In a conventional front-loaded horn, there's a sealed chamber which does a few things. First, the chamber raises the resonance of the woofer. For instance, if the woofer starts with an FS of 29hz, the sealed chamber might raise the Fb to 60hz. And then the horn is tuned to that Fb.

The problem with very small drivers is that the QTS is way too high. For instance, if I build a front-loaded horn with a prosound driver, the Fb of the system might be something like 60hz with a system 'Q' of .8 or 1.0. But these tiny TangBand and Peerless woofers have a QTS of 0.8 or 1.0 already! So if you put them in a front-loaded horn the system Q gets insanely high, like 2.0 or even 2.5.

So a simple solution is to simply ditch the sealed chamber. That transforms the enclosure, changing it from a front-loaded horn to a back-loaded horn. (In other words, we're getting output from both sides of the cone.)

Neat! Good stuff.

I've had similar designs, with open (or very large) rear chambers made that way for similar reasons. What I've sometimes done is to use a sealed rear chamber, but make it so large, it's functionally the same as being open. I just filled it full of stuffing to absorb the rear wave.

If the horn were used out in the open, I wouldn't care. Or if the rear wave was just bass, like if a low-pass filter was used, that would be OK. Then that rear wave would be just another bass node, so it would be potentially useful for helping to smooth room modes. But in my case, the rear wave also contained midrange, so I didn't want the rear wave radiated into the room for directivity and because of boundary reflections.

Last edited:

the full size high-efficiency hornsub really makes sense for large venues and outdoor events.

Wayne, you are completely correct in everything in your statement. But maybe it would be more appropriate if you give an example that is based on similar design principles. I'll make you a more realistic example of 3 cabs: Cab A and B have same dimension. All three cabs have similar response. Also the costs in drivers are from all cabs are similar:

Horn A: 18” driver, 1800W (136dB) continue, 3600W (139dB) program, 10Kw peak. Best SPL figures, since it uses the latest generation driver technology. Should be used in groups of at least 2 to give a flat response

Horn B: 2x 12”, 800 watt continue (133dB), 1600W program (136dB), 3200W peak.Best THD figures, since it uses Push-Pull. Should be used in groups of at least 4 to give a flat response.

Tapped Horn C: 18” driver, 1800W (136dB) continue, 3600W (139dB) program, 10Kw peak. Lowest Volume and lowest weight since it is 30% smaller then cab A and B and uses the same driver as Horn A. Of all three cabs this cab is worst in THD. Has the most flat response and can be used in singles without a problem.

I think it's hard to make too many comparisons, since we're talking generalities. But I think some generalizations can be made.

Comparing two traditional horns, if both are well optimized, then the size really affects the smoothness of response. I wouldn't expect two horns that are the same size and operated over the same passband to have different characteristics with respect to the number of horns needed for smooth response. This is largely a function of mouth area, or more specifically, of the flare rate, i.e. the area expansion increase.

A traditional horn is an impedance transformer, and it needs this area increase to work properly. So I wouldn't expect to need more of your "Horn B" models than "Horn A" models to get smooth response, unless "Horn A" was larger. That is assuming both are well optimized. This then makes the comparison between A and B largely a comparison of the driver(s) chosen, one having a higher thermal limit than the other. Naturally, the driver capable of handling more power will have higher output, all other things being equal.

Tapped horns can definitely be made smaller than full-size traditional horns. But that's because they are like transmission lines, not having the same area expansion as a horn nor its corresponding impedance transformation. As a result, they aren't as efficient. So while I would expect smaller size, I would also expect lower SPL output. Tapped horns and lines trade smaller size for reduced output and higher distortion. They give smoother response down low, but rougher response up high.

So I think probably the "Tapped Horn C" should not be expected to have as high SPL as the full-size "Horn A". I'm not sure how the bulk efficiency works out, but I have always read that tapped horns do not gain the same advantage in groups that full-size horns do, and that they are best used in smaller venues where large installations aren't appropriate.

One more thing I wanted to add to this discussion, but got distracted earlier and forgot. I have heard and measured several Bassmaxx hornsubs, which are good examples of traditional full size basshorns. They all use some pretty advanced drivers with kilowatt++ power handling ratings. For example, the B-Zero and family used TC-Sounds 18" woofers, which are pretty beefy. This is a real-world sample of the "Horn A" example, above. You can see its measurements in the 2005 Prosound Shootout.

