MJL21193 said:

Hmm,

There is a big difference between "doing everything that can be done" and "doing everything as effectively and efficiently as possible".

I detect a hint of snobbery in the above quote. That's to be expected of course.

Funny, I know quite a few engineers. I can actually fill a fair size room with the P.Eng's I know. They have this in common: they don't talk down to me or use a derisive tone when they refer to this "hobbyist".

I even know a few structural engineers, real structural engineers, you know, the ones that design structures? Well paid individuals, with the responsibility of peoples lives resting on their work. They don't last long in the position by doing what is merely "adequate"

You know I didn't mean anything derogatory by my post, I was basically quoting what you said some frames back about doing all you can. ("Why check one and not the other? Better to be sure and cover both") And there is nothing wrong with being a hobbiest.

But your post is clearly intentionally insulting ...

Cal Weldon said:

Add to that those who get their degrees from the back of a cereal box who tend to under design in the name of the bottom line. I'll tell you it's no fun reviewing drawings that have critical omissions that no one caught until the building collapsed. Silly engineering mistakes that cost lives. You may be right about some but you sure can't lump them all together.

Sorry for the OT but it's a sensitive subject for me.

We now return you to your regularly scheduled program...

Hi Cal,

This thread was supposed to be about MDF anyway, so everything lately is OT.

The structural engineers that I have met didn't get their degree off the back of a cereal box, that's for sure. Tons of civil engineers yes (I call them train engineers? Choo-choooo).

Structural is the top of the heap, and rightfully so.

MJL21193 said:Thank you, although something is still not clear. I'm not saying there should be more bracing , I'm saying the bracing can be more effective. That's the real difference between the full panel and the pole - effectiveness.

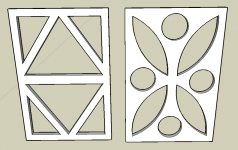

I like this one very much! It has the Gothic Maltese cross thing happening, so it get extra points for looking cool.

I whipped up a few quickly also, just for illustration. The one on the far right is my favourite.

Thanks for the "cool factor" vote. I hadn't intentionally done that, but sometimes form follows function nicely.

Also, I don't think we are as far apart as you might think, as I would agree that your "far right" drawing would indeed be a very effective brace, and illustrates the points I was not so clearly making.

In my drawing of the bracing for the speaker cabinet I recently built, if I hadn't used 1" baltic birch plywood for the 7" wide front and rear panels, I would have used a brace more like the one you have drawn. An interesting note about the bracing scheme I did use, is that the cross panel posts are not centered but are positioned at 0.618x cabinet depth, and are alternating in orientation with vertical position. This creates a very minor but measureable difference in the resonance spectrum of the cabinet: the number of resonant frequencies is increased, but the instensity of each spectrum peak is reduced, and each peak is broadened across a larger frequency range. I know, this is "Golden Ratio" hocus pocus, but it did create a beneficial effect without increasing the effort or materials required to produce it.

Originally posted by Cal Weldon

Not looking to nit pick but when they go beyond the call they have budget overruns and henceforth often do only what is adequate or acceptable. Add to that those who get their degrees from the back of a cereal box who tend to under design in the name of the bottom line. I'll tell you it's no fun reviewing drawings that have critical omissions that no one caught until the building collapsed. Silly engineering mistakes that cost lives. You may be right about some but you sure can't lump them all together.

The eternal bane of engineers, and the reason why most go grey early in life. It must absolutely positively present no hazard to llife, health, environment, etc., etc., but must not cost one penny more than is possible, and must never, ever go overschedule. Oh, yeah, you also get paid like crap for the stress and demands of the job. This is sadly one of the reasons why I have ended up in the business end of big industry and only do a marginal amount of engineering work anymore (although I still work with engineers on a daily basis). I get paid way more for being in a significantly less demanding position.

Cal, I'll fire you a PM so we can catch up.

Cheers,

Terry

gedlee said:

You know I didn't mean anything derogatory by my post, I was basically quoting what you said some frames back about doing all you can. ("Why check one and not the other? Better to be sure and cover both") And there is nothing wrong with being a hobbiest.

But your post is clearly intentionally insulting ...

Well I accomplished one thing: I broke the silent treatment you were giving me.

I'm sorry if I read something into your post that wasn't there. No harm done? I don't hold grudges. (22 years in construction will beat that out of you; I'd hate everyone by now

Honestly, no insult implied. I was only picking up on a tone that wasn't there.

MJL21193 said:

Well I accomplished one thing: I broke the silent treatment you were giving me.

I was never ignoring you, it just seemed that your mind was made up.

Honestly, no insult implied. I was only picking up on a tone that wasn't there.

This cannot accept because the insults were more than implied they were blatant and deliberate. You need to be more polite. I will ignore you if this is not the case.

