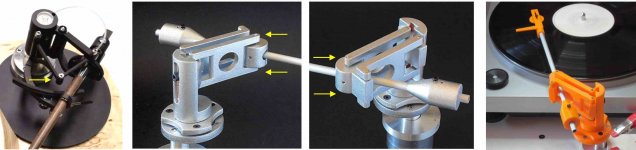

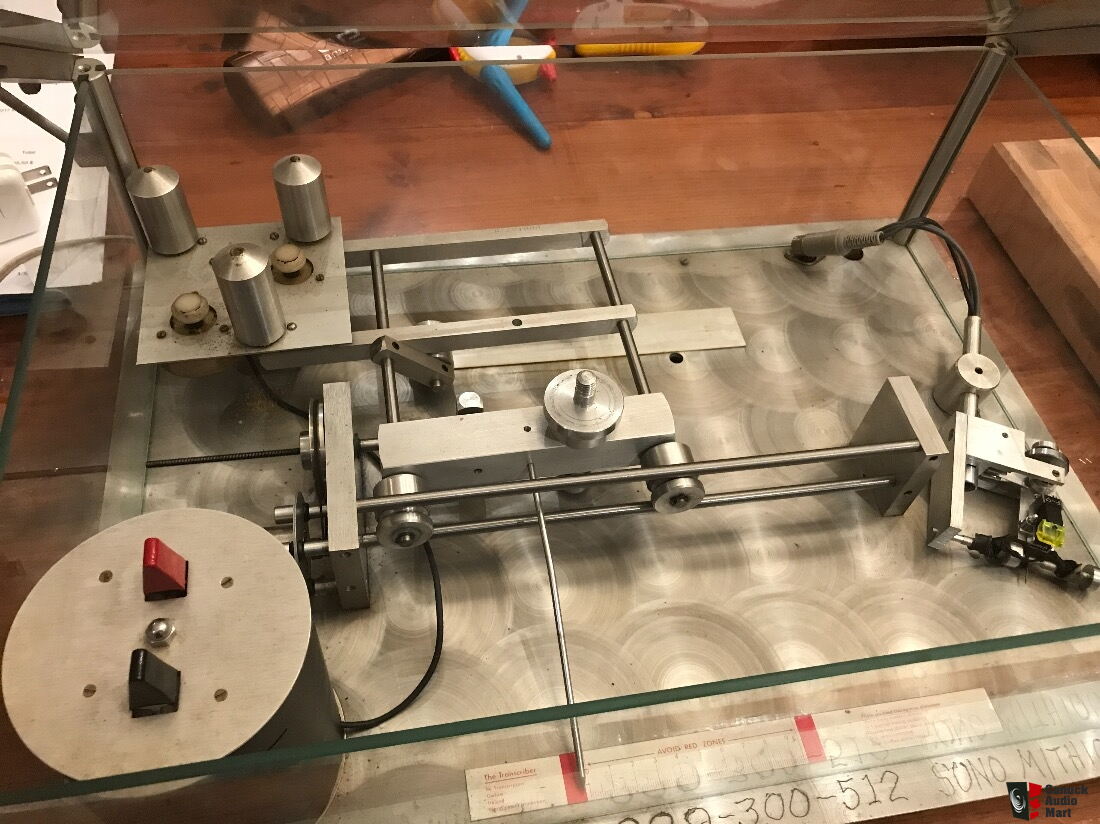

So my next question is...what makes the moving platter zero tracker ala 'Transcriber' inferior? Stationary arm, heavy, servo controlled, gear driven platter on rails.Have you seen the Italian Reed 5T?

I don't know if it's unipivot or not but it's definitely a zero tracker (electronically controlled) and they claim it has identical horizontal and vertical effective mass.

