I'll ask the moderators to allow this thread to start. It is an outgrowth of the DIY TT bearing help.

Fairly quickly it had morphed into a bit of a discussion about tone arms. So here's my first post with my ideas, hope it is OK to do this (worse case scenario is that it's killed before it starts).

Hope to limit the discussion to tonearms , there are already lots of posts about DIY turntables, and one started about the bearings. In particular any DIY types are open for discussion, Air bearings , Unipivots, DIY mods to commercial products--no discrimination against any one or anything. I only ask that the posts are :

1) Friendly

2) Non-judgemental

3) Creative criticism and references to other articles and posts (and other sites if need be)

4) Personal experiences only---please no "I read in S'file" or "TAbS "or whatever.

So my first tonearm project:

I did finish my unipivot, and so far am quite please considering the buy in of $5 Cdn. A stolen, modified sketch is attached here. I mounted an old Grado cartridge and did a favourable listening comparison to my SME 309/Grado/ Oracle Alex Mkll setup (I just placed the tonearm at an appropriate place to allow alignment on a birch ply pedestal placed on the Oracle plinth). I used a continuous run of computer mouse flexible cable (did I see that somewhere in this Forum or was it earbud cable?), some old cartridge tags and a couple of really old, really cheap Radio Shack gold flashed RCA connectors.

The "headshell is a piece of Aluminium plate cut out at 17 degrees (guess, I did measure it but am notorious for screwing things up.) and wedged into the tonearm with hardwood dowels with a hole drilled into the bottom piece). Aligned with the Oracle alignment gauge. Listening to Elton John's "Candle in the Wind" (original Yellow Brick Road , 1973 edition ).

Now a couple of things. It IS FUGLY. it is not convenient to use and care must be used not to knock the arm brg.

Hope everyone enjoys this (I know there have been other similar threads but I thought it might be nice to re-awaken or start fresh on the heels of all the great DIY turntables that are out there..).

Fairly quickly it had morphed into a bit of a discussion about tone arms. So here's my first post with my ideas, hope it is OK to do this (worse case scenario is that it's killed before it starts).

Hope to limit the discussion to tonearms , there are already lots of posts about DIY turntables, and one started about the bearings. In particular any DIY types are open for discussion, Air bearings , Unipivots, DIY mods to commercial products--no discrimination against any one or anything. I only ask that the posts are :

1) Friendly

2) Non-judgemental

3) Creative criticism and references to other articles and posts (and other sites if need be)

4) Personal experiences only---please no "I read in S'file" or "TAbS "or whatever.

So my first tonearm project:

I did finish my unipivot, and so far am quite please considering the buy in of $5 Cdn. A stolen, modified sketch is attached here. I mounted an old Grado cartridge and did a favourable listening comparison to my SME 309/Grado/ Oracle Alex Mkll setup (I just placed the tonearm at an appropriate place to allow alignment on a birch ply pedestal placed on the Oracle plinth). I used a continuous run of computer mouse flexible cable (did I see that somewhere in this Forum or was it earbud cable?), some old cartridge tags and a couple of really old, really cheap Radio Shack gold flashed RCA connectors.

The "headshell is a piece of Aluminium plate cut out at 17 degrees (guess, I did measure it but am notorious for screwing things up.) and wedged into the tonearm with hardwood dowels with a hole drilled into the bottom piece). Aligned with the Oracle alignment gauge. Listening to Elton John's "Candle in the Wind" (original Yellow Brick Road , 1973 edition ).

Now a couple of things. It IS FUGLY. it is not convenient to use and care must be used not to knock the arm brg.

Hope everyone enjoys this (I know there have been other similar threads but I thought it might be nice to re-awaken or start fresh on the heels of all the great DIY turntables that are out there..).

Attachments

Good idea for a thread. Here are some links regarding DIY tonearms to get it going.

1.The Altmann DIY Unipivot seems to be the one that started it all -- it's cheap'n'ugly, and allegedly sounds damn good. So anyone who's tried it and compared it with a mass market one (something like a Rega RB250?) please report here!

