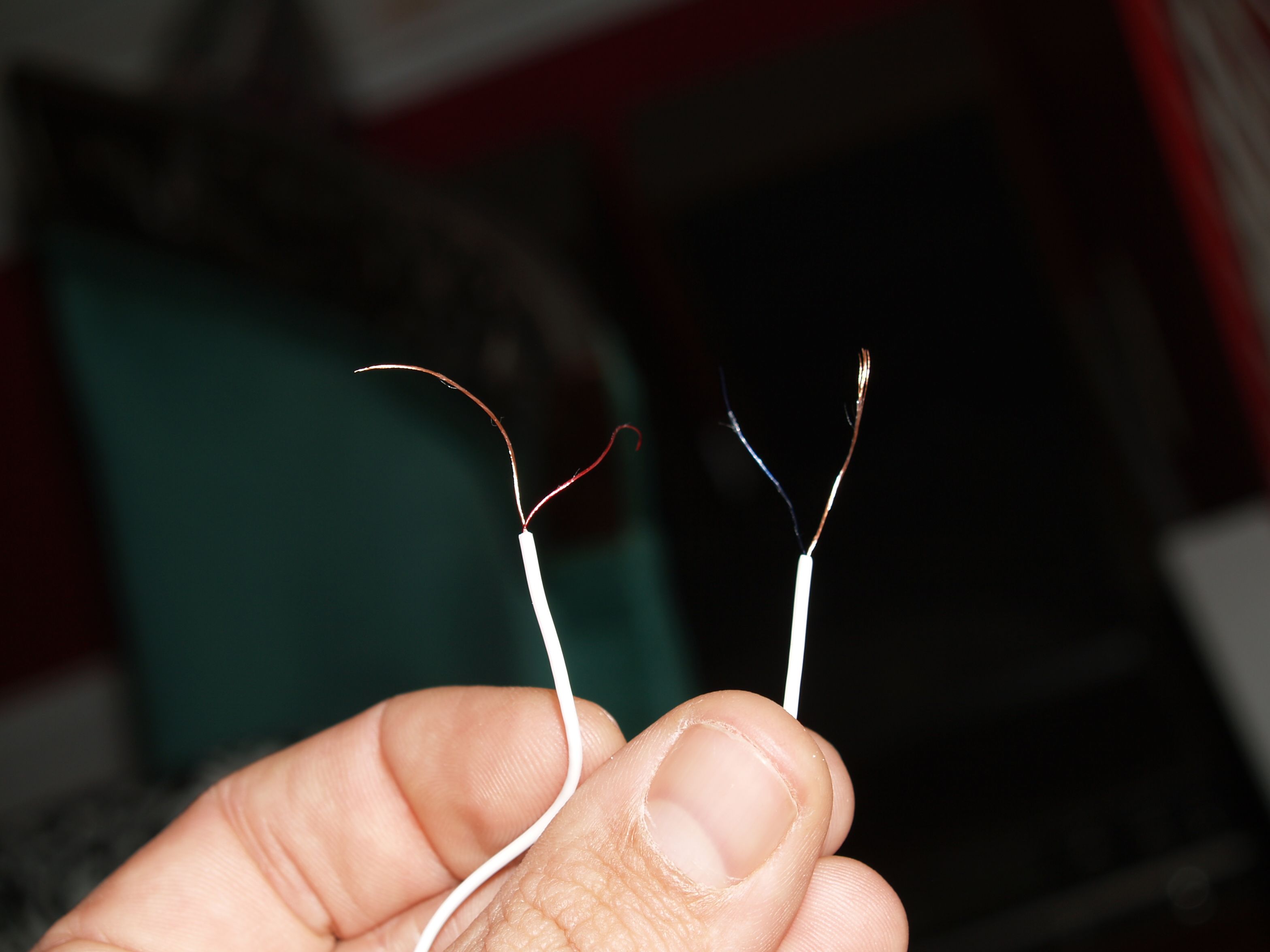

Try 1mm siver in PTFE sleeve with an air gap, beats anything else Iv'e tried. In the UK we call pure silver (FINE) don't use stirling silver

If you think our criterion for speaker cable is that is does not melt then you do not understand that which you criticise. Of course, this is a standard 'debating' trick used by people with no facts on their side: criticise something which people do not believe; so much easier than dealing with the issue.PaleRider said:Legends says that this or that kind of wiring should be "sufficient" meaning it will not overheat and burn off.

