As recommended by @NIXIE62 I used the EC113A surrounds, low cost on eBay

They were very easy to align, and the usual pegging made little difference, as they seemed to centre themselves naturally.

Overall - the replacement work with these was much more straightforward than I imagined; no trouble , despite this being my first surround job.

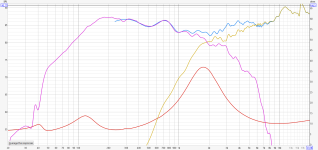

Before and after impedance plots given above. Note that Qms near doubles. After some use the speakers (ME2) are sounding superbly again.

So I certainly second the recommendation.

They were very easy to align, and the usual pegging made little difference, as they seemed to centre themselves naturally.

Overall - the replacement work with these was much more straightforward than I imagined; no trouble , despite this being my first surround job.

Before and after impedance plots given above. Note that Qms near doubles. After some use the speakers (ME2) are sounding superbly again.

So I certainly second the recommendation.

That SR115/2 not only resides on the P13, it was also used on the M13 paper cone drivers. Often the code still can be read on the old surround.I got confirmation by Scan-Speak that these were the original production surrounds.

I've used wintergreen oil on a few different drivers including said Vifas. It does soften them back to a "normal" amount. It loses effectiveness over several months.

You can check for hard surround by tapping with fingernail - will sound like hard plastic.

You can press with a fingertip to a free air or ported driver - it will take a sec or two to restore. Good surrounds should restore immediately.

Multiple applications may be needed the first time around. For large thick surrounds like 15 inch, you will need a bit of patience and ideally well ventilated.

Try not to overspill; driver facing up is best, generally just apply to curved part of surround.

Too much wintergreen oil will start mishaping the surround, eg the outer edges will rise vertically and the inner edge will flatten a little and then develop wrinkles. The driver will generally still work fine and this will dissipate as the restoring effect wears off.

Wintergreen oil doesn't seem to work on coatings on cloth surrounds. If anyone has a decent solution for this it could be useful 🙂

Of course, solvents and/or heat temporarily loosen hardened surrounds. But they evaporate very quickly

You can check for hard surround by tapping with fingernail - will sound like hard plastic.

You can press with a fingertip to a free air or ported driver - it will take a sec or two to restore. Good surrounds should restore immediately.

Multiple applications may be needed the first time around. For large thick surrounds like 15 inch, you will need a bit of patience and ideally well ventilated.

Try not to overspill; driver facing up is best, generally just apply to curved part of surround.

Too much wintergreen oil will start mishaping the surround, eg the outer edges will rise vertically and the inner edge will flatten a little and then develop wrinkles. The driver will generally still work fine and this will dissipate as the restoring effect wears off.

Wintergreen oil doesn't seem to work on coatings on cloth surrounds. If anyone has a decent solution for this it could be useful 🙂

Of course, solvents and/or heat temporarily loosen hardened surrounds. But they evaporate very quickly

My suspensions on the P13WH have failed in such a way that when I press the tire with my finger, it does not immediately return to its normal shape but slowly, for a few seconds. Otherwise, they looked quite normal. Measurement of TS parameters showed that it is over, there was no help but replacement.

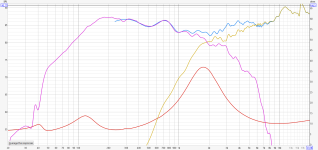

This is the measured response and impedance of a classic and beautiful sonus faber parva fm3, owned by a friend:

(Includes diffraction correction for spliced neafield response of woofer and port)

Does anyone see a chance of getting the woofer surrounds soft again?

I see the same effect @NIXIE62 is describing above (slow return of diaphragm). And of course very low woofer impedance peaks and heavily reduced output below 150 Hz.

(Includes diffraction correction for spliced neafield response of woofer and port)

Does anyone see a chance of getting the woofer surrounds soft again?

I see the same effect @NIXIE62 is describing above (slow return of diaphragm). And of course very low woofer impedance peaks and heavily reduced output below 150 Hz.

Wintergreen oil will work on those surrounds.This is the measured response and impedance of a classic and beautiful sonus faber parva fm3, owned by a friend

Does anyone see a chance of getting the woofer surrounds soft again?

I see the same effect @NIXIE62 is describing above (slow return of diaphragm). And of course very low woofer impedance peaks and heavily reduced output below 150 Hz.