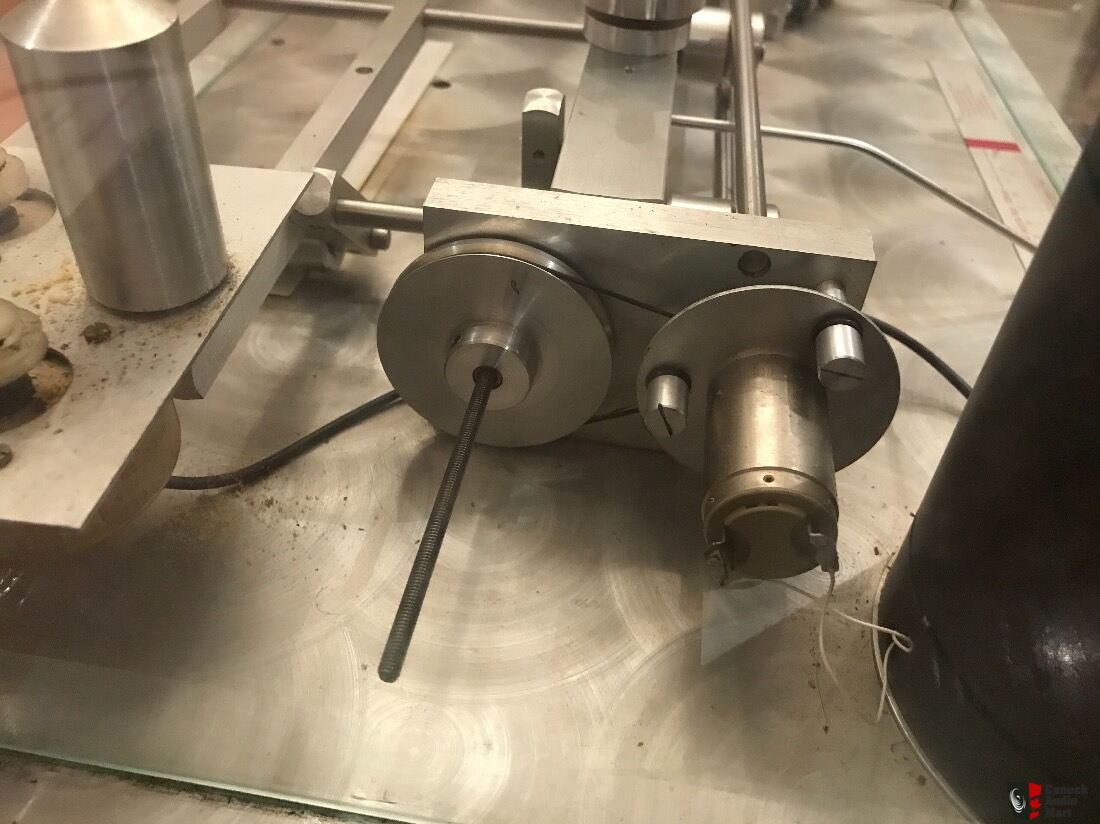

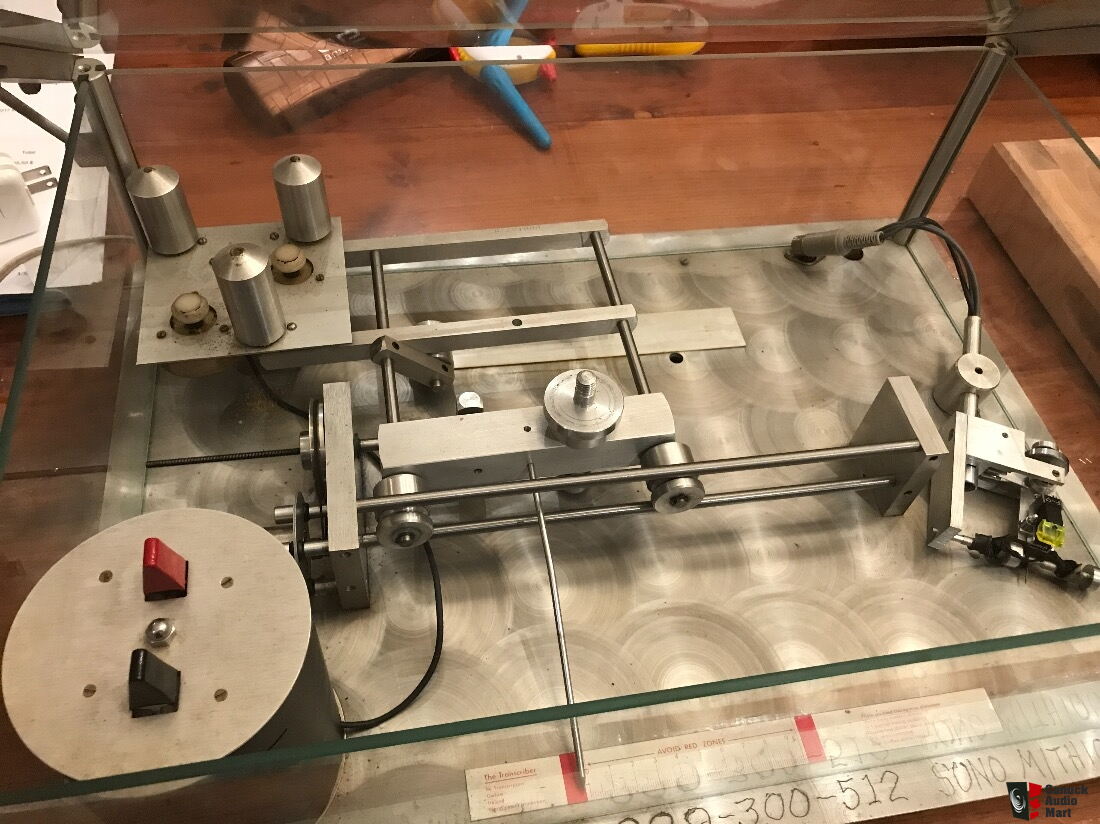

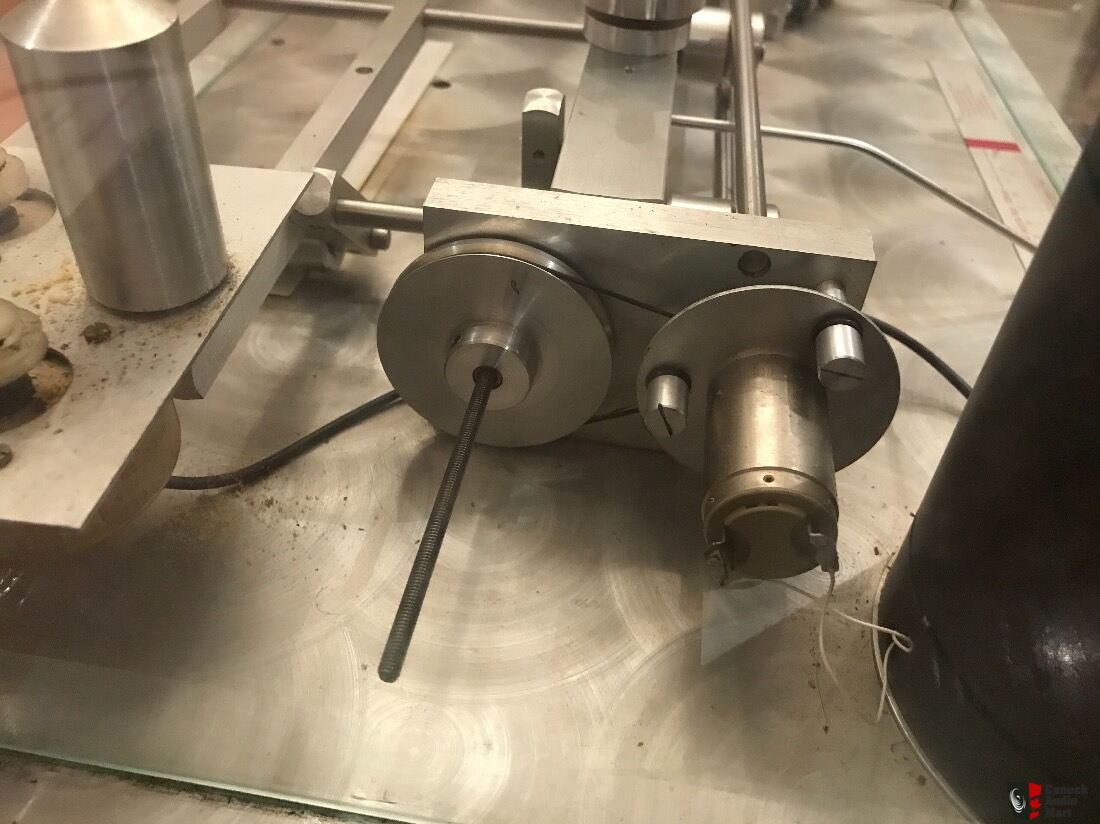

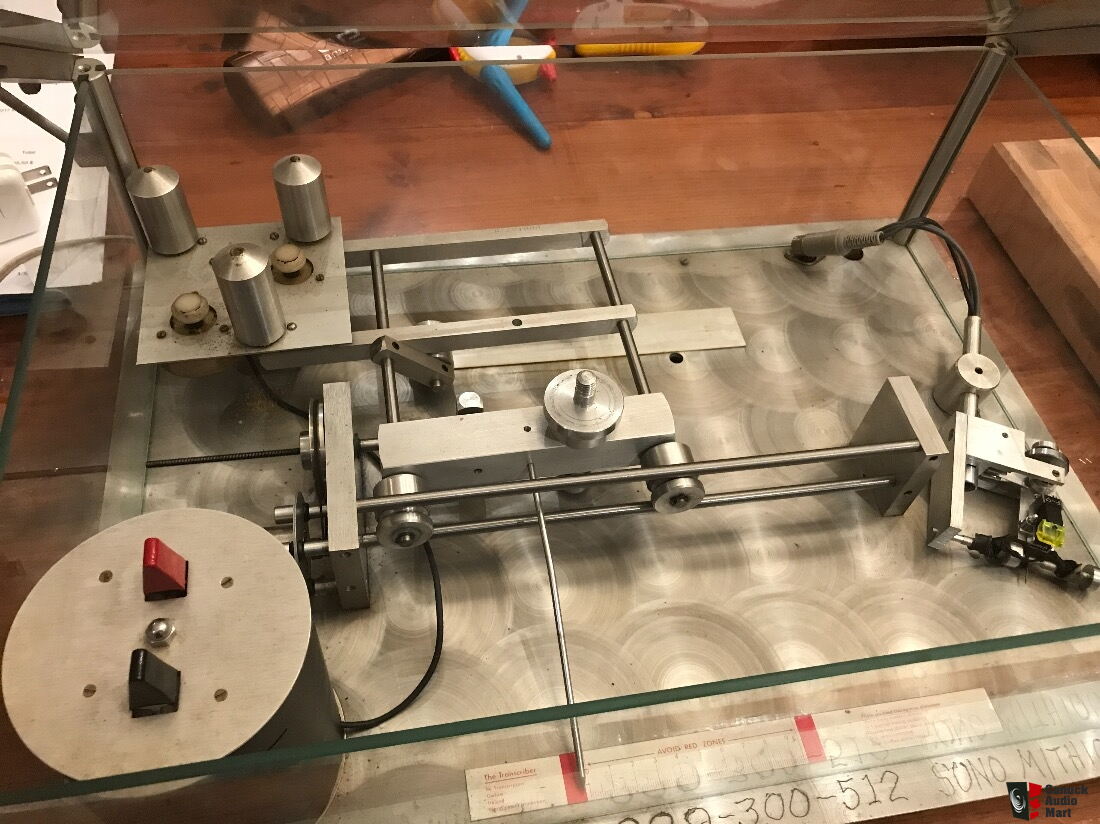

