hi all

Jack ( jzagaja ) seems have embraced a project of building bass compression drivers. That's great. I see it as a last frontier of horn speaker building. The only two companies ( Ale and Goto ) , which produce such things, ask prohibitive prices, what makes it possible only for a few fortunates, to buy and use such devices. True, these require long and big basshorns, and time delay problem arise, but in compensation clarity and transients are just in a other league, than paper cone woofers. I was sharing some ideas some time back with Mario, which posts at my forum, and has a considerable knowledge of building field coil drivers. We were figuring out what it takes to built a Thuras Bass horn driver :

Thuras bass compression driver - Audio Voice Acoustics

there was a thread some time ago at audioasylum :

Audio Asylum Thread Printer

but it did not get very far.

diaphragm and voice coil seems to be the most difficult part to built, in a DIY project. Maibe some or the other wishes to share infos and ideas. It would be interesting, if Jzagaja would share informations about his project here.

Jack ( jzagaja ) seems have embraced a project of building bass compression drivers. That's great. I see it as a last frontier of horn speaker building. The only two companies ( Ale and Goto ) , which produce such things, ask prohibitive prices, what makes it possible only for a few fortunates, to buy and use such devices. True, these require long and big basshorns, and time delay problem arise, but in compensation clarity and transients are just in a other league, than paper cone woofers. I was sharing some ideas some time back with Mario, which posts at my forum, and has a considerable knowledge of building field coil drivers. We were figuring out what it takes to built a Thuras Bass horn driver :

Thuras bass compression driver - Audio Voice Acoustics

there was a thread some time ago at audioasylum :

Audio Asylum Thread Printer

but it did not get very far.

diaphragm and voice coil seems to be the most difficult part to built, in a DIY project. Maibe some or the other wishes to share infos and ideas. It would be interesting, if Jzagaja would share informations about his project here.

hi all

Jack ( jzagaja ) seems have embraced a project of building bass compression drivers. That's great. I see it as a last frontier of horn speaker building. The only two companies ( Ale and Goto ) , which produce such things, ask prohibitive prices, what makes it possible only for a few fortunates, to buy and use such devices. True, these require long and big basshorns, and time delay problem arise, but in compensation clarity and transients are just in a other league, than paper cone woofers. I was sharing some ideas some time back with Mario, which posts at my forum, and has a considerable knowledge of building field coil drivers. We were figuring out what it takes to built a Thuras Bass horn driver :

Thuras bass compression driver - Audio Voice Acoustics

there was a thread some time ago at audioasylum :

Audio Asylum Thread Printer

but it did not get very far.

diaphragm and voice coil seems to be the most difficult part to built, in a DIY project. Maibe some or the other wishes to share infos and ideas. It would be interesting, if Jzagaja would share informations about his project here.

A front loaded horn and a compression driver are the same thing. The only difference is scale.

