The air in the enclosure is a good insulator, but the absorbent is a less good insulator, allowing heat to conduct into the absorbent.

An interesting experiment may be to incorporate fine copper strands into the absorbent material!

Yes, but I think the development I mentioned earlier was a little more elaborate than that. I have a vague feeling an improvement of something like 40-50% was mentioned. But then everything went quiet...

Thank you keithj01 and Galu. So the optimum amount of stuffing doesn’t just reduce the amount of sound bouncing around within the enclosure, it can help the system work more linearly too. That’s very good to know!

At bass frequencies, the main value is to increase the effective volume of the box. Interior wall lining is the most effective for suppressing reflections etc., in my opinion, but higher frequencies can respond well to the right kind of stuffing material...Thank you keithj01 and Galu. So the optimum amount of stuffing doesn’t just reduce the amount of sound bouncing around within the enclosure, it can help the system work more linearly too. That’s very good to know!

Why address that to me? I said that earlier in the thread, and it's something I've been saying for years.

Sorry if I've intruded on your area of expertise - that was not my intention.

I was simply expanding on your statement, and I now note your brief mention of isothermal operation in post #8.

No problem - though describing thermodynamics as an area of expertise on my part might be a bit of a stretch!Sorry if I've intruded on your area of expertise - that was not my intention.

I was simply expanding on your statement, and I now note your brief mention of isothermal operation in post #8.

Quoting this for adding information,

As can be seen in impedance measurements too 😉. Personally I use wool felt on the walls and to close off the fiberglass fill I often use (as to not have these fibers reach the drivers).

Fiberglass is used in the center of the chamber as absorbent fill. I've tried way more materials and the simple fluffy kind of fiberglass insulation is pretty hard to beat, especially

when combined with wool felt. I use gloves to handle it and make sure I'd only ever used it in closed spaces. Maybe the denim kind, available in the US could be a good substitute?

Interior wall lining is the most effective for suppressing reflections etc., in my opinion, but higher frequencies can respond well to the right kind of stuffing material...

As can be seen in impedance measurements too 😉. Personally I use wool felt on the walls and to close off the fiberglass fill I often use (as to not have these fibers reach the drivers).

Fiberglass is used in the center of the chamber as absorbent fill. I've tried way more materials and the simple fluffy kind of fiberglass insulation is pretty hard to beat, especially

when combined with wool felt. I use gloves to handle it and make sure I'd only ever used it in closed spaces. Maybe the denim kind, available in the US could be a good substitute?

Yes, but I think the development I mentioned earlier was a little more elaborate than that.

My money is on carbon nanotubes!

With a thermal conductivity 7.5 times that of copper and a density 0.15 times that of copper, they could be just right stuff to incorporate into speaker absorbent! 🤓

Could be...My money is on carbon nanotubes!

With a thermal conductivity 7.5 times that of copper and a density 0.15 times that of copper, they could be just right stuff to incorporate into speaker absorbent! 🤓

I wish I could remember more about the short article I was reading. I have to say, I was sceptical about the claims though...

That’s good to know too. What thickness of wool felt do you recommend?Quoting this for adding information,

As can be seen in impedance measurements too 😉. Personally I use wool felt on the walls and to close off the fiberglass fill I often use (as to not have these fibers reach the drivers).

Fiberglass is used in the center of the chamber as absorbent fill. I've tried way more materials and the simple fluffy kind of fiberglass insulation is pretty hard to beat, especially

when combined with wool felt. I use gloves to handle it and make sure I'd only ever used it in closed spaces. Maybe the denim kind, available in the US could be a good substitute?

Those impedance plots seem to be the ideal way of evaluating internal absorption strategies (and driver performance) with minimal effort and outlay.Quoting this for adding information,

As can be seen in impedance measurements too 😉. Personally I use wool felt on the walls and to close off the fiberglass fill I often use (as to not have these fibers reach the drivers).

Fiberglass is used in the center of the chamber as absorbent fill. I've tried way more materials and the simple fluffy kind of fiberglass insulation is pretty hard to beat, especially

when combined with wool felt. I use gloves to handle it and make sure I'd only ever used it in closed spaces. Maybe the denim kind, available in the US could be a good substitute?

It's a pity that fibreglass seems to be the ideal stuffing material, as it's so nasty! Is there any way, in your experience, that satisfactory reflection suppression can be achieved with wall-lining alone (or in conjunction with something innocuous like polyester)?

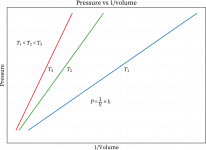

P is proportional to 1/V - describing a hyperbola rather than a straight line.

I'm not sure I follow you there.

A plot of P against 1/V is a straight line (see attachment).

Attachments

What thickness of wool felt do you recommend?

I would recommend 20 to 25 mm, especially on the rear wall, to reduce internal reflections.

Some glue it to the rear of the driver magnets as well.

Now plot P against V - which is what''s relevant here.I'm not sure I follow you there.

A plot of P against 1/V is a straight line (see attachment).

Is there any way, in your experience, that satisfactory reflection suppression can be achieved with wall-lining alone (or in conjunction with something innocuous like polyester)?

Sheep's wool (supported by nylon netting) is a very effective absorber due to the random orientation of the wool fibres.

Now plot P against V - which is what''s relevant here.

Now that is a hyperbola!

As we both knew. 😉

That’s good to know too. What thickness of wool felt do you recommend?

I bought a huge roll once that was about 7 mm thick. If needed I can double up, but even at this size it is quite effective to absorb the peak of impedance wiggles.

Those impedance plots seem to be the ideal way of evaluating internal absorption strategies (and driver performance) with minimal effort and outlay.

It's a pity that fibreglass seems to be the ideal stuffing material, as it's so nasty! Is there any way, in your experience, that satisfactory reflection suppression can be achieved with wall-lining alone (or in conjunction with something innocuous like polyester)?

Fiberglass is a good overall performer, meaning it works well over the entire range of frequencies of interest in Audio. If using it for mid frequencies, say 150 Hz and above Angel hair from Twaron is extremely effective. A little really goes a long way. I did not have success with polyester fill. I'd try long hair wool for mid frequencies if I could get it easily. (Edit: Galu beat me to it)

The fluffy fiberglass is cheap and quite a good performer, but it truly is nasty to work with.

What's up with the activated charcoal used as damping material? I think I remember Kef were on to that? And now they are using metamaterial... it's one of those firms that's quite active in finding new means...

Now plot P against V - which is what''s relevant here.

According to Boyle’s Law, the amount a gas will compress is proportional to the pressure applied.

This relationship is linear, if pressure on a gas doubles, its volume decreases by 1/2.

Provided temperature remains constant, of course.

Would that be as a lining material, as I think the role for wall lining might be slightly different from stuffing's role. Lining is mainly(???) to do with softening the air/wall interface, to reduce the amount of reflection - although absorbency (i.e. the conversion of motion to heat) would help too. Whereas stuffing is there for absorbency.Sheep's wool (supported by nylon netting) is a very effective absorber due to the random orientation of the wool fibres.

(Absorbency isn't to be confused with the heat-sink effect we've been talking about earlier, regarding isothermal/adiabatic behaviour of air as a lumped element.)

What's up with the activated charcoal used as damping material?

Cool! Next best thing to carbon nanotubes! 🙂

Not as a lining, as a central absorbent - although you can use wool felts for lining purposes.Would that be as a lining material

- Home

- Loudspeakers

- Multi-Way

- Why does a drive unit sound so different when placed in an enclosure?