Beefy woofer in Bassmaxx hornsub

Some of the later Bassmaxx models like the X2C Deuce and the X3C Tripp use several woofers of that caliper, with total power handling ratings of some 6000+ watts. These were measured at the 2006 and 2007 Prosound Shootouts.

Bassmaxx is a good example of a commercial full-size horn with a very high quality woofer, but that doesn't run push-pull drive. Measurements of various Bassmaxx hornsubs and many other basshorns are shown at the Prosound Shootout website.

Last edited:

Wayne, why do you think my in my example cab A has slightly different SPL compared to cab B? Also I like to remind you cab B is already at Max power, while cab A is just reaching its continue power. Now, you can fill in the answer where I want to use the extra 'space' for at cost of 1 or 2 dB (which can be more than made up by its headroom).

Yes, you are right the TH is overrated by 2-3dB but still outperforms cab B in singles < 40Hz. If you want more from the same money, load the same TH with a little less fancy 21” driver (1200watt – 2400Watt). That will even boost the frequencies below 50Hz -60Hz even further.

Although a TH almost has no coupling below Fb, it still has up to that point! You will need quiet some cab B’s before that point is reached. Another trick is to lower Fb a little at cost of SPL (which can be made up by power). Than 4 TH cab C’s still outperform 4 cab B’s in range and will be ending with similar SPL.

All I’m saying is that 15 year old technology can be outperformed by the latest generation because of the much higher power ratings and the much lower pwr compression figures.

Yes, you are right the TH is overrated by 2-3dB but still outperforms cab B in singles < 40Hz. If you want more from the same money, load the same TH with a little less fancy 21” driver (1200watt – 2400Watt). That will even boost the frequencies below 50Hz -60Hz even further.

Although a TH almost has no coupling below Fb, it still has up to that point! You will need quiet some cab B’s before that point is reached. Another trick is to lower Fb a little at cost of SPL (which can be made up by power). Than 4 TH cab C’s still outperform 4 cab B’s in range and will be ending with similar SPL.

All I’m saying is that 15 year old technology can be outperformed by the latest generation because of the much higher power ratings and the much lower pwr compression figures.

Last edited:

Yes, I agree that a driver that handles more power will generate more max SPL, all other things being equal. My point was that I don't think it would change the behavior with respect to number of cabinets used, i.e. "Should be used in groups of 2 for flat response." If two traditional horns are equal in all respects except the driver used, then I would expect response and group loading characteristics to be the same too. This is largely a function of mouth area. That was my point.

As for the tapped horn, it's a different animal. You can always say "load it with a bigger, more powerful woofer and it will be louder". You can say this about front loaded direct radiators too. But in large venues, I think the bulk-efficiency thing becomes more and more difficult - I don't think you can get them to work together as well as full-size basshorns in large groups. They're probably more useful in smaller venues.

Comparing two traditional horns, if both are well optimized, then the size really affects the smoothness of response. I wouldn't expect two horns that are the same size and operated over the same passband to have different characteristics with respect to the number of horns needed for smooth response. This is largely a function of mouth area, or more specifically, of the flare rate, i.e. the area expansion increase.

A traditional horn is an impedance transformer, and it needs this area increase to work properly. So I wouldn't expect to need more of your "Horn B" models than "Horn A" models to get smooth response, unless "Horn A" was larger. That is assuming both are well optimized. This then makes the comparison between A and B largely a comparison of the driver(s) chosen, one having a higher thermal limit than the other. Naturally, the driver capable of handling more power will have higher output, all other things being equal.

As for the tapped horn, it's a different animal. You can always say "load it with a bigger, more powerful woofer and it will be louder". You can say this about front loaded direct radiators too. But in large venues, I think the bulk-efficiency thing becomes more and more difficult - I don't think you can get them to work together as well as full-size basshorns in large groups. They're probably more useful in smaller venues.

What I was talking about in my last post is response shape, smoothness, and the number of horns required. The number of horns required for optimum efficiency and smoothness is really a function of mouth size. A 30Hz hornsub (used on the ground, i.e. halfspace) really needs about 5 square meters mouth area to work best. If one basshorn has mouth area of 1.0m2, it will really shine when 5 or more are used. If another has mouth size of 0.75m2, it won't be optimum until 6 or 7 horns are used.

