You don't want permalloy for the gauss/belly band.

Ordinary mild steel, or other high ferrous content iron will do perfectly well. The thicker the better.

Ordinary mild steel, or other high ferrous content iron will do perfectly well. The thicker the better.

You don't want permalloy for the gauss/belly band.........................

i am still waiting for a permalloy strip to wrap around,..............

Ordinary mild steel, or other high ferrous content iron will do perfectly well. The thicker the better.

How did you do this?but i have added a screen winding between primary and secondary.

240 is perfectly OK.I will begin to design the regulator pcb, i think i will go with irfp240/9240 as active elements, i think there are better choices out there... but i am not aware of

there are many vertical mosFETs that work well in audio amplifiers and of these the 240 are well recommended. There are a few that are specifically designed for audio output stages, but they tend to be very expensive in comparison to 240 and give a small benefit if incorporated into a design that gets the best out of them.

Look up R.Cordell's mosFET Power Amp, which uses ordinary switch mode vertical mosFETs for exemplary performance as a linear audio amplifier.

How did you do this?

They are used to put a very tight small gauge winding all around the primary and then connect only one end.

I start wondering about its effectivness.

That sounds odd.

An interwinding screen is normally a screen layer (probably aluminium) wrapped around the primary but insulated so that it cannot form a shorted turn.

That is then connected to the enclosure.

The secondary is then wound around the screening layer.

This forms a C Screen C double capacitance between the three components.

The first C is shunted by a low inductance wire to enclosure and acts as an LC+RC filter to take some of the mains interference to the chassis.

The remaining interference that is not fully attenuated to taken via the second C to the secondary.

I cannot see an inter-winding wire (with lots of inductance) achieving much C filtering.

An interwinding screen is normally a screen layer (probably aluminium) wrapped around the primary but insulated so that it cannot form a shorted turn.

That is then connected to the enclosure.

The secondary is then wound around the screening layer.

This forms a C Screen C double capacitance between the three components.

The first C is shunted by a low inductance wire to enclosure and acts as an LC+RC filter to take some of the mains interference to the chassis.

The remaining interference that is not fully attenuated to taken via the second C to the secondary.

I cannot see an inter-winding wire (with lots of inductance) achieving much C filtering.

I think you are totally right about that.That sounds odd.

An interwinding screen is normally a screen layer (probably aluminium) wrapped around the primary but insulated so that it cannot form a shorted turn.

That is then connected to the enclosure.

The secondary is then wound around the screening layer.

This forms a C Screen C double capacitance between the three components.

The first C is shunted by a low inductance wire to enclosure and acts as an LC+RC filter to take some of the mains interference to the chassis.

The remaining interference that is not fully attenuated to taken via the second C to the secondary.

I cannot see an inter-winding wire (with lots of inductance) achieving much C filtering.

I don't know why, but they have did this way for a very long time, maybe is less effective or more easy to manage for them.

I think at this point is stupid to take out the secondary winding to redo the electrostatic shielding with a copper/alluminium foil.

If it makes more damage than good i will keep it disconnected.

For the belly shielding i have taken a roll of the same material they use for the toroidal core itself, i am going to wrap around as many times i can to increase the thickness. (the foil is 0.5mm thick).

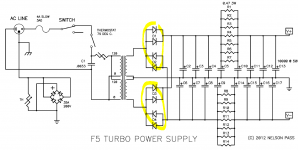

Compare to a N.Pass Zener+Follower PSU.This is the regulator i am evaluating to put in use.

irfp240/irfp9240 as pass elements.

Do you think is it suitable ? Simulated with a 4 amp constant load and it seems fine.

Compare to a N.Pass Zener+Follower PSU.

I have taken the schematic from the Zen v3 PSU.

my only concern is about filtering,

i have planned to use 22mf after bridge and 22mf after regulator.

so CRegC => 22mf -> ZenV3 -> 22mf. One for each half supply.

From simulations the output ripple is almost absent, and at the input is around 2Vptp (with 4A costant current load).

I don't know how much transients loads the capacitors/regulator. Maybe i need to add up some more capacitance in the output ? For sure i will put as much as possible of it close to the output devices.

