given that it has hardly changed since about '74, with the exception of the addition of the 'wedding veil'.

ESS

Pharos: thanks for your comments. I have a stack of NOS TAD mid-bass, 1201H. They work well sealed from about 160hz up to 800 or so. They also work very well horn loaded, but I'm not really interested right now in building a large horn. They work really well in a box as small as 1 cubic foot.

I agree with what you are saying...the woofer is going to be the issue. I see why these are so attractive to the Klipsch and Altec (and other) crowds. Do you think relieving a woofer of the duty of playing up higher would make it easier to find a good candidate for the bottom end?

Since I first posted, I talked to Rick out at ESS. I'm going to start by ordering a pair of the large drivers, and stick them on my vintage speaker.

Pharos: thanks for your comments. I have a stack of NOS TAD mid-bass, 1201H. They work well sealed from about 160hz up to 800 or so. They also work very well horn loaded, but I'm not really interested right now in building a large horn. They work really well in a box as small as 1 cubic foot.

I agree with what you are saying...the woofer is going to be the issue. I see why these are so attractive to the Klipsch and Altec (and other) crowds. Do you think relieving a woofer of the duty of playing up higher would make it easier to find a good candidate for the bottom end?

Since I first posted, I talked to Rick out at ESS. I'm going to start by ordering a pair of the large drivers, and stick them on my vintage speaker.

- Home

- Loudspeakers

- Multi-Way

- ESS AMT-1 in my projects