Just an update on the WT turntable: Those that were at the Vancouver Island DIY Meet last weekend had the oppurtunity to hear the "Golfball" in action.

A friend of mine gave me the TT for my birthday and I took it to the "Spiritual Home" of the Odd and Offbeat: Planet10!

Please note that I'm referring to the people attending, not the gear...

😀

Terry,

I hope there will be a return engagement for the "Golfball", somehow I missed hearing it.

Another Oddball.😉

I've always found it safer to use no lift mechanism... and i get really frustrated when i run around trying to figure out why i'm not getting sound only to find out someone has put the lift up.

dave

dave

Risky Business....

tonearm lifts are great for those that need them. I know lots o'folks wouldn't dream of not using one. I agree with Dave. As long as there is a tonearm rest, I'm okay without having a lift.

tonearm lifts are great for those that need them. I know lots o'folks wouldn't dream of not using one. I agree with Dave. As long as there is a tonearm rest, I'm okay without having a lift.

Ya, back ....move done, comp back up...

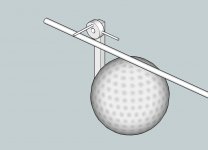

the absolute simplest idea may be something like this:

Nice to see you back. Any stuff for DIY tonearm lift with you ?

the absolute simplest idea may be something like this:

Attachments

Arm Lift on Well Tempered TT

If you think about it, you will see that it would be difficult to use a conventional arm lift on the WT tonearm, since the bearing is not 'anchored' in the horizontal plane as a conventional bearing is. Upward lift on the arm would present upward lift on the golfball, which is much lighter (intentionally) than even the bearing assembly on a unipivot arm, which relies on gravity to keep the arm from jumping off its bearing when the arm lift goes up. I expect that prototyping showed that it took the arm too long to settle back into the silicone goo after droping the arm onto the LP.

If you think about it, you will see that it would be difficult to use a conventional arm lift on the WT tonearm, since the bearing is not 'anchored' in the horizontal plane as a conventional bearing is. Upward lift on the arm would present upward lift on the golfball, which is much lighter (intentionally) than even the bearing assembly on a unipivot arm, which relies on gravity to keep the arm from jumping off its bearing when the arm lift goes up. I expect that prototyping showed that it took the arm too long to settle back into the silicone goo after droping the arm onto the LP.

Good one, Stew.

That would put the lift vector against the thread holding the arm in the horizontal plane without displacing it in the vertical. Looks to me like it should work.

I am building a WT tonearm clone for one of my ultra-lite B&O based TTs, so will try this idea 😀

That would put the lift vector against the thread holding the arm in the horizontal plane without displacing it in the vertical. Looks to me like it should work.

I am building a WT tonearm clone for one of my ultra-lite B&O based TTs, so will try this idea 😀

for my embryo (cinematic) tonearm the home minute made armlift with a "cork" (winebottle).the absolute simplest idea may be something like this:

(vinyl is almost better with good wine)

Attachments

Stew,

Thanks a lot for your reply. I was searching in the wild for an idea that was so simple like this. I will have to try it myself in the coming weekend. One more question, how can we apply the concept of silicon fluid damping with your model to slow down the tonearm fall ?

Best regards,

Bins.

Thanks a lot for your reply. I was searching in the wild for an idea that was so simple like this. I will have to try it myself in the coming weekend. One more question, how can we apply the concept of silicon fluid damping with your model to slow down the tonearm fall ?

Best regards,

Bins.

fluid dampening...

shouldn't be required. The golf ball rotating in the fluid may provide some dampening if it tries to rotate too fast. I've never tried it, but it does make sense. If the "tonearm lift" is located as close as possible to the pivot point, then the required amount of gross lift at the lift point is very small, but requires a large rotation of the arm lift.

If some dampening is required, a small tube (with the end capped), filled with fluid could be attached to the arm in some manner. I have to think a little more on this though.

shouldn't be required. The golf ball rotating in the fluid may provide some dampening if it tries to rotate too fast. I've never tried it, but it does make sense. If the "tonearm lift" is located as close as possible to the pivot point, then the required amount of gross lift at the lift point is very small, but requires a large rotation of the arm lift.

If some dampening is required, a small tube (with the end capped), filled with fluid could be attached to the arm in some manner. I have to think a little more on this though.

Last edited:

The silicone fluid on the WT arm does dampen (and slow) movement in any axis. That is the magic of the dimples in the golf ball.

The Schroeder arm has a magnetic stabilization field rather that the mechanical interaction of fluid and golf ball. It must be provided with a dampened lift like any other arm.

The Schroeder arm has a magnetic stabilization field rather that the mechanical interaction of fluid and golf ball. It must be provided with a dampened lift like any other arm.

Last edited:

...The point behind the golf ball is that the dimples act as 'drag multipliers', dramatically increasing the surface area of the ball, without increasing the size. It is the interaction of the dimples with the silicone fluid that provide useful levels of damping and control. A smooth ball would not work very well at all...

The dimples make practically no difference to the surface area of the ball.

A smooth ball would work just as well, because the grease is not slippery. If the ball was teflon coated there might be a problem.

silicone fluid viscosity

I'm still searching for the viscosity of silicone fluid that Well Tempered uses.

They avoid mentioning the viscosity anywhere & sell a small quantity for $20.

It would be nice if it turns out to be the same as DOT 5, but I suspect it's much more viscous.

dobias

I'm still searching for the viscosity of silicone fluid that Well Tempered uses.

They avoid mentioning the viscosity anywhere & sell a small quantity for $20.

It would be nice if it turns out to be the same as DOT 5, but I suspect it's much more viscous.

dobias

I'm still searching for the viscosity of silicone fluid that Well Tempered uses.

They avoid mentioning the viscosity anywhere & sell a small quantity for $20.

It would be nice if it turns out to be the same as DOT 5, but I suspect it's much more viscous.

dobias

A trip to your local hobby shop is in order. If they carry/service radio controlled cars they'll have little bottles of silicone shock fluid with various viscosity ratings. Shouldn't be more than $4 bucks a bottle.

Jeff

- Home

- Source & Line

- Analogue Source

- Well tempered labs tonearm