Hello Patrick, I guess you are very busy but I hope you are kind enough to give me an answer. I wish you good luck selling the Cosyne, too bad I live in Italy.

Regards

Guglielmo

Regards

Guglielmo

Hello Patrick, do you have any new?If you don't have time it would be enough to know if on the Unitized waveguide I can use your adapter for NE19 directly (without modifying the waveguide) Are the distances with the emission centers of the NE19 and Gento still compatible with your project?

Thanks for your patience. Guglielmo

Thanks for your patience. Guglielmo

I modified the UICW for Guglielmo by merging the adapter to the waveguide, both generously provided by Patrick Bateman as source 123d files. I also modified it so that it could be printed on my printer upright (FLSUN SR) and only with minor flaws when printed without supports.

It could be modified to be without the lips around the midranges and tweeter and then it would be perfect even when printing without supports.

If @Patrick Bateman allows, I will share the STL and STEP file here if anyone is interested. It takes around 600 g of PLA and 15 hours of printing with 0.6 mm nozzle, 0.4 mm layer and 20% infill with three perimeters. The block structure makes it rock solid and acoustically dead.

The only drawback is that it is missing the mounting lip the original had - it was removed for printing without supports.

The print shows some little overshoots on the edges, that is just how my printer does it. A Prusa print would most probably look a bit better, but I have learned to live with this and it can be quite easily removed if necessary.

I must really appreciate the original waveguide design, it is really cool.

It could be modified to be without the lips around the midranges and tweeter and then it would be perfect even when printing without supports.

If @Patrick Bateman allows, I will share the STL and STEP file here if anyone is interested. It takes around 600 g of PLA and 15 hours of printing with 0.6 mm nozzle, 0.4 mm layer and 20% infill with three perimeters. The block structure makes it rock solid and acoustically dead.

The only drawback is that it is missing the mounting lip the original had - it was removed for printing without supports.

The print shows some little overshoots on the edges, that is just how my printer does it. A Prusa print would most probably look a bit better, but I have learned to live with this and it can be quite easily removed if necessary.

I must really appreciate the original waveguide design, it is really cool.

Attachments

thank you so much!

I've been absolutely slammed at work and I've meaning to get to that for weeks

Please make any changes you'd like

I've been absolutely slammed at work and I've meaning to get to that for weeks

Please make any changes you'd like

In regards to print quality, I'm going to try and get Klipper working this week if I can find time.

I've read it both improves print quality AND speed.

It does some interesting tricks, basically modifying the gcode to cancel out vibrations. Similar to running one speaker in phase and one out-of-phase, but instead it does this with the motion of the print head.

I've read it both improves print quality AND speed.

It does some interesting tricks, basically modifying the gcode to cancel out vibrations. Similar to running one speaker in phase and one out-of-phase, but instead it does this with the motion of the print head.

Yeah, Klipper for the SR is on my to-do list, I have one printer already running it, but it is not used due to other things. If one can find the correct configuration file, it is quite easy to install. I will post the STL and STEP here tomorrow.

I forgot to mention - any thin client running Linux is much better than a RPi (3, most of them better than 4) - like HP T620 or Dell Wyse. And you can get them in perfect condition for less than a RPi.

I also want to try Klipper on my (slightly tuned) QQ-S first. The key thing for me is the linear advance feature - to reduce corner overshoots while keeping the printing speed I have now - there it should help.

Pelanj's prints are really very beautiful. When I receive them I will do some tests with the speakers and I will insert them in this interestingThread.

Thanks to Pelanj and Patrick.

Thanks to Pelanj and Patrick.

any updates..Pelanj's prints are really very beautiful. When I receive them I will do some tests with the speakers and I will insert them in this interestingThread.

Thanks to Pelanj and Patrick.

Thanks for the files!

Can you please tell me what tweeter and mids are used for this horn?

I am looking for some mids that can be bought in Europe.

Thanks!

Can you please tell me what tweeter and mids are used for this horn?

I am looking for some mids that can be bought in Europe.

Thanks!

When I built mine, I tried some Sica 2" fullrangers I had at home (I think 2H0,8SL) , they would fit. Also, IIRC, Visaton FRS5x (or maybe another model) would fit as well with a bit of effort. It would of most probably require some rework on the passive crossover. IMHO any 2" wide range driver would work pretty fine as long as it mechanically fits.

Hello,

right now I have very little time, I hope in February to do more testing.

I installed the speakers without difficulty, only the tweeter needed a little Dremel work.

I made some measurements of the frequency response which I attach.

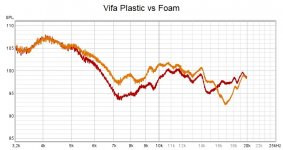

I noticed that the tweeter's response is better with a plastic-on-plastic assembly rather than with the interposition of putty.