The point that seems to get missed by many here, that I may not have made clear, is that when I say to use a rod across the cabinet I have assumed that the corners are well glued and don't bend. As I am sure Terry will confirm, this makes a huge difference since a plate clamped at the edges will respond much better to a pinned center than a free edge (or hinged) plate. And it is plates that we are talking about here, not membranes - there is a very large difference in the two. The rod idea has very little effect on a membrane but a very large effect on a clamped plate.

Of course more rods would work even better and enough rods to make a plate even better yet, but for efficiency you get the most bang from the first rod and they become progressively less effective after that.

And the diference in acoustic radiation efficiency has been completely ignored in this discussion, but it is no insignificant effect. Some vibrations radiate far better than others - basically the closer to a monpole the better the radiation. The single rod (in three directions) concept basically kills any monopole motion of the enclosure thus being by far the most effective (for a minimum of rods) at reducing SOUND radiation.

gedlee said:

I was never ignoring you, it just seemed that your mind was made up.

My mind is made up. That hasn't changed.

gedlee said:

This cannot accept because the insults were more than implied they were blatant and deliberate. You need to be more polite. I will ignore you if this is not the case.

That was me being courteous. You will have to take it whatever way you like.

I can be polite, but who started this ball rolling back in post#125?

I only give it when I get it.

As for threats about ignoring me...well I'll have to try to cope with that the best I can.

metalman said:

Thanks for the "cool factor" vote. I hadn't intentionally done that, but sometimes form follows function nicely.

Hi Terry,

I took liberties with your brace and hacked a few holes to make it more "airy" and "transparent". Hope you don't mind.

The first one is redone on Sheldon's very "sound" advise: to straighten the curved pieces. This would be a great brace for a mid-sized box, where the other would provide brute strength for a sub enclosure - a man of a brace.

Attachments

tinitus said:MJL... your fine suggestions/drawings of bracing reveals that your expertice is a complete fantacy...doesnt look like you actually know what you are doing...I only say this because you claim to be an expert, which you obviously are not

Hi,

Where did I claim to be an expert?

PS: There are many more things I could say, but I won't.

gedlee said:Lets all try and be nice OK!! There is absolutely no excuse for being rude.

Yes. This thread will be closed and we'll all be doing a stint in the sin bin if cooler heads don't prevail.

We can discuss things without one oneupmanship.

Considering the left drawing above.

The outside ribs won't do much since they are along the walls and as Jerry (and I) both point out stiffing the walls with ribs doesn't do a lot since its strictly a thickness problem.

Then consider the ribs across the corners. If the box is well glued then it won't skew, and skew doesn't generate any sound at all anyways, so they don't do much acoustically.

The really useful member then is the single brace across the enclosure - sound familiar?

gedlee said:In other words you have braced the wrong dimension and left the critical one fairly unsupported.

I found the original article* that informed my choice of brace orientation... Terry has already validated that the sides are inherently well braced.

1st lets look at what makes one brace better than another brace -- it need not be the same kind of goals that will keep a bridge or building from collapsing.

This is my reasoning:

0/ there is no such thing as a panel that doesn't resonate (and when a panel resonates it becomes largely transparent)

1/ if we place the resonances such that they are unlikely to be excited then it is almost as if they are not there.

2/ the energy available to excite a resonance is inversely proportional to the square of the frequency

so, a brace is better if it pushes the panel resonant frequency up higher

The picture now becomes pretty much self-explanatory. The diagonal is most effective, but in the case of the example i posted this would not allow the use of a single brace to deal with 4 panels (and a perpendicular brace is easier to build). Based on this data Earl's point braces are the least effective.

To get a very rough metric that shows the effect of frequency, if we take the experimental numbers (actual panel resonances will differ based on initial panel shape/proportions, and material) and calculate energy available to excite the resonance (freq(unbraced)/freq(braced))^2, set unbraced to 100%, the single centrally placed point brace would be 50%, a horizontal brace 36% and the vertical brace 14%.

*(JAES April 1973, V21#3, The Theory of Loudspeaker Cabinet Resonance, James K Iverson)

dave

Attachments

gedlee said:The outside ribs won't do much since they are along the walls and as Terry (and I) both point out stiffing the walls with ribs doesn't do a lot

The ribs will increase the stiffness of the panel, which pushes its resonance up ... if that didn't happen the T-brace (as we see in a roof, a wall or a floor) wouldn't be very effective.

I do prefer to have more meat in my braces, and more randomness.

dave

John this isn't the first time that you've treaded on toes.

I too am very familar with the construction industry and being blunt in communication is common and accepted practice there. On this board we have a wider cross section of personalities on this discussion board and such a tone isn't considered polite by the wider general populace.

When you get the same type of response from lots of different people, it's time to look in the mirror.

Hope I didn't come across as too preachy

Anyway to the most interesting discussion at hand. I'm learning alot here from all of you and I have a few questions.

