While RS Components is very short of semi conductors strangely they are also short of a lot of other things too.Ask TI?

By most accounts, the chip shortages are easing down.

Workers are trickling back, and the demand pressure from big customers is a bit less now.

Or buy complete boards, those may be adequate quality fakes.

Been trying since day 1 here.Woah!! Independent thought. Crazy!! Don't go start a trend now... 🙂

A few get it, some get angry, a couple denounce me to moderators .... yet I hope the small seed grows.

You will be surprised.It'd take more than a garage faking operation, though.

Tom

I am originally from Chivilcoy, a 65k people town in the middle of the Pampas, mostly agricultural based but with a surprising amount of Industry.

We have a strong Japanese colony and a Nisei friend of mine, after travelling to Japan , came back with a license from none less than Panasonic.

This was in the 80´s when Argentina had STRONG Tariff protection, and for most worldwide manufacturers the best way to get into our market was to set up shop here. Period.

I visited his Factory (of course 😉 ), not a garage operation but it fit comfortably into our standard City approved warehouse allotment of 8.66 by 36/40/50 meters, some 28 by 118/131/164 feet.

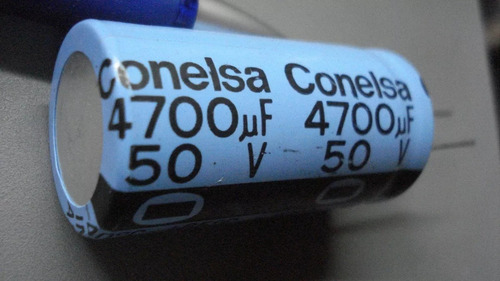

He got straight from Panasonic Japan 2 or 2.5ft wide by 6 ft long (quoting from memory) rolls of already treated aluminum foil, which came separated by dielectric strength (say 16/22/33/50 V, etc.) and each had a definite "capacitance by square cm" value, plus a process Book stating the "recipe" for each type, say: "a 10uF * 16V cap takes a 40 cm long strip of 8 mm wide 16V foil which fits on the 6 by 10 mm case" or something very close.

He had the machinery to cut the required strips, roll them up, add terminals, put them in the proper case, fill it with electrolyte (which he got in 55 gallon drums), seal and wrap it in heatshrink (the easiest part 😉 )

In all, and as long as you had the (not NASA spec by any means) machinery and supplies you could churn out good quality caps 24/7/365.

Operators (I knew many of them) were standard "Industrial School" students type, not NASA type either (not needed).

Sadly Factory failed when our Government destroyed protection and opened Customs doors wide.

Here "everybody knows" those are actually Japanese Panasonic caps, so they still appear (and are sold) in auctions, even if they are at least 20 years old. 😱

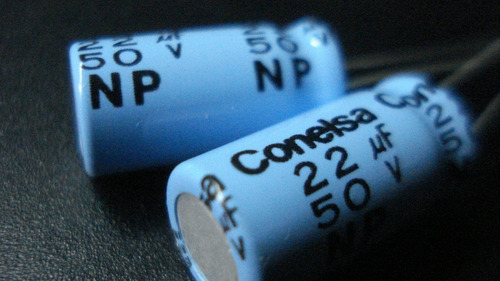

Brand was not Panasonic, of course, but CONELSA : CONdensadores ELectrolíticos Sociedad Anónima

My point is: having seen the operation with my own eyes, I can easily imagine lots of relatively small operators doing the same: buying treated aluminum foil, empty cases, cartons of rubber seals, rolls of heatshrink and setting up their own factory, not that big a deal or investment.

This can explain also the many "boutique cap" makers.

As long as you can get a supplier of treated electrolytic foil, metallized mylar, whatever, I bet the rolling and packaging machines are available on the open market.

PS: as a side note, contrary to common belief, a bipolar/NP cap does not have "two polarized ones in series inside" or rather it "does", but in a special way: it has two symmetrical layers, which get in series by definition when assembled.

Last edited:

The top and bottom on a capacitor is fairly thin aluminum, and the tooling for that is a bit difficult, as the stroke and angle of the male tool has to be done accurately.

A tool maker I knew charged a lot of money for making the lettering tools on the end caps used in fluorescent tubes, it was cursive letters on the side, and a reciprocating tool instead of rotating, and 0.3 mm sheet, more or less foil.

So the depth had to be adjusted, even thickness and depth an about 120 degrees of arc on a 26 mm tube cap.

The vents on capacitor tops are dents, deigning to open if needed, again needs a good tool.

A tool maker I knew charged a lot of money for making the lettering tools on the end caps used in fluorescent tubes, it was cursive letters on the side, and a reciprocating tool instead of rotating, and 0.3 mm sheet, more or less foil.

So the depth had to be adjusted, even thickness and depth an about 120 degrees of arc on a 26 mm tube cap.

The vents on capacitor tops are dents, deigning to open if needed, again needs a good tool.