This is a better looking version.

2.the Krishnu unipivot appears to be a more elaborate version. Check out that site in general: it has details on bearings, motors etc and a great gallery.

3.This one is even more elaborate!

4. There is a thread here on using rolled up balsa wood to make the arm -- something that looks very very nice.

My personal project is to make a tonearm based on bits of the above. Sadly it's all in my head at the moment, because figuring out a bearing and platter are holding me back -- and even if I did make a nice DIY tonearm I've nothing to play it on.... However, in my research there appears to be two issues (correct me if I'm wrong please):

- calculating the effective mass of a DIY tonearm for cartridge compatibility can be hit and miss.

- some kind of anti-skating mechanism.

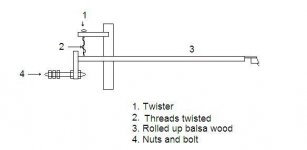

My way around the anti-skating (mentioned in the thread that started this one) is to dangle the arm from twisted threads hat can be twisted to increase or decrease the lateral force. I've attached my rather dodgy sketch again for good measure.

So, as Nanook said, anyone who's tried such designs PLEASE report here. This is crucial for noobs (just like me), because a project like this can be cheap while an RB250 can cost something like $250....

ssmith

1.The Altmann DIY Unipivot seems to be the one that started it all -- it's cheap'n'ugly, and allegedly sounds damn good. So anyone who's tried it and compared it with a mass market one (something like a Rega RB250?) please report here!

This is a better looking version.

2.the Krishnu unipivot appears to be a more elaborate version. Check out that site in general: it has details on bearings, motors etc and a great gallery.

3.This one is even more elaborate!

4. There is a thread here on using rolled up balsa wood to make the arm -- something that looks very very nice.

My personal project is to make a tonearm based on bits of the above. Sadly it's all in my head at the moment, because figuring out a bearing and platter are holding me back -- and even if I did make a nice DIY tonearm I've nothing to play it on.... However, in my research there appears to be two issues (correct me if I'm wrong please):

- calculating the effective mass of a DIY tonearm for cartridge compatibility can be hit and miss.

- some kind of anti-skating mechanism.

My way around the anti-skating (mentioned in the thread that started this one) is to dangle the arm from twisted threads hat can be twisted to increase or decrease the lateral force. I've attached my rather dodgy sketch again for good measure.

So, as Nanook said, anyone who's tried such designs PLEASE report here. This is crucial for noobs (just like me), because a project like this can be cheap while an RB250 can cost something like $250....

ssmith

Attachments

hey ssmith...noobs and all...

Did I metion I stole my sketch from you? If not , so sorry.

I have no antiskate mechanism on my tonearm, just fiddled with the wires exiting the tonearm and moved their location until there was almost no outward lateral movement of the arm on it's own.

As per saving money...like I said, I have $2.19 Cdn ( about USD $1.80) or so "tied up" into mine--wish I had a digital camera to show all. It is better looking than the one in your post , #3, but not as nice as the "better looking Altman" or the Krishnu (which looks like art!).

I had to mount an old counter weight to the arm in addition to the dice, and changed the wiring from RS "magnat" wire to 4 conductor "mouse" wire (that my wife really wanted me to throw out). I have to fashion an arm rest, but will not use a cuing lever..

The TT bearing is a real headache, but why not go to a thrift store or such and buy some old Dual or something to start with for very little money (cheapest one I've bought is a Dual 1019 for $1 Cdn or U$0.80). If it really is an issue of money, I'll give ya the old idler wheel Dual (you pay the freight). It needs the centre spindle attachment. Also in the previous thread, a $20, bearing can be had.

I have about $65 Cdn (USD $52), into a AR Sugden Connoissuer BD1, a Chinese Oak chopping block (used as a plinth) and the tonearm total.

