Ben,

Dennis (djk) graciously answered Djim’s question placed to you, “Can you show us the 'orderly' impedance plot of your Klipsch” in post #29.

I’d say that’s helping the discussion.

The charts he posted show the frequency response response of the Klipschorn bass unit only, and the complete impedance graph clearly shows the impedance peak centered around the 5 dB 75 Hz dip followed by a series of peaks rising some 20 dB above the passband response the Klipshorn exhibits.

The TH designs of Djim, myself (and dozens of others), and the PPSL BR designs of djk all have a smoother response in the bass pass band ( around 125 Hz and below) than the Klipschorn bass unit.

Most of the respondents (you being the exception) have actual experience with TH and more or less of the design process that can eliminate bad sounding cabinets from being built.

We may disagree from time to time about some of the finer points, but we recognize and respect the DIY work done by the others in their areas.

If you spent as much time learning about the various design palette available as propagating your “anti-resonance” agenda that you interject at any chance, however inappropriate, you might find that in terms of the things that really count in LF reproduction:

Smooth phase and frequency response, LF extension, moderate group delay change, efficiency, low distortion, TH can be very good in comparison to other designs.

I invite you to read, listen and learn, the long history of TH goes back before I was born, a bit before your involvement with audio.

Cheers,

Art Welter

P.S.

I sold the drapes mentioned in the Welter Systems New Mexico Music Directory listing in post #34, used some of the money to buy the B&C18SW115-4 speakers used in the Keystone TH subs before the price of neodymium went through the roof.

Even though this is the only place in the world, to my knowledge, where TH gets much "respect", advocates here will argue against any criticism as if heretical.

OK, I pardon you for trying to pull a fast one on us by posting the earthquate-to-bat-ears response (instead of just the relevant spectrum).

Yes, there are lotsa ways to produce reasonably flat acoustic output. But my point had to do with the RELATIONSHIP between cone motion and sound output.

My point, let me say again, is that in order to use feedback of cone motion it requires that there is an orderly and/or simple relation between cone motion and sound output. Tuned systems (and I include the wave-length concept of TH here) depart a lot that kind of relationship. And as a kind of aside, I tossed out the notion that that kind of stands as a sort-of criterion of sound quality for me, roughly. I'll stick with that.

It also means purists can't (or shouldn't) apply cone motional feedback with those systems. I'll stick with that too.

Where do true horns (esp. with back sealed boxes) sit on the "orderly and/or simple" issue? I am not sure (or don't remember) and I welcome somebody showing a VC impedance versus sound output chart for a Klisch bass. In any case, I ran MF with my Klipshorn bass for many years and it seemed to do some good. Naturally, when you have something that's pretty good, hard to make dramatic improvements. BTW, many discussions of the commercial dreams of MF involve lousy and/or little woofers which are then made to produce fantastic tight and extended bass.

Ummm, I seem to have touched a raw nerve when I asked Art, "Ummm, who are you?" Sorry.

Ben

Last edited:

Hey Ben,

As long as you are happy we are happy for you man.

But all this BS about the Klipschorn and MF is not going to win you any cred as a purist IMO.

As long as you are happy we are happy for you man.

But all this BS about the Klipschorn and MF is not going to win you any cred as a purist IMO.

Neither current feedback or velocity feedback will help with a typical horn.

The sound output does not follow current or cone motion.

The sound output does not follow current or cone motion.

Neither current feedback or velocity feedback will help with a typical horn.

The sound output does not follow current or cone motion.

God bless the web where anybody* can sound as authoritative as Olson handing down the 10 Commandments of audio from the mountain.

Don't laugh, but when I started studying MF at Bell Labs, Murray Hill, I used an old Karlson enclosure I had sitting around. Impulses went from sounding like "cluuuunck" to more like "click." Dramatic improvement. The traces looked a whole lot better too although still with the too many squiggles of a Karlson (at the time, we used a Polaroid instant camera attached to a storage scope.... meg-bucks for those days).

But back to djk's Oracle pronouncement. Should I apologize again for mentioning true horns in connection with MF? Even if the theory doesn't seem promising for flattening the frequency response, there are still excellent benefits to distortion and over-shoot and perhaps even some benefits to frequency response that are quite worthwhile to experience.

BTW, some of you must be wondering how a corner speaker with MF resembles an active sound absorber?

Maybe it is now time for a "show of hands." Will posters please tell us whether they are speaking theoretically or from some hands-on experience with MF, TH, or MF applied to TH, as I did earlier.

Ben

*It was tempting to use a pejorative word here instead of "anybody"

Last edited:

"Should I apologize again for mentioning true horns in connection with MF? "

Yes, you should.

Unless the mouth area and length approach infinity neither the impedance nor the cone motion will be linear.

My first use of MF was in 1975, I have used both current and velocity sensing products.