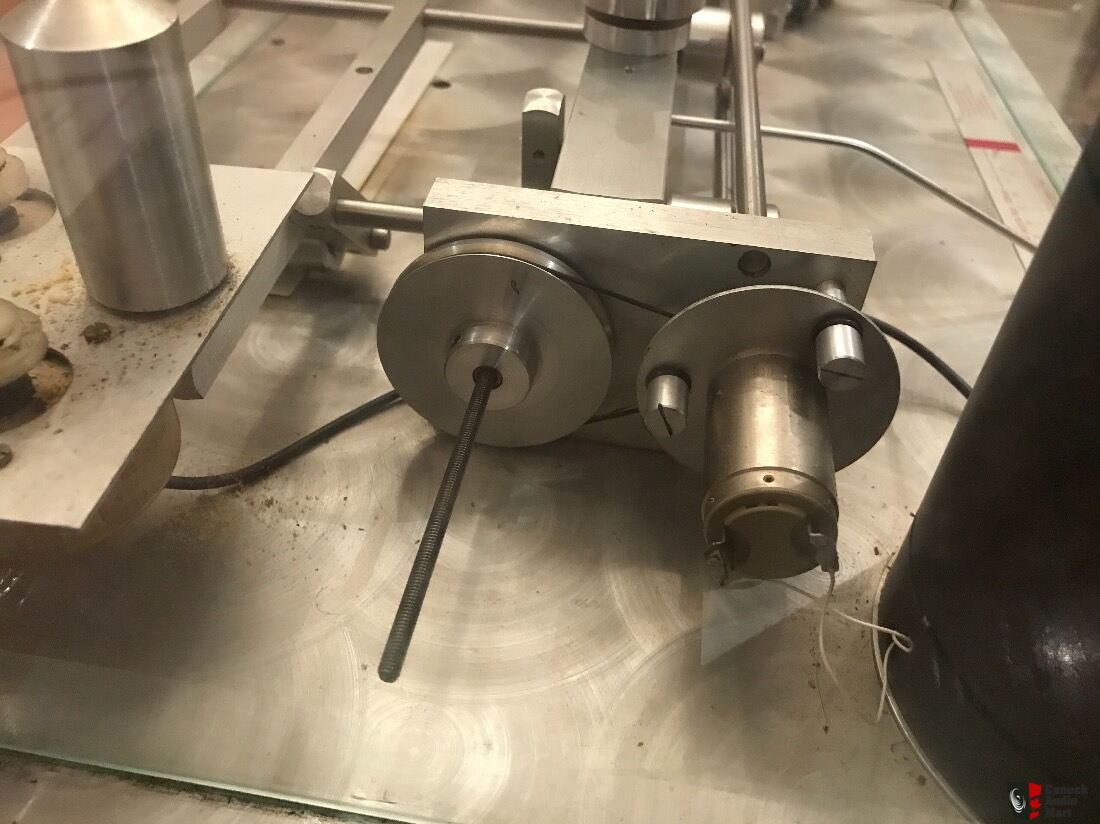

Transcriber

What do you think is easier to move: a combination of platter, motor, and carriage or just the tonearm? Not to mention if the servo tracks eccentric records or not...

what makes the moving platter zero tracker ala 'Transcriber' inferior?