See "Optimum Horn Mouth Size", by D.B. Keele

There is also the matter of directivity, and this has to do with mouth area and shape too. A larger area will be more directional, and this focuses the acoustic energy in a smaller area, raising on-axis SPL.

On the topic of advanced drivers, I think the thrust of what Djim was saying is that a more powerful driver will generate more SPL. I agree with this, of course; To me that sort of goes without saying. All other things being equal, a more powerful woofer will generate more SPL, no matter what cabinet it is used in.

That's sort of what the cooling plug does - it makes a fairly mediocre 400 watt part a little more robust, giving it 800 watt RMS capacity. I guess it's probably more like 1000 watts, when measured by EIA RS-426A, which is a 6dB crest signal. The woofer+plug handles 840 watts continuous sine, which is much harder to handle than EIA-426A. The 12Pi basshorn uses two of those woofers, so in Djim's example, it would be 2000 watts continuous (EIA-426A), 4000 watts program material.

There are always bigger, better woofers. There's no stopping progress, and who would want to. But I do think that the 12Pi hornsub has a pretty good complement of parts, and they aren't all that expensive. The cooling plug really helps make them handle the power.

See "Optimum Horn Mouth Size", by D.B. Keele

There is also the matter of directivity, and this has to do with mouth area and shape too. A larger area will be more directional, and this focuses the acoustic energy in a smaller area, raising on-axis SPL.

On the topic of advanced drivers, I think the thrust of what Djim was saying is that a more powerful driver will generate more SPL. I agree with this, of course; To me that sort of goes without saying. All other things being equal, a more powerful woofer will generate more SPL, no matter what cabinet it is used in.

That's sort of what the cooling plug does - it makes a fairly mediocre 400 watt part a little more robust, giving it 800 watt RMS capacity. I guess it's probably more like 1000 watts, when measured by EIA RS-426A, which is a 6dB crest signal. The woofer+plug handles 840 watts continuous sine, which is much harder to handle than EIA-426A. The 12Pi basshorn uses two of those woofers, so in Djim's example, it would be 2000 watts continuous (EIA-426A), 4000 watts program material.

There are always bigger, better woofers. There's no stopping progress, and who would want to. But I do think that the 12Pi hornsub has a pretty good complement of parts, and they aren't all that expensive. The cooling plug really helps make them handle the power.

No you can’t put a bigger driver in a FLH without changing the design. However, you can put a bigger driver in a TH and gain in SPL down low. For instance the Xoc1 'eats' 15s as well as 18s without any modification (besides the driver cut out).As for the tapped horn, it's a different animal. You can always say "load it with a bigger, more powerful woofer and it will be louder". You can say this about front loaded direct radiators too.

About the comparison example, just calculate the displacement of two 12” and compare it with the displacement of an 18” of realistic drivers and you know the difference. In case the two 12” drivers have the same costs as the 18” but can’t displace as much air, you can’t justify the use for 12” other than, lower THD because of PP for instance. That kind of justification will not be appreciated by the PA market.

Tapped Horns don’t couple more difficult down to their 1/3 WL than FLH’s. I think the story that TH’s don’t couple so well, comes from people that are using TH’s with a relative high 1/3WL design. Because they hear LF content below 1/3WL, they assume this will have the same coupling as above 1/3WL of the design, which isn’t the case.But in large venues, I think the bulk-efficiency thing becomes more and more difficult - I don't think you can get them to work together as well as full-size basshorns in large groups.

Maybe you’re e right and Danley should advertise "for smaller venues only".(subject TH’s) They're probably more useful in smaller venues.

I think the tapped horn is a different animal. It's more of a tapered pipe than a horn. As such, it doesn't gain the efficiency advantage of a full-sized horn, but it does save space. On the other hand, a person could probably make a tapped horn with a larger mouth and more area expansion, in order to gain efficiency. So I would expect a continuum of alignments, with smaller devices being less efficient and larger ones being more efficient.

Once you get to the larger size of a traditional full-size basshorn, I would expect little difference in efficiency. There will undoubtedly be other differences, but if the size is the same, I expect the efficiency to be about the same too, provided, of course, something isn't way off. It's all about the impedance matching, which requires throat-to-mouth area expansion.

But as for the smaller devices, it is pretty clear to me that their biggest advantage is they can get smooth response, trading efficiency in the deal. It's Hoffman's Iron Law. The smaller horns aren't as efficient and I do not expect that a large group of them would match the efficiency of an equally-sized group of (a fewer number of) large horns. The optimizations are different.