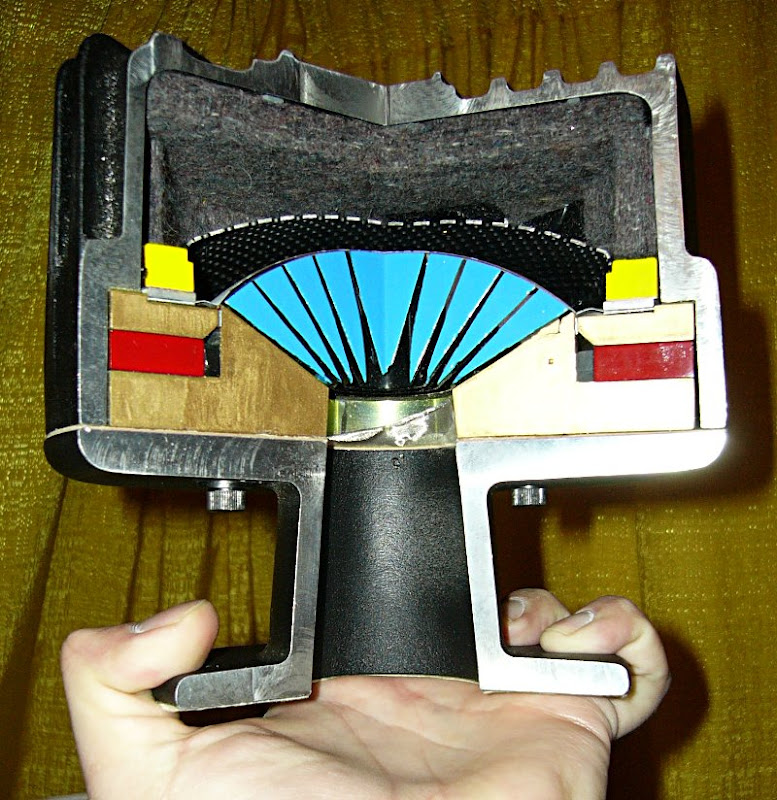

Cutaway of a tad compression driver, showing the rear chamber damped by wool, the diaphragm, and the phase plug.

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

Cutway of a bass horn, showing the rear chamber damped by egg crate foat, and the diaphragm.

There's no phase plug. If you wanted to put one there, you could. You might be on to something with that, since anything we can do to reduce diffraction in a horn will reduce "horn honk", particularly at high frequencies. (IE, a phase plug may be MORE important in a low frequency horn because it makes an improvement in a range where we're very sensitive.)

Interesting.

Maybe one should try and add a phase plug ( blue-painted og the TAD picture) to a bass unti with aluminum diaphragm, like Seas, Alcone or similar.

Maybe one should try and add a phase plug ( blue-painted og the TAD picture) to a bass unti with aluminum diaphragm, like Seas, Alcone or similar.

Interesting.

Maybe one should try and add a phase plug ( blue-painted og the TAD picture) to a bass unti with aluminum diaphragm, like Seas, Alcone or similar.

Here's a page with great info on how to do it.

Phase Plugs

here is the patent paper of the Thuras bass compression driver :

Sound translating device

this is what Steve Shell wrote about them at AA:

High Efficiency Speaker Asylum: Re: OFFICIAL bass compression driver thread................. by Steve Schell

This is A.L. Thuras' patent on his magnificent bass compression driver. Just imagine a device with 20" diameter diaphragm pressed from .004" duralumin, fitted with an 8" edgewound aluminum voice coil suspended in a 20 kilogauss magnetic field provided by a massive field coil structure. They built a number of these in the Bell Labs workshops, and they performed admirably in the Fletcher System

Of course a paper cone woofer can be regarded as a compression driver when it is used on a horn with a smaller throat than its piston area. We've all been there, done that. Several small Japanese companies over the past 40 years have found it worthwhile to produce true bass compression drivers; i.e. drivers with features similar to midrange and high frequency compression drivers but scaled up in size. I'll admit to having been skeptical of this approach in the past, thinking that such a system would be too excursion limited to produce much output. Boy was I wrong! I listened to Kevin Brooks' ALE bass horns and compression drivers two years ago in Provo, Utah and was stunned by their sound. Never before had I heard such see-through clarity and naturalness in bass reproduction.

here the comment of Reinhard from Germany, which uses Goto drivers :

For me the most important thing was the Goto SG146LD. Klaus started with a straight 10 leafs 40 cycle horn in 1983. And it was awesome. SG146LD is the only compression bass driver which does not produce boom-boom if fed right. The SG146LD contrarily is on first impression not to be heard as bass, first you think, hey it is wrong, it is not connected, but then you realize, what they are doing, they integrate completely homogeneously into the sound, totally natural, like a royal soufflé, no more "cuts" between bass and mid-range (especially in the voices), just "one" sound. Marvellous. Really marvelous. And they make the right pressure. 113 db/watt/m... and you can put some 35 watts in there... and you get volume like on stage... and nothing disturbing...

i have heard such a basshorn in Japan, several years back:

Flickr: The most complete Gallery of Hornloudspeakers !!'s Photostream

and to me, it didn't sound all that good as Steve Shell mentioned ; time delay could be heard, and there was a severe problem when playing very low frequency notes : a very strong distortion. I listened the same system twice. The first time with Endo San, owner of Ale Acoustics. He resolved to take the Ale 1260 , 100kg heavy bass compression driver from his client back to his factory, to inspect it further and eventually fix it.

