A quick update on the HPA1. I have placed a 0.8 uH inductor in parallel with the 3.3 ohm output series resistor. The amplifier remains stable into all the capacitive loads used on the original test.

Some folks like to drive their headphones from a very low Zsource, so this will be of interest to them. I’m off to Scotland at the end of the week with some visitors here this week, so when I’m back in late April, I will post up the results.

Some folks like to drive their headphones from a very low Zsource, so this will be of interest to them. I’m off to Scotland at the end of the week with some visitors here this week, so when I’m back in late April, I will post up the results.

oh, that's a good news. I calculated 15.62 turns on a 8mm air core, with 1mm diameter bare copper wire. 8mm is the size of a pencil, so it could be wound easily using just a pencil and some 1mm wire.A quick update on the HPA1. I have placed a 0.8 uH inductor in parallel with the 3.3 ohm output series resistor. The amplifier remains stable into all the capacitive loads used on the original test.

Some folks like to drive their headphones from a very low Zsource, so this will be of interest to them. I’m off to Scotland at the end of the week with some visitors here this week, so when I’m back in late April, I will post up the results.

I wound my coil around the 3.3 Ohms resistor after first putting a layer of tape over it so needed a few more turns. You can raise the resistor slightly off the board to do this and give yourself a bit more space. I secured the windings in place with a drop of superglue

Yes. That will work ok. Stick with an air core because they don’t saturate and therefore don’t cause distortion

A 0.5 to 1W air coil will work fine as the power dissipation is very low in the coil. I wound c 22 turns of #22 AWG over a 0.5 Watt 3.3 Ohm resistor on my one.

The coil resistance should not be more than .2-.5 Ohms - obviously the lower the better.

The coil resistance should not be more than .2-.5 Ohms - obviously the lower the better.

Having difficulty finding a part with a large enough inductance...my design (yes, I'm finally getting to it ahah) doesn't have a THT output resistor to wind a coil around 😀 I can put two in series though

Andrew and Bucket,

Why not wrap your own inductor around the body of a #2 pencil? Or the barrel of a pen? Then use a quick swipe of hot melt glue on the side of the inductor facing the PCB to keep it's shape while handling. Or am I completely missing something??

Why not wrap your own inductor around the body of a #2 pencil? Or the barrel of a pen? Then use a quick swipe of hot melt glue on the side of the inductor facing the PCB to keep it's shape while handling. Or am I completely missing something??

I figured it out - will be using a 3D printed plastic toroid core, hand-winding it and mounting it vertically 🙂

Excellent idea Carl! 👍👍👍👍Andrew and Bucket,

Why not wrap your own inductor around the body of a #2 pencil? Or the barrel of a pen? Then use a quick swipe of hot melt glue on the side of the inductor facing the PCB to keep it's shape while handling. Or am I completely missing something??

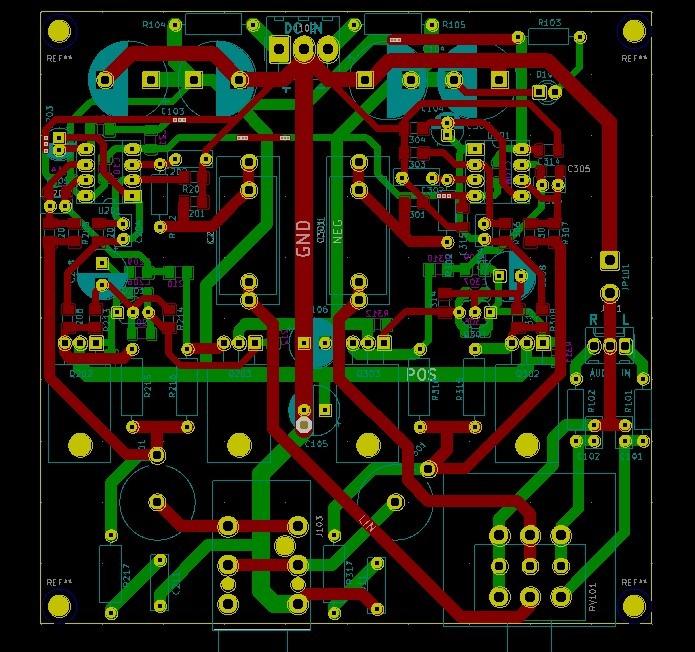

Oop R2 is upside down in that image, I've fixed that in the gerbers 😀

I'm super excited to finally hear your design though, I've been so busy with moving (funnily enough, to the UK!) that I didn't get a chance to breath until recently...

