5x5 rods

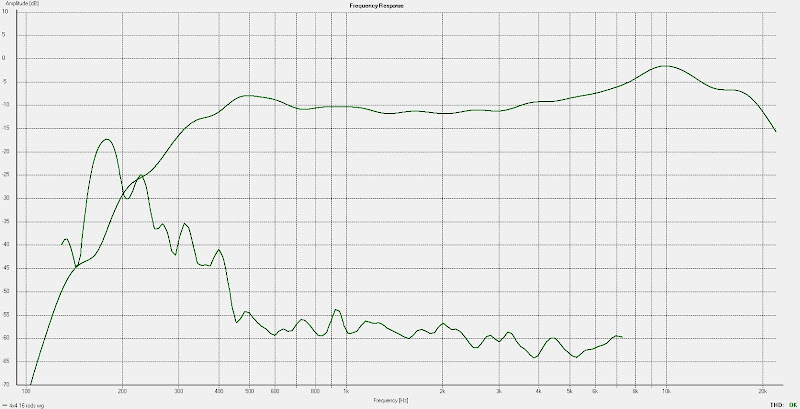

First tests with 16 5x5 iron bars:

With a wave guide for 800 Hz I get:

Ideal to XO at 800 Hz @ 24 dB/octave. Only one EQ -6 dB at 10 kHz and Q=1,24. That is acceptable in my opinion.

I also tested with 12 and 8 bars but only got lower SPL (-2 and -4 dB lower)

In fact, I also tested without any bars at all 😕 and got even lower SPL (another -6 dB) plus a distortion level at -50 dB.

Unusable for sound reproduction of course, but it opens up an easy way to tweak the membrane and its fastening to the structure and then make comparative measurements.

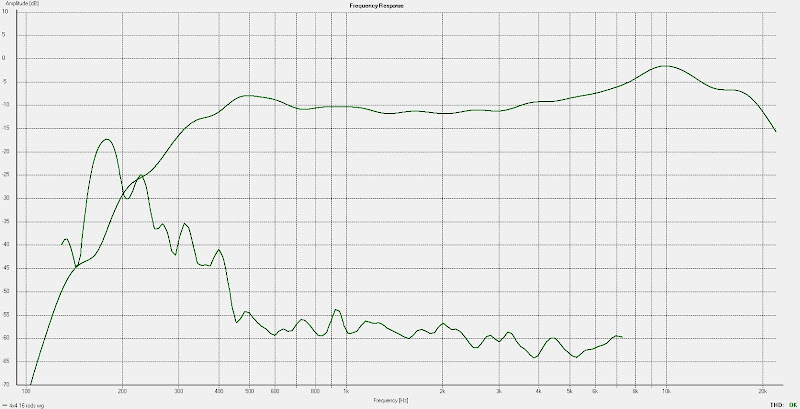

First tests with 16 5x5 iron bars:

With a wave guide for 800 Hz I get:

Ideal to XO at 800 Hz @ 24 dB/octave. Only one EQ -6 dB at 10 kHz and Q=1,24. That is acceptable in my opinion.

I also tested with 12 and 8 bars but only got lower SPL (-2 and -4 dB lower)

In fact, I also tested without any bars at all 😕 and got even lower SPL (another -6 dB) plus a distortion level at -50 dB.

Unusable for sound reproduction of course, but it opens up an easy way to tweak the membrane and its fastening to the structure and then make comparative measurements.

Good idea with etching away some aluminium after the trace cutting.

If the etchant (Natriumperoxidisulfate) is stired during etching it should be even.

It is also important that the temperature doesn´t rise.

Perhaps one can measure the resistance during etching and just stop (pull out and rinse) when desired resistance is reached?

It should be easy to test with a leftover membrane.

I would not recommend etching the al thinner. It wont be even and will find any weakness in the metal eat through that point first. Even if measures ok it may sound good at 0.5w but at 3 a dead duck.

Thanks for your caveat.

It is still worth a try on a leftover membrane or why not on a single aluminium strip.

It is still worth a try on a leftover membrane or why not on a single aluminium strip.

Thanks for your caveat.

It is still worth a try on a leftover membrane or why not on a single aluminium strip.

For an experiment sure, by all means please do test 🙂

My experience with plating and etching span some >35 years. Regardless of irrigation, fluid flow, temperature etc have never seen metals removed evenly, especially along the edges where the metal is undercut.

You're getting very good results thus far and looks well designed/made

I'll build another, one of these days for sure. Would have about 6 months ago but the total cost of the current project (going from nothing to all at once) left little for R&D 😉

I'll build another, one of these days for sure. Would have about 6 months ago but the total cost of the current project (going from nothing to all at once) left little for R&D 😉

Hey guys,

As far as etching goes, I did an experiment last week and eventually the etchant did find a weak spot. Stil, though, that took a reasonably long time. I will experiment with it further when I have a chance.

Another idea - how about electroplating more Al on BoPET film? Could this be done relatively evenly?

As far as etching goes, I did an experiment last week and eventually the etchant did find a weak spot. Stil, though, that took a reasonably long time. I will experiment with it further when I have a chance.