After a few month, i went back to japan, and resolved to listen the same system again, but alone. The distortion was still there.....

While the whole system sounded crystal clear, and amazing, the lower bass however was rather disappointing. Indeed, as Steve Shell wrote, it sounds very fast, clear and natural. No boom at all. But it can sound rather thin as well. I am convinced, no bass compression driver ala Ale or Goto, even with a 9m horn, can reproduce very deep notes, below 50hz, better than a paper cone woofer. Unless, a metal diaphragm with at least 15" size would be made...... a device that covers the range above 60,70hz to 400hz, and does it better than a cone driver, would be very interesting, combined in a system with all compression drivers above. And specially : at a reasonable price....

back some time ago, i wrote to a german company, which produces only loudspeaker cones , to ask, it they could make a cone like used in the Thuras. Their answer was :

Sehr geehrter Herr Grasso,

vielen Dank für Ihre E-Mail und Ihr Interesse an unserer Firma.

Leider haben wir in den von Ihnen gewünschten Abmessungen (Schwingspulendurchmesser 20 cm!) keinerlei Werkzeuge im Programm.

Die bei uns maximal herstellbare Membranengröße liegt bei ca. 8“ (20 cm Außendurchmesser).

Die Größe Ihrer Kompressionsmembrane (geschätzt ca. 45-50 cm Außendurchmesser) übersteigt die Möglichkeiten unserer Anlagen bei weitem.

Hierzu wären zuvor Investitionen an Maschinen erforderlich - der Aufwand wäre beträchtlich.

Bitte lassen Sie mich wissen, ob wir in irgendeiner anderen Art und Weise behilflich sein können.

Unser Internet-Katalog unter www.kurtmueller.com sollte dahingehend aussagekräftig sein.

Mit freundlichen Grüßen

Matthias Ringpfeil

Leiter Produktentwicklung/Verkauf

Dr. Kurt Müller GmbH & Co. KG

Krefelder Straße 150

47839 Krefeld

Tel 02151 73 29 40

Fax 02151 73 29 12

Mail ringpfeil@kurtmueller.com

Web www.kurtmueller.com

Handelsregister Krefeld HRA 2386

USt-IdNr.: DE120138621

Komplementärin:

Membranen GmbH, Handelsregister Krefeld HRB 1156

Geschäftsführer: Helmut Ebers

Gerichtsstand: Krefeld

in short : they did not have the tooling.

further, Mr. Ringpfeil wrote me following :

Hallo Herr Grasso,

die Materialdicke eines 4” Treibers ist bei Aluminium ca. 100 µm.

Ich würde für Ihre Anwendung nicht unter 0,2 mm (200 µm) gehen, max. 250 µm.

Eine gute Adresse, auch für kleinere Mengen ist die Firma Multifoil in England (siehe Kontakt in Anlage).

the material thickness should not be less than 0,2mm for such a diaphragm size. A source for duralumin foil they gave me was :

http://www.multifoil.co.uk/

i wrote them, but did not receive any answer.

