Hi guys/gals!.... there are just SO MUCH systems to aspire to!!!...

Been a lurker for a while, and have read pretty much every thread here, taken me about 6 months

I want to build some harveys or larger frugal spawns, but I'll start with something simple first.

So I think I'll be whippin these up for my first speaker project, as they are basic rectangles and small.

Based on Planet10 fe127 hifi fonken tuned floorstander MarkII, only it was done with 15mm material, but I could only source 12mm, but kepping the internal dimesions the same.

picked up some 12mm marine ply as best I could 3 out of 25 sheets with no knots front/back.

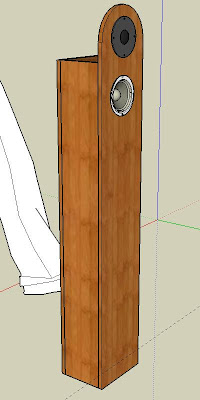

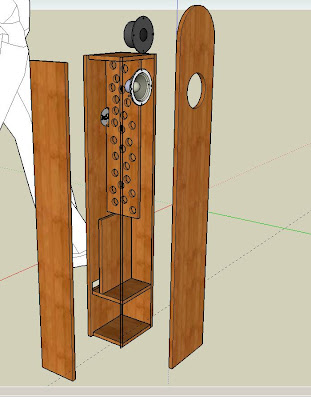

I have done a quick sketchup of the design, these are designed for full range single driver fostex fe127, and thats what I'm going to fit in them, but I also thought I might leave a curved top on it to add a tweeter at some stage if the highs did not get there with the fe127e's.

2 x fe127's on order, but I had some 100mm paper drivers with whizzer's sitting round I thought I'd throw them in till the fe's turn up.

sketchup of speakers:

Back:

front:

Exploded:

Gluing the holey brace in place:

Another angle:

finish will probably be nude wood, with some sanding priner? and a light stain with a couple of clear coats.

My edges are VERY rough as I used a circular saw to cut them out and a few peaks and troughs around the edges I think my next version I'll take the cut list to my wood supplier and get them to cut them out more exact than what I've done so far. I could have used a straight edge clamped to the wood thinking about it in hindsight, but I just cut em out. might do that next time, but anyway, will have these glued together and ready for testing by the weekend.

I think my next version I'll take the cut list to my wood supplier and get them to cut them out more exact than what I've done so far. I could have used a straight edge clamped to the wood thinking about it in hindsight, but I just cut em out. might do that next time, but anyway, will have these glued together and ready for testing by the weekend.

Been a lurker for a while, and have read pretty much every thread here, taken me about 6 months

I want to build some harveys or larger frugal spawns, but I'll start with something simple first.

So I think I'll be whippin these up for my first speaker project, as they are basic rectangles and small.

Based on Planet10 fe127 hifi fonken tuned floorstander MarkII, only it was done with 15mm material, but I could only source 12mm, but kepping the internal dimesions the same.

picked up some 12mm marine ply as best I could 3 out of 25 sheets with no knots front/back.

I have done a quick sketchup of the design, these are designed for full range single driver fostex fe127, and thats what I'm going to fit in them, but I also thought I might leave a curved top on it to add a tweeter at some stage if the highs did not get there with the fe127e's.

2 x fe127's on order, but I had some 100mm paper drivers with whizzer's sitting round I thought I'd throw them in till the fe's turn up.

sketchup of speakers:

Back:

front:

Exploded:

Gluing the holey brace in place:

Another angle:

finish will probably be nude wood, with some sanding priner? and a light stain with a couple of clear coats.

My edges are VERY rough as I used a circular saw to cut them out and a few peaks and troughs around the edges

I'm building my first fullrangers at the moment, and experiencing the same problems with getting neat cuts. I found this today, the sawboard which looks like a great idea, and will use on my next project. Your project looks great, don't you just hate having to wait to hear how they sound though !

That does look like a good tool. I am going to build at least one pair of Metronomes in the fall and one thing I'm concerned about is getting the angle cuts to all be the same, so maybe the sawboard with an angled cleat at one end will give me consistent cuts.

Use a router with a pattern following bit and straight edge to take out the peaks and valleys, or at least the peaks. Or for square sided boxes, glue it up with the peaks protruding over the side and use the side as the straight edge, with a flush cut bit.