Listening tests:

So far so good. I compared the DIY tonearm to my SME 309, using same model Grado, same Oracle Alex Mk ll turntable. I actually prefer the DIY. My youngest daughter (18 and a music lover) liked my arm better too---unsolitcited view, as did my wife. The SME sounds "dark" by comparison (or am I hearing distortions as added "sparkle"?).

This hobby does NOT have to cost alot (I know, I'm poor), can be incredibly fun, and the end result can be very musical.

Attached is an edited sketch to reflect the changes that I made to the arm and a sketch of the top view of the re-plinthed Sugden. I am no "rendring wondr" so please no comments about my primitive sketches

Did I metion I stole my sketch from you? If not , so sorry.

I have no antiskate mechanism on my tonearm, just fiddled with the wires exiting the tonearm and moved their location until there was almost no outward lateral movement of the arm on it's own.

As per saving money...like I said, I have $2.19 Cdn ( about USD $1.80) or so "tied up" into mine--wish I had a digital camera to show all. It is better looking than the one in your post , #3, but not as nice as the "better looking Altman" or the Krishnu (which looks like art!).

I had to mount an old counter weight to the arm in addition to the dice, and changed the wiring from RS "magnat" wire to 4 conductor "mouse" wire (that my wife really wanted me to throw out). I have to fashion an arm rest, but will not use a cuing lever..

The TT bearing is a real headache, but why not go to a thrift store or such and buy some old Dual or something to start with for very little money (cheapest one I've bought is a Dual 1019 for $1 Cdn or U$0.80). If it really is an issue of money, I'll give ya the old idler wheel Dual (you pay the freight). It needs the centre spindle attachment. Also in the previous thread, a $20, bearing can be had.

I have about $65 Cdn (USD $52), into a AR Sugden Connoissuer BD1, a Chinese Oak chopping block (used as a plinth) and the tonearm total.

Listening tests:

So far so good. I compared the DIY tonearm to my SME 309, using same model Grado, same Oracle Alex Mk ll turntable. I actually prefer the DIY. My youngest daughter (18 and a music lover) liked my arm better too---unsolitcited view, as did my wife. The SME sounds "dark" by comparison (or am I hearing distortions as added "sparkle"?).

This hobby does NOT have to cost alot (I know, I'm poor), can be incredibly fun, and the end result can be very musical.

Attached is an edited sketch to reflect the changes that I made to the arm and a sketch of the top view of the re-plinthed Sugden. I am no "rendring wondr" so please no comments about my primitive sketches

Attachments

ok, I'll take the bait....

well I don't have a digital camera....

so I tried my hand at image editing and a little drawing. The drawing is as accurate that I can make in my comp hack sort of way (I'm not a graphic designer or Inet guru..).

The arm and table are as described, except that mine has rounded corners and I haven't finished the wood:-(

Everybody that I have been able to suck into listening to it absolutely loves it. People I know who aren't "audiophiles", that is no pretensions regarding any sort of listener "jargon" comment on it in a very positive way. I think if you provide people with "the language" or what you hear, it is not a fair evaluation that you get, they hear what you point out.

Next up, an instructor in my Manufacturing Process Program. Hope I'm not boring anybody. Wait until the Garrard gets done....

well I don't have a digital camera....

so I tried my hand at image editing and a little drawing. The drawing is as accurate that I can make in my comp hack sort of way (I'm not a graphic designer or Inet guru..).

The arm and table are as described, except that mine has rounded corners and I haven't finished the wood:-(

Everybody that I have been able to suck into listening to it absolutely loves it. People I know who aren't "audiophiles", that is no pretensions regarding any sort of listener "jargon" comment on it in a very positive way. I think if you provide people with "the language" or what you hear, it is not a fair evaluation that you get, they hear what you point out.

Next up, an instructor in my Manufacturing Process Program. Hope I'm not boring anybody. Wait until the Garrard gets done....

Attachments

Re: EC8010 tonearm...

Here you go!

Paul.

