On the subject of thinner panels, do either of you gents have advice for cleanly cutting a piece along it's thin axis? I got some 1" xps sheets that I'd like to get it down to 1/2" without having to sand them and make a mess.

It'd be bit hard, but can be done, if you have patience (I don't have that patience). You have to fix the sheet vertically and cut it with a tight wire, pulling it down on both sides with equal pressure. If the wire is bit hot it'd be even easier.

I decided to practice paper stretching on an old 11x8 picture frame using A4 paper,boy am I glad ,what a pain in the neck!

If anything could go wrong ,it did,and still is.

It looks a right mess.

So I'm left with a bent 1mm panel card stuck to crumpled up A4 paper sort of stuck to a frame

The exciter is stuck on with pva,so is still not dry,but I could not wait and tried to take some measurements,would you believe it,the neighbour decided to replace a fence post attach to my house,unbelievable!

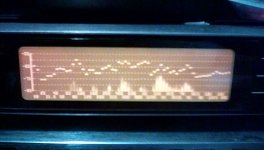

I had to have the mic about 1ft away hoping for a quiet spell,in the pic you can see the noise going on.

I have not done any serious listening yet ,but was pleased to hear plenty of LF and HF as the plot shows,strong output from 40 to 20 HZ,very similar to the canvas frame,but I believe it is more efficient.

I know the response is a bit lumpy ,but it's not as lumpy as the panel

Steve

If anything could go wrong ,it did,and still is.

It looks a right mess.

So I'm left with a bent 1mm panel card stuck to crumpled up A4 paper sort of stuck to a frame

The exciter is stuck on with pva,so is still not dry,but I could not wait and tried to take some measurements,would you believe it,the neighbour decided to replace a fence post attach to my house,unbelievable!

I had to have the mic about 1ft away hoping for a quiet spell,in the pic you can see the noise going on.

I have not done any serious listening yet ,but was pleased to hear plenty of LF and HF as the plot shows,strong output from 40 to 20 HZ,very similar to the canvas frame,but I believe it is more efficient.

I know the response is a bit lumpy ,but it's not as lumpy as the panel

Steve

Attachments

Disaster

Something not to heavy for the panel but with some dynamics.

Just the card panel on the left and the paper and card picture frame on the right, the microphone was placed in front of the right panel about 1m in distance.

Things start to buzz a bit when the LF starts about 4mins in.

But it is promising, if done right.

Steve

Something not to heavy for the panel but with some dynamics.

Just the card panel on the left and the paper and card picture frame on the right, the microphone was placed in front of the right panel about 1m in distance.

Things start to buzz a bit when the LF starts about 4mins in.

But it is promising, if done right.

Steve

Attachments

Something not to heavy for the panel but with some dynamics.

Just the card panel on the left and the paper and card picture frame on the right, the microphone was placed in front of the right panel about 1m in distance.

Things start to buzz a bit when the LF starts about 4mins in.

But it is promising, if done right.

Steve

The Bristol paper stretched over a frame, with all edges bent over and pasted to the sides, after wetting, and dried would become like a drum, but with the frame still intact. Once, it is cut off the frame, it is just a quite rigid paper, but won't act as the drum.

When you play on a drum, the vibrations that happen on the drum, surely go all the way to the edge, but never seen/heard those vibrations coming back toward the middle and cancelling the sound. Holding the edges of the panel/paper/diaphragm doesn't make the sound coming out it bad. Every commercial DML/BMR speaker maker does that.

If you have a free standard driver, and a piece of EPS, would you cut a disk to the diameter of that driver (including the surround) and paste it on top of the surround and hear what sound the disk would give, few meters away from it. (You can paste it without damaging the driver.) Maybe, later try a cardboard disk, instead of the EPS. And so on...

In the meantime, a talented self-taught guitarist playing solo with symphonic orchestra for your enjoyment.

