as for the T/S parameters, this DATS is weird, I have a calibrated Fluke meter and I get different values than DATS when I measre the Re.

I don't see how DATS can measure Re since it is an AC only system (I believe). Use your DVM to get the Re. Remember to subtract the residual resistance of the test leads.

I also used 330mm for diameter before, I m not sure how to actually get the Diameter

Just measure diameter from the center of the surround.

As for the added mass I used 68g in my first measurement but since my second time measuring I keep getting errors for anything lower than 100g, it keeps saying that the mass is too light and it need to be 25% of ... but the added mass and diameter is only for measuring mms and vas, the rest of T/S parameters is the open air measurement with no added mass, so the different QTS has nothing to do with it and the driver may need more beating ?

Can you just measure the impedance curves with and without added mass and post these curves here? We can work out the rest from this.

another problem we have is that if the tweeter fit the available WGs. I can go ahead and see what fits me betetr since i m building this, something that is widely available, and a less headache option, but I like to see others comments first rather than seeing the comments after I made a purchase.

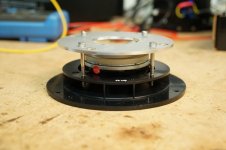

Take a look at the Heissmann link I posted earlier, as these seem to be "easy" tweeter + waveguide combinations. I also mated a WG300 to the "large" ScanSpeaks (6600, R2904, and similar) using a simple adapter plate which is easy to make. This weekend I also managed to modify a WG148 to fit on the "large" Scans. This involved some MacGyver improvisation, but the result seems to be good (see attached photos). It would be best to have some measured dispersion data from your mid drivers so that we can try to find a matching tweeter.

Attachments

I don't see how DATS can measure Re since it is an AC only system (I believe). Use your DVM to get the Re. Remember to subtract the residual resistance of the test leads.

DATS has a calibrated resistor to calibrate the software/hardware, it can measure the resistor alright, but it is not constant, I can have different results on each try. I will do that with my multimeter but I m not sure how that would help in DATS since it will change it to its own measrued number. I will look into this.

Just measure diameter from the center of the surround.

That's how i was doing it and I did it with TD8Ms, I measued 170mm ( if i remember correctlt) and used it DATS but Paul said it should be 155 as in documents 😕

Can you just measure the impedance curves with and without added mass and post these curves here? We can work out the rest from this.

o I see what you mean, I will look into this 🙂

Take a look at the Heissmann link I posted earlier, as these seem to be "easy" tweeter + waveguide combinations. I also mated a WG300 to the "large" ScanSpeaks (6600, R2904, and similar) using a simple adapter plate which is easy to make. This weekend I also managed to modify a WG148 to fit on the "large" Scans. This involved some MacGyver improvisation, but the result seems to be good (see attached photos). It would be best to have some measured dispersion data from your mid drivers so that we can try to find a matching tweeter.

O nice, I like 2904 ! this shouldn't be hard, you removed the WG backplate, probably to make the WG throat to fit 2904, and removed the 2904 front face and then sandwiched the tweeter between a backplate and the WG, correct ? do you have more pics of the process ?

Last edited:

Concerning the Sd value. 🙂

If you measure free air impedance and do "added mass" measurement, you have all TSP parameters, except Sd.

Sd can be determined placing the driver in a known volume, but that is rather complex.

Anyway Sd must have a value that the absolute SPL at 2.83Vrms that is calculated, will be measured also.

Speaker manufacturers have done the same excercise (hopefully), why not using that value.

My experience with the measurement from top to top of the surround is, that it is not accurate enough.

Using datasheet Sd, in most cases I get the same results for calculated and measured absolute SPL. But you need a calibrated SPL setup for that.

Remark that a correct Sd is only important if you like to know the sensitivity very exactly. And if you want to calculate the system resonance in a cabinet very accurately.

If you measure free air impedance and do "added mass" measurement, you have all TSP parameters, except Sd.

Sd can be determined placing the driver in a known volume, but that is rather complex.

Anyway Sd must have a value that the absolute SPL at 2.83Vrms that is calculated, will be measured also.

Speaker manufacturers have done the same excercise (hopefully), why not using that value.

