Three interesting quotes, which can be used in creating an outstanding DML panel:

The diaphragm is a three-layer sandwich, two very thin outer foils and in between there is a plastic with special (oops!) properties.

The rigidity of this thin flexible diaphragm decreases from the center to the outside at an equal ratio, similar to the basilar membrane in our ear.

High frequencies expire quickly in the inner area of the membrane, while lower frequencies move concentrically to the edge; where they encounter a matched termination and, a star-shaped absorptive damper; which, prevent reflections from returning from the edge.

(Everything is OK, except for the star-shaped absorptive damper. It'd better to have a full circle, without any edges.)

The diaphragm is a three-layer sandwich, two very thin outer foils and in between there is a plastic with special (oops!) properties.

The rigidity of this thin flexible diaphragm decreases from the center to the outside at an equal ratio, similar to the basilar membrane in our ear.

High frequencies expire quickly in the inner area of the membrane, while lower frequencies move concentrically to the edge; where they encounter a matched termination and, a star-shaped absorptive damper; which, prevent reflections from returning from the edge.

(Everything is OK, except for the star-shaped absorptive damper. It'd better to have a full circle, without any edges.)

Last edited:

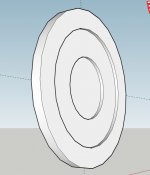

A 3 thickness composite disk. If it has to be boxed/framed, the outer round edge should be surrounded softly, elastically, more or less like a standard cone. If any waves that hit the edges and turn back, they won't go far. The different thicknesses would vibrate differently. Think of this as glasses filled in different levels, so they'd give different sound, when knocked on.

The cross section of disk could also be tapered like a cheese wedge, with the central circle flat. The cheese wedge look is even better. Can't draw it in Sketchup.

The cross section of disk could also be tapered like a cheese wedge, with the central circle flat. The cheese wedge look is even better. Can't draw it in Sketchup.

Attachments

Last edited:

My exciters should be showing up any day now and I have started collecting substrates for testing, including some sheets of acrylic, the flourescent lighting panel components I was asking about, assorted Ply and manufactured panels, and some Foamular 150.

Question about the foam - I know that the sanding and application of the PVA/water mix is the de facto approach. Does one just sand the front and rear surfaces, or the edges as well? And why sand off the heat-sealed skin if you're just going to re-skin with the PVA, at least on the surface that's going to have the exciter attached? It feels like you're taking off a shirt just to put on another shirt. Is the PVA skim coat just a more desirable surface for response vs SPL?

Thanks! Sorry again if some of my questions and concepts have already been covered but after having read the entirety of this thread is less than 72 hours I'm sure I have just forgotten or glazed over some things. Bottom line is that I am captivated by everything you folks have done. Looking forward to getting some things up and running, and certainly experimenting with multi-substrate/size arrays with 2 way crossovers.

Question about the foam - I know that the sanding and application of the PVA/water mix is the de facto approach. Does one just sand the front and rear surfaces, or the edges as well? And why sand off the heat-sealed skin if you're just going to re-skin with the PVA, at least on the surface that's going to have the exciter attached? It feels like you're taking off a shirt just to put on another shirt. Is the PVA skim coat just a more desirable surface for response vs SPL?

Thanks! Sorry again if some of my questions and concepts have already been covered but after having read the entirety of this thread is less than 72 hours I'm sure I have just forgotten or glazed over some things. Bottom line is that I am captivated by everything you folks have done. Looking forward to getting some things up and running, and certainly experimenting with multi-substrate/size arrays with 2 way crossovers.

Last edited:

A few years back now I had the idea of removing the eps skin to try and remove the characteristic sound it produced and replacing it with a far better sounding surface.

I posted my findings on the audiocircle NXT RUBBISH THINK AGAIN forum I used to use.

Over the years people seem to have got the idea that coating the panel in pva was to dampen the panel sound,this was the last thing I wanted to do ,and the opposite is true.