For the rectifier bridge i also paln to "recycle" the same MUR3020 that we need in the output stage. I think the parameters are fine to support this workload.

Little update.

Today has arrived all the MUR3020 didoes, low power resistors (Royal Ohm), source degeneration resistors (Vishay, i will match them to be equal as possible) cascode BJTs (SA1837 / SC4793) and other minor parts.

I have made some measurements on the real transformers.

and i got 50.5v [DC] loaded with 3 ampere (used an electronic load).

in this situation, with only 22mf of filtering after bridge i got ~850mVpp.

I fear that the regulator (inspired by Zenv3) will dissipate too much and maybe the "easy" way is to filter the ripple with a stronger capacitor bank + LC filtering.

Said that less ripple is always the best, in your experience with thoose topology how much of the PSRR i would expect ? in other words, there a safe "threshold" of ripple to avoid too much noise in the output ?

Today has arrived all the MUR3020 didoes, low power resistors (Royal Ohm), source degeneration resistors (Vishay, i will match them to be equal as possible) cascode BJTs (SA1837 / SC4793) and other minor parts.

I have made some measurements on the real transformers.

and i got 50.5v [DC] loaded with 3 ampere (used an electronic load).

in this situation, with only 22mf of filtering after bridge i got ~850mVpp.

I fear that the regulator (inspired by Zenv3) will dissipate too much and maybe the "easy" way is to filter the ripple with a stronger capacitor bank + LC filtering.

Said that less ripple is always the best, in your experience with thoose topology how much of the PSRR i would expect ? in other words, there a safe "threshold" of ripple to avoid too much noise in the output ?

Hi guys,

still waiting for the pcb to arrive....

I am making some cam program for my hurco to make pockets, hole, threads for all the mosfets and pcbs...

any advice on where to put the thermistor ? i got that is for reducing thermal drift, but i have seen a lot of pictures where many users puts them either straight over mosfet of other over the pcb...

Can you advice a good spot to mount them ?

Thanks

still waiting for the pcb to arrive....

I am making some cam program for my hurco to make pockets, hole, threads for all the mosfets and pcbs...

any advice on where to put the thermistor ? i got that is for reducing thermal drift, but i have seen a lot of pictures where many users puts them either straight over mosfet of other over the pcb...

Can you advice a good spot to mount them ?

Thanks

you know for any picture of Papa's F5T ?

... mhhh only from other users, maybe i've missed something important 🙁

as usual , there are plenty of details to learn , just looking at pictures of origin

in a meantime , as you're searching for either F5 or F5T origin pictures , place body of NTC right against ceramic part of mosfet body

take care that legs of NTC are well away of any metal part , or even better - insulate them.

in a meantime , as you're searching for either F5 or F5T origin pictures , place body of NTC right against ceramic part of mosfet body

take care that legs of NTC are well away of any metal part , or even better - insulate them.

as usual , there are plenty of details to learn , just looking at pictures of origin

in a meantime , as you're searching for either F5 or F5T origin pictures , place body of NTC right against ceramic part of mosfet body

take care that legs of NTC are well away of any metal part , or even better - insulate them.

There's need to clamp it on the ceramic, or is just enough to bend the insulated legs against the mosfet ?

bend legs to lean NTC to ceramic part of mosfet

as you can see on pictures here : 6moons audio reviews: FirstWatt F5 , Pa is putting NTC in proximity of mosfet mid pin ; that's convenient enough , with his pcb and parts arrangement (Him - being Founder of FAB Club)

I don't know which pcbs are you using and where exactly NTCs are situated , but you can always extend NTC legs ( heatshrink!!)

wherever you put NTC , difference is just in biasing behavior in time domain ....... more intimate thermal bond of NTC with mosfet case/surround is resulting in lesser and faster Iq change

though , ceramic part of mosfet case is most secure position ....... not one F5 gone Dodo , due to poor NTC going nude in hostile environment

http://www.6moons.com/audioreviews/firstwatt7/2_7.jpg

http://www.6moons.com/audioreviews/firstwatt7/2_7.jpg

as you can see on pictures here : 6moons audio reviews: FirstWatt F5 , Pa is putting NTC in proximity of mosfet mid pin ; that's convenient enough , with his pcb and parts arrangement (Him - being Founder of FAB Club)

