Offtopic, practical tips... when you think there is something resonating. First take normal oñaxis measurement and look at distortion. Then use REW's tone generator and play that freq sine and use your ears and fingers to check what is making the noise. You might have to increase sound level too, to excite the resonance. Then find and test ways to fix it.

Have fun! Making scientific article about it gives higher standards for methods, documenting and reporting, but this is just a hobby forum, not ASR!

that’s a good idea.

thanks!

and thank god it’s not ASR here. Lol

Why/how is a phono pickup awkward to implement as a sensor for panel vibrations?It is awkward to implement

I was a machinery vibration analyst for 30 years, although we were instrumented up the wazoo (accelerometers, eddy probes and velometers ) and recorded and analyzed everything, it was also very obvious by sight and feel when you hit a resonance.

Run a sweep signal through the speaker and put your hand on the box, I now use an FFT analyzer on my phone for frequency ID, it’s amazingly accurate...Not that instrumenting up isn’t the coolest thing ever, we had our signals in software which would show resonances and phase relationships which also tells you a lot.

Run a sweep signal through the speaker and put your hand on the box, I now use an FFT analyzer on my phone for frequency ID, it’s amazingly accurate...Not that instrumenting up isn’t the coolest thing ever, we had our signals in software which would show resonances and phase relationships which also tells you a lot.

I ordered an accelerometer from meniscus audio and plan to use it with my focusrite recording interface for measurements.

sure! why not?so basically what you are telling me is that.

yes there is a science to this. ( which ok is a given)

but most people just brace cabinets with a certain amount of math and not much else to really pinpoint things.

so I should brace and see what it sounds like.

lol

what makes you think your speakers are not braced enough as to make their cab resonance audible?

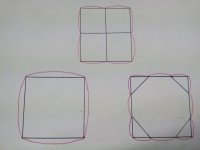

why I chose 45 deg corner braces instead of conventional cross bracing

You have used the same amount of material to divide the panels being braced into 3 instead of 2. That is good.

Also each panal is braces aginst the 2 nearest panels, as opposed to the opposite panel.

On the downside, the forces are at an angle to the brace, but with typical box construction that is likely moot.

dave

sure! why not?

what makes you think your speakers are not braced enough as to make their cab resonance audible?

my speakers aren’t braced at all actually

They are well braced, its just that there is no internal bracing of the type you want to introduce.

Refer back to our discussions in your parallel thread.

Refer back to our discussions in your parallel thread.

In your parallel thread you told us, "Yeah I abandoned the idea of bracing."

https://www.diyaudio.com/community/...l-bracing-to-commercial-speaker.386891/page-9

You'll remember the contribution from FirstWatt2019 from ProAc Speaker Group who seconded my suggestion that you should not add internal bracing to your ProAc DT8 speakers.

According to FirstWatt:

"All ProAc models use hd mdf or whatever it’s called not standard mdf

25mm front and back with 18mm sides, top and bottom

And the bigger ones are

25mm front back and sides with 18mm top and bottom"

Very heavy and inert for such a compact enclosure.

https://www.diyaudio.com/community/...l-bracing-to-commercial-speaker.386891/page-9

You'll remember the contribution from FirstWatt2019 from ProAc Speaker Group who seconded my suggestion that you should not add internal bracing to your ProAc DT8 speakers.

According to FirstWatt:

"All ProAc models use hd mdf or whatever it’s called not standard mdf

25mm front and back with 18mm sides, top and bottom

And the bigger ones are

25mm front back and sides with 18mm top and bottom"

Very heavy and inert for such a compact enclosure.

Well I changed my mind.

btw I measured the MDF and it’s 19mm front baffle and 18mm sides

and it’s MDF not HDF

btw I measured the MDF and it’s 19mm front baffle and 18mm sides

and it’s MDF not HDF

Yes HDF, that was the term FirstWatt was searching for - very dense and inert.

19 mm is still pretty thick, but did you include the rebates?

What I really mean to say is that your ProAc DT8s are not the best vehicle for your series of investigations.

It's too 'firm' a base on which to experiment.

It would be better to construct your own speaker system, with all it faults, and experiment on methods of bracing its enclosure etc. etc..