What do you think is easier to move: a combination of platter, motor, and carriage or just the tonearm? Not to mention if the servo tracks eccentric records or not...

Last edited:

I dunna know, it's not like there's a colony of ants under the platter trying to muscle itWhat do you think is easier to move: a combination of platter, motor, and carriage or just the tonearm? Not to mention if the servo tracks eccentric records or not...

The Transcriber is designed as an integrated system, tonearm plus turntable. Any other tangential tonearm in whatever genre can be used in any turntable. An arm can be as complicated or simple as you want it to be. Regardless of its design, I certainly would not want to restrict what kind of turntable I want to use. To be honest, other than its novelty, there's really no reason to build something like that when you can accomplish the exact same funtion on a servo tonearm. This product has been covered here briefly before and the reaction was less than flattering, for good reason. This is one of those products that is a solution in search of a problem. For anyone who owns a Transcriber, it certainly makes a great conversation piece!

I don't own one but there was one for sale recently on CAM in like new condition I'm still not sure I'm sorry I didn't purchase. It was on and off numerous times for months but I was suspicious of it's performance.The Transcriber is designed as an integrated system, tonearm plus turntable. Any other tangential tonearm in whatever genre can be used in any turntable. An arm can be as complicated or simple as you want it to be. Regardless of its design, I certainly would not want to restrict what kind of turntable I want to use. To be honest, other than its novelty, there's really no reason to build something like that when you can accomplish the exact same funtion on a servo tonearm. This product has been covered here briefly before and the reaction was less than flattering, for good reason. This is one of those products that is a solution in search of a problem. For anyone who owns a Transcriber, it certainly makes a great conversation piece!

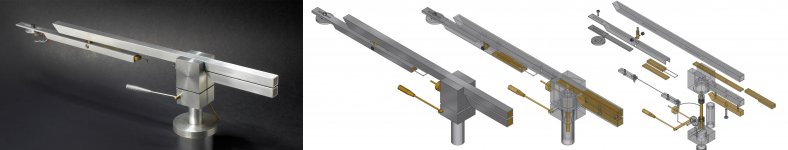

Reed 5A

I don't know it's true or not that this prototype from Reed is POSSIBLY inspired or tickled by this thread. They even use this thread's title in their blurb below! If it's true, I think all who participated in this thread would feel really flattered! The prototype appears to be a passive version of their 5T model minus the servo. It also reminds me of Carlo's 3DTOY PLT creation.

I don't know it's true or not that this prototype from Reed is POSSIBLY inspired or tickled by this thread. They even use this thread's title in their blurb below! If it's true, I think all who participated in this thread would feel really flattered! The prototype appears to be a passive version of their 5T model minus the servo. It also reminds me of Carlo's 3DTOY PLT creation.

In this years Audio Gourmet 2019 show in Vilnius, we’ll be unveiling the prototype of a new Reed 5A tonearm. Introduced as angling-90-tangential-pivot-tonearm, it is based on Double Birch/Thales geometry and will complement our tangential tonearm lineup.

As Reed 5A is still in development, neither its price tag nor market launch date is currently set.

Below is scheme of Double Birch/Thales geometry.

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

Last edited:

Maybe Doug, who invented the double pivot geometry, is entitled to royalties!

It is nice though that Reed clearly indicates the origin of their project: far differently from many other "inventors"

Personally I don't see the advantage of having the vertical pivot on the rear side of the double crank, lengthening the wand and increasing the horizontal eff. mass, but certainly Reed will have good reasons to do so (hope not because of the 3DToy existence).

carlo

It is nice though that Reed clearly indicates the origin of their project: far differently from many other "inventors"

Personally I don't see the advantage of having the vertical pivot on the rear side of the double crank, lengthening the wand and increasing the horizontal eff. mass, but certainly Reed will have good reasons to do so (hope not because of the 3DToy existence).

carlo

Last edited:

Personally I don't see the advantage of having the vertical pivot on the rear side of the double crank, lengthening the wand and increasing the horizontal eff. mass

Since it's a prototype and they're possibly just reusing the same armwands from the 5T or other existing stock parts. Also, it's easier to implement a cueing device this way than if the vertical arm is in the front of the polygon then the cueing holder will be jutting out further into the platter area. I do agree with your rationale of keeping vertical mass lower though. But sometimes for a commercial product, you gotta think for the users as there's always theoretical ideal conflicting with user friendliness.

I wonder if they will ever implement an anti-skating device in that design...