My experience with the measurement from top to top of the surround is, that it is not accurate enough.

Using datasheet Sd, in most cases I get the same results for calculated and measured absolute SPL. But you need a calibrated SPL setup for that.

Remark that a correct Sd is only important if you like to know the sensitivity very exactly. And if you want to calculate the system resonance in a cabinet very accurately.

Last edited:

mm I think I understand what you mean, I don't see why calibrating the mic for SPL would be a problem, and we can use provided SD from datasheet ofcourse.

I will try to provide the basic needed measurements as soon as I can so we can jump to the fun part 😀

I will try to provide the basic needed measurements as soon as I can so we can jump to the fun part 😀

DATS has a calibrated resistor to calibrate the software/hardware, it can measure the resistor alright, but it is not constant, I can have different results on each try. I will do that with my multimeter but I m not sure how that would help in DATS since it will change it to its own measrued number. I will look into this.

How variable are the resistor readings? Can you try a resistor as the DUT (instead of the loudspeaker)?

O nice, I like 2904 ! this shouldn't be hard, you removed the WG backplate, probably to make the WG throat to fit 2904, and removed the 2904 front face and then sandwiched the tweeter between a backplate and the WG, correct ? do you have more pics of the process ?

Well, almost... You need to modify the WG148 to fit the R2904 (or 6600 etc.).

First, take a look at an the unmodified WG148 here.

The thing is that even if you take off the face plate from the R2904 (or 6600 etc.), the throat of the waveguide still needs to "dive" in to the tweeter assembly. This means that the flange of the WG cannot be flat. You need to machine the waveguide in a similar way as described by Pida here (take a look at the attachment).

However, it's a bit more complicated with the R2904 or the 6600 etc. These tweeters require a slightly larger throat diameter of 39 or 39.5 mm instead of the original 38 mm of the WG148. To this end, I machined the WG148 by removing some material from its back flange until I got about 39.2 mm diameter. Then I cut a 3mm deep ring around the throat, similar as shown in Pidas drawing. Note that this means I actually cut away all the material of the flange back plate of the WG148 as shown on the first photo of my previous post. I only left the outer ring with the mounting holes/threads. The trick is to leave the right amount of material at the throat so that this part "dives" into the tweeter and seals the WG148 to the tweeter. I attached another photo showing the backside of the throat in more detail.

Attachments

Last edited:

Why not using Seas Noferro-900?

Test Seas Noferro-900 Visaton Waveguide WG-148R - Heissmann Acoustics

“To mount the Seas Noferro-900 to the WG148R you only have to widen the screw holes of the tweeter from 4,5 to approx. 6mm.”

It is a lot more simple to fix the waveguide on that tweeter.

Test Seas Noferro-900 Visaton Waveguide WG-148R - Heissmann Acoustics

“To mount the Seas Noferro-900 to the WG148R you only have to widen the screw holes of the tweeter from 4,5 to approx. 6mm.”

It is a lot more simple to fix the waveguide on that tweeter.

I still think Seas H1318-06 29TFF/W is the closest of the modern drivers.

But I already mentioned this unit, and there did not seem to be any interest.

H1318-06 29TFF/W

Noferro 900 is very nice, but what about availability?

But I already mentioned this unit, and there did not seem to be any interest.

H1318-06 29TFF/W

Noferro 900 is very nice, but what about availability?

Well, almost... You need to modify the WG148 to fit the R2904 (or 6600 etc.).

...

Ok that is abit out of comfort zone 😀 I do not have access to a CNC or manual machining anymore.

Just out of curiosity, do you have any broken WG148 that we can trace a profile from ?

Last edited:

as for the Seas Noferro-900, I think it's obsolete, couldn't find any retailers here, there are some european stores carrying it but probably old stock.

Kaffimann, what about the convex shape face ? it won't fit a WG like that.

I still think Seas H1318-06 29TFF/W is the closest of the modern drivers.

But I already mentioned this unit, and there did not seem to be any interest.

H1318-06 29TFF/W

Noferro 900 is very nice, but what about availability?

Kaffimann, what about the convex shape face ? it won't fit a WG like that.

I still think Seas H1318-06 29TFF/W is the closest of the modern drivers.