I don't know which pcbs are you using and where exactly NTCs are situated , but you can always extend NTC legs ( heatshrink!!)

wherever you put NTC , difference is just in biasing behavior in time domain ....... more intimate thermal bond of NTC with mosfet case/surround is resulting in lesser and faster Iq change

though , ceramic part of mosfet case is most secure position ....... not one F5 gone Dodo , due to poor NTC going nude in hostile environment

Last edited:

bend legs to lean NTC to ceramic part of mosfet

as you can see on pictures here : 6moons audio reviews: FirstWatt F5 , Pa is putting NTC in proximity of mosfet mid pin ; that's convenient enough , with his pcb and parts arrangement (Him - being Founder of FAB Club)

I don't know which pcbs are you using and where exactly NTCs are situated , but you can always extend NTC legs ( heatshrink!!)

wherever you put NTC , difference is just in biasing behavior in time domain ....... more intimate thermal bond of NTC with mosfet case/surround is resulting in lesser and faster Iq change

though , ceramic part of mosfet case is most secure position ....... not one F5 gone Dodo , due to poor NTC going nude in hostile environment

Perfect, got it.

Today i have ordered to a local company 4x inductors, 1mH / 0.04Ω rated for 10A. They'll make on a toroidal iron core.

The main PCB was stuffed with all the components, and this weekend i will CNC-drill all the holes on the heatsinks so i can start attaching the boards and start some preliminary tests.

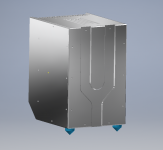

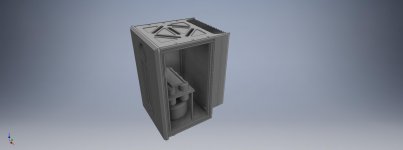

The finished case form-factor will be something like the images attached.

Wish me luck 😀

Attachments

Last edited:

some days are passed. And i still trying to recover from a bad flu.

Next step will be the machining of the heatsink, so i can finally attach the mosfets and start tuning the system.

In the meantime i have received previous ordered inductances of 2mH 10A.

i start planning the power supply for the tests.

I have on hand a 1400VA toroid with 230v input and 2x38Vac secondaries.

I have made some pcbs to mount the same MUR3020 i use on the channel for rectification... and my idea is to make a 38-0-38 Center tap, with dual bridge and then 44mF+2mH+44mF each rail. this will end up in something like 55Vdc unloaded.

What do you think about this arrangement ?

There are advantages (from your honorable experiences) in using a 0-38 + 0-38 with dual bridge over a center tapped solution ?

Next step will be the machining of the heatsink, so i can finally attach the mosfets and start tuning the system.

In the meantime i have received previous ordered inductances of 2mH 10A.

i start planning the power supply for the tests.

I have on hand a 1400VA toroid with 230v input and 2x38Vac secondaries.

I have made some pcbs to mount the same MUR3020 i use on the channel for rectification... and my idea is to make a 38-0-38 Center tap, with dual bridge and then 44mF+2mH+44mF each rail. this will end up in something like 55Vdc unloaded.

What do you think about this arrangement ?

There are advantages (from your honorable experiences) in using a 0-38 + 0-38 with dual bridge over a center tapped solution ?

Attachments

Last edited:

some days are passed. And i still trying to recover from a bad flu.

Next step will be the machining of the heatsink, so i can finally attach the mosfets and start tuning the system.

In the meantime i have received previous ordered inductances of 2mH 10A.

i start planning the power supply for the tests.

I have on hand a 1400VA toroid with 230v input and 2x38Vac secondaries.

I have made some pcbs to mount the same MUR3020 i use on the channel for rectification... and my idea is to make a 38-0-38 Center tap, with dual bridge and then 44mF+2mH+44mF each rail. this will end up in something like 55Vdc unloaded.

What do you think about this arrangement ?

There are advantages (from your honorable experiences) in using a 0-38 + 0-38 with dual bridge over a center tapped solution ?

anyone ?

Attachments

- Status

- Not open for further replies.

- Home

- Amplifiers

- Pass Labs

- Y.A.F5Tv3.B.T. Yet another F5Tv3 Build Thread