Thanks Chris,

The reason I was asking is, I am building a servo linear and this might serve well as the arm wand and be easy to construct............

The reason I was asking is, I am building a servo linear and this might serve well as the arm wand and be easy to construct............

Thanks Chris sadly my build has been gathering dust on the self for quite some time even though it's 3/4 complete😱

Hi Keith

Come on -you can do better than that! It's worth finishing I assure you. By the way- how's the bamboo arm doing?

Best Wishes

Chris

Come on -you can do better than that! It's worth finishing I assure you. By the way- how's the bamboo arm doing?

Best Wishes

Chris

Hi Chris;

I dusted it down and will hopefully get it finished shortly.

The Bamboo arm is continuing to delight. I don't think my Decca cartridge has sounded so good helped of course by my home built system courtesy of excellent designs on this forum.

I dusted it down and will hopefully get it finished shortly.

The Bamboo arm is continuing to delight. I don't think my Decca cartridge has sounded so good helped of course by my home built system courtesy of excellent designs on this forum.

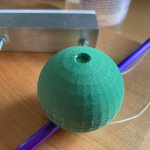

I made one of these for my arm, but it was never finished. It was printed in two parts as opposed to a single ball like these. Once filled with sand it was the same weight as a standard golf ball.

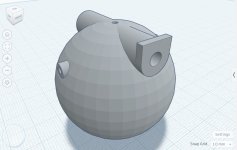

The flat fringe in the front is so you can turn it upside down and sit it flat on a plane. This will allow you to fully align it with your cartridge.

The side wholes are 2mm diameter and are independent to the internals of the ball, no sand will come out. Will take a small brass pipe if you wish to run that through.

The top hole is 2mm and can be drilled(carefully) out if you wanted to run your wires out the top. Or again, set it upside down using a small nail through cardboard or the likes and set you pivot to stylus length if wished.

The inconsistency in the outer skin with mimic the standard golf balls behaviour in silicon (it is hoped) so was left.

A 6mm hole in the base for ease of filling, can be epoxied up once full.

Have added a few pics of the first prototype I made, you can see the skin effect. Ignore the hideous spray paint (not my doing) on this one. Along with a brass rod threaded through. You will see it’s different as the brass rod inhibits any sand from coming out, but the final design stops this and allows you to just run thread through if you wish.

The flat fringe in the front is so you can turn it upside down and sit it flat on a plane. This will allow you to fully align it with your cartridge.

The side wholes are 2mm diameter and are independent to the internals of the ball, no sand will come out. Will take a small brass pipe if you wish to run that through.

The top hole is 2mm and can be drilled(carefully) out if you wanted to run your wires out the top. Or again, set it upside down using a small nail through cardboard or the likes and set you pivot to stylus length if wished.

The inconsistency in the outer skin with mimic the standard golf balls behaviour in silicon (it is hoped) so was left.

A 6mm hole in the base for ease of filling, can be epoxied up once full.

Have added a few pics of the first prototype I made, you can see the skin effect. Ignore the hideous spray paint (not my doing) on this one. Along with a brass rod threaded through. You will see it’s different as the brass rod inhibits any sand from coming out, but the final design stops this and allows you to just run thread through if you wish.

Attachments

For those of you who want to know the maths behind the bias compensation, look up the "Bizarrm" Wireless World article from December 1977 (pre-dates Firebaugh's 1986 US patent). https://www.worldradiohistory.com/UK/Wireless-World/70s/Wireless-World-1977-12.pdf

- Home

- Source & Line

- Analogue Source

- Well tempered labs tonearm