I'm super excited to finally hear your design though, I've been so busy with moving (funnily enough, to the UK!) that I didn't get a chance to breath until recently...

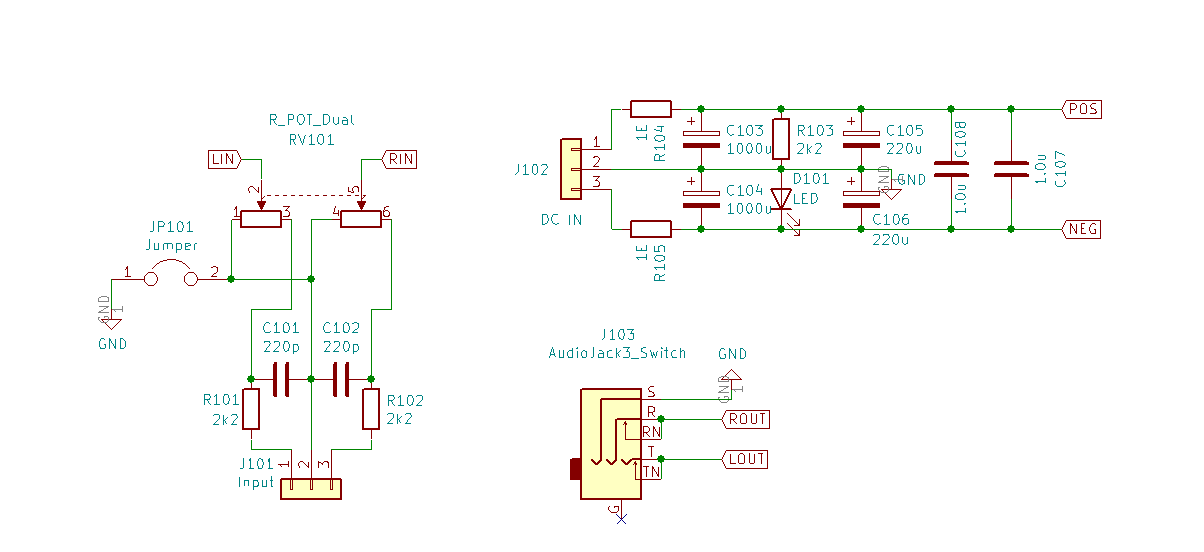

