I'm planning on trying several approaches. One being with a two bearing, Dif-e-Yo Yo-Yo's

and a more narrow, 5/6/7mm tube. I have a question though. Should I choose to mount a glass tube differently, lets say in the groove of an angle aluminum. Would a bed of epoxy or silicone be better.

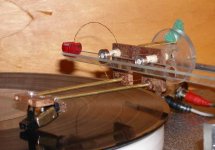

You can use window glass for your track. Not sure that adding a metal angle provides much more for the added complexity and thickness. Take a look at a build by one of the members. Best regards Moray James.

Attachments

I think he wants to hold the tube up by placing it in the center of the "V" of some angle aluminum...

...I'm not so clear on putting the bearing running down the center of a glass "V"... seems like it wants to slide one way or the other, given the opportunity... perhaps a much lower angle "V" might be preferable?

_-_-

...I'm not so clear on putting the bearing running down the center of a glass "V"... seems like it wants to slide one way or the other, given the opportunity... perhaps a much lower angle "V" might be preferable?

_-_-

I think he wants to hold the tube up by placing it in the center of the "V" of some angle aluminum...

...I'm not so clear on putting the bearing running down the center of a glass "V"... seems like it wants to slide one way or the other, given the opportunity... perhaps a much lower angle "V" might be preferable?

_-_-

I got that but I am not sure there is any advantage of doing so. From what I recall Bill had this arm working well, perhaps he will chime in and comment. The glass angles seemed to work as well as a tube. You really only want the arm to slide in the horizontal and the up and down is just to accommodate small warps the less the arm moves moves up and down the better really. Best regards Moray James.

http://www.diyaudio.com/forums/analogue-source/34126-opus-3-cantus-parallel-tracking-arm-47.html

Your correct Bear. and Moray, had I seen that when it was done I probably would have tried a version earlier than now.

What I was proposing is the use of a special bearing made for yoyo's. It has a concave(follow my previous link) raceway. I do not have one in posession yet, but believe the radius to be about six degreee. Using a 6 deg. tube, would be too small a inner hole to fit with all thread. No.8 or 3mm screw would be too small a size for weight. So a need to bed it on something. The neat thing of a race with a radii, is it should ride the tube, and when stressed for verticle movement, it only need rock. no sliding or scratching, along the two pieces. Imagine a tubeless(only rims) bicycle, on a high wire. I like the OP's project but two less bearing is 5-6 grams less weight. And is part of this an exercise in weight management.

The next way I would try all this is akin to Morays post. Again, two bearing is less weight.

What I was proposing is the use of a special bearing made for yoyo's. It has a concave(follow my previous link) raceway. I do not have one in posession yet, but believe the radius to be about six degreee. Using a 6 deg. tube, would be too small a inner hole to fit with all thread. No.8 or 3mm screw would be too small a size for weight. So a need to bed it on something. The neat thing of a race with a radii, is it should ride the tube, and when stressed for verticle movement, it only need rock. no sliding or scratching, along the two pieces. Imagine a tubeless(only rims) bicycle, on a high wire. I like the OP's project but two less bearing is 5-6 grams less weight. And is part of this an exercise in weight management.

The next way I would try all this is akin to Morays post. Again, two bearing is less weight.

I got that but I am not sure there is any advantage of doing so. From what I recall Bill had this arm working well, perhaps he will chime in and comment. The glass angles seemed to work as well as a tube. You really only want the arm to slide in the horizontal and the up and down is just to accommodate small warps the less the arm moves moves up and down the better really. Best regards Moray James.

http://www.diyaudio.com/forums/analogue-source/34126-opus-3-cantus-parallel-tracking-arm-47.html

You are right Moray, the V groove track works extremely well and is easy to implement. DTUT and I have experimented with some various V angles and our conclusion was that angle didn't matter much if at all. By no means is that the final word though. See the OPUS 3 CANTUS thread for full disclosure. The pic that Moray posted is of an early prototype. I will try to post pic of a more uptodate version. It realty is the same as the crude version but is a more elegantly done piece. Do I think that a more shallow V angle would work better? I don't know. Part of my desire to experiment with the 4 bearings on the outside of the 10mm tube is to get a test of the bearings riding on a smooth round track as opposed to a 90 degree angle slab sided track.

Good luck with your project,

BillG

Your correct Bear. and Moray, had I seen that when it was done I probably would have tried a version earlier than now.

What I was proposing is the use of a special bearing made for yoyo's. It has a concave(follow my previous link) raceway. I do not have one in posession yet, but believe the radius to be about six degreee. Using a 6 deg. tube, would be too small a inner hole to fit with all thread. No.8 or 3mm screw would be too small a size for weight. So a need to bed it on something. The neat thing of a race with a radii, is it should ride the tube, and when stressed for verticle movement, it only need rock. no sliding or scratching, along the two pieces. Imagine a tubeless(only rims) bicycle, on a high wire. I like the OP's project but two less bearing is 5-6 grams less weight. And is part of this an exercise in weight management.

The next way I would try all this is akin to Morays post. Again, two bearing is less weight.

There is no scratching there is only sliding with warps. I see (as far as the motion of the carriage goes) no difference between sliding on the outside of the glass tube or on the inside. There are other issues but as far as this goes they are the same to me. Best regards Moray James.