Placing the shaft on the rear crank does not give geometric advantages, instead it adds unuseful constructive issues, imho. The forward crank has now to move above the shaft and therefore does not contribute to the needed rigidity of the whole. A longer shaft also means a heavier CW too, and therefore more horizontal. eff. mass, more stress on the bearings etc. The stiffness of articulations, and the difference between hor. vs vert. effective mass are the concern on these PLTs.

The simple - closed box-like - structure of the 3DToy leaves also the place to install a cueing device, since there no overlapping on platter, even at max extension.

carlo

.

The simple - closed box-like - structure of the 3DToy leaves also the place to install a cueing device, since there no overlapping on platter, even at max extension.

carlo

.

Attachments

H ≠ V

I agree with most of your points and shortening the vertical arm makes sense. Again, it's a prototype and reusing or repurposing existing parts makes sense for the manufacturer. And who knows what they will come up in the end. And user friendliness, in this case, trumps theoretical ideal.

But the above concern with differences in horizontal and vertical mass seems to have been addressed more accurately and eloquently than I ever could by Niffy already in previous posts (forgive me that I haven't located the exact posts) and other threads, ie, they do not have to be the same or similar. In most audio press and magazines (eg, Michael Fremer a la Stereophile for one) there seem to be a universal agreement the two masses should be the same but they hardly want to question the rationale.

Recently I acquired a Dynavector tonearm of split-plane design that vertical mass is much less than horizontal mass and it works beautifully. Based on observation and mulling over concepts, I am now convinced H&V masses do not have to the same, at least it's not a detriment to performance. And it is possibly an advantage to make them independent from each other and preferably less in vertical mass and more in horizontal mass.

"and the difference between hor. vs vert. effective mass are the concern on these PLTs."

I agree with most of your points and shortening the vertical arm makes sense. Again, it's a prototype and reusing or repurposing existing parts makes sense for the manufacturer. And who knows what they will come up in the end. And user friendliness, in this case, trumps theoretical ideal.

But the above concern with differences in horizontal and vertical mass seems to have been addressed more accurately and eloquently than I ever could by Niffy already in previous posts (forgive me that I haven't located the exact posts) and other threads, ie, they do not have to be the same or similar. In most audio press and magazines (eg, Michael Fremer a la Stereophile for one) there seem to be a universal agreement the two masses should be the same but they hardly want to question the rationale.

Recently I acquired a Dynavector tonearm of split-plane design that vertical mass is much less than horizontal mass and it works beautifully. Based on observation and mulling over concepts, I am now convinced H&V masses do not have to the same, at least it's not a detriment to performance. And it is possibly an advantage to make them independent from each other and preferably less in vertical mass and more in horizontal mass.

Last edited:

My doubts are only about that prototype; probably Reed is exploring a different solution, otherwise they shouldn't have a hard time shortening a wooden shaft.

I know well the opinions on effective masses of Niffy and other linear tracker experts, deeply discussed also on the other thread. So well argued that I am certainly unable to counter argue. However, I'm still with the basic doubts also exposed in that forum:

- tracking movements of the stylus are always vertical-horizontal combined movements

- cartridge manufacturers use an homogeneous elastomer, with symmetrical sections (cylindrical or prismatic, no physical structures to aid or counteract different eff. masses).

- 99.99% pivoted tonearms have same H&V masses (..... billions of flies can't be wrong

After some experiences on pivoted vs linears arms (diy and commercial) I have the feeling that this topic has a lot to do with the "different" sound they produce.

However; if it is better to have some difference, how much difference? big as for LTs, medium as for PLTs, small as for split plane pivoted ones? and for which specific cartridge?

What i've learned for PLTs is that the Rabbit, that uses a spring to halve the CW, (and therefore hor. mass too) sounds cleaner than the previous Bunny, with regular CW. With same geometry, same materials and bearings.

carlo

I know well the opinions on effective masses of Niffy and other linear tracker experts, deeply discussed also on the other thread. So well argued that I am certainly unable to counter argue. However, I'm still with the basic doubts also exposed in that forum:

- tracking movements of the stylus are always vertical-horizontal combined movements

- cartridge manufacturers use an homogeneous elastomer, with symmetrical sections (cylindrical or prismatic, no physical structures to aid or counteract different eff. masses).

- 99.99% pivoted tonearms have same H&V masses (..... billions of flies can't be wrong

After some experiences on pivoted vs linears arms (diy and commercial) I have the feeling that this topic has a lot to do with the "different" sound they produce.

However; if it is better to have some difference, how much difference? big as for LTs, medium as for PLTs, small as for split plane pivoted ones? and for which specific cartridge?