With those Seas drivers is easy; lie the speaker on its back and brush lightly the oil on the inverted roll part. You may only need one or two applications ; and you can also measure the impedance curve to see the resonance peak go down in frequency. You'll probably have larger double peak like most ported enclosures should.

You'll probably have to apply a coat of wintergreen oil every 6 months or so as it's not permanent.

You used to be able to buy new genuine replacement inverted surrounds for those woofers, but they don't seem available now or at least I can't find them on the site they were on. Audio friends or speaker repair shop NL

I wanted to share an interesting discovery I made while trying to repair the surrounds on these P13s.

I tried (just for kicks) to clean up the discolored surface of the old surround on the one driver using some old vodka I found in our pantry. I figured, what the heck and started applying it to the one surround, wiping it on with a folded paper towel.

I used heavy applications of this ethyl alcohol and kept re-applying before it evaporated. After several applications, wiping up most of the discoloration, I noticed the surrounds become very pliable, almost like new. I checked Fs, which dropped considerably down to about 70 hz. Surprisingly, it remained close to this for a few days (give or take a few hz). The surround felt almost normal and would bounce right back when pushed against. Before it would remain dented for several hours. This was a huge improvement.

If the other driver hadn't developed a crack in the surround, I would have been able to rejuvenate it with the above method. Hopefully someone can benefit from this info, being how difficult it is to obtain the correct surrounds. These P13s are arguably some of the best cone mids I've ever used and are worth the effort of repairing. The don't sound like your typical veiled poly cone driver.

I tried (just for kicks) to clean up the discolored surface of the old surround on the one driver using some old vodka I found in our pantry. I figured, what the heck and started applying it to the one surround, wiping it on with a folded paper towel.

I used heavy applications of this ethyl alcohol and kept re-applying before it evaporated. After several applications, wiping up most of the discoloration, I noticed the surrounds become very pliable, almost like new. I checked Fs, which dropped considerably down to about 70 hz. Surprisingly, it remained close to this for a few days (give or take a few hz). The surround felt almost normal and would bounce right back when pushed against. Before it would remain dented for several hours. This was a huge improvement.

If the other driver hadn't developed a crack in the surround, I would have been able to rejuvenate it with the above method. Hopefully someone can benefit from this info, being how difficult it is to obtain the correct surrounds. These P13s are arguably some of the best cone mids I've ever used and are worth the effort of repairing. The don't sound like your typical veiled poly cone driver.

I received my surrounds from Speakerrepairshop.nl and they fit absolutely perfectly, just like the originals. The compliance is also correct, as well as the cone attachment angle. These are part number R5C11. If you have some P13WH-00-08 mids with hardened surrounds, this is your best option. These surrounds aren't cheap Chinese copies. These are excellent quality pieces for a reasonable price. I ordered 2 pairs just in case I screw up, so I'll probably have a second pair left over if someone needs a set.

They turned out pretty well. The fit was great. It was a bit tricky getting the VC to line up exactly without pulling the dust cap, but it gets easier the many times I've replaced surrounds on small drivers with tight VC gaps.

Bought on ebay. They fit the P13WH perfectly.As recommended by @NIXIE62 I used the EC113A surrounds, low cost on eBay

They were very easy to align, and the usual pegging made little difference, as they seemed to centre themselves naturally.

Overall - the replacement work with these was much more straightforward than I imagined; no trouble , despite this being my first surround job.

Before and after impedance plots given above. Note that Qms near doubles. After some use the speakers (ME2) are sounding superbly again.

So I certainly second the recommendation.

Attachments

I haven't glued these yet. I bought it because I'm planning on getting a few more used P13WHs for a project. So I have a replacement. These suspensions are cheap and fit the dimensions. I don't know about glue, I have some, I guess it's good for PP membranes. I will inquire when the time comes. For now, I'm looking for drivers, or used speakers with those drivers. These two with spongy suspension go for mini monitors with Vifa XT25.

I don't know that anyone has compared directly, but my review is very simple: the EC113A was very easy to fit, and almost aligned itself without adjustment.

On completion they measured as new, bar Qms, which doubled.

The restored sound is tremendous, including a stereo 3D illusion of concert hall size from Joanna MacGregor's grand piano.

On completion they measured as new, bar Qms, which doubled.

The restored sound is tremendous, including a stereo 3D illusion of concert hall size from Joanna MacGregor's grand piano.

PVA - super tacky version, premium quality from a craft shop.Which glue did you use?

- Home

- Loudspeakers

- Multi-Way

- VIFA P13WH-00-08 surround hardening