Last edited:

Nigel, this will be a bit political...

China makes many things apart from electronics, and in many case they have a near monopoly, such as the ICs / PCBs used for wall clock movements.

And in many other seemingly insignificant things, in textiles, briefcase locks (!), and many other items, too many to count.

I have relatives in Dubai, and in their group of friends and acquaintances, there are traders who buy in bulk from China, and sell them onward, in the Gulf, and Africa as well.

They have been grumbling about erratic supply since June, and the pandemic situation was said to be terrible there since August, it is only now that the outside world has seen news about it.

But that news may be exaggerated as well, so I would take it with a pinch of salt as the news is coming from Arabic sources at times, not from Reuters, or the NY Times, for example.

In any case, on a small scale, our purchases are not important, we have to buy locally.

I would suggest checking stocks at other vendors before concluding that the item is not available, it may be that RS has decided that their stock and sales are not important, and the item is not to be ordered any more, or not in the near future.

As an aside, some popular cars are back on year end discount here in India.

That implies parts shortages are easing, though our cars have less electronics...the latest US Jeep seems like a luxury vehicle, not a basic off roader, like the earlier models. Loaded with displays, HVAC, complex sheet metal, automatic gearbox (for me, it takes the fun out of mud plugging), and so on, all of which need more chips than the cars here.

China makes many things apart from electronics, and in many case they have a near monopoly, such as the ICs / PCBs used for wall clock movements.

And in many other seemingly insignificant things, in textiles, briefcase locks (!), and many other items, too many to count.

I have relatives in Dubai, and in their group of friends and acquaintances, there are traders who buy in bulk from China, and sell them onward, in the Gulf, and Africa as well.

They have been grumbling about erratic supply since June, and the pandemic situation was said to be terrible there since August, it is only now that the outside world has seen news about it.

But that news may be exaggerated as well, so I would take it with a pinch of salt as the news is coming from Arabic sources at times, not from Reuters, or the NY Times, for example.

In any case, on a small scale, our purchases are not important, we have to buy locally.

I would suggest checking stocks at other vendors before concluding that the item is not available, it may be that RS has decided that their stock and sales are not important, and the item is not to be ordered any more, or not in the near future.

As an aside, some popular cars are back on year end discount here in India.

That implies parts shortages are easing, though our cars have less electronics...the latest US Jeep seems like a luxury vehicle, not a basic off roader, like the earlier models. Loaded with displays, HVAC, complex sheet metal, automatic gearbox (for me, it takes the fun out of mud plugging), and so on, all of which need more chips than the cars here.

Last edited:

On the other side we are missing a good closeup of the rubber seal, which certainly can tell its side of the story 😱

Seems good, or a close copy, the work on the tools is well done.

On top left one, the lead looks off center.

If they measure okay, use them.

You can further check with the Elna website, some catalogs are available to download.

On top left one, the lead looks off center.

If they measure okay, use them.

You can further check with the Elna website, some catalogs are available to download.

They are Good as long as I know, I bought many of those, I especially like ELNA capacitors,Seems good, or a close copy, the work on the tools is well done.

On top left one, the lead looks off center.

If they measure okay, use them.

You can further check with the Elna website, some catalogs are available to download.

I just wanted to see, what will other say about them.

I'm working on a LM1875T Diy-kit , that's why bought many components, but can't find out Dale RN60D & RN55D Resistors, also Panasonic 3W Resistors

Can Someone help me out with those Resistors

Thanks VIPINSA

The question actually was not for me, but so others using confirmed good ones can compare to these and say whether they look original or not.

I am assuming a faker will concentrate on labels (which I said before are not hard to clone) and not on rubber seals which are presumed not much checked by buyers.

The question actually was not for me, but so others using confirmed good ones can compare to these and say whether they look original or not.

I am assuming a faker will concentrate on labels (which I said before are not hard to clone) and not on rubber seals which are presumed not much checked by buyers.

Why those specific brands?They are Good as long as I know, I bought many of those, I especially like ELNA capacitors,

I just wanted to see, what will other say about them.

I'm working on a LM1875T Diy-kit , that's why bought many components, but can't find out Dale RN60D & RN55D Resistors, also Panasonic 3W Resistors

Can Someone help me out with those Resistors

Resistors must be the most generic part there is .

I have seen many fake capacitors too , you can tell them apart from Original just by looking at Rubber seal and top vent signature of specific brand capacitorThanks VIPINSA

The question actually was not for me, but so others using confirmed good ones can compare to these and say whether they look original or not.

I am assuming a faker will concentrate on labels (which I said before are not hard to clone) and not on rubber seals which are presumed not much checked by buyers.

I can get 1% Metal File too and found some 0.1 & 0.5% tolerance Resistors but people don't find them eyes 👀 catching or eye 🍬 candy .Why those specific brands?

Resistors must be the most generic part there is .