Now if you had said you tried using a condenser mic capsule in front of the driver as feedback you would have received a different response. I have used this with a 15" Tannoy co-ax, and it might help a Klipschorn.

I have described three methods, which are you attempting to describe?

Yes, you should.

Unless the mouth area and length approach infinity neither the impedance nor the cone motion will be linear.

My first use of MF was in 1975, I have used both current and velocity sensing products.

Now if you had said you tried using a condenser mic capsule in front of the driver as feedback you would have received a different response. I have used this with a 15" Tannoy co-ax, and it might help a Klipschorn.

I have described three methods, which are you attempting to describe?

Last edited:

Hi, I found this detailed plan for a DIY front loaded Corner Horn with 2x12"-Eminence-Woofers which received good feedback in reviews. The plan is extremely detailed : eBay: Neue und gebrauchte Elektronikartikel, Autos, Kleidung, Sammlerst?cke, Sportartikel und mehr ? alles zu g?nstigen Preisen. Just a notice, not too off-topic, I hope

Ben,Don't laugh, but when I started studying MF at Bell Labs, Murray Hill, I used an old Karlson enclosure I had sitting around. Impulses went from sounding like "cluuuunck" to more like "click." Dramatic improvement.

Should I apologize again for mentioning true horns in connection with MF?

Maybe it is now time for a "show of hands." Will posters please tell us whether they are speaking theoretically or from some hands-on experience with MF, TH, or MF applied to TH, as I did earlier.

Ben

Rather than using motional feedback, one can simply use properly tuned ports with properly placed damping material to change impulse response from a "cluuuunck" sound to more like "click", a dramatic improvement costing a bit of time and understanding of basic principles and pennies in material.

With attention to detail, BR, TH, IB, and FLH can all be designed to have a “tight” sound without motional feedback.

I fail to understand your reason for bringing up motional feedback in a thread titled “What is a tapped horn subwoofer?” but would point out that using the proper algorithms and filters (as used in Gunness Focusing) motional feedback can be applied to any speaker design, TH, BR, IB, and FLH being among them.

Dave Gunness, inventor of Gunness Focusing is a speaker engineer who worked for Electo-Voice back in the 1980s, then went on to EAW (Eastern Acoustic Works) where he started focusing more on the electronic correction of inherent problems in horn and BR speakers, and now has his own company.

Art

Outsider's comment:

(1) Its probably impossible to intelligently evaluate various proponents' claims in regard to relative merits of BR, TH, IB, and FLH from the posts.

(2) Nor can anyone else make a decision based on frequency-response alone, as important as that is.

I would suggest you start a thread, with the best version(s), appropriately matched in size/watts/cost.

Each post could have:

(a) An actual build-plan and parts-list for a real, tested example.

(b) A frequency response chart, and other charts, say impedance etc.

(c) An impartial review after performance/play testing.

i.e., a competition.

(1) Its probably impossible to intelligently evaluate various proponents' claims in regard to relative merits of BR, TH, IB, and FLH from the posts.

(2) Nor can anyone else make a decision based on frequency-response alone, as important as that is.

I would suggest you start a thread, with the best version(s), appropriately matched in size/watts/cost.

Each post could have:

(a) An actual build-plan and parts-list for a real, tested example.

(b) A frequency response chart, and other charts, say impedance etc.

(c) An impartial review after performance/play testing.

i.e., a competition.

Ok so in a horn you want a robust driver with lotsa xmax.

If you read the whitepaper for the Carver sunfire sub he talks about motor efficency increasing as you move away from stall.

So would one of the sunfire driver not make an exceptional driver in a tapped horn.

I've seen them for sale on fleabay.

If you read the whitepaper for the Carver sunfire sub he talks about motor efficency increasing as you move away from stall.

So would one of the sunfire driver not make an exceptional driver in a tapped horn.

I've seen them for sale on fleabay.

Can someone give me a simple definition of what a tapped horn sub is?

I did a search for examples of them so I'm not looking for links to builds that dont talk about the simple definition of what one is.

Just going back to the original question for a moment before the performance discussion broke out.

The question was asked to try understand the basic principals of a Tapped Horn, if possible I would really like to see this thread return to that in order to get a basic understanding of why people choose this option.

Like SpinMonster I can find build logs to explain how to optimise a design, but that doesn't really help if it is way over your head to start with.

I would like to know some really basic stuff like how do you get the straight horn results from Hornresp into the folded up box that everyone is winding up with.

Guessing this is done by taking measurements at certain point from Hornresp and applying that dimension to the folded box?

What knowledge can you experienced people who have built multiple cabinets before offer the complete novice on building their first cabinet?

What size board is recommended? what type of material is best suited to this enclosure type? Is acoustic dampening typically used? where is it placed?

Having never built one it would be really good to get a sound understanding of the fundamentals before worrying about which driver has the higher SPL...

