How do you set up and test the glass surface for being parallel, and also adjust it if it is less than perfect?

Also, wondering about the precision required to get the arm wand into the bearing block with the parallel relationship to the two bearings exactly? (the holes in the plate being the presumed centers, but maybe not?)

Also, wondering about the precision required to get the arm wand into the bearing block with the parallel relationship to the two bearings exactly? (the holes in the plate being the presumed centers, but maybe not?)

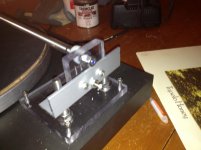

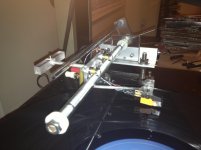

The carriage, this is as ideal as I can get it. If I had one single observation in all of this, for a mechanical linear arm it must be light, under 25 grams for flawless performance, and rigid as possible. If you are unable to keep mass to 25 grams ultimately you will run into issues on off center discs and have to use too high a tracking force. Arm length too, the longer it is the more stress on the stylus, 2-2.5 inches is about max you will want to get, as the longer it is the more side forces placed at the bearings which means friction laterally  . Vertical friction, albeit a small bit seems to be of benefit, sort of the equivalent if an air bearing using a damping trough to damp vertical movement-resonances. No wonder many companies won't touch linear arms, it is far easier to design a functioning pivoted arm!, but if you can get a linear arm working properly its well worth the sonic results.

. Vertical friction, albeit a small bit seems to be of benefit, sort of the equivalent if an air bearing using a damping trough to damp vertical movement-resonances. No wonder many companies won't touch linear arms, it is far easier to design a functioning pivoted arm!, but if you can get a linear arm working properly its well worth the sonic results.

Colin

Colin

Attachments

Few more questions

1) Must the cartridge be dead level when it sits on the record?

2) What do I type into ebay to order the right bearings? It says 5 x 9mm with 5mm centre I don't know what this means. This is the first time I have had to order something like this.

3) Mounting the assembly? Does the bottom plate (which the fixing bolts will secure the tone arm assembly to the platter) have to have any sort of anti vibration set up?I am going to use a direct drive technics SL1400 which has a broken existing tone arm.

4) The metal screw rod in the glass tube is floating. If you extended the rod and supported its end at the other side of the platter, would that improve the tone arm? Or, would it merely pick up more vibration from the drive motor in the platter and transfer it to the cartridge?

Thanks Alan

1) Must the cartridge be dead level when it sits on the record?

2) What do I type into ebay to order the right bearings? It says 5 x 9mm with 5mm centre I don't know what this means. This is the first time I have had to order something like this.

3) Mounting the assembly? Does the bottom plate (which the fixing bolts will secure the tone arm assembly to the platter) have to have any sort of anti vibration set up?I am going to use a direct drive technics SL1400 which has a broken existing tone arm.

4) The metal screw rod in the glass tube is floating. If you extended the rod and supported its end at the other side of the platter, would that improve the tone arm? Or, would it merely pick up more vibration from the drive motor in the platter and transfer it to the cartridge?

Thanks Alan

Hi Alan,

You've brought up some good questions. For level of the arm I assume that you mean Vta instead of azimuth, as far as Vta is concerned I use a slight slope towards the record instead of parallel, this can be dialed in by ear as the way I've built the base allows for Vta adjustment.

The bearings are 9mm outer height by 5mm center diameter by 3mm width, the glass tube is 10mm and the space between he bearin races should be 4-5mm to ride in the tube, this spacing is critical and needs to be close to that range regardless of bearing width for a 10mm tube.

For vibration that's where the set screws at the base come in, this isolates the coupling to four small points instead of a base fully resting on the plinth.

As far as the suspended rod, I thought about mounting the other side but then realized its probably unnecessary since it would place another obstacle in the way of changing records, I did a tap test while playing and it was just a dead thump so the resonance control is already good.

Colin

You've brought up some good questions. For level of the arm I assume that you mean Vta instead of azimuth, as far as Vta is concerned I use a slight slope towards the record instead of parallel, this can be dialed in by ear as the way I've built the base allows for Vta adjustment.

The bearings are 9mm outer height by 5mm center diameter by 3mm width, the glass tube is 10mm and the space between he bearin races should be 4-5mm to ride in the tube, this spacing is critical and needs to be close to that range regardless of bearing width for a 10mm tube.

For vibration that's where the set screws at the base come in, this isolates the coupling to four small points instead of a base fully resting on the plinth.

As far as the suspended rod, I thought about mounting the other side but then realized its probably unnecessary since it would place another obstacle in the way of changing records, I did a tap test while playing and it was just a dead thump so the resonance control is already good.

Colin

Alan,

Another point I forgot to add is counterweight. Design this so that it hangs further away from the pivot which makes it lighter (decreases a lateral mass), but!, with the added benefit of increasing vertical effective mass. I've tried different materials down to aluminum and polycarbonate has the best dynamics and involving sound.

Colin

Another point I forgot to add is counterweight. Design this so that it hangs further away from the pivot which makes it lighter (decreases a lateral mass), but!, with the added benefit of increasing vertical effective mass. I've tried different materials down to aluminum and polycarbonate has the best dynamics and involving sound.

Colin

Hi Colin,

What a great project. Thanks very much for inspiring me and so many others! As you say, different from working on pure electronics.

I, for one, had no idea this could be done and it is going to be a fascinating build.

Any chance of a few more dimensions please?