I am reading some of the earlier posts in the thread and I see numerous mentions about how to test a panel/find nodes/resonant areas by supporting it horizontally at the corners and moving the exciter around to find the optimal sound. The MO for this seems to be for it to be "step 1", then people just affix their exciter and treat it like it's static from that point on. But then you move on to modifying, damping, framing, etc. to chase down and resolve unwanted qualities, all the while leaving the exciter put. Pardon my ignorance here but don't all of those further steps change the harmonics of the panel overall, and maybe shift the locations of the good and bad nodes on the substrate? Wouldn't you want to reconduct the same test after each modification step, and probably even try other exciters? Otherwise it seems like you're missing or ignoring possibly critical secondary/tertiary effects of your changes. Sure, you added more damping and checked your REW and now you see improvements in some areas overall but consequential reductions or lack of change in others. Why not play around with the exciter and see what happens rather than just being like "Well, I picked my exciter and it's location. Nothing I can do about it now" and convincing yourself that whatever negative side effects that occur in the process of improving other issues just have to be taken for granted? I mean, it's worth a shot, and if nothing good comes of it, put it back where it was right? I guess I am just surprised I haven't seen more people posting about doing this.

NG,

I myself am one of those that have advocated the idea of supporting the panel horizontally and moving the exciter (or exciters) around to find the be best position. But I for one certainly have never suggested that once you find the best location for a particular set of conditions (support locations, damping, etc) that you can assume it's also the best location for some other set of conditions. In fact, I completely agree with you that any change you make to the type or location of the supports, added damping, or frankly any modification to the panel whatsoever, is likely to change the location of the optimum position(s) for the exciters(s).

In my experimentation, I have done pretty much exactly as you suggest. every time I try a new panel material, or a new panel support, etc. I repeat the test of exciter positions, and usually different exciter models in each position.

Eric

Not such a disaster

This is probably the last recording of the card and paper panel before I take it apart.

The sound is pretty good,next, I'm thinking of gluing the card panel straight to the frame to see what happens.

Maybe.

Steve

This is probably the last recording of the card and paper panel before I take it apart.

The sound is pretty good,next, I'm thinking of gluing the card panel straight to the frame to see what happens.

Maybe.

Steve

Attachments

Jesus, dude. $22k? That better be real gold all over it. LOL

Acrylic plate, though. Dave's 2x4x1/4 plexi panels supposedly sounded amazing so I'm I'm starting to see a pattern here. Polycarbonates are dilefinitely on my short list for builds.

Jesus, dude. $22k? That better be real gold all over it. LOL

Thin gold foil can be bought very much cheaper. All these high-enders are just looking for the gullible.

By the way, gold foil can be pasted over a thin, but rigid material, especially near the centre, to get the high notes, and a thicker ring could be pasted at the edges, for example, even gypsum powder mixed with water painted over that ring to get the lows. But, you can get those high sounds with the bottom of a beer can.

Acrylic panel or honeycomb plexi-glass would give you somewhat suffocated higher sounds.

Negativeghostrider.

The land of OZ is exactly where the panel would have ended up if I hadn't managed to wrestle it to the ground and lie on it spead-eagled

If you look in the uploaded link,you will find albums by sedge,there you will see the offending panel lying on the table with a chunk missing on the right.

I managed to keep hold of that piece and glue it back on

Making your own foam cutter is another big job.

My get around is to thin the panel in the exciter area ,This is the primary radiation area,a bit like having a cone or small concave tweeter in the centre of the exciter area.

This gives more presence to voice and such in the room ,rather than coming from behind the panel.

XPS struggles to let mid and HF through the panel,so the thinner the better,but don't go too thin!

I use various items to give a smooth recess in that area.

Steve.

The land of OZ is exactly where the panel would have ended up if I hadn't managed to wrestle it to the ground and lie on it spead-eagled

If you look in the uploaded link,you will find albums by sedge,there you will see the offending panel lying on the table with a chunk missing on the right.

I managed to keep hold of that piece and glue it back on

Making your own foam cutter is another big job.

My get around is to thin the panel in the exciter area ,This is the primary radiation area,a bit like having a cone or small concave tweeter in the centre of the exciter area.

