That’s something that would be cool to do but a ton of work. A lot of that work is figuring out the production bugs and errors. I have spent months on that to get the TPa3255 to its current production ready status. A major board respin would be just too much to take on for me at this point.

Have you tried driving the TPA3255 straight from the OPA1637 (just like on the front cover of the datasheet!)?

Would be a very nice design to merge the latest BTSB and the class-D part of the TPA3255 board....

Would be even nicer if there was some provision for a volume control !!

I would like the option to purchase with all the smd devices already soldered and as somebody already said even completed or supplied as a kit with all the through hole components as buying small quantities from Mouser can get really expensive.

I think the point has been made further up the thread that just purchasing a bare PCB and then going to Mouser to buy a one off set of components is not very cost effective. Volume pricing is so much cheaper for many of these components and shipping costs can be prohibitive for small purchases !

Add to that the pain of soldering ever smaller SMD components and it becomes even less attractive.

So for all these boards (TPA3255 and BTSB) I think a welcome compromise would be to supply the PCB with a full set of components required to finish the board. The SMD ones could be already soldered to the board leaving the (time consuming) Through Hole components for the purchaser to solder.

My TH BTSB has yet to arrive in the UK but I am certainly looking forward to assembling my amplifier with the BTSB as the front end.

James.

Add to that the pain of soldering ever smaller SMD components and it becomes even less attractive.

So for all these boards (TPA3255 and BTSB) I think a welcome compromise would be to supply the PCB with a full set of components required to finish the board. The SMD ones could be already soldered to the board leaving the (time consuming) Through Hole components for the purchaser to solder.

My TH BTSB has yet to arrive in the UK but I am certainly looking forward to assembling my amplifier with the BTSB as the front end.

James.

Hi I am thinking that the most cost efficient is bare PCB with bag full of components. And when I am looking for pictures I don't see any problem with soldering. The space between C and R is enough. So I agree with bushellj but I think that prepopulated SMD is redundant. Just my opinion.

BTW bushellj how long are you waitng on your package? Becase on last when I bought something from USA I had to wait about 5 moths xD because of CoVid, but it was 7 months ago.

BTW bushellj how long are you waitng on your package? Becase on last when I bought something from USA I had to wait about 5 moths xD because of CoVid, but it was 7 months ago.

With my soldering skills (and equipment) I am happy to solder components down to the SOIC-8 OPA1656 chips but anything smaller than this I can’t see the bloody things, never mind solder them !!

It is usually quite cheap to get the SMD stuff soldered and more expensive for the hand soldering of Through Hole and larger components such as capacitors and connectors. These bigger components though are very easy to solder by amateurs such as myself !!

Small runs may still be a problem but I don’t know how many of these boards are sold ??

It is usually quite cheap to get the SMD stuff soldered and more expensive for the hand soldering of Through Hole and larger components such as capacitors and connectors. These bigger components though are very easy to solder by amateurs such as myself !!

Small runs may still be a problem but I don’t know how many of these boards are sold ??

I am sorry I cannot provide "kits" with all parts needed to assemble the projects. It is a simple matter to order the parts from Mouser using the BOM provided (or sometimes a helpful soul will provide a link to a Mouser shopping cart). Mouser makes the "kit" for you and sends everything labeled with silkscreen component number and in individual bags. The labor to make such kits is immense and not something I can afford to or want to do.

You can also sign up for the RTR TPA3255 or SSR speaker protection pre-built boards in the GB's and save yourself the effort of making it. The TPA3255 is no small DIY task at 200+ SMT and through hole components, it requires experience with SMT, steady hands, good eyes, a hot air pencil and a hot plate. Plus binocular flip up magnifiiers or a stereo microscope helps a lot if you are over 40, good tweezers, solder paste, etc...

There are still boards available for the TPA3255 and speaker SSR's but I do not have any RTR BTSB's yet. If there is enough interest here, I can start a GB. Will need at least 40 boards in an interest list to do this.

You can also sign up for the RTR TPA3255 or SSR speaker protection pre-built boards in the GB's and save yourself the effort of making it. The TPA3255 is no small DIY task at 200+ SMT and through hole components, it requires experience with SMT, steady hands, good eyes, a hot air pencil and a hot plate. Plus binocular flip up magnifiiers or a stereo microscope helps a lot if you are over 40, good tweezers, solder paste, etc...

There are still boards available for the TPA3255 and speaker SSR's but I do not have any RTR BTSB's yet. If there is enough interest here, I can start a GB. Will need at least 40 boards in an interest list to do this.