No idea what you are talking about. OPT wiring? If so, blindingly obvious.1: When it comes to wiring; what might be sufficient on the primary side will be a restriction on the secondary side.

Not true. Music is mainly about frequency and time - what note was played when? How loud also matters, but is less important. In any case, what has 'dynamics' got to do with speaker cables? (Unless they are nearly melting)2: Music is all about dynamics. Dynamic headroom is a keyword. (sounds easy)

Nonsense. Two sorts of nonsense. Resistance does not limit dynamic range; it affects quite and loud passages equally. Resistance actually affects frequency response, as speakers are not constant loads.If we limitate the current-flow in a system we might still not burn off or even heat up the speaker-wires, but the system will sound "thinner". A lot thinner. A frequency-test will show exactly the same result.

No.To make this story short; even the smallest amount of serial resistanse will reduce a systems dynamic capacity. This will be most audible in the lower range since this is where the power is needed. (ever noticed that your amp`s meters "follows" the bass-rythm?)

Almost true, but sort of false too. Speaker wiring which has a resistance equal to the nominal speaker impedance will drop the power by about 6dB - so the amp will seem weaker. 6dB is not a big drop in power, so the user will barely notice the power drop. He will notice the disturbance in frequency response, but in some cases may even prefer it!The thinner wiring will make your amp perform like if it was weaker, smaller and not capable to run your speakers. And you might never get it because you have never tried to run real sufficient** wires.

Short as reasonably possible, yes - because there is no reason to make them longer. Stranded or solid does not matter for electricity, but stranded cables are more flexible to easier to install or move. Designers have not "grasped this" because is it not true. The reason OPT secondaries use solid cable is all about mechanical stability and nothing to do with sound, so no harm whatsoever in continuing with flexible cable.Speakerwires should be kept as short as possible, (max 3 meters) not stranded/twisted or any other "configuration" but thick and solid*, **fun begins at 9awg. Solid core copper, + and - separated.

* speakerwires must be seen as an extension of the power-amps secondary circuit, as well as the speakers internals. How many designers seems to have grasped this?

Btw; if there is any kind of multistrand-wiring in your equipment ( like ac-intake to powerswitch) you might do some easy upgrading.

Is someone offering a prize for the post containing the most audio myths?

Try 1mm siver in PTFE sleeve with an air gap, beats anything else Iv'e tried. In the UK we call pure silver (FINE) don't use stirling silver

How...

Ellipsis (plural ellipses; from the Ancient Greek: ἔλλειψις, élleipsis, "omission" or "falling short") is a series of dots (typically three, such as "…") that usually indicates an intentional omission of a word, sentence, or whole section from a text without altering its original meaning.

Somebody suggested thicker cable is better for speakers, I gave it a try, I must say that regardless of sonics, it is quite inconvenient...

Later, I experimented with very thin wires. I couldn't discern much difference, though it must be said that a crane isn't usually necessary for proper handling. That's a benefit, as far as I can tell.

Someone joins the forum, then makes the first post 3 years lager about snake oil item.

You guys are being gotten by a sleeper troll. 🙄

You guys are being gotten by a sleeper troll. 🙄

This system is an overkill .... just heavy copper wire .... and if you are afraid of signal refexions and other dtufff just put a 0.047 uF cap with a 22 ohms resistor at the far end of the wire to make a termination.

#0000 welding cable flexible and readily available .000025 Ohms/ft. Any contractors outlet has suitable bolt on terminations at ~$11 @.

#0000 welding cable flexible and readily available .000025 Ohms/ft. Any contractors outlet has suitable bolt on terminations at ~$11 @.

The limit on welding cable is the thin insulation! Typically rated for less than 100 volts and sometimes as low as 30! Some idiots use it for lighting feeds.