Just for people

offtopic :

I have build LM3886. Sound was good. I read LM3886 output stage is quasi complementary. Probably it depends on design and quasi complementary can be good design, but out of curiosity are there any complementary output stage audio power ICs ? Or are they difficut to manufacture ?

thanks

I have build LM3886. Sound was good. I read LM3886 output stage is quasi complementary. Probably it depends on design and quasi complementary can be good design, but out of curiosity are there any complementary output stage audio power ICs ? Or are they difficut to manufacture ?

thanks

Last edited:

High quality PNP has always been a problem in bipolar IC processes, requiring ion implantation.offtopic :

I have build LM3886. Sound was good. I read LM3886 output stage is quasi complementary. Probably it depends on design and quasi complementary can be good design, but out of curiosity are there any complementary output stage audio power ICs ? Or are they difficut to manufacture ?

thanks

ISTR Harris were the the first to make opamps with good PNP transistors

Yeah... In most BiCMOS processes you get really crappy PNPs. That's because they're lateral devices rather than vertical ones.Or are they difficut to manufacture ?

An NPN device in a P+ substrate is made by ion implanting an N+ collector 'tub'. Then a P+ implant is added on top for the base. Then on top of that you have another N+ implant for the emitter. The thickness of this implant controls the thickness ('length') of the base region. The thinner the base region is, the higher the transistor beta (current gain). The process engineers can control the thickness of the base region pretty tightly so NPNs have good beta that's pretty tightly controlled. Note that the current flow is vertical - from the bottom to the top of the die – which is why they're called vertical devices.

So why don't they just do the same thing for PNP devices then? Well... They could – and do – but then all PNP collectors get connected together to the P+ substrate, which is typically electrically connected to the DAP (die attach paddle) in the package, which is connected to the lowest voltage in the circuit. That's not impossible to work with, but as you can imagine it imposes some severe restrictions on the circuit design. To avoid this, you'd need a deep N+ implant to isolate the collector tub from the substrate. Then build the PNP into this N+ well. I don't know why the process guys don't do this (I'm an electrical engineer, not a process engineer), but it could be due to the added implant (-> added mask, time, materials = cost) or maybe physics start to get cranky and impose restrictions. Instead, PNP devices are often built much like they're shown in basic semiconductor physics textbooks: P+, N+, P+ regions placed side-by-side (or rather two P+ implants into an N+ well). The current flow is lateral, i.e., parallel to the die surface. The thickness/'length' of the base region is limited by the photolithography used to define the P+ regions. Photolithography does not offer the precision of ion implant technology, so lateral PNPs have garbage beta that varies all over the place (10 on a good day, consider yourself lucky if it's above 1.0 on a bad day).

Because they are so bad PNPs are only very rarely used. And because they're rarely used, they don't receive top priority when it comes to modelling either. So the simulation models tend to be mediocre at best. So as a circuit designer I get a device that's garbage and poorly modelled to work with. Yay... (or not). So they're only used when there's no other way to accomplish what you need. I designed analog ICs for over a decade and have never used a PNP in a non-SOI process (see below).

If you really, really want good PNPs, one solution is to add an insulator to the top of the wafer before production starts. That's easy to do in an oxidation furnace. Then you grow an epitaxial layer of silicon on top into which you build your devices as normal. This is known as silicon-on-insulator (SOI). The devices can be isolated from each other with a trench of silicon dioxide. I used to work in a process like that, the National Semiconductor VIP50 process. The PNPs were actually slightly better than the NPNs in that process. I loved that process because the devices behaved as they would in a discrete circuit (which was my background when I started at National). SOI processes have a few drawbacks, though. One is cost. The starting material is expensive. In addition, electrical insulators tend to be thermal insulators as well and that layer of insulating oxide limits the allowed power dissipation in the IC. So SOI is useful for opamps that draw little power, but I doubt you'll ever see something like an LM3886 in an SOI process.

Disclaimer: I'm an electrical engineer – not a process engineer – and have been out of IC design for 7+ years now, so I may have some minute process details wrong, but above is reasonably representative of reality.

Tom

Last edited:

I recommend SiteGround. They're pretty inexpensive and include a bunch of nice features, including a CDN via CloudFlare as part of their product. I was with them until I moved to Shopify.Looks like it'll have to wait until I get myself a website together so I can link a custom named domain's email to it.

Bummer that you can't access samples (for now) though.

Tom

So, Simon, the paperwork indicates that you got these parts from TI, unless you bought them from someone who supposedly bought them from TI. If you bought or sampled them from TI, then of course they're genuine. If not from TI, it depends on who you got them from. I wouldn't be surprised for a counterfeiter to include a copy of genuine-looking paperwork. Also, even magnifying your picture I can't read the marking. The 'TF' (insulated) units look a bit ragged on the molding and appear to have been unsoldered from something.

- Home

- Amplifiers

- Chip Amps

- What's going on with LM3886 availability?