Nanook said:Sy,

Thanks for the encouragement

EC8010 is online now, but doesn't accept emails. Did a search to no avail. Do you have a link to his tonearm?

Here you go!

Paul.

thanks for the link, ....

I really did a search...

Wow the arm looks very impressive...

and it costs a lot more than a single quid to make .....

(mine cost $2.19 Cdn, or about a single British pound).

for the pivot I used a 1mm ball point pen refill that I cleaned out and filled w/mineral oil (I was just being a little anal..), I used "JB Weld" to hold an inverted brass pipe plug into the arm tube for the bearing.

But wow does the arm by EC8010 look great, I'll read the complete thread..

thanx for the link

stew

I really did a search...

Wow the arm looks very impressive...

and it costs a lot more than a single quid to make .....

(mine cost $2.19 Cdn, or about a single British pound).

for the pivot I used a 1mm ball point pen refill that I cleaned out and filled w/mineral oil (I was just being a little anal..), I used "JB Weld" to hold an inverted brass pipe plug into the arm tube for the bearing.

But wow does the arm by EC8010 look great, I'll read the complete thread..

thanx for the link

stew

Hi stew,

After my string idea, I realised the only way to stabilise the arm would be use magnets like in the Schroeder arm. Looks a bit complicated, so now I'm looking at doing a more simple unipivot - something like the scheu classic

Just a U-channel of aluminium, brass counterweight and other bits and pieces.

BTW, after weeks on the drawing board, I took the first step -- which was buying a very impressive 30V DC motor (Russian made, cost $12) and a Laboratory DC PSU (Iranian made, cost $30). The motor kicks in at 1.2v and speed is variable all the way up to 32V. Think it should work out fine...

After my string idea, I realised the only way to stabilise the arm would be use magnets like in the Schroeder arm. Looks a bit complicated, so now I'm looking at doing a more simple unipivot - something like the scheu classic

Just a U-channel of aluminium, brass counterweight and other bits and pieces.

BTW, after weeks on the drawing board, I took the first step -- which was buying a very impressive 30V DC motor (Russian made, cost $12) and a Laboratory DC PSU (Iranian made, cost $30). The motor kicks in at 1.2v and speed is variable all the way up to 32V. Think it should work out fine...

ss don't give up....

the magnets can be really easy to implement ....

2 small but strong magnets, attracting one another, one on the bottom of the arm, the other below the arm in good alignment with the thread...and a means to adjust the tension (so the thread better be strong), everything else a s a simple unipivot. I will (or rather can) tell you that thesimplest cheapest arm is the Altman or a similarly cheap "Nanooks $2.19 tonearm" (sorry for the plug...

It took me very little time, very little $$, very few brain cells, and scrounged stuff.

I'll draw out a "non magnetic" thread style unipivot and post it ...

stew

the magnets can be really easy to implement ....

2 small but strong magnets, attracting one another, one on the bottom of the arm, the other below the arm in good alignment with the thread...and a means to adjust the tension (so the thread better be strong), everything else a s a simple unipivot. I will (or rather can) tell you that thesimplest cheapest arm is the Altman or a similarly cheap "Nanooks $2.19 tonearm" (sorry for the plug...

It took me very little time, very little $$, very few brain cells, and scrounged stuff.

I'll draw out a "non magnetic" thread style unipivot and post it ...

stew

hehe-I'm almost boring with this line: "old hard disk is good for many parts "......meaning of pretty solid ball bearing (for sort of arm?) and magnets ,too ...........

I just tried today few pairs (from few different HDDs) of magnets ,nad that look promising.....just to find somewhere few good pics of Shroeder Model one........

I just tried today few pairs (from few different HDDs) of magnets ,nad that look promising.....just to find somewhere few good pics of Shroeder Model one........

easton aluminium

Easton is just a brand name, they use several different grades. depending on what for, price etc. some aluminium is better for welding, some is better for machining.