Once you get to the larger size of a traditional full-size basshorn, I would expect little difference in efficiency. There will undoubtedly be other differences, but if the size is the same, I expect the efficiency to be about the same too, provided, of course, something isn't way off. It's all about the impedance matching, which requires throat-to-mouth area expansion.

But as for the smaller devices, it is pretty clear to me that their biggest advantage is they can get smooth response, trading efficiency in the deal. It's Hoffman's Iron Law. The smaller horns aren't as efficient and I do not expect that a large group of them would match the efficiency of an equally-sized group of (a fewer number of) large horns. The optimizations are different.

Last edited:

Wayne I'll give it another try. Maximum output is directly linked to excursion. That means when the FLH’s start to couple the excursion increases with the same amount of input energy. But the driver will face the same physical excursion limit (Xvar) as when it was put in a TH, although with less power. Today’s reality is that drivers and amplifiers are more than capable of handling that extra power that is needed for the TH to make up the difference in efficiency.

If you can save 1 guy each gig (cause you need at least 2 guys to handle FLH in the order we are talking) that means a saving of 60Euro an hour. If you only have one gig a week, that would save about 8 x 60Euro = 480Euro a week. That means in a couple of months it already makes up the difference in amplifier costs. Now expand that though to a medium sized company that can save a few people each week... I’m afraid that is the reality of today’s business where costs can make the difference and were accountants rule more than purist thinking.

Now that brings us back to the question that everybody has to answer for himself;

Can a FLH with lower THD be justified over a smaller and lighter package, capable of doing the same thing, at costs of double amount of power, higher THD and higher group delay?

If you can save 1 guy each gig (cause you need at least 2 guys to handle FLH in the order we are talking) that means a saving of 60Euro an hour. If you only have one gig a week, that would save about 8 x 60Euro = 480Euro a week. That means in a couple of months it already makes up the difference in amplifier costs. Now expand that though to a medium sized company that can save a few people each week... I’m afraid that is the reality of today’s business where costs can make the difference and were accountants rule more than purist thinking.

Now that brings us back to the question that everybody has to answer for himself;

Can a FLH with lower THD be justified over a smaller and lighter package, capable of doing the same thing, at costs of double amount of power, higher THD and higher group delay?

Hi Wayne,

In all your cooling plug and power related research, have you evaluated the effect of the cooling system on instantaneous peak power handling? It seems to me, that the power still has to be transferred from the inside of the copper wire through the insulation to the coil former, and so on. There are quite a few thermal resistances in the thermal circuit before the heat can be transferred to your cooling plug, and then out to the air. I'm wondering if the ultimate peak power is still about the same, even while the average power handling is substantially improved. Does the increase in average power handling not automatically lead to a reduction of headroom (because we are now getting closer to an only marginally improve peak power handling level), and an increased need for some form of electronic peak limiting? Or, in other words, if I'm shooting for a certain given average SPL and a given dynamic headroom above that, will improved cooling applied as a retrofit to an existing driver really get me there? It is obvious, that the improved cooling will help the average SPL, and most likely the reliability (and that alone makes it well worth it). Just pondering.

Regards,

In all your cooling plug and power related research, have you evaluated the effect of the cooling system on instantaneous peak power handling? It seems to me, that the power still has to be transferred from the inside of the copper wire through the insulation to the coil former, and so on. There are quite a few thermal resistances in the thermal circuit before the heat can be transferred to your cooling plug, and then out to the air. I'm wondering if the ultimate peak power is still about the same, even while the average power handling is substantially improved. Does the increase in average power handling not automatically lead to a reduction of headroom (because we are now getting closer to an only marginally improve peak power handling level), and an increased need for some form of electronic peak limiting? Or, in other words, if I'm shooting for a certain given average SPL and a given dynamic headroom above that, will improved cooling applied as a retrofit to an existing driver really get me there? It is obvious, that the improved cooling will help the average SPL, and most likely the reliability (and that alone makes it well worth it). Just pondering.

Regards,

Can a FLH with lower THD be justified over a smaller and lighter package, capable of doing the same thing, at costs of double amount of power, higher THD and higher group delay?