The reasoning behind using the threaded rod for me was ease of assembly, and the ability to replace the tube should it break or another idea pops up. Perhaps a long video of it in action might just go to put away the reasoning for why it shouldn't work 🙂. On warped records, despite the friction I cannot see any stylus deflection taking up the warps, arm carriage pivots as it should to accomadate a warp. This means clearly mass and friction is low enough to be easily overcome.

Colin

Colin,

Something I haven't seen it this discussion is bearing lubrication. If you are using the ceramic bearings from acerracing, they are shipped with a very light oil film in them. We have found it necessary to flush them out thoroughly and run them dry in the Cantus clones. You don't say whether or not you clean them or use them as shipped. Please inform.

BillG

Read up on some of the yoyo forums(again, ughh!) There are plenty of vids on propper cleaning etc. The ceramics never need any lube, just a good cleaning. Acetone, and or compressed air will do. I have this dry product and it seems to be the beees knees. Terrapin Dry Lube by Terrapin - YoYoExpert

There is no scratching there is only sliding with warps.

My mistake, slides would be the word.

Hi Bill,

The bearings are used as shipped, I've also seen mention of bearing weight, I'll be lucky if these bearings even weight a gram each 🙂. One must remember too in this design the bearings don't need to entirely rely on the bearing races, the brass spacer/tube will take up any resistance encountered. I'm sure as it comes apart the beautiful simplicity of it will reveal itself. In essence it has a back up system for lateral movement.

Colin

The bearings are used as shipped, I've also seen mention of bearing weight, I'll be lucky if these bearings even weight a gram each 🙂. One must remember too in this design the bearings don't need to entirely rely on the bearing races, the brass spacer/tube will take up any resistance encountered. I'm sure as it comes apart the beautiful simplicity of it will reveal itself. In essence it has a back up system for lateral movement.

Colin

Oh and to add, no ceramic bearings are used, just standard low friction bearings. Ceramics are really a rip off and we aren't going to have any heat generated since about the only place we will reach an excess of 1 rpm is in the runout, lol 😀

Aside from all this, a friend mentions that the "word on the street" is/was that all of the arms built on this scheme (bearings sliding on glass) required a very slight downward slope (toward the spindle) to "bias" the sliding assembly...

...any comments?

...any comments?

Aside from all this, a friend mentions that the "word on the street" is/was that all of the arms built on this scheme (bearings sliding on glass) required a very slight downward slope (toward the spindle) to "bias" the sliding assembly...

...any comments?

yes and no I use a slight tilt a friend does too Bo did not. They are tweaky to set up but lock in when done and stay put that the end of my first hand knowledge. Best regards Moray James.

PS: solvent clean bearing and track are the order of the day which is one of the other reasons inside a tube is a good thing.

Yeah, went back and read through the "original" thread... much was covered there. Sorry to re-hash some things, being late to that party.

Did a consensus appear on the relative benefits and sonics of the different type and grades of bearings?

_-_-

Did a consensus appear on the relative benefits and sonics of the different type and grades of bearings?

_-_-

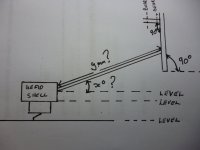

Chokesrule,

Looking at your diagram I must point out that the higher you place the tube and the lower you put the headshell the more a small warp will cause a loss of tangency to the proper cutter head replication. Even with the angle of the tonearm this is the same as placing it at 90 degrees in line with the headshell.

Colin

Looking at your diagram I must point out that the higher you place the tube and the lower you put the headshell the more a small warp will cause a loss of tangency to the proper cutter head replication. Even with the angle of the tonearm this is the same as placing it at 90 degrees in line with the headshell.

Colin

Bear,

I've heard of some arms requiring a slight tilt to bias, I've noticed that can be mass dependant too, with the heavier carriage I needed a small tilt towards the spindle, not the case with anything under 25 grams I've found. IMHO the carriage should be light enough so that the groov has no problem on and off center record pulling the carriage at level without skewing the cantilever.

For a 36g mono cart, that's heavy, at best this would work out to 70 grams total, depends on the compliance and tracking force, but this may just be a case where it wouldn't work, that's a heavy bastard!!.

Colin

I've heard of some arms requiring a slight tilt to bias, I've noticed that can be mass dependant too, with the heavier carriage I needed a small tilt towards the spindle, not the case with anything under 25 grams I've found. IMHO the carriage should be light enough so that the groov has no problem on and off center record pulling the carriage at level without skewing the cantilever.

For a 36g mono cart, that's heavy, at best this would work out to 70 grams total, depends on the compliance and tracking force, but this may just be a case where it wouldn't work, that's a heavy bastard!!.

Colin

Colin, as far as I understood, you are using a 10mm glass tube. I do have some 20mm glass tubes. Could that work or should I try to find 10mm tubes?

Does anyone know?

Use what you have

that way if you decide to try a smaller dia. tube later you can compare. Uses Bo's feedback test and make a note of where your large tube breaks into resonance and then you can compare that to a smaller tube later on. Best regards Moray James.

Does anyone know?

that way if you decide to try a smaller dia. tube later you can compare. Uses Bo's feedback test and make a note of where your large tube breaks into resonance and then you can compare that to a smaller tube later on. Best regards Moray James.

- Home

- Source & Line

- Analogue Source

- DIY linear tonearm