What i've learned for PLTs is that the Rabbit, that uses a spring to halve the CW, (and therefore hor. mass too) sounds cleaner than the previous Bunny, with regular CW. With same geometry, same materials and bearings.

carlo

Last edited:

help needed

just a minute friends, we're talking of hor eff mass, but what's the right way to calculate the horizontal eff. mass on a PLT? on the pivoted ones we use the formula, or a spreadsheet, on a linear tracker is equal to the total weight of the mobile masses. Easy and reliable.

But here? So far I have added the weight of the mobile masses (cranks + pulley + vertical pivot support) to that of the Cw, and then I have calculated like a pivoted one.

But. thinking better, maybe this is completely wrong: e.g. for the horizontal mass the lever is class 2, not 1. Which is the fulcrum? And the angle has a role? and the fulcrum-to-load distance is variable or not?

Someone knows how to?

thanks in advance - carlo

just a minute friends, we're talking of hor eff mass, but what's the right way to calculate the horizontal eff. mass on a PLT? on the pivoted ones we use the formula, or a spreadsheet, on a linear tracker is equal to the total weight of the mobile masses. Easy and reliable.

But here? So far I have added the weight of the mobile masses (cranks + pulley + vertical pivot support) to that of the Cw, and then I have calculated like a pivoted one.

But. thinking better, maybe this is completely wrong: e.g. for the horizontal mass the lever is class 2, not 1. Which is the fulcrum? And the angle has a role? and the fulcrum-to-load distance is variable or not?

Someone knows how to?

thanks in advance - carlo

Recently I acquired a Dynavector tonearm of split-plane design that vertical mass is much less than horizontal mass and it works beautifully.

I am very interested in the Dynavector design and have always wanted to run some test record signals on it in order to observe its behavior at resonance. Perhaps you might indulge me? PM sent.

Ray K

After some experiences on pivoted vs linears arms (diy and commercial) I have the feeling that this topic has a lot to do with the "different" sound they produce.

carlo

You are rubbing elbows with a million-dollar question: If one observes differences with/between/among the different arm design categories, then does that also mean that one is ‘better’, and not just ‘different’? Shouldn’t the ideal arm have no sound of its own? If we understand the design aspects of each arm design category which make it sound ‘different’, can we then apply that knowledge universally to make all arm design categories sound better, i.e., each have no characteristic sound at all? In the battle of design categories, shouldn’t the winner be the one we can’t hear in the system at all? Also, can that winning podium be shared by more than one contender? This is what drives diy’ers like us, and I think we have all accepted that challenge.

Ray K

help needed

just a minute friends, we're talking of hor eff mass, but what's the right way to calculate the horizontal eff. mass on a PLT?

thanks in advance - carlo

It's sure over my head. With a PLT the entire mass of the arm has some forward motion as the arm moves toward the spindle, and this should affect the mass calculation, whatever the correct way may be. Also, the forward motion decreases as the arm gets closer to the spindle. Theoretically then, the horizontal mass will change as the arm traverses the record. What a mathematical nightmare.

Ray K

You are rubbing elbows with a million-dollar question: (Dd)

Absolutely agree: each arm has its sound, more, just moving an O ring along the shaft, or reinserting twice the same cables "tunes" it differently. A thousand things affect it, a matter of pure inner resonances.

But it exists too a "family feeling" that I have learned slowly to recognize: the unipivots sound different from the gimbals, and the linear ones from the pivoted. Better or worse I don't care, if an arm sounds clearly different from my references I'm worried, and I try to understand why.

We all think that LTs sound different because of no-skating (but they have a similar side force) and 0 tracking error, and this is certainly true: but exploring over the years almost all types of TAs (except suspended) I began to think that different masses (very, very different in the linear trackers) had some responsibility in coloring the sound.

Why? because both on the PLT and LTs I have worked a lot to reduce the H vs V mass difference, and reducing the weight of the carrriage on the Lil Casey, or of the mobile masses in the Rabbit, the sound has started to resemble that of the references.

More - I never listened to a Dynavector, but years ago I built this split plane (CUBE TA - attachment) and, listening to it again recently, is the pivoted that most resemble a linear one. What have they in common? nothing, only an horizontal mass different from the vertical one. Strange, isn'it?

What a mathematical nightmare (Ray)

I'm trying to figure it out, but it's too complex for my knowledge. it would take Prof. Panayotis....

carlo

Absolutely agree: each arm has its sound, more, just moving an O ring along the shaft, or reinserting twice the same cables "tunes" it differently. A thousand things affect it, a matter of pure inner resonances.

But it exists too a "family feeling" that I have learned slowly to recognize: the unipivots sound different from the gimbals, and the linear ones from the pivoted. Better or worse I don't care, if an arm sounds clearly different from my references I'm worried, and I try to understand why.