Steve

I posted my findings on the audiocircle NXT RUBBISH THINK AGAIN forum I used to use.

Over the years people seem to have got the idea that coating the panel in pva was to dampen the panel sound,this was the last thing I wanted to do ,and the opposite is true.

Steve

Atmos.

Atmos is produced electronically when mixing,using directional ,normal pistonic speakers of similar design,the reflections are beamed towards the listener.

An omnidirectional speaker would probably destroy the sound scape the engineers were trying create.

Steve

Atmos is produced electronically when mixing,using directional ,normal pistonic speakers of similar design,the reflections are beamed towards the listener.

An omnidirectional speaker would probably destroy the sound scape the engineers were trying create.

Steve

A few years back now I had the idea of removing the eps skin to try and remove the characteristic sound it produced and replacing it with a far better sounding surface.

I posted my findings on the audiocircle NXT RUBBISH THINK AGAIN forum I used to use.

Over the years people seem to have got the idea that coating the panel in pva was to dampen the panel sound,this was the last thing I wanted to do ,and the opposite is true.

Steve

Thanks. Since it's so cheap I am planning on experimenting with, and hopefully taking measurements of, all combinations of sanded, unsanded, and sealed surfaces. I'm guessing with sanded and unsealed I may have to get creative with securing the exciters to the surface.

Was it you that had dog damage to some panels and had to glue them back together? I got 2x2' xps panels and thought I may want to combine some to make a 2x4 at some point but I couldn't remember if the ones I saw were eps and/or what adhesive was used.

Atmos.

Atmos is produced electronically when mixing,using directional ,normal pistonic speakers of similar design,the reflections are beamed towards the listener.

An omnidirectional speaker would probably destroy the sound scape the engineers were trying create.

Steve

This was my same thought/concern - that the bipolar/diffuse nature would blow out the object staging. At the same time sometimes despite optimization and critical speaker-to-sweet-spot placement some content seems to just lack a nice immersive stage. I thought integrating some DMLs would maybe give me more of that depth and complexity. I'm sure some of it comes down to my room acoustics, and the mixing process of the source material as well. I don't see many people running bipoles in atmos in general, except maybe as surrounds in a 5.2.6 with a higher grade of processing than my Marantz. If I stumble on some panel designs that I like well enough I may experiment with them as FL/FR/RR/RL using some atmos demo tracks just for grins, but I agree that the height and center channel would probably suffer far beyond practicality.

A different density same material disk panel speaker of the 70s.

Here's where a guy gets sound out of a polystyrene plate. The important part is how the low sounds appeared, when he picked it up, that is, fixing and damping the edges.

There's also a youtube video, where the DIYer had scraped the middle out, so polystyrene panel had 2 different thickness, which gave some sort of full range sound. Can't find it atm.

Anyway, I am not just talking theory. I have a lot of polystyrene sheets of different thicknesses, shapes and honeycomb cardboard and some hardboard, leftover from packaging, and some left over furniture panels. I also have two full range 6.5" drivers, standard cone drivers. I haven't damaged them by cutting off the cone or anything, but I fix the driver on to the panels to check/test. Sometimes, pasting a small paper tube(s) to the panel, so it touches the cone. I am not spending any money on these. I can't remember, when I bought the speakers, but they didn't cost much.

I took time to read through the long thread, there had been lot of testing, but no one had found a solution for a speaker that might allow the standard cone speakers to be put aside.

Most of the panel/DML/BMR speakers in the market are "high-end," meaning high priced, so practically useless. Can get Sony APms or Technics SB-X.. quite cheaply, but seeing how the flat panels in them are made, don't feel like doing so. The Technics are actually very pretty, though 🙂 The attached pair is just $180.

Here's where a guy gets sound out of a polystyrene plate. The important part is how the low sounds appeared, when he picked it up, that is, fixing and damping the edges.

There's also a youtube video, where the DIYer had scraped the middle out, so polystyrene panel had 2 different thickness, which gave some sort of full range sound. Can't find it atm.