I work at a high end road bicycle store that has its own brand. and i see all the emails from china and taiwan, and the same factories in taiwan/china put the brand "easton" officially on exactly the same products as they will happily sell you with your brand on. and that includes the fabulous "scandium" aluminium alloy concoction.

dont be fooled by china and taiwan either. they can make some top grade stuff, as well as what they are known for.

"scandium" no matter if its easton or not when used in a bike, is a lot lighter than a normal 6000 or 7000 series aluminium frame they can use a lot less of it to get the same trade off between fatigue and weight. they are almost as light as some of the new carbon fiber offerings. it is horible to ride because it is much to rigid and harsh. but rigidity is what you want in an arm tube right?

i think if you want to use aluminium for an arm, i would try and get scandium.. just a bit of tube as a "sample" might be easy to get and cost almost nothing if you go to the right place.

Easton is just a brand name, they use several different grades. depending on what for, price etc. some aluminium is better for welding, some is better for machining.

I work at a high end road bicycle store that has its own brand. and i see all the emails from china and taiwan, and the same factories in taiwan/china put the brand "easton" officially on exactly the same products as they will happily sell you with your brand on. and that includes the fabulous "scandium" aluminium alloy concoction.

dont be fooled by china and taiwan either. they can make some top grade stuff, as well as what they are known for.

"scandium" no matter if its easton or not when used in a bike, is a lot lighter than a normal 6000 or 7000 series aluminium frame they can use a lot less of it to get the same trade off between fatigue and weight. they are almost as light as some of the new carbon fiber offerings. it is horible to ride because it is much to rigid and harsh. but rigidity is what you want in an arm tube right?

i think if you want to use aluminium for an arm, i would try and get scandium.. just a bit of tube as a "sample" might be easy to get and cost almost nothing if you go to the right place.

I understand Easton is a brand name..

the actual aluminum is 7178-T9 alloy. it has ayield strength of

because I did no machining the hardness was not an issue, but drilling into was, creating stress cracks. I had to dremel the in itial hole to clean up the edges of the hole and the JB Welded brass pipe plug covered the edge a little too.

I fully understand materials science. I can also tell you I bought these at an archery range, and they indicated that it was suitable for a practice arrow now, as it had a bend in it towards the tip end..,,

like I said I paid $1.50 cdn for them each so it was no big deal. I bought em cause they were cheap, a lesser alloy would have sufficed.

I haven't weighed it but it is way lighter than the shaft on my Magnesium/aluminum SME (new style 309) and if memory serves me correctly, similar in weight to the 9" SME titanium wand on my old SME llls tonearm I had, but this one is 14" total in length

As far as "hardness" goes it isn't harder, it is stronger. The differences in strength, hardness,toughness and ductility are well known in alloying and materials data sheets. but any aluminum in the 97 ksi yield strength is plenty strong enough.

the actual aluminum is 7178-T9 alloy. it has ayield strength of

because I did no machining the hardness was not an issue, but drilling into was, creating stress cracks. I had to dremel the in itial hole to clean up the edges of the hole and the JB Welded brass pipe plug covered the edge a little too.

I fully understand materials science. I can also tell you I bought these at an archery range, and they indicated that it was suitable for a practice arrow now, as it had a bend in it towards the tip end..,,

like I said I paid $1.50 cdn for them each so it was no big deal. I bought em cause they were cheap, a lesser alloy would have sufficed.

I haven't weighed it but it is way lighter than the shaft on my Magnesium/aluminum SME (new style 309) and if memory serves me correctly, similar in weight to the 9" SME titanium wand on my old SME llls tonearm I had, but this one is 14" total in length

As far as "hardness" goes it isn't harder, it is stronger. The differences in strength, hardness,toughness and ductility are well known in alloying and materials data sheets. but any aluminum in the 97 ksi yield strength is plenty strong enough.

Re: easton aluminium

When I used to follow bike magazines ~12 years ago, Easton E9 was the cream of the aluminum crop. But that's when most bike companies were using 6061 due to its weldability. Now, you can get a 7005 aluminum frame on some department store bikes.