Kind regards

Paul

What a great project. Thanks very much for inspiring me and so many others! As you say, different from working on pure electronics.

I, for one, had no idea this could be done and it is going to be a fascinating build.

Any chance of a few more dimensions please?

Kind regards

Paul

Hi Paul,

Yes it can be done with some work , the dimensions have stayed somewhat the same as its been a work in progress, but functional for a while now. Just tried a different counterweight idea, the idea being to spread the mass across the bearings helping stability laterally, not there was an issue but thought I'd give it a try since we're dealing with such an important role in playback.

, the dimensions have stayed somewhat the same as its been a work in progress, but functional for a while now. Just tried a different counterweight idea, the idea being to spread the mass across the bearings helping stability laterally, not there was an issue but thought I'd give it a try since we're dealing with such an important role in playback.

Colin

Yes it can be done with some work

Colin

Attachments

To all,

Has anyone started building one of these yet?, I've gone back to the low slung weight, better bass by a small margin. One thing that still gets me is how this arm can take a 100 dollar cartridge and make it sound like a cartridge 10 times its price, coming up soon will be dimensions and parts list since there have been some small changes and some further drilling to decrease mass. I've ran this with an at120e, at95e and a shure m97xe and they all perform fabulous. One catch is that you must adopt a suitable counterweight so that it extends out as almost as far as it can go for the appropriate tracking force which will decrease mass proportionately.

Colin

Has anyone started building one of these yet?, I've gone back to the low slung weight, better bass by a small margin. One thing that still gets me is how this arm can take a 100 dollar cartridge and make it sound like a cartridge 10 times its price, coming up soon will be dimensions and parts list since there have been some small changes and some further drilling to decrease mass. I've ran this with an at120e, at95e and a shure m97xe and they all perform fabulous. One catch is that you must adopt a suitable counterweight so that it extends out as almost as far as it can go for the appropriate tracking force which will decrease mass proportionately.

Colin

Has anyone started building one of these yet?

Not yet, Colin. But I am following your thread since the beginning and will built one after the summer. I have lots of glass tubes and all kinds of metal and perspex pieces. Also I have some ideas how to make the arm nice looking

Heinz

5x10 bearings should also work, but they will have more inertia to stop. I originally used 5x8mm. I look forward to seeing the different iterations, remember to post photos  . I imagine there will be some great different ideas, I went with the industrial/business look, wholly designed to dig out the most from the groove. In fact looking at the cutting lathes, they are always such a thing of beauty!!.

. I imagine there will be some great different ideas, I went with the industrial/business look, wholly designed to dig out the most from the groove. In fact looking at the cutting lathes, they are always such a thing of beauty!!.

Colin

Colin

To all building,

One key note, make sure when testing to dig up your most off center, loudest cut vinyl for the torture test, if it will track this without skipping the mass is just right, if it skips at all mass is too high or bearing assembly needs to be revisited. the brass shim is 4.76mm, and the washers used are to220 tophats which help center the shim.This has proven to be the best test of lateral mass inertia, also pay close attention to what the cantilever does and use a cheap cart while getting set up.

Colin

One key note, make sure when testing to dig up your most off center, loudest cut vinyl for the torture test, if it will track this without skipping the mass is just right, if it skips at all mass is too high or bearing assembly needs to be revisited. the brass shim is 4.76mm, and the washers used are to220 tophats which help center the shim.This has proven to be the best test of lateral mass inertia, also pay close attention to what the cantilever does and use a cheap cart while getting set up.

Colin

To all building,

One key note, make sure when testing to dig up your most off center, loudest cut vinyl for the torture test, if it will track this without skipping the mass is just right, if it skips at all mass is too high or bearing assembly needs to be revisited. the brass shim is 4.76mm, and the washers used are to220 tophats which help center the shim.This has proven to be the best test of lateral mass inertia, also pay close attention to what the cantilever does and use a cheap cart while getting set up.

Colin

Hi Colin,

You have a very interesting project going. There are some real differences between the Cantus 3 bearing configuration and yours with the 4 ball bearings. I'm not going to discuss them from a theoretical standpoint, but I do wish to try your design and compare the two. I have two good 4 x 10 x 4 bearings and will need only to buy 2 more to get going. I do not think there will be significantly greater inertia over the 5 x 9 x 3 bearings to deal with as the motion is exceedingly small as is the acceleration. Unless you can say that my bearings just won't do a good job, I think I'll go with the 4 x 10 ones

for starters.

I'm sorry for not understanding what your "shim" is and does. Where I come from a shim is simply a thin piece of anything to slip between 2 things to take up a space or to space them a few thousandths of an inch closer together or further apart. Is your shim a piece of brass tube of an outside diameter such that there will be a smooth sliding fit into the bearing ID? Or, does it provide a spacer between the 2 bearings of a pair so that there will be a fixed position for the bearing to ride upon on the OD of the glass tube? Please shed some light on the function of the shim? I can easily machine a mounting rod of the correct dimensions to hold and position the bearings so why would I bother with shimming anything?

Keep up the good work, I'm eager to give it a go.

BillG

Last edited:

Ok, after looking at the last image posted, and thinking some more, I do have a question. You know that regarding the bearings and the vertical motion I have had some questions/reservations... so here is the big question: If you balance the arm for "zero" tracking force, so that the cartridge hangs above the platter, what happens if you very lightly blow on the cartridge side or the counter weight side?

Last edited:

- Home

- Source & Line

- Analogue Source

- DIY linear tonearm