No problem Tom, your amp is worthy of the praise it gets. Here's a picture of the speakers it was driving at the Wigwam Show - you get an idea of the size of the room. Now getting started on the new preamp🙂

Hmm, sometimes I wonder why speaker measurements are taken on axis when people are listening off axis.

so both you and your brothers vocabulary in the way the amplifier sounds is exceptional?! really??....what does exceptional sound like?

for the love of ... can people please......... expand your vocabulary WHAT DOES THE AMP SOUND LIKE....what do you like about its sound?? what don't you like about its sound??!! please make references to what musical instruments sound like...oh wait you prob never been too or heard REAL MUSICAL instrument! ...

well Thanks anyways for the useless review LOL...

Sometimes the it expresses exactly what it heard. Very careful reviewers/auditors are hard to find. It really takes dedicated effort to be able to get trained to the point where you can point out many things. For example, a long time ago, I could choose the more preferred listening of music consistently on my system by comparison. Now I can just start playing any track and know whether it is the right polarity. Once in a while I check my reference table, and the choice is 99% consistent.

Sometimes the it expresses exactly what it heard. Very careful reviewers/auditors are hard to find. It really takes dedicated effort to be able to get trained to the point where you can point out many things.

The fundamental problem I have with many hifi reviewers is that they use vocabulary that has no meaning or is very ambiguous at best. In the 1980ies and 1990ies, everybody was into veil-lifting. "It is as if a veil has been lifted." What does that mean? If I put two in parallel, will they lift two veils or only 1.414 veils? I'm confused. In the late 1990ies, I was reading High Fidelity, a Danish hifi magazine. It was actually pretty good. It was a good mix of reviews of equipment, music, as well as DIY articles. One of their advertisers was Dali, the speaker company. Wouldn't you know it?! All reviews of Dali speakers were glowingly positive. But I'm sure that was just a coincidence. The reviewers were unbiased, I'm sure. Yes. That was sarcasm.

These days, I gather we're onto describing hifi using terms such as "musicality", "tempo", "speed" (isn't that the same as tempo?), "timing", and other nonsensical terms. Does my car stereo have better tempo if I drive faster?

People use the same terms to describe different things. In some cases, you hear people describing the same sound, say a high-Q resonance peak from the cone breakup on a metallic cone driver, in polar opposite terms. Some will call it harsh and others will call it precise. A frequency sweep will tell you what it is so you can go and fix it.

Then you add the known issues with sighted tests. Olive & Toole showed at Harman Kardon how people prefer hifi equipment that looks expensive, has a high price tag, or looks pretty. In the sighted trials, the preferences of the listeners changed once the price tags were removed. In a blind trial, their preferences for the same set of equipment changed again.

What does correlate with a positive listening experience (according to Olive & Co) is good measurements (plural!) This is why I rely on measurements. Good measurements <-> good listening experience.

That's were I'm coming from. Others are free to disagree.

Tom

As I said at the beginning of this thread. I follow the Putzeys approach. I want my amplifiers to sound of nothing. I have enough trouble fighting my room and speakers without the amplifier messing with things.

As I said at the beginning of this thread. I follow the Putzeys approach. I want my amplifiers to sound of nothing. I have enough trouble fighting my room and speakers without the amplifier messing with things.

Yep. I want my amplifier to be just that. An amplifier. If I wanted an effects box, I'd design one and market it a such.

Tom

I find it difficult to claim an amplifier have no sound coloration when the loudspeaker is the significantly dominating sound coloration source. You can detect differences between amplifiers, but it seems unreasonable to claim one specific amplifier does not contribute.

Normally when I ask for private review during a development process, I like to ask for detection of negative effect. Like Douglas Self had mentioned, we just want the devices in the playback chain to be as blameless as possible. So with that in mind, each negative pointed out gets looked into to see if it can be associated with a design issue. Normally I go and listen during the review to personally understand what the reviewer is hearing when a deficiency is pointed out, which is the only way I can fully understand the expression terms used by each individual.

Normally when I ask for private review during a development process, I like to ask for detection of negative effect. Like Douglas Self had mentioned, we just want the devices in the playback chain to be as blameless as possible. So with that in mind, each negative pointed out gets looked into to see if it can be associated with a design issue. Normally I go and listen during the review to personally understand what the reviewer is hearing when a deficiency is pointed out, which is the only way I can fully understand the expression terms used by each individual.

I find it difficult to claim an amplifier have no sound coloration when the loudspeaker is the significantly dominating sound coloration source. You can detect differences between amplifiers, but it seems unreasonable to claim one specific amplifier does not contribute.

I think you just did, actually. The conclusion or take-home message from your paragraph above is: To be inaudible in the playback system, the amplifier should contribute significantly less artifacts than the speakers. That's pretty easy to do - at least with semiconductors - as most speaker drivers have a hard time getting below 1 % THD at normal listening levels and a very hard time getting below 0.1 %.

One can also take a more scientific approach, as Belcher did back in 1978. If you read his paper here: Belcher (1978), you'll find that according to his work, THD below 0.1 % is not having an impact on the perceived sound quality. He goes on to propose a multi-tone test as it provides better correlation with the perceived sound quality than THD does.