See, there's the rub. I think your assumption is that with more power, the efficiency difference can be made up. This is true, of course, in theory, but I don't think we see this in practical application. A 3dB difference of a single box means it would have to also handle twice the power - long term - and we're not talking small numbers here, we're talking 2000 watt devices.

We're all kind of hitting the same ceiling there. Most of the high-power prosound subs are maxed out at about 2000 watts continuous RMS. Not that the ceiling won't raise over time, but right now, the high-power brute-force boxes are all in that same general ballpark. I'm not seeing a woofer that handles significantly more power than that.

I think there's a maximum SPL that can be reached with current technology, with respect to size. You can load a box with a bunch of high-power woofers to get that MAX SPL up, but the larger radiating surface of multiple drivers means larger throats to maintain the compression ratio. That, in turn, makes the mouth size requirement rise to get the flare rate (area expansion) right. So you can do it with one monster woofer or several smaller woofers, the results are the same.

Now then, what does it take to get that maximum SPL up? It takes maximum efficiency, period. You can't just raise power handling, because then your competition can use that same technology in a device with higher efficiency. Efficiency is key. That's what is required for maximum SPL. Power is cheap, sure, but efficiency can't be simply disregarded. It truly is the key. One must combine high-efficiency and high-power if maximum SPL is the goal.

As for the numbers of crew needed to move these big boxes, I've found unanimous agreement of crews that a small number of large subs on castor wheels is easier to load than a large number of smaller subs. They can roll sixteen subs off the truck and onto the floor in ten minutes, piece of cake. They're driving the truck up to a dock or using a ramp. If they have to carry double or triple that number of subs, then the load time is also double or triple. It's different than the needs of a crew setting up a smaller venue.

In all your cooling plug and power related research, have you evaluated the effect of the cooling system on instantaneous peak power handling? It seems to me, that the power still has to be transferred from the inside of the copper wire through the insulation to the coil former, and so on. There are quite a few thermal resistances in the thermal circuit before the heat can be transferred to your cooling plug, and then out to the air. I'm wondering if the ultimate peak power is still about the same, even while the average power handling is substantially improved. Does the increase in average power handling not automatically lead to a reduction of headroom (because we are now getting closer to an only marginally improve peak power handling level), and an increased need for some form of electronic peak limiting? Or, in other words, if I'm shooting for a certain given average SPL and a given dynamic headroom above that, will improved cooling applied as a retrofit to an existing driver really get me there? It is obvious, that the improved cooling will help the average SPL, and most likely the reliability (and that alone makes it well worth it). Just pondering.

The cooling plug is primarily there for thermal protection during long term use. It is not intended to dissipate instantaneous thermal stress, nor could it. But where it does help with peaks is that it shifts the local ambient temperatures down (over 100 degrees). If the core temperature is 120 degrees at full power, a peak that bumps up the coil 250 degrees is probably survivable. But if the core temperature is already 220 degrees, then the extra 250 degrees will probably breakdown the adhesive holding the voice coil to the former.

The cooling vent is still used, and this helps cool the voice coil, particularly in transients. That's really what it does best. The cooling plug cools the motor core, which is heated largely by magnetic eddy currents, and also by radiation and convection. But the motor core is not cooled by the vent, so without a cooling plug, the internal parts closest to the voice coil will heat up to a couple hundred degrees in a few minutes. This tends to heat soak the coil. As I said above, the whole approach of the coolling plug is to reduce the local ambient temperature, to prevent voice coil failure after long term continuous use.

TSCH = Tapped So Called Horn

I agree, & that's why i've previously in other threads referred to them as TSCH's = Tapped So Called Horns

Originally Posted by Wayne Parham

I think the tapped horn is a different animal. It's more of a tapered pipe than a horn

I agree, & that's why i've previously in other threads referred to them as TSCH's = Tapped So Called Horns

Wayne, in respond to your post 170, nobody was or is questioning that the FLH have the highest efficiency! So there is no issue or misunderstanding about that.

This whole discussion was and is about: 2 x 12” drivers ‘old’ style (Lab12 with cooling-plug) in FLH, against latest generation 18”driver (B&C18SW115 for instance) in a TH that is 30% smaller.

I’ll explain my earlier response once more because I know my English (reads as Swahili) sometimes doesn’t seem to come across...

By enlarging the power capabilities of a driver, by using extra cooling, it can enlarge the continue power rating figure of a driver. However, it will not change the Xmax or Xvar. Therefore efficient cooling can not generate 1dB more headroom.