Another idea - how about electroplating more Al on BoPET film? Could this be done relatively evenly?

https://en.wikipedia.org/wiki/Anodizing

It is non conductive and too brittle at the thickness we would require

It is non conductive and too brittle at the thickness we would require

Here is the patent of Jack R. Smiley, which is the inventor of the air motion transformer sold through Paul Squillo :

What?s New | Paul Squillo Music Systems

Loudspeaker apparatus - Smiley, Jack R.

What?s New | Paul Squillo Music Systems

Loudspeaker apparatus - Smiley, Jack R.

In the frequency response curves, the distortion looks a little bit high.

Or am I misinterpreting the curves?

Or am I misinterpreting the curves?

Last edited:

Here is the patent of Jack R. Smiley, which is the inventor of the air motion transformer sold through Paul Squillo :

What?s New | Paul Squillo Music Systems

Loudspeaker apparatus - Smiley, Jack R.

A dipole AMT with a tuned rear cavity and (poor) horn loading, yawn, did I miss anything?

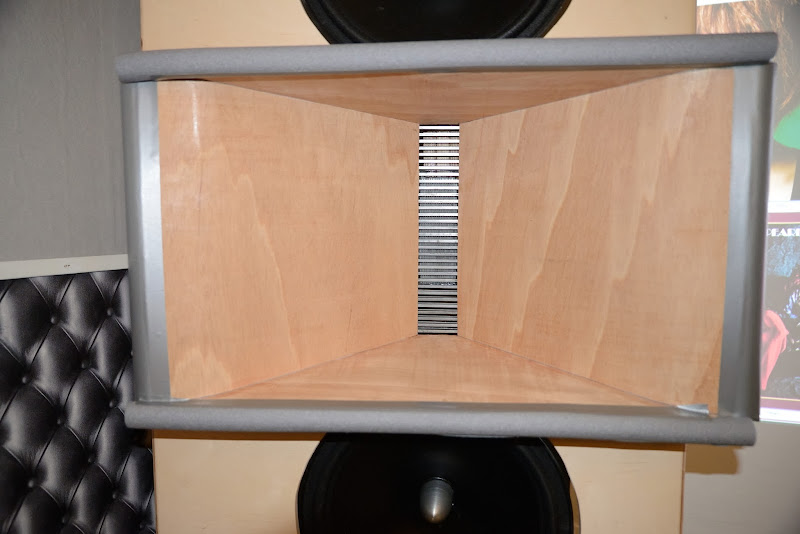

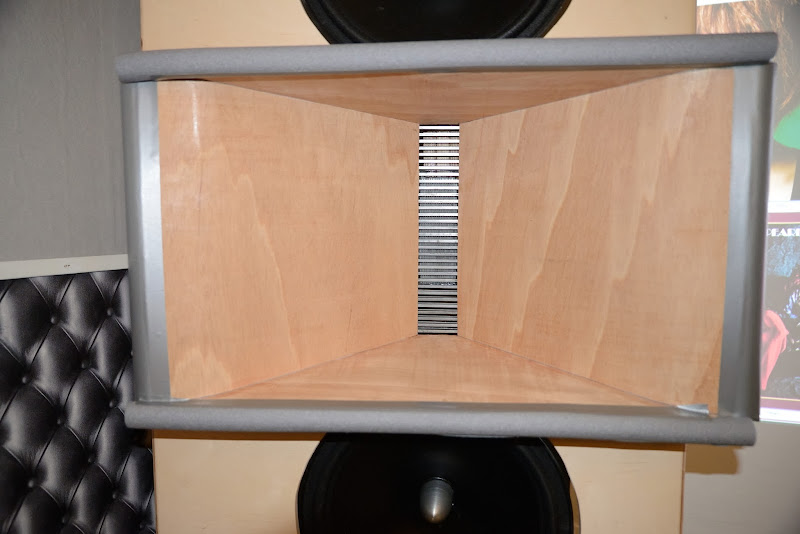

Newmotor, new waveguide, new setup.

Still have to do new membranes to the new motor as it is somewhat wider and double the height of the old one.

I plan to have two membranes in series for each motor.

Still have to do new membranes to the new motor as it is somewhat wider and double the height of the old one.

I plan to have two membranes in series for each motor.

Wow

Those are big

Even the 15" speakers looks small.

It is a good idea to make 2 diaphragms .

How many pleats? Width,depth and hight?

Do you need 7my alu/paper? I got some.I have 10my alu/paper too.

Bernt

Those are big

Even the 15" speakers looks small.

It is a good idea to make 2 diaphragms .

How many pleats? Width,depth and hight?

Do you need 7my alu/paper? I got some.I have 10my alu/paper too.

Bernt

- Status

- Not open for further replies.

- Home

- Loudspeakers

- Planars & Exotics

- Yet another DIY AMT

, so the tweaking begins!

, so the tweaking begins! to Copenhagen this summer I have all the 10 um alu/paper I need, thank you for the tip on where to find it

to Copenhagen this summer I have all the 10 um alu/paper I need, thank you for the tip on where to find it