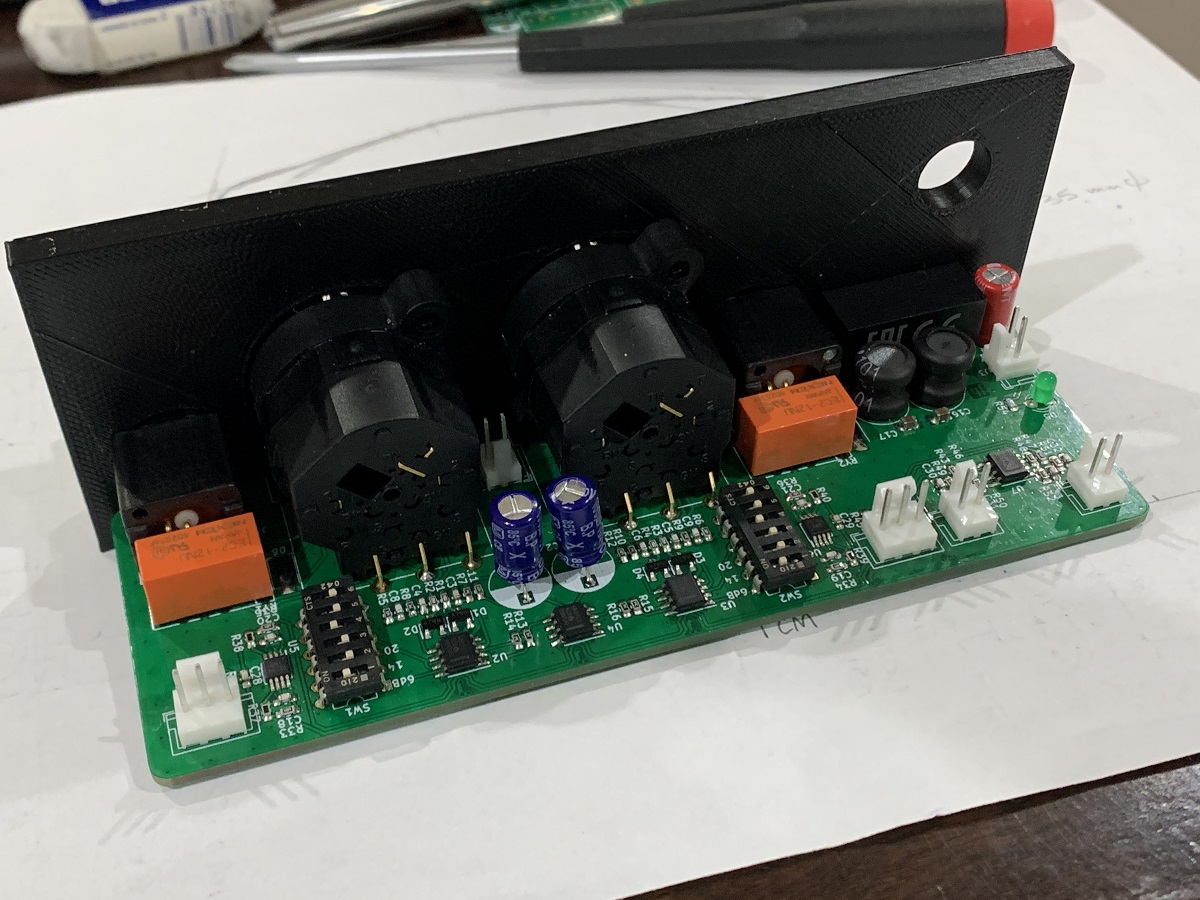

I made a 3D print of a test front/rear panel for the BTSB Panel Mount edition. I had concerns that the locking XLR tab would make it hard to slip all 4 jacks through the panel cutouts. But apparently, it is not an issue for a 4.7mm thick panel with 1mm chamfer on the back. This will make for a nice compact little bench tool to allow conversion from SE/Bal to SE & Bal.

Attachments

In depend on cost and time to arrive of package I am interested in two bare PCB.

X is there any way how to send the package duty free? Because in case that the price of package is less then 26 USD the package is without duty and taxes.

X is there any way how to send the package duty free? Because in case that the price of package is less then 26 USD the package is without duty and taxes.

I have received several requests via PM to offer the BTSB Panel Mount Edition, despite it being an SMT based board.

I just added the BTSB Panel Mount edition (v1.2P) to my shop. It’s available as SMT bare board only. You will need to be comfortable soldering 0603 parts. It’s not that hard if you use paste solder in a syringe. See my video on how here:

XRKaudio SMT Method Demo - YouTube

I just added the BTSB Panel Mount edition (v1.2P) to my shop. It’s available as SMT bare board only. You will need to be comfortable soldering 0603 parts. It’s not that hard if you use paste solder in a syringe. See my video on how here:

XRKaudio SMT Method Demo - YouTube

Last edited:

I use one of these (or similar). There are dozens of these cheap ones from Amazon, eBay or Aliexpress.

https://www.amazon.com/dp/B08T9KZNL...abc_6ZNES1VP9XM0PF63DHNN?_encoding=UTF8&psc=1

If you want to make it work even better, put the board on an old aluminum skillet on an electric hot plate. Heat the PCB to 120C - monitor with IR thermometer. Then applying the hot air rework pencil locally heats up a spot instantly and it flows better. Only spots that are heated by air go up to solder melt temp and this also helps reduce the exposure of the components to long periods of high temperatures.

https://www.amazon.com/dp/B08T9KZNL...abc_6ZNES1VP9XM0PF63DHNN?_encoding=UTF8&psc=1

If you want to make it work even better, put the board on an old aluminum skillet on an electric hot plate. Heat the PCB to 120C - monitor with IR thermometer. Then applying the hot air rework pencil locally heats up a spot instantly and it flows better. Only spots that are heated by air go up to solder melt temp and this also helps reduce the exposure of the components to long periods of high temperatures.