19 mm is still pretty thick, but did you include the rebates?

What I really mean to say is that your ProAc DT8s are not the best vehicle for your series of investigations.

It's too 'firm' a base on which to experiment.

It would be better to construct your own speaker system, with all it faults, and experiment on methods of bracing its enclosure etc. etc..

Why is it to firm a base to experiment?

the braces are completely 100% reversible with no marks.

🤷♂️

the braces are completely 100% reversible with no marks.

🤷♂️

so basically, the cabinet resonance is way down in DB and entirely silent.In your parallel thread you told us, "Yeah I abandoned the idea of bracing."

https://www.diyaudio.com/community/...l-bracing-to-commercial-speaker.386891/page-9

You'll remember the contribution from FirstWatt2019 from ProAc Speaker Group who seconded my suggestion that you should not add internal bracing to your ProAc DT8 speakers.

According to FirstWatt:

"All ProAc models use hd mdf or whatever it’s called not standard mdf

25mm front and back with 18mm sides, top and bottom

And the bigger ones are

25mm front back and sides with 18mm top and bottom"

Very heavy and inert for such a compact enclosure.

OP is waisting his time. but he might learn a thing or two!

By too 'firm', I mean the enclosure is already practically resonant free.Why is it to firm a base to experiment?

You need an enclosure that is far from resonant free so you can experiment on it.

I like wasting my time.

and no the cabinet is not entirely silent.

if you put your hands on the sides you can feel the vibrations quite a bit.

on the baffle, no.

lower on the sides below the woofers. Hardly.

but on the sides at the height of the woofers. Yes.

honestly. I don’t get some of you guys.

this is supposed to be DIY, and it seems to me you have no DIY spirit in the least.

here someone is telling you that they are new to this, can do a mod/experiment to learn and have fun……..and you are simply dissuading any such attempt.

Now granted it doesn’t bother me or affect me in the least.

But I have to wonder , why such the anti-DYI attitude ?

Especially for something that is 100% reversible. Its not like I said I would take a chainsaw to my speakers. Lol

When I was modding my Marshall tube amps and learned how to do it, I had others asking me what I did and how. even if I didn’t like a specific value change or change in the circuit , I never once told someone “ no dont try that! It won’t sound good”

I would always tell them, “ yeah try it out, you might like it and you might not, but you will learn a lot on how it affects the circuit”.

Do you guys actually like doing this hobby or is it something miserable to you ?

just bizarre.

ok as you were.

ha

and no the cabinet is not entirely silent.

if you put your hands on the sides you can feel the vibrations quite a bit.

on the baffle, no.

lower on the sides below the woofers. Hardly.

but on the sides at the height of the woofers. Yes.

honestly. I don’t get some of you guys.

this is supposed to be DIY, and it seems to me you have no DIY spirit in the least.

here someone is telling you that they are new to this, can do a mod/experiment to learn and have fun……..and you are simply dissuading any such attempt.

Now granted it doesn’t bother me or affect me in the least.

But I have to wonder , why such the anti-DYI attitude ?

Especially for something that is 100% reversible. Its not like I said I would take a chainsaw to my speakers. Lol

When I was modding my Marshall tube amps and learned how to do it, I had others asking me what I did and how. even if I didn’t like a specific value change or change in the circuit , I never once told someone “ no dont try that! It won’t sound good”

I would always tell them, “ yeah try it out, you might like it and you might not, but you will learn a lot on how it affects the circuit”.

Do you guys actually like doing this hobby or is it something miserable to you ?

just bizarre.

ok as you were.

ha

This is supposed to be DIY, and it seems to me you have no DIY spirit in the least.

What I am suggesting is true, proper DIY!

Build your own enclosures, or buy a 2nd hand pair of the most inexpensive budget tower speakers you can find - they will almost certainly resonate and will allow you to better learn how to stop them resonating.

What I am suggesting is true DIY!

Build your own enclosures, or buy a 2nd hand pair of the most inexpensive budget tower speakers you can find - they will almost certainly resonate and will allow you to better learn how to stop them resonating. Hi

- Home

- Loudspeakers

- Multi-Way

- What do I need to measure speaker cab resonances?