I just work at a regular bicycle store.

By "brand" do you mean you get your frames from overseas and slap some stickers on 'em?

What does a brand name mean anymore?

I would hazard to say that a taiwanese factory that pumps out frames by the thousand makes a better product than many small custom builders in the western world. If you only build a few frames a year, how good of a weld job are you going to do? Especially with exotic materials: Do you have the technology to back purge the weld zone with argon? Do you have proper heat treating facilities? Are your mitres spot-on? And with plain old chromoly:Are braze-ons going to be straight? Will parts fit properly? Sure, the builder might care more about the end product, but how practised are they? I've seen many custom frames and most of them have had some quirk or another (or several) that cause issues trying to fit standard parts. Not to mention undercutting of fillet brazed joints, dropout misalignments, screwy handling due to poor steering geometry. I do know what to look for, having built a few frames for myself.

Just use a smaller tube diameter to get rid of the harsh ride.

I guess. But c'mon, what kind of load is your tonearm subject to?

Heck, why not use beryllium. Never mind the cancer or whatever.

I think 6061 from your local metal supermarket ought to do just fine. For your tonearm, that is. For your road bike, stick with steel.

Sorry about the off-topic rant.

Max

neutron7 said:Easton is just a brand name, they use several different grades. depending on what for, price etc. some aluminium is better for welding, some is better for machining.

When I used to follow bike magazines ~12 years ago, Easton E9 was the cream of the aluminum crop. But that's when most bike companies were using 6061 due to its weldability. Now, you can get a 7005 aluminum frame on some department store bikes.

I work at a high end road bicycle store...

I just work at a regular bicycle store.

...that has its own brand.

By "brand" do you mean you get your frames from overseas and slap some stickers on 'em?

and i see all the emails from china and taiwan, and the same factories in taiwan/china put the brand "easton" officially on exactly the same products as they will happily sell you with your brand on. and that includes the fabulous "scandium" aluminium alloy concoction.

What does a brand name mean anymore?

dont be fooled by china and taiwan either. they can make some top grade stuff, as well as what they are known for.

I would hazard to say that a taiwanese factory that pumps out frames by the thousand makes a better product than many small custom builders in the western world. If you only build a few frames a year, how good of a weld job are you going to do? Especially with exotic materials: Do you have the technology to back purge the weld zone with argon? Do you have proper heat treating facilities? Are your mitres spot-on? And with plain old chromoly:Are braze-ons going to be straight? Will parts fit properly? Sure, the builder might care more about the end product, but how practised are they? I've seen many custom frames and most of them have had some quirk or another (or several) that cause issues trying to fit standard parts. Not to mention undercutting of fillet brazed joints, dropout misalignments, screwy handling due to poor steering geometry. I do know what to look for, having built a few frames for myself.

"scandium" no matter if its easton or not when used in a bike, is a lot lighter than a normal 6000 or 7000 series aluminium frame they can use a lot less of it to get the same trade off between fatigue and weight. they are almost as light as some of the new carbon fiber offerings. it is horible to ride because it is much to rigid and harsh.

Just use a smaller tube diameter to get rid of the harsh ride.

but rigidity is what you want in an arm tube right?

I guess. But c'mon, what kind of load is your tonearm subject to?

i think if you want to use aluminium for an arm, i would try and get scandium.. just a bit of tube as a "sample" might be easy to get and cost almost nothing if you go to the right place.

Heck, why not use beryllium. Never mind the cancer or whatever.

I think 6061 from your local metal supermarket ought to do just fine. For your tonearm, that is. For your road bike, stick with steel.

Sorry about the off-topic rant.