Haha... new SMT stunts for your fingers! 🙂

It’s actually quite fun to do. And in the long run, faster than TH as you don’t need to insert, solder , cut and flip board over and over all the time.

Here is a video of SMT soldering with just a hot plate and skillet (before I got a hot air rework tool):

SMT Reflow with Hotplate - YouTube

It’s actually quite fun to do. And in the long run, faster than TH as you don’t need to insert, solder , cut and flip board over and over all the time.

Here is a video of SMT soldering with just a hot plate and skillet (before I got a hot air rework tool):

SMT Reflow with Hotplate - YouTube

Last edited:

indeed🙂. Certainly looks faster as well.

Do you think it's possible to do the whole TPA3255 reference with this method?

Do you think it's possible to do the whole TPA3255 reference with this method?

Yes, that’s how I did the first one. I worked in sections, the on board buck converter first. Then the LDOs etc and checked that it powered up and made the 15v, 12v, then 3.3v as I went along. Then the front end opamps. Then the main TPA3255 and inductors and output filters. It’s a lot of parts so easier to work sections at a time. Tough to install 200+ parts in one sitting.

Good tweezers are a must. Here is what I have been using for past 10 years.

Techni-Tool 00-SA Strong Sharp Precision Swiss Tweezer 00 | JENSEN Tools + Supply

If you are over 40, you will also need flip up binocular magnifiers to see the parts:

https://www.amazon.com/dp/B07T4KPYN...abc_HDYNXAKSECWBR6CJ66MK?_encoding=UTF8&psc=1

Use these tips 21ga tapered nozzles for paste application:

https://www.amazon.com/dp/B07GLJZWL8/ref=cm_sw_r_cp_apip_bre4Ok2fwA2s1

And this no clean solder paste flows smoothly:

https://www.amazon.com/dp/B0195V1QEI?ref=ppx_pop_mob_ap_share

Good tweezers are a must. Here is what I have been using for past 10 years.

Techni-Tool 00-SA Strong Sharp Precision Swiss Tweezer 00 | JENSEN Tools + Supply

If you are over 40, you will also need flip up binocular magnifiers to see the parts:

https://www.amazon.com/dp/B07T4KPYN...abc_HDYNXAKSECWBR6CJ66MK?_encoding=UTF8&psc=1

Use these tips 21ga tapered nozzles for paste application:

https://www.amazon.com/dp/B07GLJZWL8/ref=cm_sw_r_cp_apip_bre4Ok2fwA2s1

And this no clean solder paste flows smoothly:

https://www.amazon.com/dp/B0195V1QEI?ref=ppx_pop_mob_ap_share

Last edited:

Very nice links XRK! I like the 21 AWG tapered nozzles. They remind me of the pipets back in the biochem lab when I was at the NCI (@NIH) way back when!

Best,

Anand.

Best,

Anand.

Last edited:

Very nice links XRK! I like the 21 AWG tapered nozzles. They remind me of the pipets back in the biochem lab when I was at the NCI (@NIH) way back when!

Best,

Anand.

Those 21ga nozzles are just the right size and make application very precise. Since they flex, you can push down slightly at an angle and it pinches off the solder paste into a bolus. Combined with the free flowing paste I linked, you can apply tiny little accurate traces on even 0.5mm pitch traces such as on the OPA1637.

The nozzles are not easy to find. They are listed under “Henna nozzles”. Basically used for non permanent body tattoo art work. Great for adhesive application too.

Hi guys.

Would i benefit from using an BTSTB?

My system goes DAC >Salas DCG3 (single ended preamp)>3255.

The 'DAC' whichever it may be is generally used SE due to the DCG3 being SE input only but I can configure most of my available dacs DIFF if needs be.

Would I benefit going from my DACs in DIFF into a BTSTB and converting to SE for the DCG3? What would I gain if anything? I have the DCG3 set with approx 3x gain so I would set the BTSTB to 0x. Seems a lot of work when I can just DAC SE out straight into DCG3. Or do I miss something?

Thanks!

Would i benefit from using an BTSTB?

My system goes DAC >Salas DCG3 (single ended preamp)>3255.

The 'DAC' whichever it may be is generally used SE due to the DCG3 being SE input only but I can configure most of my available dacs DIFF if needs be.

Would I benefit going from my DACs in DIFF into a BTSTB and converting to SE for the DCG3? What would I gain if anything? I have the DCG3 set with approx 3x gain so I would set the BTSTB to 0x. Seems a lot of work when I can just DAC SE out straight into DCG3. Or do I miss something?

Thanks!

- Home

- Group Buys

- BTSB Buffer - SE/Bal to SE/Bal Buffer GB