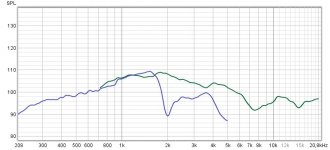

I plan to match inexpensive PEERLESS SDS-P830656 5-1/4" woofers and did some response tests through a cavity with 18mm and 30mm thickness.

The result seems satisfactory to me.

I am now preparing a test box with 4 woofers placed on the vertices from the horn.

Stay tuned.

Ciao

Guglielmo

Translated with www.DeepL.com/Translator (free version)

right now I have very little time, I hope in February to do more testing.

I installed the speakers without difficulty, only the tweeter needed a little Dremel work.

I made some measurements of the frequency response which I attach.

I noticed that the tweeter's response is better with a plastic-on-plastic assembly rather than with the interposition of putty.

I plan to match inexpensive PEERLESS SDS-P830656 5-1/4" woofers and did some response tests through a cavity with 18mm and 30mm thickness.

The result seems satisfactory to me.

I am now preparing a test box with 4 woofers placed on the vertices from the horn.

Stay tuned.

Ciao

Guglielmo

Translated with www.DeepL.com/Translator (free version)

Attachments

-

Modifica sede tweeter.jpg133.7 KB · Views: 211

Modifica sede tweeter.jpg133.7 KB · Views: 211 -

Vifa evidenziato senza stucco.png36.4 KB · Views: 199

Vifa evidenziato senza stucco.png36.4 KB · Views: 199 -

Gento+Vifa senza stucco.jpg61.9 KB · Views: 202

Gento+Vifa senza stucco.jpg61.9 KB · Views: 202 -

20221202_112211.jpg61.9 KB · Views: 196

20221202_112211.jpg61.9 KB · Views: 196 -

20221202_113325.jpg44.7 KB · Views: 220

20221202_113325.jpg44.7 KB · Views: 220 -

20221202_120904.jpg40.5 KB · Views: 209

20221202_120904.jpg40.5 KB · Views: 209 -

Comfronto woofer con pannello 18 e 30mm.jpg74.7 KB · Views: 206

Comfronto woofer con pannello 18 e 30mm.jpg74.7 KB · Views: 206

Hello,

sorry but I am very slow, and not having much expertise on speakers I am trying to understand what I am doing.

1. I have used foam between the tweeter and the horn, the shape needs to be done carefully (I can do better) but it works better than all the previous plastic vs foam pairings (highlighted)

2. I made a test box with 4 woofers placed on the vertices of the horn, the box has openings on the sides at the woofers of the same size as the front throat.

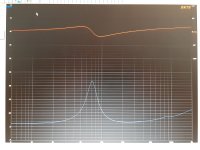

3. I measured the impedance and Qtc =0.61 Fs =86Hz I attach the impedance graph

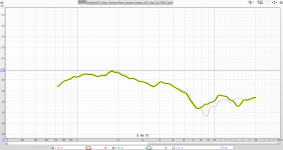

4 I measured the on-axis response at 50cm and at 100cm (much depends on my room).

5. I then added 2 side wings of 8cm each side to see if the frequency response changed but I didn't see much difference

6. I closed the side holes and measured the impedance and Qtc =0.82 Fs =72Hz I attach the impedance graph in closed box

7.I measured the on-axis response at 50cm and at 100cm (much depends on my room.

8. I made comparisons between closed and open box measurements.

In your opinion, since I will then use a sub, is it better to use the closed or open box?

Can the openings on the sides help the control of low frequencies in the listening room?

Sorry about my poor English, I used DeepL.

Best regards

Guglielmo

sorry but I am very slow, and not having much expertise on speakers I am trying to understand what I am doing.

1. I have used foam between the tweeter and the horn, the shape needs to be done carefully (I can do better) but it works better than all the previous plastic vs foam pairings (highlighted)

2. I made a test box with 4 woofers placed on the vertices of the horn, the box has openings on the sides at the woofers of the same size as the front throat.

3. I measured the impedance and Qtc =0.61 Fs =86Hz I attach the impedance graph

4 I measured the on-axis response at 50cm and at 100cm (much depends on my room).

5. I then added 2 side wings of 8cm each side to see if the frequency response changed but I didn't see much difference

6. I closed the side holes and measured the impedance and Qtc =0.82 Fs =72Hz I attach the impedance graph in closed box

7.I measured the on-axis response at 50cm and at 100cm (much depends on my room.

8. I made comparisons between closed and open box measurements.

In your opinion, since I will then use a sub, is it better to use the closed or open box?

Can the openings on the sides help the control of low frequencies in the listening room?

Sorry about my poor English, I used DeepL.

Best regards

Guglielmo

Attachments

- Home

- Loudspeakers

- Multi-Way

- "Unitized" Image Control Waveguide