Like Douglas Self had mentioned, we just want the devices in the playback chain to be as blameless as possible.

That is my goal as well. You'll notice that Douglas Self's work focused on driving the THD down as low as possible. That's precisely what I am doing. It just so happens that the way I do it (composite architecture) provides a bunch of other quantifiable improvements as well.

Tom

THD is one factor, but it can get low enough that it is not the dominating factor. For example, there was a time that Japanese amplifiers had much lower distortion numbers the European brands or some American brands, but they sounded terribly fatiguing! Generally when you get to good specs, it is time to do criticizing the design through listening tests, similar concept we used to do "test analyze and fix", this is the process where you start learning things that are not available in publications. The Japanese just went ahead and bought some European companies.

Audiophiles tweak component usage or mix and match equipment because they lack the knowledge to do the detailed analysis, nothing to laugh about because they lack the resources to do else wise.

Audiophiles tweak component usage or mix and match equipment because they lack the knowledge to do the detailed analysis, nothing to laugh about because they lack the resources to do else wise.

Last edited:

quote:Lol - insults being thrown on the internet always makes me laugh - it's so easy to do from the comfort of a keyboard and knowing that the target of said insult isn't going to come over and smash your face in

wow so your saying that you would smash my face if i said the above to you?

my writings are not insults and I resent that ...

turning to violence is not something i am cool with ...but if you insist I can give you my address come on over ...once you "smash my face in" you will be hearing from my lawyer...I do not take this lightly! its not funny really! and should be not tolerated😱

pm me for my address I dare you 😉 😀

Wow!!! Why on earth do you think I am talking about you? I hate to upset you, however your user name never entered my mind when I wrote that. Sorry.

Last edited:

THD is one factor, but it can get low enough that it is not the dominating factor. For example, there was a time that Japanese amplifiers had much lower distortion numbers the European brands or some American brands, but they sounded terribly fatiguing!

Yeah. That's usually what happens when the THD is great at 1 kHz but rises dramatically at higher frequencies. I can measure that in about 30 seconds with my APx525.

You may also find the AES papers on slewing-induced distortion from the late 70ies and early 80ies to be informative. Measuring the slew rate is not complicated.

So you're right. THD isn't the only measurement to take. You have to take many measurements. Still. I can take those measurements in half a day, whereas, a controlled listening trial would take much longer and be a few orders of magnitude more expensive to conduct.

More importantly, I can simulate many of the measurements. This allows me to validate circuit parameters and topologies without heating up the soldering iron. It saves time and cost. Reality is usually slightly less forgiving than the circuit simulator, but it's pretty easy to work out a correlation between the two and use a correction factor during the simulation process.

It's this methodology that allows me to see the big picture while others argue whether it should be a Black Gate or an Unobtanium Brand capacitor.

Tom

I'm still waiting for my replacement speaker binding posts to ship from the Netherlands, so no more listening updates; listening to one speaker doesn't do it for me 😀

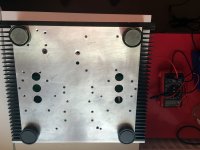

Anyway, I thought I'd post some pictures of the build, or what I'm calling the swiss cheese amp - this is the 3rd amp to be put into this homebuilt chassis, so the base has loads of holes from various layout configurations. The Modulus will be the last amp to use this.

Heatsinks are 300mm length, 40mm wide, and 100mm tall, and from Fischer Elektronik, rated at 0.4 C/W. Massive overkill for the amps for 99.9% of their lifespan, but for the 0.1% where they get really cranked up high, the sinks will at least keep the chips running.

I like these heatsinks because they have 10mm of solid aluminium at the base of the fins. This allowed them to be milled so that I could have the top and bottom panel flush with the heatsink.

Front plate is 10mm thick aluminium, milled to have a bit of character to it. The milling cost a lot, hence why this chassis keeps getting reused. The two holes in the front were for previous LED lights, but they need filling with epoxy metal, and a single hole for an LED light drilled.

Everything is bolted together with countersunk allen bolts, all of which I drilled. All connecting faces on the metal are bare to ensure everything is electrically connected back to safety earth. Speaking of the safety earth, you can see a closer shot of how I've connected it using star washers to ensure it bites into the metal, then bolted down, followed by the ground from the power supply, which is bolted down, followed by a locking nut to secure everything. I don't think that's coming undone, and pretty sure that's what the instructions meant when describing how to connect the ground from the power supply to the chassis.

It's halfway through having the paint stripped off so I can paint it again, but that'll have to wait until the weather gets warmer.

The black rectangle in the middle of the chassis is a soft start from Per Anders, and works well. However, as everything is at mains potential, I knocked up a cover for it out of 2mm plastic card, drilled a few holes for cooling (the power resistor gets warm), and then painted black. I've always had problems with close connected fuses blowing, hence the soft start.

The feet are from a Hong Kong seller on ebay - took me a long time to find these, but they're well made (solid aluminium), and not stupid money. The bases are recessed and that allowed me to glue circles of 2mm sorbothane to them for vibration isolation/protect my oak rack from scratches.