Max

bike guys...cool

as far as riding goes,...

keep it reel....keep it steel(' ')

')

Easton Scanium is good material for bike frames because it allows for better cold working and weldability...not really a weight reduction, however a really nice side benefit. It's yield strength is in the 68ksi range (Easton's own numbers) while the 7070-"E" 9 is good for 97ksi, so there really is no comparisonn as long as we're not welding tonearms...

ss, you're right, the Easton tent poles are very similar to the arrow shafts that I used and if available inexpensively from a supplier on an each basis would probably be a great source

Let's not diverge too much from the topic,

but I will agree that yes many offshore bicycle plants make some good quality frames. I don't know now (been away from cycling for a while), but U remember when Norco began a good concerted effort to improve their bicycles and their image in the early-mid 1990's? Tange Ultimate, Infinity and tpg steel tube sets (if I remember), on midrange bikes were not usual at all for most other brands..But it wasn't just the material that made the bike, it was good basic design and it was also the excellent welds availble on them. Some were a little rough but most were very clean. Besides that , Norco also were machine building their wheelsets themselves and hand finishing them.

The same can be said with the Fisher line of bikes (2 of my brothers own and ride these). Excellent manufactured frames.

As far as custom builders go , they can offer a custom fit, and if well practiced and skilled they can produce some of the most beautifull frames on the planet (Davidson from Washington state comes to mind, but Paul Brodie can run a pretty nice bead as well---my brother actually watched him hand fabricate a steel motorcycle gas tank and shook his head ---My brother is a welder but suggested that Brodie was a god...)

I know elsewhere others have made comments about using bicycle components and bearings for DIY turntables, etc. and it does make sense.However, these material discussions are a little over the top compared to what's needed here. Yes, I can read and understand ASTM specifications. I can figure out the metallurgy. I can argue for or against a particular material. BUT the point here is to "run what ya brung". My choices were because of an inexpensive readily available supply, Not because of materials engineering or specifying. It is just a happy occurance that resulted in my use of the arrow shafts---nuttin more.

as far as riding goes,...

keep it reel....keep it steel('

Easton Scanium is good material for bike frames because it allows for better cold working and weldability...not really a weight reduction, however a really nice side benefit. It's yield strength is in the 68ksi range (Easton's own numbers) while the 7070-"E" 9 is good for 97ksi, so there really is no comparisonn as long as we're not welding tonearms...

ss, you're right, the Easton tent poles are very similar to the arrow shafts that I used and if available inexpensively from a supplier on an each basis would probably be a great source

Let's not diverge too much from the topic,

but I will agree that yes many offshore bicycle plants make some good quality frames. I don't know now (been away from cycling for a while), but U remember when Norco began a good concerted effort to improve their bicycles and their image in the early-mid 1990's? Tange Ultimate, Infinity and tpg steel tube sets (if I remember), on midrange bikes were not usual at all for most other brands..But it wasn't just the material that made the bike, it was good basic design and it was also the excellent welds availble on them. Some were a little rough but most were very clean. Besides that , Norco also were machine building their wheelsets themselves and hand finishing them.

The same can be said with the Fisher line of bikes (2 of my brothers own and ride these). Excellent manufactured frames.

As far as custom builders go , they can offer a custom fit, and if well practiced and skilled they can produce some of the most beautifull frames on the planet (Davidson from Washington state comes to mind, but Paul Brodie can run a pretty nice bead as well---my brother actually watched him hand fabricate a steel motorcycle gas tank and shook his head ---My brother is a welder but suggested that Brodie was a god...)

I know elsewhere others have made comments about using bicycle components and bearings for DIY turntables, etc. and it does make sense.However, these material discussions are a little over the top compared to what's needed here. Yes, I can read and understand ASTM specifications. I can figure out the metallurgy. I can argue for or against a particular material. BUT the point here is to "run what ya brung". My choices were because of an inexpensive readily available supply, Not because of materials engineering or specifying. It is just a happy occurance that resulted in my use of the arrow shafts---nuttin more.

Just to share my cycle building experience....

