Thanks, and to clarify you may not want to hook up the wall wart up that way because if you do the SG4 will stay energized. I ended up moving the wires to come off of the power transformer. Sorry for the confusion.

Attachments

Last edited:

Using a Variac with a Kill-A-Watt meter to plug the motor control in to help control any collateral damage along with Fast-Blo fuses. Working up to 125v meter showing .16 amps 7.9 watts in standby mode. With standby turned off only change was watts usage went up to 8.6.

Where are you reading 125V? Is this AC volts? At the input to the power supply? At the output of the power supply?

7.9W is about right. I'm reading 7.5W.

But having problem with AC output at 92.7 volts.

This is at the output of the power supply going to the motor?

Rest of voltage readings starting with the two power transformers. The one going to power Amplifier is 125v and output is 15.28v to each side of amplifier input. Next power transformer is the wall wart going to the SG4 input. 125v to wall wart and 12.19vdc at input on SG4.

Those all seem about right.

From the output of the SG4 to input of power Amplifier is 2.5vdc. From the power Amplifier to the step up transformer left channel 6.208 and right channel 6.21 then output side as stated above 92.7. All measurements were in default mode and double checked the step down voltage option and was indeed at 128.

6.2VAC (RMS?) seems a bit low. It should be ~8.4VRMS.

If I'm reading your post correctly, everything is working, just the output is low (92.7 v 120VAC)? That would be consistent with the 6.2VRMS coming out of the MK-154 instead of 8.4VRMS. Can you confirm the resistors that you replaced are 2.2K (Red-Red-Red)? If everything else is working properly, you could try boosting the output by changing the 2.2K to 2.7K.

It's difficult to tell from your picture, but are both the L & R inputs to the MK-154 going to the 0° output of the SG-4?

I probably should've posted some voltage readings before. All of these were taken with the MK-154 modified (22k replaced by 2k2), SG4 NOT in standby (60Hz output), 120VAC input to the power transformer and no load on the output transformer:

SG4 Output______2.5_______1.75_________5.0

MK-154 Output____0________8.4_________24.2

Output Xfmr______0________123_________360

Pwr Xfmr->MK154__0_______14.5_________20.5

The DC voltage on the 2 large electrolytic caps on the MK-154 should be ±18.84VDC.

VDC_______VRMS_______VPP

MK-154 Output____0________8.4_________24.2

Output Xfmr______0________123_________360

Pwr Xfmr->MK154__0_______14.5_________20.5

The DC voltage on the 2 large electrolytic caps on the MK-154 should be ±18.84VDC.

Where are you reading 125V? Is this AC volts? At the input to the power supply? At the output of the power supply?

125vac was at IEC socket and then again at the input pins 1&2 and 3&4 on the 24-2000 power transformer for the MK154 amplifier.

This is at the output of the power supply going to the motor?

Yes 92.7vac output socket to turntable motor.

6.2VAC (RMS?) seems a bit low. It should be ~8.4VRMS.

If I'm reading your post correctly, everything is working, just the output is low (92.7 v 120VAC)? That would be consistent with the 6.2VRMS coming out of the MK-154 instead of 8.4VRMS. Can you confirm the resistors that you replaced are 2.2K (Red-Red-Red)? If everything else is working properly, you could try boosting the output by changing the 2.2K to 2.7K.

Yes output is low going to turntable motor. Checked the 2.2k resistors and they do have the three red bands. Will try the 2.7k resistors and retake voltage measurements.

It's difficult to tell from your picture, but are both the L & R inputs to the MK-154 going to the 0° output of the SG-4?

Yes L and R are tied together coming out of the 0 phase shift to the input of the MK154 amplifier.

Thank you for your help and I apologize for not making myself clearer in my explanations of what is happening.

I received the TDA7492 Class D amp from e-Bay yesterday:

TDA-7492 50WPC Class D Amp

The PCB is 3" x 2.5", about the same size as the SG4. I connected the outputs to an Amgis L01-6362 12V toroid transformer and powered the amp using a GST60A24 24VDC 60W wall adapter. To drive the toroid output to 120VAC no load, you will need to reduce the output of the SG4 to 920mVPP using a pot or a fixed voltage divider of 8.2K and 1.8K resistors.