The FLH has 3dB more sensitivity as the TH at the start. When the FLH is running into its max excursion (max SPL) the 12”drivers run into power compression no matter how much you cool them. I’ll be very generous to the 12” drivers and say the power compression at this point is no more then 3dB because of efficient cooling (remember we are talking Xvar here where BL or Cms is only 50%).

At this point the TH with its B&C 18” is running at just less than AES power rating and has less than 2,5dB power compression at this point. That means the TH has only to make up for that 2,5dB (About this number 2,5dB at AES, that is an realistic figure from RCF, 18Sound & B&C at the moment for their extended LF PA drivers of the latest generation, some are even lower.)

However, the reality is below 50Hz the FLH will drop in efficiency rapidly and it can’t make up the difference from the start! Only in stacks of > 6 units it will but till that point the TH clearly sets the definition in LF content.

You can debate whether or not the TH is capable of delivering and that is a discussion of a more general nature.

This whole discussion was and is about: 2 x 12” drivers ‘old’ style (Lab12 with cooling-plug) in FLH, against latest generation 18”driver (B&C18SW115 for instance) in a TH that is 30% smaller.

I’ll explain my earlier response once more because I know my English (reads as Swahili) sometimes doesn’t seem to come across...

By enlarging the power capabilities of a driver, by using extra cooling, it can enlarge the continue power rating figure of a driver. However, it will not change the Xmax or Xvar. Therefore efficient cooling can not generate 1dB more headroom.

The FLH has 3dB more sensitivity as the TH at the start. When the FLH is running into its max excursion (max SPL) the 12”drivers run into power compression no matter how much you cool them. I’ll be very generous to the 12” drivers and say the power compression at this point is no more then 3dB because of efficient cooling (remember we are talking Xvar here where BL or Cms is only 50%).

At this point the TH with its B&C 18” is running at just less than AES power rating and has less than 2,5dB power compression at this point. That means the TH has only to make up for that 2,5dB (About this number 2,5dB at AES, that is an realistic figure from RCF, 18Sound & B&C at the moment for their extended LF PA drivers of the latest generation, some are even lower.)

However, the reality is below 50Hz the FLH will drop in efficiency rapidly and it can’t make up the difference from the start! Only in stacks of > 6 units it will but till that point the TH clearly sets the definition in LF content.

You can debate whether or not the TH is capable of delivering and that is a discussion of a more general nature.

Last edited:

By enlarging the power capabilities of a driver, by using extra cooling, it can enlarge the continue power rating figure of a driver. However, it will not change the Xmax or Xvar. Therefore efficient cooling can not generate 1dB more headroom.

Ah, now I see where the misunderstanding is. You are assuming the horn is reaching a mechanical limit before it reaches its thermal limit. But that's not true, because the horn's woofers are not excursion limited in the passband, far from it. The limit is thermal, so by raising the the thermal limit, you raise the dynamic range and headroom, and make the system more robust in general.

In fact, even with the cooling plugs, the limit is still thermal. It's much higher, but that's still the limiting factor within the passband.

Okay, that would be indeed a misunderstanding from my side. What you actually saying is that the Lab12’s is not able to reach its Xmax? So that means there is only disagreement about if a TH is able to to deliver -3dB in efficiency from a FLH, correct?

Last edited:

Actually, call me crazy, but from what I have looked at the TH is the more efficient cab. Restrict your cab size to whatever you want it to be. Pick any driver you would like. Pick a cut off. The FLH and the TH both receive the same restrictions. Go crazy in whichever horn modeling program you choose. The TH will have better low end efficiency. Forget even using the same driver in both cabs. Model the best FLH you can. Now model the best TH you can giving it the same external cabinet size and same cut off. The TH should be the more efficient low bass reproducer. For fun do the same with a vented alignment. Again the external cab size and cut off should remain the same.

I'm sure you can make an efficient tapped horn, but it would be large. The smaller devices are definitely not as efficient as full-size horns.

Hi Y'all,

How about jbell's SS15 (or Xoc1's TH)? We know the dimensions, the driver, the performance, the Hornresp Input, can somebody design a FLH with equal or better SPL around that format? Or, as a professional example the same around Danley's TH-115?

Regards,

How about jbell's SS15 (or Xoc1's TH)? We know the dimensions, the driver, the performance, the Hornresp Input, can somebody design a FLH with equal or better SPL around that format? Or, as a professional example the same around Danley's TH-115?