Anyway, I am not just talking theory. I have a lot of polystyrene sheets of different thicknesses, shapes and honeycomb cardboard and some hardboard, leftover from packaging, and some left over furniture panels. I also have two full range 6.5" drivers, standard cone drivers. I haven't damaged them by cutting off the cone or anything, but I fix the driver on to the panels to check/test. Sometimes, pasting a small paper tube(s) to the panel, so it touches the cone. I am not spending any money on these. I can't remember, when I bought the speakers, but they didn't cost much.

I took time to read through the long thread, there had been lot of testing, but no one had found a solution for a speaker that might allow the standard cone speakers to be put aside.

Most of the panel/DML/BMR speakers in the market are "high-end," meaning high priced, so practically useless. Can get Sony APms or Technics SB-X.. quite cheaply, but seeing how the flat panels in them are made, don't feel like doing so. The Technics are actually very pretty, though 🙂 The attached pair is just $180.

Attachments

Yes it was I ,having an excitable dog in a room full of large eps panels is not a good idea!

I have only used 5mm or less xps,as the hf rolls off heavily with thicker xps material ,as shown in the parts express measurements.

Xps also traps the moisture in so pva would not be the best choice,I haven't tried epoxy but the tech ingredients guy does a video using epoxy as a coating which could be interesting.

Gluing the exciter on to the scuffed xps surface with pva will be no problem and a little help from a not too hot hair dryer will shorten drying time,but remember that it will take at least a few days before pva hardens enough to produce a good HF response.

The tech ingredients guy also liked the the sound of the scuffed surface which I think he said acts as a room sound deadening panel?

I have a large scuffed eps panel that I have not coated yet ,but find the sound a little too soft for me,but others might like.

Stevd.

I have only used 5mm or less xps,as the hf rolls off heavily with thicker xps material ,as shown in the parts express measurements.

Xps also traps the moisture in so pva would not be the best choice,I haven't tried epoxy but the tech ingredients guy does a video using epoxy as a coating which could be interesting.

Gluing the exciter on to the scuffed xps surface with pva will be no problem and a little help from a not too hot hair dryer will shorten drying time,but remember that it will take at least a few days before pva hardens enough to produce a good HF response.

The tech ingredients guy also liked the the sound of the scuffed surface which I think he said acts as a room sound deadening panel?

I have a large scuffed eps panel that I have not coated yet ,but find the sound a little too soft for me,but others might like.

Stevd.

A different density same material disk panel speaker of the 70s.

Here's where a guy gets sound out of a polystyrene plate. The important part is how the low sounds appeared, when he picked it up, that is, fixing and damping the edges.

By all appearances it's not his manipulation of the bowl or any damping effect that changes the sound, its the depth of the magnet stack. When he first sets it on the table the magnets are deep in the coil. You hear a slight sound which gets louder as he lifts the bowl. That's the field changing in the coil tube. Shortly thereafter when he's holding up the bowl sideways and sliding the magnets in and out and you hear the sound level oscillate as the stack approaches and passes the sweet spot. At least that is my interpretation.

Post that other video if you find it. It would be cool to see. I know Jmatt experimented with cnc carved eps/polystyrene back in the early pages of the thread but never really spoke about the results that I recall. Post 799/800. And the Bertagni speaker in post 667 also had molded or carved EPS.

Last edited:

I have only used 5mm or less xps,as the hf rolls off heavily with thicker xps material ,as shown in the parts express measurements.

Why are you (and others) consider Parts Express as the main knowledge behind the DML panels? Isn't Part Express the owner of Dayton Audio?

Post that other video if you find it. It would be cool to see. I know Jmatt experimented with cnc carved eps/polystyrene back in the early pages of the thread but never really spoke about the results that I recall. Post 799/800. And the Bertagni speaker in post 667 also had molded or carved EPS.

Will do that. Searching for it.

