I've seen Nextel react with the metal substrate over time to turn gooey. Never happens on wood or plastic.

I've seen Nextel react with the metal substrate over time to turn gooey. Never happens on wood or plastic.

Thanks for clarifying. At Avalon, the Nextel was on a wood-based substrate. I had a Versa 1.0 that was painted on an aluminum substrate. I bought it new in 1989 or 1990 and sold it 12 or 13 years later. At that time, the paint was exactly as new.

Perhaps JB had the aluminum anodized before painting - I simply don't know. But that is a distinct possibility that could explain the differences being reported. If the Revox and Systemdek 'tables were not anodized and the Versa was, perhaps that would explain the difference between the different (presumably metal) turntables. Another possibility is that the Revox and Systemdek were steel rather than aluminum, and that Nextel is not gas-tight and allowed the steel underneath to corrode and react with the paint.

This reminds me a bit of the old McIntosh and Marantz tube amps from the '50s and '60's. The chassis were nickel-plated steel. If you lived within 100 miles of the ocean, after a few decades the salt in the atmosphere would corrode the steel, creating pits and bubbles in the plating. Yet if you lived in the Mid-West US, 1000 miles from the ocean, they could still look fine.

That is why all of my current products have chassis made entirely from anodized aluminum and stainless steel. They will still look fine after many decades of use.

This is great thread my buddy just pointed me to...

I'm a former 1.0 owner from back in the day around '90-91. I have experience with Nextel because I was spraying speakers enclosures with it around '92. Its the same paint Celestion used on the SL600/700. At the time Red Spot paint and varnish in the mid west was the sole mfr/dist in the states. they bought the patent/license from 3m - i think. you could only purchase it in 5 gal drums and I want to say it was like $400 back then, it's catalyzed, diluted with MEK and had a very short pot life. To atomize the paint properly I used a conventional spray rig similar to whats used for painting automobiles. The stuff is super bad for you to the extreme, a good respirator is mandatory.

Anyways, I spoke with JB about a week ago he's in New Mexico now and still enthusiastic about his 'old' tables. I reached out to him because i'm the 'new' owner of a previously loved 2.0 table. It was prided off the hands of a dead guy (really!) actually it turned up at an estate sale of its deceased owner.

I almost have it my trusty hands but that's another story top be continued very soon. BTW we talked about the platter mat because someone out there has gone to the trouble of sourcing the material from the mfr and making a die to stamp new ones. I believe the material is teflon membrane used as gasket material in hydraulics, like everyone said its use is mandatory with a Versa.....more to follow.

I'm a former 1.0 owner from back in the day around '90-91. I have experience with Nextel because I was spraying speakers enclosures with it around '92. Its the same paint Celestion used on the SL600/700. At the time Red Spot paint and varnish in the mid west was the sole mfr/dist in the states. they bought the patent/license from 3m - i think. you could only purchase it in 5 gal drums and I want to say it was like $400 back then, it's catalyzed, diluted with MEK and had a very short pot life. To atomize the paint properly I used a conventional spray rig similar to whats used for painting automobiles. The stuff is super bad for you to the extreme, a good respirator is mandatory.

Anyways, I spoke with JB about a week ago he's in New Mexico now and still enthusiastic about his 'old' tables. I reached out to him because i'm the 'new' owner of a previously loved 2.0 table. It was prided off the hands of a dead guy (really!) actually it turned up at an estate sale of its deceased owner.

I almost have it my trusty hands but that's another story top be continued very soon. BTW we talked about the platter mat because someone out there has gone to the trouble of sourcing the material from the mfr and making a die to stamp new ones. I believe the material is teflon membrane used as gasket material in hydraulics, like everyone said its use is mandatory with a Versa.....more to follow.

Last edited:

With Teflon, the record may slip on the plater.

Don't you think ?

To take benefit of the succion, the cover must be porous.

Don't you think ?

To take benefit of the succion, the cover must be porous.

Suction platter and therefore no slip

He gets 375$ for this membrane? Maybe gold in there too..,

He gets 375$ for this membrane? Maybe gold in there too..,

This is great thread my buddy just pointed me to...