Sound translating device

this is what Steve Shell wrote about them at AA:

High Efficiency Speaker Asylum: Re: OFFICIAL bass compression driver thread................. by Steve Schell

This is A.L. Thuras' patent on his magnificent bass compression driver. Just imagine a device with 20" diameter diaphragm pressed from .004" duralumin, fitted with an 8" edgewound aluminum voice coil suspended in a 20 kilogauss magnetic field provided by a massive field coil structure. They built a number of these in the Bell Labs workshops, and they performed admirably in the Fletcher System

Of course a paper cone woofer can be regarded as a compression driver when it is used on a horn with a smaller throat than its piston area. We've all been there, done that. Several small Japanese companies over the past 40 years have found it worthwhile to produce true bass compression drivers; i.e. drivers with features similar to midrange and high frequency compression drivers but scaled up in size. I'll admit to having been skeptical of this approach in the past, thinking that such a system would be too excursion limited to produce much output. Boy was I wrong! I listened to Kevin Brooks' ALE bass horns and compression drivers two years ago in Provo, Utah and was stunned by their sound. Never before had I heard such see-through clarity and naturalness in bass reproduction.

here the comment of Reinhard from Germany, which uses Goto drivers :

For me the most important thing was the Goto SG146LD. Klaus started with a straight 10 leafs 40 cycle horn in 1983. And it was awesome. SG146LD is the only compression bass driver which does not produce boom-boom if fed right. The SG146LD contrarily is on first impression not to be heard as bass, first you think, hey it is wrong, it is not connected, but then you realize, what they are doing, they integrate completely homogeneously into the sound, totally natural, like a royal soufflé, no more "cuts" between bass and mid-range (especially in the voices), just "one" sound. Marvellous. Really marvelous. And they make the right pressure. 113 db/watt/m... and you can put some 35 watts in there... and you get volume like on stage... and nothing disturbing...

i have heard such a basshorn in Japan, several years back:

Flickr: The most complete Gallery of Hornloudspeakers !!'s Photostream

and to me, it didn't sound all that good as Steve Shell mentioned ; time delay could be heard, and there was a severe problem when playing very low frequency notes : a very strong distortion. I listened the same system twice. The first time with Endo San, owner of Ale Acoustics. He resolved to take the Ale 1260 , 100kg heavy bass compression driver from his client back to his factory, to inspect it further and eventually fix it.

After a few month, i went back to japan, and resolved to listen the same system again, but alone. The distortion was still there.....

While the whole system sounded crystal clear, and amazing, the lower bass however was rather disappointing. Indeed, as Steve Shell wrote, it sounds very fast, clear and natural. No boom at all. But it can sound rather thin as well. I am convinced, no bass compression driver ala Ale or Goto, even with a 9m horn, can reproduce very deep notes, below 50hz, better than a paper cone woofer. Unless, a metal diaphragm with at least 15" size would be made...... a device that covers the range above 60,70hz to 400hz, and does it better than a cone driver, would be very interesting, combined in a system with all compression drivers above. And specially : at a reasonable price....

back some time ago, i wrote to a german company, which produces only loudspeaker cones , to ask, it they could make a cone like used in the Thuras. Their answer was :

Sehr geehrter Herr Grasso,

vielen Dank für Ihre E-Mail und Ihr Interesse an unserer Firma.

Leider haben wir in den von Ihnen gewünschten Abmessungen (Schwingspulendurchmesser 20 cm!) keinerlei Werkzeuge im Programm.

Die bei uns maximal herstellbare Membranengröße liegt bei ca. 8“ (20 cm Außendurchmesser).

Die Größe Ihrer Kompressionsmembrane (geschätzt ca. 45-50 cm Außendurchmesser) übersteigt die Möglichkeiten unserer Anlagen bei weitem.

Hierzu wären zuvor Investitionen an Maschinen erforderlich - der Aufwand wäre beträchtlich.

Bitte lassen Sie mich wissen, ob wir in irgendeiner anderen Art und Weise behilflich sein können.

Unser Internet-Katalog unter www.kurtmueller.com sollte dahingehend aussagekräftig sein.