I answered inline. Sorry no emphasis.

Just going back to the original question for a moment before the performance discussion broke out.

The question was asked to try understand the basic principals of a Tapped Horn, if possible I would really like to see this thread return to that in order to get a basic understanding of why people choose this option.

Like SpinMonster I can find build logs to explain how to optimise a design, but that doesn't really help if it is way over your head to start with.

I would like to know some really basic stuff like how do you get the straight horn results from Hornresp into the folded up box that everyone is winding up with.

I see people using Autocad to do this, it lets you start with a structure, the straight line of the horn, and manipulate it without changing the dimensions of the structure.

Others are just really good with 3d drawing sofware and can conceptualize a fold in their brain.

Guessing this is done by taking measurements at certain point from Hornresp and applying that dimension to the folded box?

What knowledge can you experienced people who have built multiple cabinets before offer the complete novice on building their first cabinet?

If you want a simple cabinet and have a little room to play with perhaps a single fold box?

What size board is recommended? what type of material is best suited to this enclosure type? Is acoustic dampening typically used? where is it placed?

Board size is often determined by box dimensions and a panels propensity to vibrate(bad) within the enclosure. That said often 3/4" baltic birch plywood gets the most positive feedback for strength, sound quality and lower weight. It costs more though. Damping is used in some horns, theres a price though(smoothing for efficency) and you will walk a razors edge determining your best placement.

Having never built one it would be really good to get a sound understanding of the fundamentals before worrying about which driver has the higher SPL...

Last edited:

Thanks Ectocynned that's a good starting point. I noticed in another post someone made mention of the angle of the bend. Again only guessing but is this so the sound doesn't come back on itself i.e. no 180 degree bends...

is there a preferred angle? Are there any you just don't do's in designing this type of box?

Any basic help is really of great assistance when building your first box.

is there a preferred angle? Are there any you just don't do's in designing this type of box?

Any basic help is really of great assistance when building your first box.

The angle doesnt really matter. Wavelengths are so big that reflected sound will probably not happen, at least in a typical subwoofer enclosure. If you go pro-sound with higher cutoff, you might want to have more bends, so pathways that form resonances are shorter, leading to higher frequency resonance. 90 or 180 degree are the most practical bends, from a assembling standpoint, but everything goes if you can build it.

Reality Check: I use tapped horns as subwoofers, over 2 meters long with a single 180 bend. Sounds and measures just fine with cutoffs up to 200hz (didnt try higher). If they have resonances, then my room masks them.

Reality Check: I use tapped horns as subwoofers, over 2 meters long with a single 180 bend. Sounds and measures just fine with cutoffs up to 200hz (didnt try higher). If they have resonances, then my room masks them.

A tapped horn seems to require higher Xmax to get higher SPL.

A horn requires a "normal" Xmax to get very high SPL.

A normal Horn and a Tapped Horn are very different animals.

A horn requires a "normal" Xmax to get very high SPL.

A normal Horn and a Tapped Horn are very different animals.

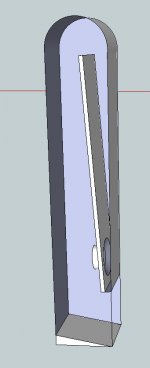

Fewer bends make cabinet construction simpler.Something like this MaVo...

Is there an advantage / disadvantage to fewer / more bends?

Fewer bends result in a long thin box, often better for hiding in the home, laid down or standing up.

More bends can result in a more square box, better for stacking in a PA.

It is preferable to do more bends at the throat end and less at the mouth end.

The example you showed has a rounded end, a superfluous detail that wastes internal cabinet space.

Build the box out of 3/4" plywood, brace it well.

As someone who has always respected the capriciousness of practice as compared to theory, if I ever wanted to make TH, I'd try a design with a path length that I could fudge.

B.

B.

Ok so in a horn you want a robust driver with lotsa xmax.

If you read the whitepaper for the Carver sunfire sub he talks about motor efficency increasing as you move away from stall.

So would one of the sunfire driver not make an exceptional driver in a tapped horn.

I've seen them for sale on fleabay.

Interesting reading. Makes me think of the old saying, "statistics don't lie but liars use statistics."

Much strangeness. Giant magnet - can't imagine the cost. Betcha the moving parts are inconceivably heavy to make the system compute. With ordinary (non-hyped) drivers with familiar max excursion and far smaller magnets, the iron pole pieces get all the magnetic juice they can handle.

The analogy to internal combustion engines is interesting. True they have least torque at stall. Which makes that kind of motive power stupidly unsuitable for vehicles (but fueling with petroleum is a great idea, engineering-wise). But electric motors don't have that shortcoming.

Ben

- Status

- Not open for further replies.

- Home

- Loudspeakers

- Subwoofers

- What is a tapped horn subwoofer?