Thank you for pointing at these posts. You kept notes. 🙂

DMLBES is mostly right.

When you get the EPS/XPS, and if you have a free normal driver, just put it on it and tell us how you hear the sound. Your subjective feeling. Thinner the panel, better sound or otherwise. Thanks.

Also, if you have a passive radiator, just put the "exciter" on the radiator panel. From the back and from the front.

Last edited:

Will do that. Searching for it.

Thank you for pointing at these posts. You kept notes. 🙂

DMLBES is mostly right.

When you get the EPS/XPS, and if you have a free normal driver, just put it on it and tell us how you hear the sound. Your subjective feeling. Thinner the panel, better sound or otherwise. Thanks.

No worries. It didn't take too much searching. I was just reading those sections a few hours ago LOL

I am going to be building my first panels next week so I am sure I will figure a lot of this out firsthand soon.

I also found this video - SIMPLE SPEAKER with Neodymium Magnet , Homemade Headset | Magnetic Games - YouTube where dude makes some headphones like the guy did with the bowl speaker. It's kind of worthless though because there's zero commentary or anything about the process.

I also found this video - SIMPLE SPEAKER with Neodymium Magnet , Homemade Headset | Magnetic Games - YouTube where dude makes some headphones like the guy did with the bowl speaker. It's kind of worthless though because there's zero commentary or anything about the process.

Sure, useless. 🙂

But, when we were small kids, we used two cups and a string to make a telephone line.

You might've seen flat speakers like this.

Interesting. Tapered and offset in its frame, and an isolated 2 way design. I was wondering about doing something like this (2 panels in one unit, not the taper part) but I figured there would need to be more difference in the size of the high/mid-low panels, and possibly more damping on one than the other.

Sure, useless. 🙂

But, when we were small kids, we used two cups and a string to make a telephone line.

You might've seen flat speakers like this.

I didn't mean the product was useless in application, I meant the video was useless more-or-less on an instructional level vs the bowl one you posted. 😅 There's no discussion of the materials or process, sans a little in the information drop down. It's pretty straightforward if you understand moving coil basics but if you don't you're like "OK. There's circles of wire and a round thing and it makes sound from your phone."

Jmatt.

I intend during lockdown to try some brown paper on a frame to see what happens.

I have an old frame I used to mount a 5mm xps sheet to,the sound wasn't good so I dumped it in the garden,I've found what's left of it and cleaned off the green algae,amazing what a good scrub and bleach can do.

The smallest dimension is going to be 10 or 12inches depending upon where I glue the paper.

I'm not expecting much but am always willing to be surprised.

I think I might try gluing the exciter on the paper as tight as possible first ,then testing the panel again after shrinking.

If all goes well I will then attempt to attach a 2mm balsa or card panel ,not sure which yet.

The picture of the frame,needs a bit of drying out before cutting.

Steve

I intend during lockdown to try some brown paper on a frame to see what happens.

I have an old frame I used to mount a 5mm xps sheet to,the sound wasn't good so I dumped it in the garden,I've found what's left of it and cleaned off the green algae,amazing what a good scrub and bleach can do.

The smallest dimension is going to be 10 or 12inches depending upon where I glue the paper.

I'm not expecting much but am always willing to be surprised.

I think I might try gluing the exciter on the paper as tight as possible first ,then testing the panel again after shrinking.

If all goes well I will then attempt to attach a 2mm balsa or card panel ,not sure which yet.

The picture of the frame,needs a bit of drying out before cutting.

Steve

Attachments

Why are you (and others) consider Parts Express as the main knowledge behind the DML panels? Isn't Part Express the owner of Dayton Audio?

I don't really know what you mean by this,but parts express sell the exciter negativeghostrider has ordered and they have a FR plot of the xps material he is thinking of using ,I just thought this might be helpful.

Steve.

- Home

- Loudspeakers

- Full Range

- A Study of DMLs as a Full Range Speaker