But I already mentioned this unit, and there did not seem to be any interest.

H1318-06 29TFF/W

Yes, but that driver is so ugly just knowing it hides behind the nice waveguide would make you cringe... 😀

Kaffimann,I still think Seas H1318-06 29TFF/W is the closest of the modern drivers.

But I already mentioned this unit, and there did not seem to be any interest.

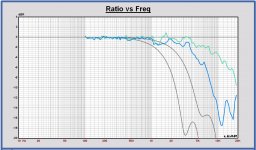

If you compare 30 and 60 deg normalized off axis response of this Seas (color) with the AE TD8M (grey), you can see that is not directional enough with its little waveguide.

Attachments

Just out of curiosity, do you have any broken WG148 that we can trace a profile from ?

Uhm, yes! Of course I messed up the first attempt of machining the WG148. There are a few mm of the throat missing, but it should be easy to reconstruct that if necessary. Or just buy another one, they are cheap.

Jonasz, indeed. Not the prettiest unit around, but reasonably priced in relation to performance.

Paul, but the Noferro 900 is not easily available to all, and there have been suggestions of modifying a waveguide anyway. I don't mind using a CD + horn to reach the goal, but I think no matter what solution to go for it should be max 200$ total for the tweeter section. The selection of domes is limited in comparison to compression drivers for the desired sensitivity.

Paul, but the Noferro 900 is not easily available to all, and there have been suggestions of modifying a waveguide anyway. I don't mind using a CD + horn to reach the goal, but I think no matter what solution to go for it should be max 200$ total for the tweeter section. The selection of domes is limited in comparison to compression drivers for the desired sensitivity.

Uhm, yes! Of course I messed up the first attempt of machining the WG148. There are a few mm of the throat missing, but it should be easy to reconstruct that if necessary. Or just buy another one, they are cheap.

O nice, I thought about buying one and cut it but if you already have one that is awesome, can you trace the throat profile fromt it ? like just put it on a paper and trace it as close as you can ? I can do the rest in soldworks 😀

I also got this from visaton and I can trace it from here, do you think the throat shape is close enough to real thing ? (please see the attachment)

Attachments

O nice, I thought about buying one and cut it but if you already have one that is awesome, can you trace the throat profile fromt it ? like just put it on a paper and trace it as close as you can ? I can do the rest in soldworks 😀

I also got this from visaton and I can trace it from here, do you think the throat shape is close enough to real thing ? (please see the attachment)

Not sure how accurate the Visaton drawing is. What would you do after tracing the profile? Send it to a 3D printer?

yeah that is what I was thinking, tracing an 8" WG from WG148 is not difficult and I can make it fit any tweeter face and shape we want with fitting throat size, but the key here is the accuracy, I m not sure how accurate is that drawing and unless we do it with a machine it will not be exact but maybe good enough 😉.

we did have some 3d laser scanning at work, not sure if we still have, but I will look into this.

this is just an off topic experience out of curiosity.

EDIT: Forgot to mention that I wanted to see if I can scale it to 40mm deep so it would be AC aligned.

we did have some 3d laser scanning at work, not sure if we still have, but I will look into this.

this is just an off topic experience out of curiosity.

EDIT: Forgot to mention that I wanted to see if I can scale it to 40mm deep so it would be AC aligned.

Last edited:

yeah that is what I was thinking, tracing an 8" WG from WG148 is not difficult and I can make it fit any tweeter face and shape we want with fitting throat size, but the key here is the accuracy, I m not sure how accurate is that drawing and unless we do it with a machine it will not be exact but maybe good enough 😉.

we did have some 3d laser scanning at work, not sure if we still have, but I will look into this.

this is just an off topic experience out of curiosity.

EDIT: Forgot to mention that I wanted to see if I can scale it to 40mm deep so it would be AC aligned.

That's a cool idea... I have no clue about 3D printing though.

NoFerro 900 isn't that just the german name for one of the standard Seas tweeters?

Seas Noferro 900 = H1025 = 27TF1 and is available from stock at here:

Strassacker: Speaker Building, Components

- Home

- Loudspeakers

- Multi-Way

- Open Source "Tower XL"