Use a router with a pattern following bit and straight edge to take out the peaks and valleys, or at least the peaks. Or for square sided boxes, glue it up with the peaks protruding over the side and use the side as the straight edge, with a flush cut bit.

finish will probably be nude wood, with some sanding priner? and a light stain with a couple of clear coats. [/B]

Nice work! You'll be shocked at the quality of sound you'll get from the Fonkens. Re the finish, this might be of interest to you: one of the late, great Terry Cain's favoured methods of finsihing birch (& marine) ply:

http://www.diyaudio.com/forums/showthread.php?postid=1247866#post1247866

zacster said:

Use a router with a pattern following bit and straight edge to take out the peaks and valleys, or at least the peaks. Or for square sided boxes, glue it up with the peaks protruding over the side and use the side as the straight edge, with a flush cut bit.

Don't worry about getting perfect cuts with a saw. As has been said, use a straight cut or a pattern-following router bit.

Doug

how brilliant is that!... a saw board...

just did a google and found a couple of sites but this was a good explination:http://members.aol.com/woodmiser1/sawbd.htm

gonna build one tonight and test it out on speaker2

that finishing technic looks tops! going to try that too.

spellings a bit off, posting on my pda

just did a google and found a couple of sites but this was a good explination:http://members.aol.com/woodmiser1/sawbd.htm

gonna build one tonight and test it out on speaker2

that finishing technic looks tops! going to try that too.

spellings a bit off, posting on my pda

You don't realize how small these are until you stand next to them... 12mm material is fine... Chris & i sort of decided to standardize on 15mm for most everything so we could justify buying a lift at a time (and then they ran out of 15 for a bit) So we are now working thru a lift of 12.

Here is a picture of the original build of these for inspiration, now residing in NY, NY

dave

Here is a picture of the original build of these for inspiration, now residing in NY, NY

dave

Attachments

Scottmoose said:Now for speakers, especially floorstanders, those are cute.

and compared to the "classic" Fonken, almost any member of this or the MLVoigt family are an easy build.

what this set of pictures doesn't fully reveal is the nice wrap-around grain matching the small enclosure size allowed

update:

almost finished one box, just got to find some 1/2" cotton/felt carpet underlay or something.

I have plenty of polyester 'wadding' , I used to make my bass traps, it's around 10mm thick, and fairly light/hollow, ie you can blow through it.

ie like this stuff:

Will that do for stuffing, ie glue it down to the insides? or am I better off getting something more dense like carpet underlay to glue to the sides, plus some polyester wadding jammed in the free air sections...

Also what do people do if they want to remove the back and do some tweaking?, ie If I glue the lot together & find it's too muffled, I will need to remove the back or front to remove wadding, etc...

just clamped the front/back on to see how it's going to look before I stuff it & lose it up.

Bit fuzzy, but internals:

Back:

Front:

I guess if I don't glue the front on, but clamp it together with a few clamps and test it out, then I can adjust the fill till I think it's right, then seal it up when I'm done...

almost finished one box, just got to find some 1/2" cotton/felt carpet underlay or something.

I have plenty of polyester 'wadding' , I used to make my bass traps, it's around 10mm thick, and fairly light/hollow, ie you can blow through it.

ie like this stuff:

Will that do for stuffing, ie glue it down to the insides? or am I better off getting something more dense like carpet underlay to glue to the sides, plus some polyester wadding jammed in the free air sections...

Also what do people do if they want to remove the back and do some tweaking?, ie If I glue the lot together & find it's too muffled, I will need to remove the back or front to remove wadding, etc...

just clamped the front/back on to see how it's going to look before I stuff it & lose it up.

Bit fuzzy, but internals:

Back:

Front:

I guess if I don't glue the front on, but clamp it together with a few clamps and test it out, then I can adjust the fill till I think it's right, then seal it up when I'm done...

stevodude said:update:

almost finished one box, just got to find some 1/2" cotton/felt carpet underlay or something.

I have plenty of polyester 'wadding' , I used to make my bass traps, it's around 10mm thick, and fairly light/hollow, ie you can blow through it.

ie like this stuff:

Will that do for stuffing, ie glue it down to the insides? or am I better off getting something more dense like carpet underlay to glue to the sides, plus some polyester wadding jammed in the free air sections...