Regards,

I'd say this falls into the realm of "Hoffman's Iron Law". First formulated back in the early 1960's by Anthony Hoffman (the H in KLH), Hoffman's Iron Law is a mathematical formula that was later refined by Thiele and Small, whose work now forms the basis of all modern loudspeaker design.

Hoffman's Iron Law states that the efficiency of a woofer system is directly proportional to its cabinet volume and the cube of its cutoff frequency (the lowest frequency it can usefully reproduce). The obvious implication is that to reduce the cutoff frequency by a factor of two, e.g. from 40 Hz to 20 Hz, while still retaining the same system efficiency, you need to increase the enclosure volume by 23=8 times. In other words, to reproduce ever lower frequencies at the same output level you need an extremely large box!

However, box size isn't the only variable. You can continue to use a small box by accepting a much lower efficiency. In order to retain the same sound pressure level (SPL, meaured in dB's), though, this requires both a very large amplifier and a driver that can handle a lot of power and move a lot of air (requiring high excursions). Furthermore, it must be able to do so with minimal distortion. This is exacerbated by power compression, a phenomenon where the power heating of the driver's voice coil results in a non-linear relationship (read "distortion") between the electrical power in and the acoustical power out.

Hoffman's Iron Law states that the efficiency of a woofer system is directly proportional to its cabinet volume and the cube of its cutoff frequency (the lowest frequency it can usefully reproduce). The obvious implication is that to reduce the cutoff frequency by a factor of two, e.g. from 40 Hz to 20 Hz, while still retaining the same system efficiency, you need to increase the enclosure volume by 23=8 times. In other words, to reproduce ever lower frequencies at the same output level you need an extremely large box!

However, box size isn't the only variable. You can continue to use a small box by accepting a much lower efficiency. In order to retain the same sound pressure level (SPL, meaured in dB's), though, this requires both a very large amplifier and a driver that can handle a lot of power and move a lot of air (requiring high excursions). Furthermore, it must be able to do so with minimal distortion. This is exacerbated by power compression, a phenomenon where the power heating of the driver's voice coil results in a non-linear relationship (read "distortion") between the electrical power in and the acoustical power out.

Hi Wayne,

I was not referring to Hoffman's Iron Law, I was trying to see if we could get some parameters set that make a comparison reasonable, maybe:

- same size,

- same driver(s),

- same -3dB (6db?,10db?) low end corner, and

- a minimum of 2 octave range.

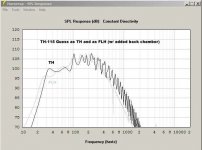

That should result in a similar cost factor, and than we have something to compare. For example a long time ago I compared my guess at a Hornresp simulation for the TH-115 (using 15TBX100) w/ the same simulation w/ rear and throat chambers added, and was surprised at how close they were, and in this case the TH was about 80 litres smaller than the FLH. Was it optimized? No. Do I know what the inside of a TH-115 looks like? No. Do I know which one is the better one for XYZ application? No. I also don't sell any loudspeakers (heck, recently I have had neither time nor residual energy to build any 🙂), and thus have no need to promote one technology over another.

Regards,

I was not referring to Hoffman's Iron Law, I was trying to see if we could get some parameters set that make a comparison reasonable, maybe:

- same size,

- same driver(s),

- same -3dB (6db?,10db?) low end corner, and

- a minimum of 2 octave range.

That should result in a similar cost factor, and than we have something to compare. For example a long time ago I compared my guess at a Hornresp simulation for the TH-115 (using 15TBX100) w/ the same simulation w/ rear and throat chambers added, and was surprised at how close they were, and in this case the TH was about 80 litres smaller than the FLH. Was it optimized? No. Do I know what the inside of a TH-115 looks like? No. Do I know which one is the better one for XYZ application? No. I also don't sell any loudspeakers (heck, recently I have had neither time nor residual energy to build any 🙂), and thus have no need to promote one technology over another.

Regards,

Attachments

I think the tapped horn's biggest strength is what it does at the low end, from cutoff to the frequency where path-length is 1/2 wavelength. That's where the tapped horn is optimized.

I also think that most have used this approach in order to make a small device get deep bass. These small tapped horns are more like tapered pipes than horns, trading efficiency for deep bass. They're very much like mass-loaded quarter-wave pipes.