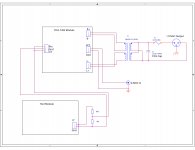

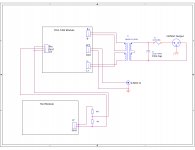

Below are the schematics for single phase 115 and 230VAC outputs as well as a picture of the supply powering a 19W Lenco motor. The TDA-7492 PCB comes with its own heat sink, and because it is Class D, requires no additional heatsinking (the temp topped out at ~100°F after 1 hour.

The amp was $10, the wall adapter to power it was $18 and the toroid is $25.

Be sure to observe the polarity markings on the transformer and the TDA-7492 outputs.

TDA-7492 50WPC Class D Amp

The PCB is 3" x 2.5", about the same size as the SG4. I connected the outputs to an Amgis L01-6362 12V toroid transformer and powered the amp using a GST60A24 24VDC 60W wall adapter. To drive the toroid output to 120VAC no load, you will need to reduce the output of the SG4 to 920mVPP using a pot or a fixed voltage divider of 8.2K and 1.8K resistors.

Below are the schematics for single phase 115 and 230VAC outputs as well as a picture of the supply powering a 19W Lenco motor. The TDA-7492 PCB comes with its own heat sink, and because it is Class D, requires no additional heatsinking (the temp topped out at ~100°F after 1 hour.

The amp was $10, the wall adapter to power it was $18 and the toroid is $25.

Be sure to observe the polarity markings on the transformer and the TDA-7492 outputs.

Attachments

Yes L and R are tied together coming out of the 0 phase shift to the input of the MK154 amplifier.

Thank you for your help and I apologize for not making myself clearer in my explanations of what is happening.

No problem. It sounds as if everything is working, but for some reason you are getting lower output voltage. If the output transformer is a LP12-1900, the secondary windings are 6VAC and will need ~8.4VAC to drive the primary to 120VAC.

Can you confirm the output of the SG4 is 5VPP or ~1.75VRMS?

If everything is as it should be and you are still getting only 93VAC output, then increase the 2.2K resistor to increase the gain of the amp.

Pyramid,

Do you have an easy way to test the output capability of that setup? ie the question is how much motor can it drive. I can do the expected calcs, but always feel better with tested results.

I am planning on driving some larger motors than normally encountered on turntables.

thanks,

Alan

Do you have an easy way to test the output capability of that setup? ie the question is how much motor can it drive. I can do the expected calcs, but always feel better with tested results.

I am planning on driving some larger motors than normally encountered on turntables.

thanks,

Alan

Pyramid,

Do you have an easy way to test the output capability of that setup? ie the question is how much motor can it drive. I can do the expected calcs, but always feel better with tested results.

I am planning on driving some larger motors than normally encountered on turntables.

thanks,

Alan

If you are talking about the TDA-7492, the Amgis xfmr is rated at 25W, I wouldn't exceed that. They make a 35W toroid, but it is more expensive and difficult to find. The amp is rated at 100W, I wouldn't push it past 50W. Above 25-30W you will need a larger wall adapter or other power supply. I would leave at least 3dB of headroom (the wall adapter should be rated for twice the load).

Ok I have some new voltage readings with the variac set at 120v and the 2.2k resistors replaced with 2.7k resistors. And with no turntable motor plugged in to controller the kill a watt meter shows 11 watts.

pyramids numbers

VDC_______VRMS_______VPP

SG4 Output______2.5_______1.75_________5.0

MK-154 Output____0________8.4_________24.2

Output Xfmr______0________123_________360

Pwr Xfmr->MK154__0_______14.5_________20.5

My numbers

VDC_______VRMS_______VPP

SG4 Output______2.5_______1.77_________5.0

MK-154 Output____0________7.75_________21.1

Output Xfmr______0________115_________280

Pwr Xfmr->MK154__0_______14.5_________

pyramids numbers

VDC_______VRMS_______VPP

SG4 Output______2.5_______1.75_________5.0

MK-154 Output____0________8.4_________24.2

Output Xfmr______0________123_________360

Pwr Xfmr->MK154__0_______14.5_________20.5

My numbers

VDC_______VRMS_______VPP

SG4 Output______2.5_______1.77_________5.0

MK-154 Output____0________7.75_________21.1

Output Xfmr______0________115_________280

Pwr Xfmr->MK154__0_______14.5_________

I received the TDA7492 Class D amp from e-Bay yesterday:

TDA-7492 50WPC Class D Amp

The PCB is 3" x 2.5", about the same size as the SG4. I connected the outputs to an Amgis L01-6362 12V toroid transformer and powered the amp using a GST60A24 24VDC 60W wall adapter. To drive the toroid output to 120VAC no load, you will need to reduce the output of the SG4 to 920mVPP using a pot or a fixed voltage divider of 8.2K and 1.8K resistors.

Below are the schematics for single phase 115 and 230VAC outputs as well as a picture of the supply powering a 19W Lenco motor. The TDA-7492 PCB comes with its own heat sink, and because it is Class D, requires no additional heatsinking (the temp topped out at ~100°F after 1 hour.

The amp was $10, the wall adapter to power it was $18 and the toroid is $25.

Be sure to observe the polarity markings on the transformer and the TDA-7492 outputs.

Do you think i can use a 12V, 6amp supply with the TDA-7492? The seller's PS guidelines are based on a speaker's ohm rating (doesn't he know about us?

Also a general note to all - i believe China starts their holiday season soon, if not already. Many sellers on ebay have closed shop until late February.

Do you think i can use a 12V, 6amp supply with the TDA-7492? The seller's PS guidelines are based on a speaker's ohm rating (doesn't he know about us?) i ask just because i have a bunch of the 12V/6A lying around.

According to the data sheet the TDA-7492 can be powered from 12VDC, but the power out capability will be only 25% of that at 24V (-6dB or 12.5WPC vs 50WPC). You would also need an output transformer with a 6V secondary which lowers the impedance seen by the amp by a factor of 4 (vs a 12V xfmr). The chip shuts down at ~3A (over current protection) which will occur sooner with a 6V xfmr. In the case of the 19W Lenco motor, the motors impedance=115^2/19=696 Ω. The 12V xfmr has a turns ratio ~8:1 so the impedance seen by the amp is 10.9 Ω. With a 6V xfmr, the impedance seen by the amp will be ~2.7 Ω.

The 24V wall adapter is only $18. It's small, has over current protection and the output is well regulated with no PS ripple. Hard to beat that.

Last edited:

I will be building one soon as well. Thanks to all involved

You were the first to contact me so the boards are yours.

Will mail them tomorrow

Ok I have some new voltage readings with the variac set at 120v and the 2.2k resistors replaced with 2.7k resistors. And with no turntable motor plugged in to controller the kill a watt meter shows 11 watts.

My numbers

VDC_______VRMS_______VPP

SG4 Output______2.5_______1.77_________5.0

MK-154 Output____0________7.75_________21.1

Output Xfmr______0________115_________280

Pwr Xfmr->MK154__0_______14.5_________

Those numbers look fairly reasonable, with the exception of the output xfmr VPP. If the output waveform is a sinewave, 115VRMS should be 325VPP.

There may be different versions of the amp with subtle differences and component values. 115VRMS output is pretty typical; if you want slightly more, you could further increase the 2.7K resistor (->2.8K or 2.9K), but depending on your application, I wouldn't worry about it.

Okay thanks, I will double check my reading on the Output Xfmr. This controller will be given to a friend with a Marantz TT-15S1 and the motor from what I have seen only uses 5W. So should be good to go.

Off topic, by chance is RA behind the Cheddar Curtain? If so and you happen to go in June would like to treat you to a beer and one of Sheboygan's best if so inclined.

Off topic, by chance is RA behind the Cheddar Curtain? If so and you happen to go in June would like to treat you to a beer and one of Sheboygan's best if so inclined.

- Home

- Source & Line

- Analogue Source

- 60 WPC Amplifier for DIY Turntable Motor Drive