Also what do people do if they want to remove the back and do some tweaking?, ie If I glue the lot together & find it's too muffled, I will need to remove the back or front to remove wadding, etc...

just clamped the front/back on to see how it's going to look before I stuff it & lose it up.

Bit fuzzy, but internals:

Back:

Front:

I guess if I don't glue the front on, but clamp it together with a few clamps and test it out, then I can adjust the fill till I think it's right, then seal it up when I'm done...

Steve, the problem with "tuning" a plywood box this small with the clamps still on, is that they'll very likely change the tuning of the box, possibly substantially.

You might be better off using packing tape - really! I think of it as adjustable, self-adhesive, disposable band clamps

Steve what you need to do is make two front baffles out of sturdy but CHEAP material and screw them on, rather than gluing. Once you're through with the tweaking, just make two good fronts and glue them into place.

Do this to the fronts rather than the backs, so that if needed, you can alter the driver position.

cheers

Doug

Do this to the fronts rather than the backs, so that if needed, you can alter the driver position.

cheers

Doug

stevodude said:OK thanks for that, I think I'll try some duct-tape band clamps

also should I put a 'notch filter' ito go with these box's?...

FWIW, I'm not a big fan of notch filters at all, but YMMV - at the very least, I'd suggest listening to them both seriously and casually (background) for at least several days before deciding. If anything, in consideration of the high Baffle Step loss frequency such a narrow enclosure is likely to enjoy, you might want to consider a BSC fliter. No doubt other builders can point you to formulas or on-line calculators to assist, should the need become apparent.

Since I recall from your first post that the FE127's are "on order", ensure that they are well broken in (i.e. several hundred hours of not to gentle playing) before critically assessing the tonal balance, articulation and dynamics.

Out of the box, they can be less than you expected, and premature and excessive "correction" can ultimately take them to a dark and bad place.

yea, that is correct from what I've heard, best to let em 'run in' for a bit, no problems here

Drivers should turn up sometime this week, hopefully tomorrow... freight in this part of the country is somewhat dodgy. I can order stuff from Hong Kong that can turn up within 3 days, yet something from Brisbane ( a smidgen under 1000km) can take 2 weeks...

I basically will be doing a simple wool/felt dense underlay on the backing/walls and basic polyester fill, leaving the port area free, box up and test for a while, and while thats 'curing' start on my dual frugal horns and probably some style of power tube woofers ie those 8 foot kind

and probably some style of power tube woofers ie those 8 foot kind  , but we won't go there yet, getting ahead of myself

, but we won't go there yet, getting ahead of myself

My parents are turning up later this week from NZ and haven't seen them for a couple of years, so I'm sure to have a yarn with 'the old man' in the shed about speakers/audio etc... bound to be some alcohol involved somewhere in the process... probably as soon as they get here hopefully get them semi finished for some sound'n'beer testing

hopefully get them semi finished for some sound'n'beer testing  hehehe

hehehe

And after some extensive run-in I might do the mods if needed.

I'm exited!... damn freight taking so long

Drivers should turn up sometime this week, hopefully tomorrow... freight in this part of the country is somewhat dodgy. I can order stuff from Hong Kong that can turn up within 3 days, yet something from Brisbane ( a smidgen under 1000km) can take 2 weeks...

I basically will be doing a simple wool/felt dense underlay on the backing/walls and basic polyester fill, leaving the port area free, box up and test for a while, and while thats 'curing' start on my dual frugal horns

My parents are turning up later this week from NZ and haven't seen them for a couple of years, so I'm sure to have a yarn with 'the old man' in the shed about speakers/audio etc... bound to be some alcohol involved somewhere in the process... probably as soon as they get here

And after some extensive run-in I might do the mods if needed.

I'm exited!... damn freight taking so long

received my 127's on monday and wacked one in to see how they go...

Not very impressive on initial listen with single driver, but then I haven't packed the enclosure yet, so sounded thin, volume was limited compared to my cheapo desktop speakers, but front panel is not sealed properly yet, guess I should be patient and do the stuffing & seal properly hehehe...

hehehe...

Not very impressive on initial listen with single driver, but then I haven't packed the enclosure yet, so sounded thin, volume was limited compared to my cheapo desktop speakers, but front panel is not sealed properly yet, guess I should be patient and do the stuffing & seal properly

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Full Range

- fonken floorstanders mkII in progress