Mit freundlichen Grüßen

Matthias Ringpfeil

Leiter Produktentwicklung/Verkauf

Dr. Kurt Müller GmbH & Co. KG

Krefelder Straße 150

47839 Krefeld

Tel 02151 73 29 40

Fax 02151 73 29 12

Mail ringpfeil@kurtmueller.com

Web www.kurtmueller.com

Handelsregister Krefeld HRA 2386

USt-IdNr.: DE120138621

Komplementärin:

Membranen GmbH, Handelsregister Krefeld HRB 1156

Geschäftsführer: Helmut Ebers

Gerichtsstand: Krefeld

in short : they did not have the tooling.

further, Mr. Ringpfeil wrote me following :

Hallo Herr Grasso,

die Materialdicke eines 4” Treibers ist bei Aluminium ca. 100 µm.

Ich würde für Ihre Anwendung nicht unter 0,2 mm (200 µm) gehen, max. 250 µm.

Eine gute Adresse, auch für kleinere Mengen ist die Firma Multifoil in England (siehe Kontakt in Anlage).

the material thickness should not be less than 0,2mm for such a diaphragm size. A source for duralumin foil they gave me was :

http://www.multifoil.co.uk/

i wrote them, but did not receive any answer.

Last edited:

I was thinking about this. A "compression" bass driver seems attractive on the surface...

But, afaik, there is no real reason to make a "phase plug" for a driver used in a basshorn, unless you intend to make it go pretty high in frequency... If you look at the WE folded basshorn you can see that it had to make it high enough to mate with the multicells above! And, presumably they wanted similar sensitivity.

It's probably well known and understood by everyone here that by making a volume in front of the driver in a basshorn, you can create a LP filter... so short of wanting response way up high, why the phase plug?

I guess that if the goal is absolute maximum sensitivity, then there is a yin/yang between the flux in the gap, the number of turns in the gap, the xmax and the Sd... just like with a standard driver.

Community Sound made an 8" diaphragm mid-bass pure compression driver some years ago, I think they are still made. Perhaps this is the point of departure for such a design? But again this driver was trying to have high output and go up pretty high, plus this driver used a roll type outer suspension, iirc, for larger excursions.

Thin foil seems inappropriate for a true bass driver... hard to maintain sufficient stiffness in the face of the forces placed on it from the combination of excursion and pressure...

But, I am often wrong about these things too...

So, when then is the purpose of creating a "true" compression driver for bass application?

_-_-bear

But, afaik, there is no real reason to make a "phase plug" for a driver used in a basshorn, unless you intend to make it go pretty high in frequency... If you look at the WE folded basshorn you can see that it had to make it high enough to mate with the multicells above! And, presumably they wanted similar sensitivity.

It's probably well known and understood by everyone here that by making a volume in front of the driver in a basshorn, you can create a LP filter... so short of wanting response way up high, why the phase plug?

I guess that if the goal is absolute maximum sensitivity, then there is a yin/yang between the flux in the gap, the number of turns in the gap, the xmax and the Sd... just like with a standard driver.

Community Sound made an 8" diaphragm mid-bass pure compression driver some years ago, I think they are still made. Perhaps this is the point of departure for such a design? But again this driver was trying to have high output and go up pretty high, plus this driver used a roll type outer suspension, iirc, for larger excursions.

Thin foil seems inappropriate for a true bass driver... hard to maintain sufficient stiffness in the face of the forces placed on it from the combination of excursion and pressure...

But, I am often wrong about these things too...

So, when then is the purpose of creating a "true" compression driver for bass application?

_-_-bear

Before we go into details let me simulate "Thuras" driver.

1) Outer diameter 20"

2) VC diameter 8"

3) Optimum coil mass for 8" is 32g

4) Membrane thickness is ca. 0.1mm

5) Membrane mass is then 8.3g (plus suspension)

6) Assumed Bl is 30Tm, Re=6R.

7) Total Mmd is then 40.3g

8) Resulting Fs=53Hz and Qt=0.12 for Cms=1.6E-04 m/N

9) Optimal throat S1=210cm2 for Rg->0.

Largest domestic horn S2=18000 cm2, length 400-500cm, Hypex 0.6.

1) Outer diameter 20"

2) VC diameter 8"

3) Optimum coil mass for 8" is 32g

4) Membrane thickness is ca. 0.1mm

5) Membrane mass is then 8.3g (plus suspension)

6) Assumed Bl is 30Tm, Re=6R.