This gives more presence to voice and such in the room ,rather than coming from behind the panel.

XPS struggles to let mid and HF through the panel,so the thinner the better,but don't go too thin!

I use various items to give a smooth recess in that area.

Steve.

right is the 40cm 10mm thick panel with cone shape in centre

in this link you can see ,On the right is my eps HD 10mm x40cm panel,you can see the small carved cone in the centre.

Steve

in this link you can see ,On the right is my eps HD 10mm x40cm panel,you can see the small carved cone in the centre.

Steve

This is the primary radiation area,a bit like having a cone or small concave tweeter in the centre of the exciter area.

This gives more presence to voice and such in the room ,rather than coming from behind the panel.

Have you thought of how to contain the sound coming from behind and/or use it directed to front some way?

Negativeghostrider.

Making your own foam cutter is another big job.

My get around is to thin the panel in the exciter area ,This is the primary radiation area,a bit like having a cone or small concave tweeter in the centre of the exciter area.

This gives more presence to voice and such in the room ,rather than coming from behind the panel.

XPS struggles to let mid and HF through the panel,so the thinner the better,but don't go too thin!

I use various items to give a smooth recess in that area.

Steve.

I have a camping saw that's just a stretch of abrasive cable with a ring on each end. I may just make a bough out of some pipe and 2 90 degree bends and string the cable saw between. If I put felt pads on the ends of the bends and set the cable height at one inch I can rest the ends on the surface the foam is sitting on and run the saw horizontally, like the things bakers use to level cakes on those dessert competitions. Should help keep the cut uniform.

I'll definitely try your recessed method too. I can see how it would help with the initial transfer but the overall thickness may still cause diminished SPL. All part of the testing process though, right? Wheeee!

Have you thought of how to contain the sound coming from behind and/or use it directed to front some way?

Interesting idea. As opposed to just putting a spline on the back, what if one was to straight-up embed the exciter. Cut a recess deeper than the exciter, glue it in, then cap off the back with the removed material. It would have to be thick foam, and heat would probably kill the exciter pretty quickly. Maybe a patch of aluminum foil something that would reflect the sound/transfer the vibrations back to the panel but still conduct some of the heat outwards like a heat sink?

I just remembered that I did intend to make inward dome into a wave guide but decided to take the easy root with an concave dome shape.

It would be so much easier for a manufacturer to mould the panel with the wave guide from scratch rather than trying to it bodge afterwards.

I try to keep the back as open as possible,the only problem is the exciter itself,which has noise issues and phase problems and obviously covering a crucial part of the back.

Good luck with the cutting.

Steve

It would be so much easier for a manufacturer to mould the panel with the wave guide from scratch rather than trying to it bodge afterwards.

I try to keep the back as open as possible,the only problem is the exciter itself,which has noise issues and phase problems and obviously covering a crucial part of the back.

Good luck with the cutting.

Steve

The sound coming from behind of a DML must be much louder than sound coming from the front?

When you place a normal driver cone facing upwards on a table and connect it to a amp, the table top too becomes speaker, even though it is only touching the magnet, not the cone, or the VC.

When you place a normal driver cone facing upwards on a table and connect it to a amp, the table top too becomes speaker, even though it is only touching the magnet, not the cone, or the VC.

Last edited:

Chdsl.

If you are using something like 1inch XPS then yes, but it will have peaks and troughs at the rear in the response,

because of the exciter itself.

I heard this when they first demonstrated the podiums, you could walk round the back and it sounded like there was more life to the sound.

I tried this at home ,but I didn't take long to realise there was something wrong .

Try it yourself and see what you think.

Steve

If you are using something like 1inch XPS then yes, but it will have peaks and troughs at the rear in the response,

because of the exciter itself.

I heard this when they first demonstrated the podiums, you could walk round the back and it sounded like there was more life to the sound.

I tried this at home ,but I didn't take long to realise there was something wrong .

Try it yourself and see what you think.

Steve

- Home

- Loudspeakers

- Full Range

- A Study of DMLs as a Full Range Speaker