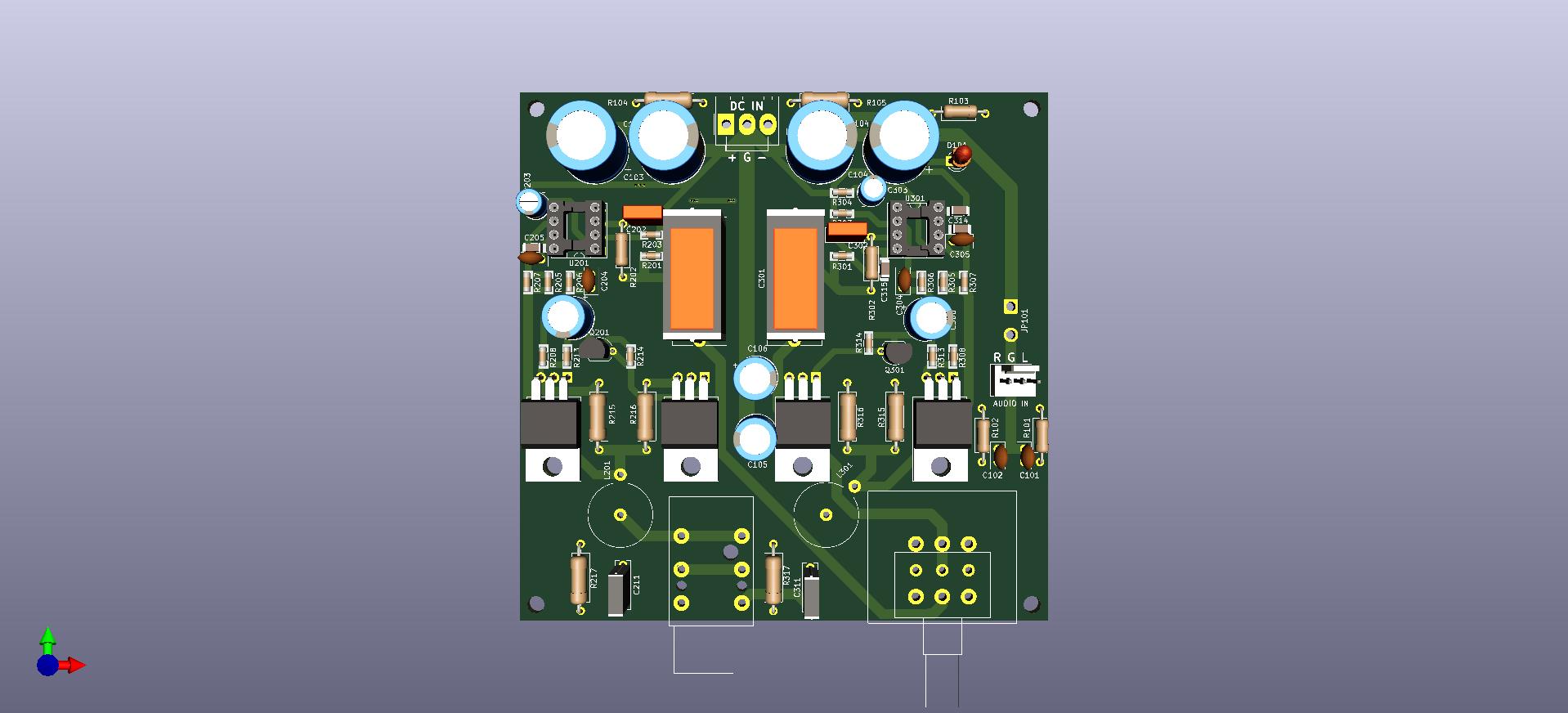

I will try my version, including volume pot and output socket into PCB. I put filter at the input before volume pot, not sure if it's a good idea. Any suggestion is very much appreciated.

Last edited:

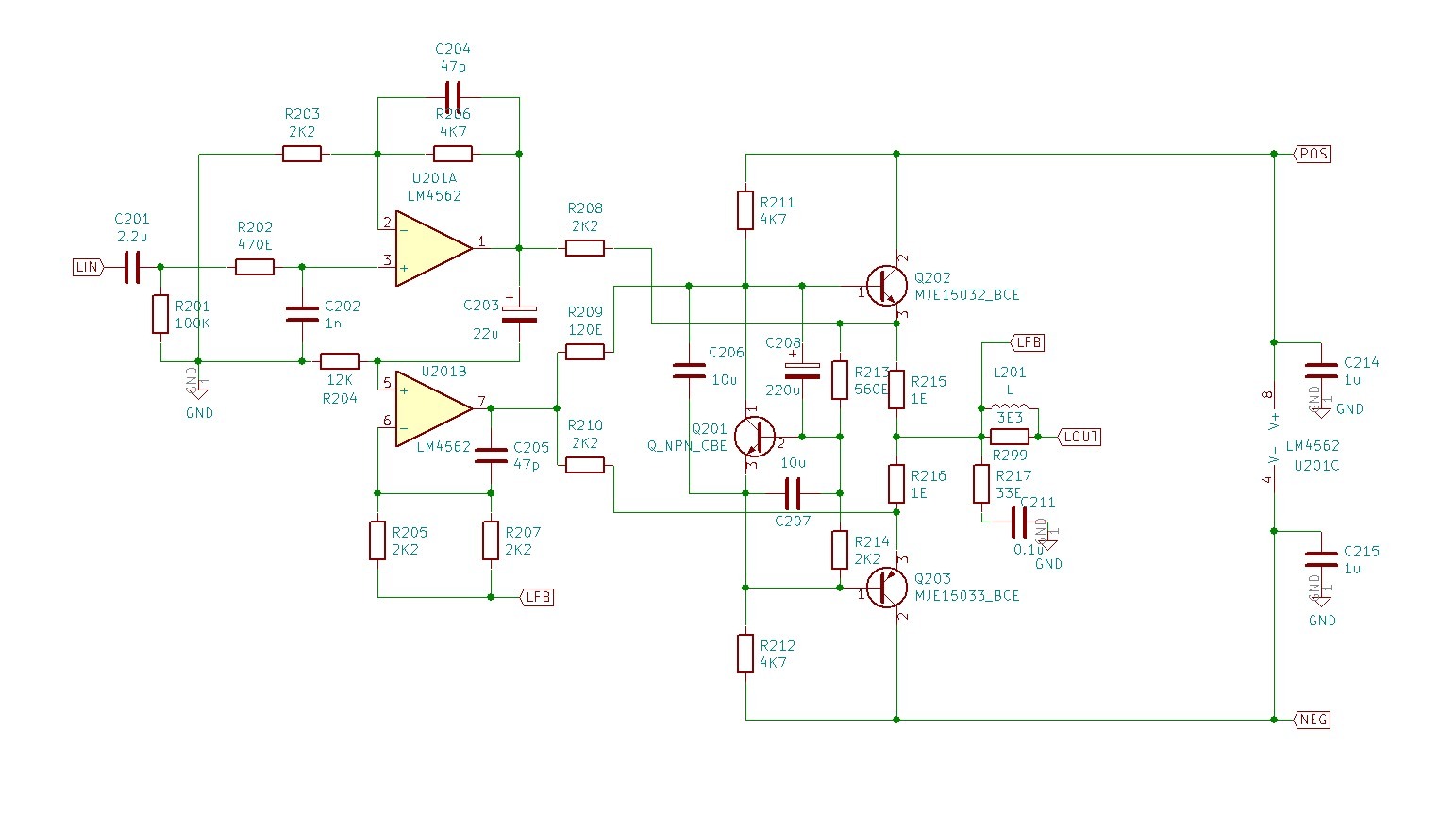

You have a big loop area between your power ground and the input signal ground. Run the input signal ground round towards the front and then down the middle of the board to the power connector 0V and connect it star-ground. Keep the signal ground and the power ground as close as possible to each other until you join them back at the main incoming power ground.

Each transistor will dissipate about 1.5W on +-15V rails, so my suggestion is that you put the transistors under the board with the leads bent upwards so they are pressing on a heatsink, or, you bolt them to the bottom plate of the amp assuming the chassis is aluminium 3mm thick minimum.

I can't see where C214/215 are, but they must be as close to the opamps as possible - especially if you are using the LM4562 which have c. 55MHz GBW.

Note, I also built and measured this with the OPA1642 - I think its a bit better sounding with that opamp, but to be honest the measurements were almost exactly the same as the LM4562. Make sure you can get the opamps you are going to use in the DIP8 package otherwise its mostly SO8 nowadays.

Otherwise, layout looks good - nice and compact!

👍

Each transistor will dissipate about 1.5W on +-15V rails, so my suggestion is that you put the transistors under the board with the leads bent upwards so they are pressing on a heatsink, or, you bolt them to the bottom plate of the amp assuming the chassis is aluminium 3mm thick minimum.

I can't see where C214/215 are, but they must be as close to the opamps as possible - especially if you are using the LM4562 which have c. 55MHz GBW.

Note, I also built and measured this with the OPA1642 - I think its a bit better sounding with that opamp, but to be honest the measurements were almost exactly the same as the LM4562. Make sure you can get the opamps you are going to use in the DIP8 package otherwise its mostly SO8 nowadays.

Otherwise, layout looks good - nice and compact!

👍

- Home

- Amplifiers

- Headphone Systems

- X-Altra HPA-1 Class A Headphone Amplifier