We all think that LTs sound different because of no-skating (but they have a similar side force) and 0 tracking error, and this is certainly true: but exploring over the years almost all types of TAs (except suspended) I began to think that different masses (very, very different in the linear trackers) had some responsibility in coloring the sound.

Why? because both on the PLT and LTs I have worked a lot to reduce the H vs V mass difference, and reducing the weight of the carrriage on the Lil Casey, or of the mobile masses in the Rabbit, the sound has started to resemble that of the references.

More - I never listened to a Dynavector, but years ago I built this split plane (CUBE TA - attachment) and, listening to it again recently, is the pivoted that most resemble a linear one. What have they in common? nothing, only an horizontal mass different from the vertical one. Strange, isn'it?

What a mathematical nightmare (Ray)

I'm trying to figure it out, but it's too complex for my knowledge. it would take Prof. Panayotis....

carlo

Attachments

Last edited:

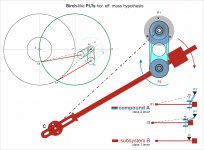

an attempt - some hypothesis for the analysis of horizontal effective mass in PLTs Birch like. (belt-type - double pivot - guided - etc.)

The complex of the mobile masses may be -maybe- regarded as split in the subsystem B (headshell + shaft + CW) and in the compound A of the whole (subsystem B + cranks + pulley + bearings + vertical pivot support)

B is a class one lever on P2 fulcrum, and can be calculated as a normal pivoted one, both for vertical and horizontal mass.

A is instead a class 2 lever on P1 fulcrum, with the load roughly located at the mobile pivot P2. However, the length of the lever (segment C - P1) and the position of the load is variable, in relationship with the angle. (attachment)

This greatly complicates the calculations, and brings an Hor. effective mass to some extent variable. The Beta angle variation of the rotation of the subsystem B is strictly tight to the corresponding variation of the Alpha of the compound A, where Beta = 2/3 Alpha ca. and in this proportion its hor. eff. mass should perhaps affect the total.

To make it worse, as rightly noted by Ray, it should be added that the movement is not a simple rotation, but also an advancement (32 mm ca.), that perhaps should be computed as simple weight, similarly to that of the carriage on linear trackers.

Forgive my naivety, it's just to solicit qualified interventions

carlo

In what sort of a mess we came into?

The complex of the mobile masses may be -maybe- regarded as split in the subsystem B (headshell + shaft + CW) and in the compound A of the whole (subsystem B + cranks + pulley + bearings + vertical pivot support)

B is a class one lever on P2 fulcrum, and can be calculated as a normal pivoted one, both for vertical and horizontal mass.

A is instead a class 2 lever on P1 fulcrum, with the load roughly located at the mobile pivot P2. However, the length of the lever (segment C - P1) and the position of the load is variable, in relationship with the angle. (attachment)

This greatly complicates the calculations, and brings an Hor. effective mass to some extent variable. The Beta angle variation of the rotation of the subsystem B is strictly tight to the corresponding variation of the Alpha of the compound A, where Beta = 2/3 Alpha ca. and in this proportion its hor. eff. mass should perhaps affect the total.

To make it worse, as rightly noted by Ray, it should be added that the movement is not a simple rotation, but also an advancement (32 mm ca.), that perhaps should be computed as simple weight, similarly to that of the carriage on linear trackers.

Forgive my naivety, it's just to solicit qualified interventions

carlo

In what sort of a mess we came into?

Attachments

For a regular pivot arm, its internal damping is neglected to simplify the calculation of effective mass. But for linear arms and tangential pivot tonearms, it may not be neglectable. Therefore, it is better to directly measure resonance frequency.

For a tangential pivot arm, its effective mass may change. I don't know it is a shortcoming or it is an advantage of a tangential pivot arm.

For a tangential pivot arm, its effective mass may change. I don't know it is a shortcoming or it is an advantage of a tangential pivot arm.

Last edited:

Therefore, it is better to directly measure resonance frequency. (super10018)

You're right. But does this allow us to distinguish the resonances related to the horizontal mass from that of the vertical one? And since we are measuring a system, how can we separate the behaviors of the arm from those of the cartridge used?

The intent of this reasoning would be to predict the consequences, not to measure them; to design the PLTs on factual data, as is done with the other types of tonearms.

carlo

You're right. But does this allow us to distinguish the resonances related to the horizontal mass from that of the vertical one? And since we are measuring a system, how can we separate the behaviors of the arm from those of the cartridge used?

The intent of this reasoning would be to predict the consequences, not to measure them; to design the PLTs on factual data, as is done with the other types of tonearms.

carlo

- Home

- Source & Line

- Analogue Source

- Angling for 90° - tangential pivot tonearms