1) Are there only 2 sources of resonances in a speaker? The direct mechanical vibration of the drivers and the vibration caused by the airwave. Any others? Is decoupling of the driver from the enclosure a more effective way of dealing with the former?

2) What types of forces are in action which cause the resonances we are trying to eliminate? Compression, expansion, shear...? The sort of forces we are trying to counteract would determine what sort of bracing and materials would be more effective and efficient.

3) What sort of enclosures are we talking about here? Won't different cabinet designs be more subseptible to different sorts of resonances?

I too am very familar with the construction industry and being blunt in communication is common and accepted practice there. On this board we have a wider cross section of personalities on this discussion board and such a tone isn't considered polite by the wider general populace.

When you get the same type of response from lots of different people, it's time to look in the mirror.

Hope I didn't come across as too preachy

Anyway to the most interesting discussion at hand. I'm learning alot here from all of you and I have a few questions.

1) Are there only 2 sources of resonances in a speaker? The direct mechanical vibration of the drivers and the vibration caused by the airwave. Any others? Is decoupling of the driver from the enclosure a more effective way of dealing with the former?

2) What types of forces are in action which cause the resonances we are trying to eliminate? Compression, expansion, shear...? The sort of forces we are trying to counteract would determine what sort of bracing and materials would be more effective and efficient.

3) What sort of enclosures are we talking about here? Won't different cabinet designs be more subseptible to different sorts of resonances?

gedlee said:

The outside ribs won't do much since they are along the walls and as Jerry (and I) both point out stiffing the walls with ribs doesn't do a lot since its strictly a thickness problem.

I'll go back to my floor analogy. The floor supported on a single post will collapse unless there is a beam between the floor and the post. The beam carries the floor load and transfers this to the post.

Same deal with the ribs part of the panel. They span the distance between support points.

gedlee said:

Then consider the ribs across the corners. If the box is well glued then it won't skew, and skew doesn't generate any sound at all anyways, so they don't do much acoustically.

The really useful member then is the single brace across the enclosure - sound familiar?

Ok, the panels flex outwards and this will change the angle in the corner. If you lock the angle in the corner at 90* with a triangular brace, the panels can't flex outwards (or inwards for that matter).

Yes, the pole in the centre tries to stop this flex also, but the point halfway to the corner from the centre is now the problem - it will flex

zBuff said:John this isn't the first time that you've treaded on toes.

No, and it probably won't be the last...

Thanks for the tips though.

planet10 said:

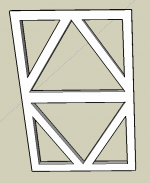

I do prefer to have more meat in my braces, and more randomness.

That one, done with 3/4" BB, all widths 1 1/2" except for the middle, which could be 2", would be very solid. And virtually transparent.

I'm just going to go ahead and give it a name - "The triangular Six-pack" and call it the official brace of this thread.

Attachments

gedlee said:The mechanical force due to the driver is very small compared to the pressure force from the driver... this force can be very large and simply dwarfs the mechanical reaction force.

If we look at it from the energy imparted into the cabinet ... a simplistic analysis.

The cone moves back & forth. 1/2 the energy umparted to the air goes into the cabinet, 1/2 goes out to the world for us to hear (ignoring energy coming back thru the cone). Conservation of energy says that energy equivalent to the total energy imparted to the air is imparted to the box (ignoring that lost as heat in the spider & voice coil)

So right off the bat we have ~2x the energy coupled directly into the box mechanically. Ludwig showed that at least some of the airspace energy can be turned to heat with damping, and if we have a vented box then significant energy is redirected outside. This reduces the energy inside the box to significantly less than half of that mechanicall coupled to the box.

So i don't think that the direct energy mechanically coupled into the box can be discarded so casually.

If it could then push-push would not work anywhere near as well as it does.

dave

gedlee said:The center board is kind of a waste since it is far stronger than needed, in the wrong plane, and the holes etc. do not help the acoustics.

With holes in it, and a mass suspended to it, the baffle is the weakest part of the box. The brace is strong because part of its purpose is to make the baffle an i-beam --- the baffle is rigidly coupled to both the driver & the back of the box, making the back part of the baffle. (and the top & bottom too). This also spreads the mechanically coupled energy to more of the box, decreasing the energy density imparted into the panels (reducing the liklihood that they will be excited)

At low frequencirs the brace is unseen. At frequencies on the order of the width of the box, we have a non-constant side-to-side distance making standing wave behaviour more complex (at just off centre it is also a useful place to hang damping where it will be most effective)

At higher frequencies it can be reflective, but leading edges are shaped to minimize this, and the cones are treated to improve opacity... that is a compromise i can live with, given its other benefits.

dave

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Multi-Way

- Discussion arising from Geddes loudspeaker