Question about wear:

thoriated tungsten VT25/10Y is specified as 7.5V AC or DC. Some say, no, it is 7.2 volts. Others even claim not to do more than 6.3V.

I used 7.4V AC for years, no change in transmission or sound at all.

So I say: no wear.

Plain DC will throw a big initial current. - I changed to a ccs and gyrator .

thoriated tungsten VT25/10Y is specified as 7.5V AC or DC. Some say, no, it is 7.2 volts. Others even claim not to do more than 6.3V.

I used 7.4V AC for years, no change in transmission or sound at all.

So I say: no wear.

Plain DC will throw a big initial current. - I changed to a ccs and gyrator .

Think of Barkhausen's curves when the filament is operated on DC.

There is no change over time.

Now, think real hard about Barkhausen's curves when the filament is operated on AC.

That is a dynamic situation, constantly changing over time, according to the AC waveform.

Doubt that? Then look at this . . .

Part of the time, the voltage differential along the filament is Zero Volts (0, 180, 360 degrees)

Part of the time, the voltage differential along the filament is at 1/2 of Peak Volts (30, 150, 210, 330 degrees)

Part of the time, the voltage differential along the filament is Peak Volts (90, 270 degrees)

Perhaps with the above dynamic differential voltage along the filament from the AC, there might be sidebands occuring on musical notes and harmonics.

There is no change over time.

Now, think real hard about Barkhausen's curves when the filament is operated on AC.

That is a dynamic situation, constantly changing over time, according to the AC waveform.

Doubt that? Then look at this . . .

Part of the time, the voltage differential along the filament is Zero Volts (0, 180, 360 degrees)

Part of the time, the voltage differential along the filament is at 1/2 of Peak Volts (30, 150, 210, 330 degrees)

Part of the time, the voltage differential along the filament is Peak Volts (90, 270 degrees)

Perhaps with the above dynamic differential voltage along the filament from the AC, there might be sidebands occuring on musical notes and harmonics.

The Utracer is a characteristic tester which plots curves in software. For directly heated types, the cathode sense has to either be connected to the positive or negative side of the filament. For a 2.5v tube, if I was reference the cathode sense to the negative side and plot curves for -30v and -27.5v. Then retest at -30v but with the the cathode sense connected to the positive side it will produce a curve aligned to the previous curve taken at -27.5v.I don't understand what you're describing here. Would you mind rephrasing it?

My understanding (which could be wrong), was that the Barium oxide version was created for the purpose of mobile applications (aircraft bombers) where the filament would be subjected to battery/alternator variation in voltage and vibration. Thoriated types with their thinner/hotter filaments would probably break in such applications. I suspect those 7.2v and 6.3v references apply to the Barium version only. Thoriated types should not be operated at less than 90 or was it 95% of nominal voltage otherwise there will be premature loss of emmision.Question about wear:

thoriated tungsten VT25/10Y is specified as 7.5V AC or DC. Some say, no, it is 7.2 volts. Others even claim not to do more than 6.3V.

I used 7.4V AC for years, no change in transmission or sound at all.

So I say: no wear.

Plain DC will throw a big initial current. - I changed to a ccs and gyrator .

If you are using a current-driven filament supply, it ispossibe to find an optimal operating value of filament voltage [Uf] for any unkown sample of Thoriated Tungsten filament 10Y/801A/VT-25 &c:Question about wear:

thoriated tungsten VT25/10Y is specified as 7.5V AC or DC. Some say, no, it is 7.2 volts. Others even claim not to do more than 6.3V.

I used 7.4V AC for years, no change in transmission or sound at all.

So I say: no wear.

Plain DC will throw a big initial current. - I changed to a ccs and gyrator .

- Connect the tube with a resistor anode load. Preferably, use a Data-Sheet value for Ua and Ia.

- Apply a small signal to the grid.

- Adjust the filament supply to give the lowest data-sheet voltage across the filament: 7,2V for example. Measure the filament current (voltage across sense ressitor)

- measure the output signal voltage, calculate the signal current, and the value of gm.

You can try increased values of filament voltage, up to 7,5V - but I think it is best to stop if the filament current reaches 1,25A for a 10Y/801A.

Now you can try lower filament voltages: Thoriated filaments can operate at reduced voltage, to get longer lifetime, but at the Uf value where gm falls substantially, the sound may be degraded, so keep checking the gm, and compare with the data sheet expected gm (for the Ua and Ia).

OTOH, Oxide coated filaments are best operated right at the nominal voltage.

I wasn't sure if in your original comaprison you were switching the cathode to ground connection together with the filament supply or not.The Utracer is . . . .