I almost have it my trusty hands but that's another story top be continued very soon. BTW we talked about the platter mat because someone out there has gone to the trouble of sourcing the material from the mfr and making a die to stamp new ones. I believe the material is teflon membrane used as gasket material in hydraulics, like everyone said its use is mandatory with a Versa.....more to follow.

That would be me. 🙂 Still working on getting them back into production.

Congrats on the 2.0! I've never even seen one.

Before bumping into this thread I had never heard of Versa Dynamics turntables. That won't stop me from offering a suggestion: those of you who don't like all the noise caused by the compressor should consider using nitrogen. Tanks can be had in several sizes, the largest would probably last a very long time. I'm sure it would be inaudible. The initial expense would be less than a mid-level cartridge and refills are relatively inexpensive. Nitrogen is an extremely common gas, is odorless, non-corrosive, non-polluting and non-toxic. If you set up your tank and primary regulator in the garage you can even run a branch to run your pneumatic tools a la Formula 1. It is also clean and dry, no need to worry about corrosion or dirt in your precision bearing or air bearing arm. Run a branch hose a small hand gun and use it to blow dust off your records before playing.

The only drawback I can think of is that it is single ended: no vacuum for your record hold-down.

The only drawback I can think of is that it is single ended: no vacuum for your record hold-down.

Interesting idea but the lack of vacuum is a huge drawback. You don't want to run a Versa without the vacuum hold-down.

If you are going to go to all that trouble to put a nitrogen tank in the garage you may as well put the compressor out there instead (which is what I did). I did T off the air line for an air "gun" too though. That is a good tip for versa owners. Just takes another pressure regulator and a typical compressor air-blower. I also use it to conveniently fill the air bladders in my Arcici suspense rack when they inevitably leak.

If you are going to go to all that trouble to put a nitrogen tank in the garage you may as well put the compressor out there instead (which is what I did). I did T off the air line for an air "gun" too though. That is a good tip for versa owners. Just takes another pressure regulator and a typical compressor air-blower. I also use it to conveniently fill the air bladders in my Arcici suspense rack when they inevitably leak.

Before bumping into this thread I had never heard of Versa Dynamics turntables. That won't stop me from offering a suggestion: those of you who don't like all the noise caused by the compressor should consider using nitrogen. Tanks can be had in several sizes, the largest would probably last a very long time. I'm sure it would be inaudible. The initial expense would be less than a mid-level cartridge and refills are relatively inexpensive. Nitrogen is an extremely common gas, is odorless, non-corrosive, non-polluting and non-toxic. If you set up your tank and primary regulator in the garage you can even run a branch to run your pneumatic tools a la Formula 1. It is also clean and dry, no need to worry about corrosion or dirt in your precision bearing or air bearing arm. Run a branch hose a small hand gun and use it to blow dust off your records before playing.

The only drawback I can think of is that it is single ended: no vacuum for your record hold-down.

That would be me. 🙂 Still working on getting them back into production.

Congrats on the 2.0! I've never even seen one.

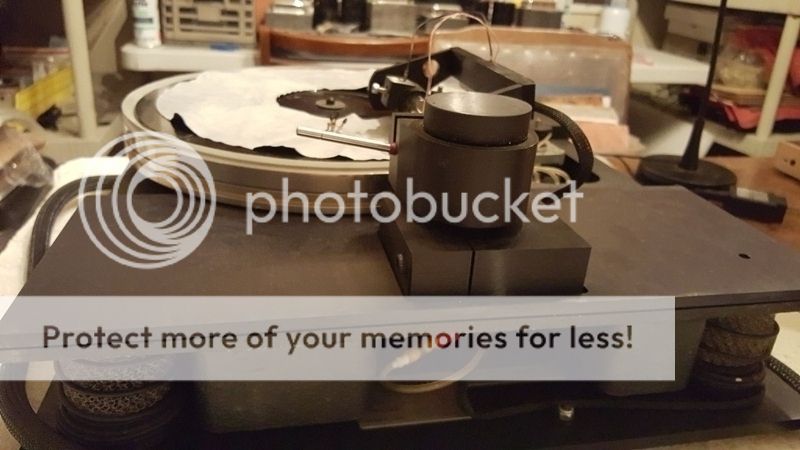

Photobucket wont flip the pic correctly but attached are a few naked picks.

its in remarkable condition given the fact its about 27 yrs old. the rosewood surround, control box and dustcover are also in great shape. unfortunately the shipper didn't follow my instructions re the Teflon mat, it came through mangled. 🙁

Interesting idea but the lack of vacuum is a huge drawback. You don't want to run a Versa without the vacuum hold-down.