I also used to work for a racing cycle frame builder on weekends as a lad, doing finishing work. Twas a long time ago, but I distinctly remember that the main advantage of small frame builders, as opposed to mass-produced frames, was they were tailor made. The frame builder I worked with was like a tailor. A customer would come in and he'd get his measuring tape and weighing scales out... then watch the customers' riding style, and then scribble loads of incomprehensible notes, and then build. His logic was that a frame should 'fit'.

Once he also explained to me that different races needed different geometries -- such as mountain stages, sprint road races etc. In addition, each pro team would also have its own frame 'tailor', who'd put together the frames and the sponsoring company would put the relevant stickers on... this particular builder worked at the Olympics and various tours.

The whole business is an art, and from what I was told is not just down to finishing, parts and quality -- which any decent factory and workshop can provide. The difference to the customer was merely the same difference between buying an off the shelf suit or one from Saville Row. The materials and the stitching can be of equally high quality, but does it fit?

Just like with high-end audio, it may have been just voodoo. But I met pro cyclists who would come in and order special frames for racing on cobbles, in city centres, hill climbing and so on. They could tell the difference, apparently, and it was not down to brazing quality.

What's my point? ummmmmmm..... can't remember.

Just to try and put this back on topic, after reading all of this I'm so tempted to experiment with different arms - rolled up balsa, aluminium tubing, aluminium U-channels, all built around two parts I found on smallparts.com thanks to this forum:

VJ-1244 Vee jewel, sapphire: $14.00 (one for each arm)

VJPX-7D S/S Vee jewel pivot, 0.4" long: $3.70 (one for the arm base)

That way I can swap arms for different music.. aluminium for techno, brass tubing for Miles Davis, and balsa for classical....

I also used to work for a racing cycle frame builder on weekends as a lad, doing finishing work. Twas a long time ago, but I distinctly remember that the main advantage of small frame builders, as opposed to mass-produced frames, was they were tailor made. The frame builder I worked with was like a tailor. A customer would come in and he'd get his measuring tape and weighing scales out... then watch the customers' riding style, and then scribble loads of incomprehensible notes, and then build. His logic was that a frame should 'fit'.

Once he also explained to me that different races needed different geometries -- such as mountain stages, sprint road races etc. In addition, each pro team would also have its own frame 'tailor', who'd put together the frames and the sponsoring company would put the relevant stickers on... this particular builder worked at the Olympics and various tours.

The whole business is an art, and from what I was told is not just down to finishing, parts and quality -- which any decent factory and workshop can provide. The difference to the customer was merely the same difference between buying an off the shelf suit or one from Saville Row. The materials and the stitching can be of equally high quality, but does it fit?

Just like with high-end audio, it may have been just voodoo. But I met pro cyclists who would come in and order special frames for racing on cobbles, in city centres, hill climbing and so on. They could tell the difference, apparently, and it was not down to brazing quality.

What's my point? ummmmmmm..... can't remember.

Just to try and put this back on topic, after reading all of this I'm so tempted to experiment with different arms - rolled up balsa, aluminium tubing, aluminium U-channels, all built around two parts I found on smallparts.com thanks to this forum:

VJ-1244 Vee jewel, sapphire: $14.00 (one for each arm)

VJPX-7D S/S Vee jewel pivot, 0.4" long: $3.70 (one for the arm base)

That way I can swap arms for different music.. aluminium for techno, brass tubing for Miles Davis, and balsa for classical....

Hi,

the url linked to my old website in the second or third post in this thread is no longer active. (in the thread mentioned "krishnu" but should be "krishu") please go via www.krishu.de > hifi stuff > turntable > ...

apart from that does anybody have a drawing of a cueing lever (tonearm lift)?

Kind Regards

Christian.

the url linked to my old website in the second or third post in this thread is no longer active. (in the thread mentioned "krishnu" but should be "krishu") please go via www.krishu.de > hifi stuff > turntable > ...

apart from that does anybody have a drawing of a cueing lever (tonearm lift)?

Kind Regards

Christian.

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Source & Line

- Analogue Source

- a continuation of DIY TT bearing...But now Tonearms!