I see no reason that a larger tapped horn cannot be built that is more in scale with a full-size horn. If, for example, a tapped horn was made having the same path length and same throat to mouth area expansion as a full-size horn, I see no reason it wouldn't be as efficient as the full size horn. I don't know, I haven't studied that.

What I would expect in such a comparson would be that in single units, the tapped horn would be louder from cutoff to (path length equal to) one-half wavelength. At that point, the full horn and the tapped horn would be approximately equal in SPL. Above that, the tapped horn would enter it's peaky response region, where it probably shouldn't be used. The full size horn would be louder above 1/2 wavelength (where it reaches max efficiciency), except of course, for the tapped horn spikes.

What would be interesting would be to see what groups of horns did. The traditional horn benefits from groups - up to the point where mouth size becomes optimum (see the Keele link/reference in my earier post, a page or two back). When grouped, the low end efficiency comes up because the mouth size is made optimal. This brings up the quarter-wave to half-wave region. It also maximizes bulk efficiency, because the system becomes near to the theoretical max efficiency.

My guess is that a (large) tapped horn - one that was as large as a traditional tapped horn - should perform almost the same in groups. I am assuming this hypothetical tapped horn it is optimized the same, not scaled for small size, not made to work at lower frequency - but optimized the same with respect to lower cutoff and size.

I would not expect a smaller tapped horn - one that is optimized for size, with the same cutoff frequency - to be as efficient, even if more are used that match the total (volume) bulk as the larger horns. The optimizations are different. It cannot be expected to get the same efficiency advantage, because it does not have the right flare rate (area expansion) for maximum efficiency, even in groups.

So to me, it really is about size. There is no way to cheat the size thing, where efficiency is concerned. If the tapped horn is made the same size and has the same path length and flare rate, then I would expect efficiency to rise to match the full size horn. There is no size advantage either way. But then we're not talking efficiency, we're talking other charateristics, like distortion and peaks in the band, where they fall. The tapped horn is smoother down low, the full size horn is smoother up high.

I also think that most have used this approach in order to make a small device get deep bass. These small tapped horns are more like tapered pipes than horns, trading efficiency for deep bass. They're very much like mass-loaded quarter-wave pipes.

I see no reason that a larger tapped horn cannot be built that is more in scale with a full-size horn. If, for example, a tapped horn was made having the same path length and same throat to mouth area expansion as a full-size horn, I see no reason it wouldn't be as efficient as the full size horn. I don't know, I haven't studied that.

What I would expect in such a comparson would be that in single units, the tapped horn would be louder from cutoff to (path length equal to) one-half wavelength. At that point, the full horn and the tapped horn would be approximately equal in SPL. Above that, the tapped horn would enter it's peaky response region, where it probably shouldn't be used. The full size horn would be louder above 1/2 wavelength (where it reaches max efficiciency), except of course, for the tapped horn spikes.

What would be interesting would be to see what groups of horns did. The traditional horn benefits from groups - up to the point where mouth size becomes optimum (see the Keele link/reference in my earier post, a page or two back). When grouped, the low end efficiency comes up because the mouth size is made optimal. This brings up the quarter-wave to half-wave region. It also maximizes bulk efficiency, because the system becomes near to the theoretical max efficiency.

My guess is that a (large) tapped horn - one that was as large as a traditional tapped horn - should perform almost the same in groups. I am assuming this hypothetical tapped horn it is optimized the same, not scaled for small size, not made to work at lower frequency - but optimized the same with respect to lower cutoff and size.

I would not expect a smaller tapped horn - one that is optimized for size, with the same cutoff frequency - to be as efficient, even if more are used that match the total (volume) bulk as the larger horns. The optimizations are different. It cannot be expected to get the same efficiency advantage, because it does not have the right flare rate (area expansion) for maximum efficiency, even in groups.

So to me, it really is about size. There is no way to cheat the size thing, where efficiency is concerned. If the tapped horn is made the same size and has the same path length and flare rate, then I would expect efficiency to rise to match the full size horn. There is no size advantage either way. But then we're not talking efficiency, we're talking other charateristics, like distortion and peaks in the band, where they fall. The tapped horn is smoother down low, the full size horn is smoother up high.

Last edited:

- Status

- Not open for further replies.

- Home

- Loudspeakers

- Subwoofers

- Wayne's 12Pi sub