7) Total Mmd is then 40.3g

8) Resulting Fs=53Hz and Qt=0.12 for Cms=1.6E-04 m/N

9) Optimal throat S1=210cm2 for Rg->0.

Largest domestic horn S2=18000 cm2, length 400-500cm, Hypex 0.6.

Attachments

Before we go into details let me simulate "Thuras" driver.

1) Outer diameter 20"

2) VC diameter 8"

3) Optimum coil mass for 8" is 32g

4) Membrane thickness is ca. 0.1mm

5) Membrane mass is then 8.3g (plus suspension)

6) Assumed Bl is 30Tm, Re=6R.

7) Total Mmd is then 40.3g

8) Resulting Fs=53Hz and Qt=0.12 for Cms=1.6E-04 m/N

9) Optimal throat S1=210cm2 for Rg->0.

Largest domestic horn S2=18000 cm2, length 400-500cm, Hypex 0.6.

hi Jack

wow, excellent !! could you reproduce the Thuras ? i would be the first buyer. :=))

here is the patent paper of the Thuras bass compression driver :

When i see that construction you need a SB acoustic driver and place a horn on the air vent.😀

An externally hosted image should be here but it was not working when we last tested it.

Will become useless big.880 cm2.

Last edited:

Now let me optimize (according to Leach) the "Thuras" driver for this particular (big) horn keeping Bl=30Tm - S1 reduced to 160cm2, Re=4R.

Qtc 0.29

Qes 0.27

fs 42 Hz

Vas 81 litres

Cmd 6.85E-05 m/N

Mmd 207 g

n 44.6 %

f3 363 Hz (upper freq. limit)

and put the data into Hornresp to compare results.

Qtc 0.29

Qes 0.27

fs 42 Hz

Vas 81 litres

Cmd 6.85E-05 m/N

Mmd 207 g

n 44.6 %

f3 363 Hz (upper freq. limit)

and put the data into Hornresp to compare results.

Attachments

Looks interesting, but the HF response seems to suffer, and this is what was needed to meet those WE multicell horns... of course, today we may not have the same constraints...

_-_-bear

_-_-bear

No problem we can lower Qtc and Mms to 60grams to met 1kHz but then horn should be pretty straight. Thuras has Mmd below 10grams. Should we add some part of the suspension - 50%?

Good question... what is the effect of the surround on the moving mass?

I didn't look at the patent, what was the suspension, was it spec'd??

When you say the horn should be pretty straight, are you speaking of a new horn, or the horn that is linked to in the earlier posts, by WE?? (this one: http://www.pat2pdf.org/patents/pat1970926.pdf)

And, Jack what is your view on the need for a "compression driver" construction vs. the more or less standard slotted baffle in front of a standard bass driver??

_-_-bear

I didn't look at the patent, what was the suspension, was it spec'd??

When you say the horn should be pretty straight, are you speaking of a new horn, or the horn that is linked to in the earlier posts, by WE?? (this one: http://www.pat2pdf.org/patents/pat1970926.pdf)

And, Jack what is your view on the need for a "compression driver" construction vs. the more or less standard slotted baffle in front of a standard bass driver??

_-_-bear

In wide bandwidth woofer - Bandor for example, suspension is very soft ca. 2mm/N, membrane thickness varies from 0.26 to 0.47mm. With strong motor modes are nicely damped. Now compare it to the Thuras with 0.1mm. Making suspension stiffer than of a typical PA woofer (3E-04 m/N) makes sense so that horn resonances are better damped. This is important as we always use rather undersized horn. Displacement is then less than 0.5mm for 1 Watt.

In the meantime I'll try design nice and domestically acceptable horn for this driver.

In the meantime I'll try design nice and domestically acceptable horn for this driver.

- Status

- Not open for further replies.

- Home

- Loudspeakers

- Multi-Way

- DIY bass compression drivers