Cool! I tried to find a fold where you would not have any wasted space. But, sometimes you gotta do what you gotta do!

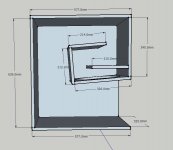

And this is how it is gonna look like in wood:

Yeah. Will calculate segment areas and the length of the horn one more time and see how it deviates from unfolded sim. I think i grasp the idea of calculating distance with centerline method (well, if i read about it one more time). But do i have to measure segment area in each of the fold and enter new values in horresp sim? I guess, i will run out of segments, since i have 5 folds. I guess AkAbak allows to use unlimited amount of segments in the sim?

Cool! I tried to find a fold where you would not have any wasted space. But, sometimes you gotta do what you gotta do!

Yeah. Will calculate segment areas and the length of the horn one more time and see how it deviates from unfolded sim. I think i grasp the idea of calculating distance with centerline method (well, if i read about it one more time). But do i have to measure segment area in each of the fold and enter new values in horresp sim? I guess, i will run out of segments, since i have 5 folds. I guess AkAbak allows to use unlimited amount of segments in the sim?

Attachments

Check out the BOXPLAN-MTH, BOXPLAN-MTHALT and BOXPLAN-OTHORN workbooks from my Horn Folding page at my website. Those should give you some ideas on how to optimize the folding for your build.

You have to break up the horn path into sections. Double folds are normally 4 sections. You can use a MTH (pic 1) or THAM (pic 2) type fold.

A 10ft horn = 4 x 30" sections.

If your expansion is going from 4" to 12", then your four 2" expansion paths look like this....

Section 1 = 4" to 6" rise for 30".

Section 2 = 6" to 8" rise for 30".

Section 3 = 8" to 10" rise for 30".

Section 4 = 10" to 12" rise for 30".

Height = 30" + 0.75" (the 1 internal perpendicular panel) + (2 external panels x 0.75") = 32.25".

Depth = 4" + 12" + 8" + 8" + [(3 internal panels + 2 external panels) x 0.75"] = 35.75".

Width for a 12" sub = at least 12.5" + (2 external panels x 0.75") = 14".

Bare in mind, I did this post on my phone while sitting on the throne

A 10ft horn = 4 x 30" sections.

If your expansion is going from 4" to 12", then your four 2" expansion paths look like this....

Section 1 = 4" to 6" rise for 30".

Section 2 = 6" to 8" rise for 30".

Section 3 = 8" to 10" rise for 30".

Section 4 = 10" to 12" rise for 30".

Height = 30" + 0.75" (the 1 internal perpendicular panel) + (2 external panels x 0.75") = 32.25".

Depth = 4" + 12" + 8" + 8" + [(3 internal panels + 2 external panels) x 0.75"] = 35.75".

Width for a 12" sub = at least 12.5" + (2 external panels x 0.75") = 14".

Bare in mind, I did this post on my phone while sitting on the throne

Attachments

My fault, my post is based on the alternative MTH mouth.

Reverse direction for T-TQWT (negative flare TH).

Reverse direction for T-TQWT (negative flare TH).

Attachments

Last edited:

Been trying to wrap my head around those workbooks, Brian. Will do one more try, thank you.

BTW, in hornresp model, the volume is about 280 liters. The volume of the box i made in SketchUp is about 440 liters 🙂

BTW, in hornresp model, the volume is about 280 liters. The volume of the box i made in SketchUp is about 440 liters 🙂

I was able to get a nice and flat model out of BOXPLAN-OTHORN.

Here is how it models in HornResp:

Looks in spreadsheet:

A nice surprise was a group delay graph, which was a lot lower than in my model:

The downside is low end - it is only good to about 28-30Hz.

Any way to make it longer in the spreadsheet and still be able to optimize the folds? I would really like to tune it to about 19-22Hz.

Here is how it models in HornResp:

Looks in spreadsheet:

A nice surprise was a group delay graph, which was a lot lower than in my model:

The downside is low end - it is only good to about 28-30Hz.

Any way to make it longer in the spreadsheet and still be able to optimize the folds? I would really like to tune it to about 19-22Hz.

Keep adding the same amount of length in each spreadsheet segment until you get to the desired tune in HR.

FWIW, the HF corner is governed by its effective upper mass corner: [Fhm] = 2*Fs/Qts'

Acoustic path-length: [Fb or Fp] = SoS/4/frequency

Qts': Qts + any added series resistance [Rs]: Calculate new Qts with Series Resistor

Qts' = ~0.774

Fhm = ~2*33.65/~0.774 = ~84 Hz

Fp = ~34400/4/19 Hz = ~453 cm S2-S3 or S4

~34400/4/84 = ~102 cm divided between S1-S2, S3-S4 or S4-S5

~453+102 = ~555 cm total length

Acoustic path-length: [Fb or Fp] = SoS/4/frequency

Qts': Qts + any added series resistance [Rs]: Calculate new Qts with Series Resistor

Qts' = ~0.774

Fhm = ~2*33.65/~0.774 = ~84 Hz

Fp = ~34400/4/19 Hz = ~453 cm S2-S3 or S4

~34400/4/84 = ~102 cm divided between S1-S2, S3-S4 or S4-S5

~453+102 = ~555 cm total length

Attachments

You definitely need to add length to S1-S2 to get that 2nd peak to 80hz.

Hmm, couldn't move it above Fhm in a TH sim, only in a T-TQWT. 🙁

HUGE enclosure!

Yeah, weak motor tuned so far below Fs = mega box to get any efficiency.

Hmm, couldn't move it above Fhm in a TH sim, only in a T-TQWT. 🙁

Did you try a straight flare TH (TQWP)?

- Home

- Loudspeakers

- Subwoofers

- Will this driver in the Tapped Horn configuration?