If you are going to go to all that trouble to put a nitrogen tank in the garage you may as well put the compressor out there instead (which is what I did). I did T off the air line for an air "gun" too though. That is a good tip for versa owners. Just takes another pressure regulator and a typical compressor air-blower. I also use it to conveniently fill the air bladders in my Arcici suspense rack when they inevitably leak.

What Versafan said. The control box for the 2.0 wont run the motor without seeing both vacuum or sufficient air pressure. it takes 65 psi for the air bearing platter and 45 psi to run the 'arm. you'd' have to jerry rig the control box to bypass the logic functions which control everything.

I used to run an ET2 arm off compressed air from a scuba tank, its nice and dry and it would last a few months with regular weekly use.

Last edited:

Just an update on the mats. I have received a quote. Minimum quantity is 10 but they are expensive. I have sent another request for a quote from a different supplier to see if I can get a better deal, however if there are enough people in a hurry I can order from the expensive supplier.

Just an update on the mats. I have received a quote. Minimum quantity is 10 but they are expensive. I have sent another request for a quote from a different supplier to see if I can get a better deal, however if there are enough people in a hurry I can order from the expensive supplier.

I'd be interested in securing a lifetime's supply🙂 (say, three) but no rush.

I'm so rammed at work that my fettling of the TT is taking place very slowly.

As a matter of interest what's the ballpark cost per unit from supplier #1?

Thanks for taking this iniatitive.

Peter

Thanks.

That does not seem altogether unreasonable. But it would be nice if the price were lower😀.

I'll kick off. Please put me down for three, but we can wait to see if you get a better price from #2!

Best

Peter

That does not seem altogether unreasonable. But it would be nice if the price were lower😀.

I'll kick off. Please put me down for three, but we can wait to see if you get a better price from #2!

Best

Peter

platter mats

Yes I am hoping this other supplier will get back to me this week. Supplier #1 is so high because the material is custom-ordered. They don't have the 0.5mm thickness available "off the shelf". The other supplier does but they may require me to order quite a few pieces as a minimum order. Waiting to hear.

Yes I am hoping this other supplier will get back to me this week. Supplier #1 is so high because the material is custom-ordered. They don't have the 0.5mm thickness available "off the shelf". The other supplier does but they may require me to order quite a few pieces as a minimum order. Waiting to hear.

Thanks.

That does not seem altogether unreasonable. But it would be nice if the price were lower😀.

I'll kick off. Please put me down for three, but we can wait to see if you get a better price from #2!

Best

Peter

Supplier #2 got back to me very quickly and is more reasonable on price. I will be able to offer these at $100 each.

I have ordered 25 of them to start with and will hope to at least recoup my costs on them. They should arrive in 2 or 3 weeks. I will need to evaluate them and make sure they are suitable but I am hopeful that they will be as good or better than the samples I got from "supplier #1". Stay tuned! - Mark

I have ordered 25 of them to start with and will hope to at least recoup my costs on them. They should arrive in 2 or 3 weeks. I will need to evaluate them and make sure they are suitable but I am hopeful that they will be as good or better than the samples I got from "supplier #1". Stay tuned! - Mark

Supplier #2 got back to me very quickly and is more reasonable on price. I will be able to offer these at $100 each.

I have ordered 25 of them to start with and will hope to at least recoup my costs on them. They should arrive in 2 or 3 weeks. I will need to evaluate them and make sure they are suitable but I am hopeful that they will be as good or better than the samples I got from "supplier #1". Stay tuned! - Mark

- Home

- Source & Line

- Analogue Source

- Versa Dynamics TT owners - calling all!

Thank you.

Thank you.