As to the resistance of a loudspeaker cable it should be less than 5% of the minimum loudspeaker impedance. The minimum impedance can be as low as one half of the rated impedance.

Now with marginally stable audio power amplifiers the loudspeaker wire can have a real influence. So if increasing the wire spacing in a cable has an effect I would look at the audio power amplifier. If you wish to reduce the charafteristic impedance of the cable the wires should be close to each other.

Now twisting the wire helps to reduce EMI pick up.

I use long cable runs on my systems and cable construction can become an issue. Mostly from the standard approach ignores all the secondary effects of the system.

I just run lengths of bellwire inside an outer shell of thick rubber garden hose . Sounds fine and impresses my "audiophile " vistors when they see my seemingly enormous and obviously expensive cables snaking around the floor . 🙂

If you are truly OCD, and having fun experimenting you can try the following:

Flatten your 1 mm silver wire in a pasta machine or have it done at a local machine shop. Solder it to solid wire to pass into the teflon tubing. Proper diameter will allow just the edges of the wire to contact the teflon.

This theoretically accomplishes two audiophile holy grails...mostly air dielectric and maximizes surface effect.

It is also a hair shirt fragile set up so beware. I'm not sure I could tell a difference, but it was a fun project. (Next project is the Pass vfet amp... awaiting the build guide and parts)

Flatten your 1 mm silver wire in a pasta machine or have it done at a local machine shop. Solder it to solid wire to pass into the teflon tubing. Proper diameter will allow just the edges of the wire to contact the teflon.

This theoretically accomplishes two audiophile holy grails...mostly air dielectric and maximizes surface effect.

It is also a hair shirt fragile set up so beware. I'm not sure I could tell a difference, but it was a fun project. (Next project is the Pass vfet amp... awaiting the build guide and parts)

The limit on welding cable is the thin insulation! Typically rated for less than 100 volts and sometimes as low as 30! Some idiots use it for lighting feeds.

Mine says 600V.

#4/0 (AWG #0000) flexible fine strand welding cable. Dual jacket. 600 volt AC or DC rating. Only Red & Black are stocked in 3/0 and 4/0 cable sizes - other colors available on special order at higher cost (2-6 week lead times). Minimum order on this item is 5 feet per color.

Last edited:

Oh, he is more than just that! This kind of sense of humor makes threads like this to be worth of paying attention at all.

Amen! I for one really enjoyed that contribution. 😀

Mine says 600V.

That is unusual. At 600 volts it is standard power cable. Actually useful for more than welding. Next thing to look for is UL rating.

I did once score a reel of 25mm tri rated switchgear cable from a lab we were building. I used to make roving jump leads off a gert big UPS battery that was otherwise going in the skip. I did think of making some speaker cables out of that but was very silly. Gave it to a mate with a garage in the end and he was chuffed to bits with it.

I also dallied with the idea of Anderson connectors...

I also dallied with the idea of Anderson connectors...

Originally Posted by JMFahey View Post

Nonsense.

ANY conductor is flat down to DC by definition , there is no Bass deeper than DC, so conductor type or material can NOT affect Bass depth at all.

IF you claim to hear otherwise, fine, but attribute it to subjective opinion.

So you attack my *personality* .... I´d rather prefer you attack my *Physics*Well you are sufficiently arrogant, mybe even a bit over the edge. And you are wrong too.

Show me a conductor which has higher/improved/better/different frequency response at low audio frequencies or shut up.

I mean *measured* different. 🙄

Next thing to look for is UL rating.

I'm have to look but there is a UL rating, remember this stuff has become popular for solar installations and I suspect there is enough money involved to make a UL submission to meet codes for large series PV installations.

So you attack my *personality* .... I´d rather prefer you attack my *Physics*

Show me a conductor which has higher/improved/better/different frequency response at low audio frequencies or shut up.

I mean *measured* different. 🙄

I thought Christmas was for elves not trolls.

- Status

- Not open for further replies.

- Home

- Member Areas

- The Lounge

- ultimate speaker cable design diy