For what it's worth, my 833C amps have been running 10V, 10A DC from Coleman regulators (v4) for 10 years now, producing up to 200WPC from a single tube. The 833C is a thoriated tungsten DHT.

Still the original tubes, still sounds great.

Still the original tubes, still sounds great.

TT filaments should be operated as close to nominal voltage as possible. At the optimal operating temperature of 1960K, there is equilibrium between surface thorium evaporation and replenishment. Even small deviations (plus-minus 50 degrees) from this temperature accelerate filament deterioration. Deterioration due to over-temperature is irreversible, deterioration due to under-temperature can be reversed by a period of heating at 1960K.

Constant voltage is more conducive to maintaining the optimum temperature than constant current. As TT filament ages, its conductivity increases due to conversion of tungsten carbide to metallic tungsten, but increased current will compensate for increased filament metal mass. At constant current, filament temperature will decrease with wear.

Constant voltage is more conducive to maintaining the optimum temperature than constant current. As TT filament ages, its conductivity increases due to conversion of tungsten carbide to metallic tungsten, but increased current will compensate for increased filament metal mass. At constant current, filament temperature will decrease with wear.

Last edited:

Agree absolutely that the greatest care should be taken to avoid overtemperature of thoriated tungsten filaments.

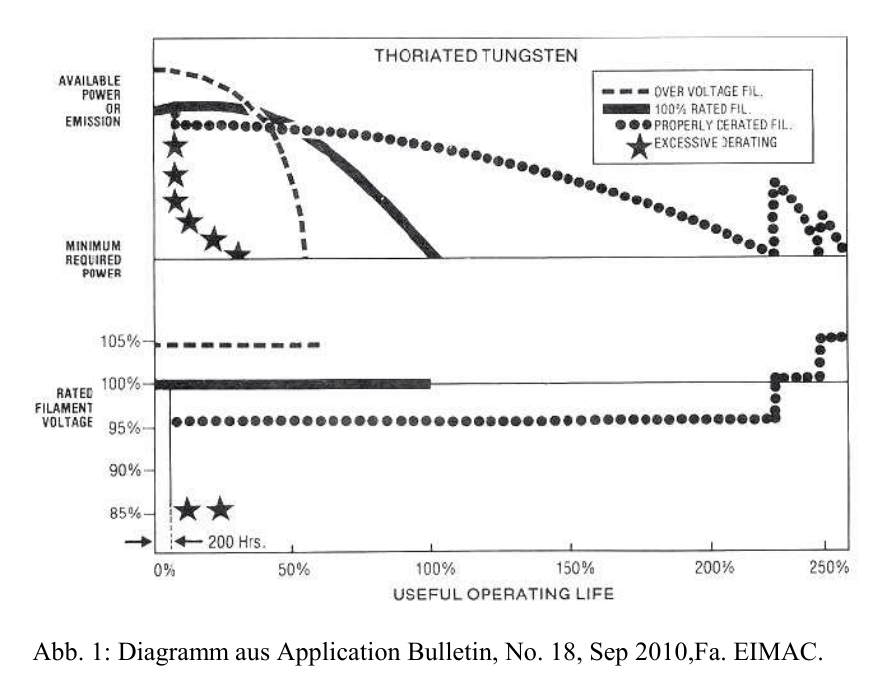

But if you have an adjustable DC filament supply, you can follow the advice of Transmitting Tube manufacturer EIMAC, and run the filament at -5% from nominal voltage over the majority of the filament lifetime; and then near the end-of-life, adjust upward in steps to get the maximum possible running life.

The timing of the upward adjustment is best determined by observing gm; with audio output valve, the sound is likely to tell the tale.

Extract of EIMAC AB18 illustrates graphically the huge potential for increased life of the valve, if this regime is folllowed: 250% of nominal lifetime, or 500% compared to running 5% too high. This appears far too good to ignore, I believe.

But if you have an adjustable DC filament supply, you can follow the advice of Transmitting Tube manufacturer EIMAC, and run the filament at -5% from nominal voltage over the majority of the filament lifetime; and then near the end-of-life, adjust upward in steps to get the maximum possible running life.

The timing of the upward adjustment is best determined by observing gm; with audio output valve, the sound is likely to tell the tale.

Extract of EIMAC AB18 illustrates graphically the huge potential for increased life of the valve, if this regime is folllowed: 250% of nominal lifetime, or 500% compared to running 5% too high. This appears far too good to ignore, I believe.