The big holes in the bottom and top plates are for cooling - the top holes still need some fine metal mesh glued to them (on the inside), to stop dust, etc, from getting in.

It's fair to say that everything on it is over engineered, but what the heck 😀

Anyway, I thought I'd post some pictures of the build, or what I'm calling the swiss cheese amp - this is the 3rd amp to be put into this homebuilt chassis, so the base has loads of holes from various layout configurations. The Modulus will be the last amp to use this.

Heatsinks are 300mm length, 40mm wide, and 100mm tall, and from Fischer Elektronik, rated at 0.4 C/W. Massive overkill for the amps for 99.9% of their lifespan, but for the 0.1% where they get really cranked up high, the sinks will at least keep the chips running.

I like these heatsinks because they have 10mm of solid aluminium at the base of the fins. This allowed them to be milled so that I could have the top and bottom panel flush with the heatsink.

Front plate is 10mm thick aluminium, milled to have a bit of character to it. The milling cost a lot, hence why this chassis keeps getting reused. The two holes in the front were for previous LED lights, but they need filling with epoxy metal, and a single hole for an LED light drilled.

Everything is bolted together with countersunk allen bolts, all of which I drilled. All connecting faces on the metal are bare to ensure everything is electrically connected back to safety earth. Speaking of the safety earth, you can see a closer shot of how I've connected it using star washers to ensure it bites into the metal, then bolted down, followed by the ground from the power supply, which is bolted down, followed by a locking nut to secure everything. I don't think that's coming undone, and pretty sure that's what the instructions meant when describing how to connect the ground from the power supply to the chassis.

It's halfway through having the paint stripped off so I can paint it again, but that'll have to wait until the weather gets warmer.

The black rectangle in the middle of the chassis is a soft start from Per Anders, and works well. However, as everything is at mains potential, I knocked up a cover for it out of 2mm plastic card, drilled a few holes for cooling (the power resistor gets warm), and then painted black. I've always had problems with close connected fuses blowing, hence the soft start.

The feet are from a Hong Kong seller on ebay - took me a long time to find these, but they're well made (solid aluminium), and not stupid money. The bases are recessed and that allowed me to glue circles of 2mm sorbothane to them for vibration isolation/protect my oak rack from scratches.

The big holes in the bottom and top plates are for cooling - the top holes still need some fine metal mesh glued to them (on the inside), to stop dust, etc, from getting in.

It's fair to say that everything on it is over engineered, but what the heck 😀

Attachments

Yes, a very smart build - I particularly like your case - it looks a bit like mine🙂

Lol - yes, it does, but cost a lot more. Bespoke engineering jobs cost (if you can actually find someone in this country who will do it - a lot of engineering companies advertising "we will do one off small jobs" never got back to my emails. I could have phoned them, but if they couldn't be bothered to reply after I chased them on email, why phone?).

I've had this case for about 3 years now, although it's a bit like Trigger's Broom, it's had a few replacement back panels in its time (but it's still the same chassis).

For those who are wondering who Trigger is, and what his broom has to do with anything, it's a character from a brilliant situation comedy called Only Fools and Horses. Trigger isn't the sharpest tool in the box, it's fair to say, and he wins an award for having the same broom after 17 years (he sweeps the streets) - except it isn't the same broom... https://www.youtube.com/watch?v=HisD_pqlRHQ

Last edited:

Back on track now. My amp is dead, dead silent, even with the placement of the toroid so close to the left channel.

I really am trying not to be a cheerleader, but I can't deny the truth.

I really am trying not to be a cheerleader, but I can't deny the truth.

Heatsinks are 300mm length, 40mm wide, and 100mm tall, and from Fischer Elektronik, rated at 0.4 C/W. Massive overkill for the amps for 99.9% of their lifespan, but for the 0.1% where they get really cranked up high, the sinks will at least keep the chips running.

The heat sinks I use for testing are 0.4 K/W as well. Running the MOD86 at peak power dissipation into a 4 Ω load (AFAIR) got the heat sink up to 40 ºC after an hour. This in a somewhat toasty room (24-25 ºC). You'll only hit this operating condition if you excite the amp with a sine wave at half the rated output power (or I suppose music with 6 dB crest factor cranked to the onset of clipping). You'll be fine.

Also note that the 0.4 K/W you mention don't take the rest of the chassis into account. I was rather surprised by how much a few sheets of 3 mm aluminum for top/bottom/rear panels and a 10 mm aluminum front panel helped on the heat sink efficiency of the BZ4309 chassis I used.

Front plate is 10mm thick aluminium, milled to have a bit of character to it.

I like it.

Speaking of the safety earth, you can see a closer shot of how I've connected it using star washers to ensure it bites into the metal, then bolted down, followed by the ground from the power supply, which is bolted down, followed by a locking nut to secure everything. I don't think that's coming undone, and pretty sure that's what the instructions meant when describing how to connect the ground from the power supply to the chassis.

Yep. That's exactly what I intended for you to do.

Nice work. I like it. Thanks for sharing.

Tom

- Home

- Amplifiers

- Chip Amps

- Modulus-86 build thread