Didn't realise the 833 (and perhaps others?), had their filament wired parallel inside. I see four springs in those monster tubes; did they parallel all four or just in pairs. I am drawn to the looks of the 833; would make for a nice winter warmer, but those voltages make me think twice and Rp looks bit high at around 8k.My one and only 833 is a dud. One half of the filament broke in shipping.

The working half of the filament is 10V @ 5A.

It makes a beautiful bright Christmas Lamp!

The 833 plate impedance of 8k might allow someone to make a push pull direct drive amplifier for electrostatic speakers.

Unfortunately, the very high Push and Pull voltages would have to be applied to the outside screens, not to the electrostatic element.

The electrostatic element would be grounded.

No voltage step up transformer needed.

Because of the high voltage on the screens, you would have to put extra screens outside of the driven screens.

Those outer screens would be grounded, and protect curious fingers from dangerous shock.

Nice idea, but far too much work for me.

Unfortunately, the very high Push and Pull voltages would have to be applied to the outside screens, not to the electrostatic element.

The electrostatic element would be grounded.

No voltage step up transformer needed.

Because of the high voltage on the screens, you would have to put extra screens outside of the driven screens.

Those outer screens would be grounded, and protect curious fingers from dangerous shock.

Nice idea, but far too much work for me.

So in the case of undervolting the heater of Barium Oxide or Thoriated, the surface layer would slowly(?) be exhausted of it's available Barium / Thorium, in the case of Thoriated types taking as long as 200 hours. The instant changes I noted in my Utracer tests, then would not show the full impact, perhaps just showing a change in the space charge.

I wonder if resoration would take equally as long by restoring to normal voltage.

I wonder if resoration would take equally as long by restoring to normal voltage.

The restoration at the optimal TT filament temperature is quick, less than an hour.So in the case of undervolting the heater of Barium Oxide or Thoriated, the surface layer would slowly(?) be exhausted of it's available Barium / Thorium, in the case of Thoriated types taking as long as 200 hours. The instant changes I noted in my Utracer tests, then would not show the full impact, perhaps just showing a change in the space charge.

I wonder if resoration would take equally as long by restoring to normal voltage.

Maybe of course a silly remark (ref. “less than an hour”) but would a strong current at every start-up that a battery produces (i.e. a voltage source) remedy the slow drop in transconductance?

[I have thought such a battery power supply gave the black sediment of evaporated metals on the glass]

[I have thought such a battery power supply gave the black sediment of evaporated metals on the glass]

Strong start-up current - yes. Start-up overheating - no. It's self regulated: temperature increases, current drops. The only difference - constant voltage is faster than constant current in bringing filament to working temperature.

So the required migration of molecules (borium??) to the surface will not take place in those short spurts.

- I have 18042 in triode mode, originals from below the sealevel. They were designed for >10 years/120K hours) but might have another 10years in stock for me. [But it is not DHT, so off-track regarding OP. Anyway here we also have a layer of oxides that need carefull managing.].

I attach some pondering about the long life management of repeater tubes (again, not DHT). And not about uneven wear of two halves.

But there is one interesting picture (fig. 6): how the barium/platinum barrier gets poisoned dependent on the cathode current. So with a ground referenced heating source, not floating as Depanatoru describes.

Which leads me to think (like OldHektor) that potentially there is an effect of uneven wear in two halves of a DHT. Some have applauded the idea of changing the polarity with a battery operation every so many hours.

- I have 18042 in triode mode, originals from below the sealevel. They were designed for >10 years/120K hours) but might have another 10years in stock for me. [But it is not DHT, so off-track regarding OP. Anyway here we also have a layer of oxides that need carefull managing.].

I attach some pondering about the long life management of repeater tubes (again, not DHT). And not about uneven wear of two halves.

But there is one interesting picture (fig. 6): how the barium/platinum barrier gets poisoned dependent on the cathode current. So with a ground referenced heating source, not floating as Depanatoru describes.

Which leads me to think (like OldHektor) that potentially there is an effect of uneven wear in two halves of a DHT. Some have applauded the idea of changing the polarity with a battery operation every so many hours.

Attachments

Last edited:

No - the migration of the Barium from the subsurface is controlled by temperature. But while the startup current is high, the temperature is below the normal running value. Once the running temperature is reached, the current has already dropped to the normal level.

Running at normal voltage for some time (depending on how depleted the surface region is) can restore the activity, but is not guaranteed to work.

Running at normal voltage for some time (depending on how depleted the surface region is) can restore the activity, but is not guaranteed to work.

- Home

- Amplifiers

- Tubes / Valves

- Uneven Filament Wear of DC heated DHT’s, Truth or Myth